Subsensitive lactalbumin hydrolysate and preparation method thereof

A technology of whey protein hydrolysis and whey protein, which is applied in the field of food bioengineering, can solve the problem that no complex enzymes have been found to produce low-sensitivity whey protein products, cow milk has not attracted enough attention, and there are few statistical reports on cow milk allergy and other problems, to reduce or eliminate milk allergic reaction, high inhibition rate, and reduce anaphylaxis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

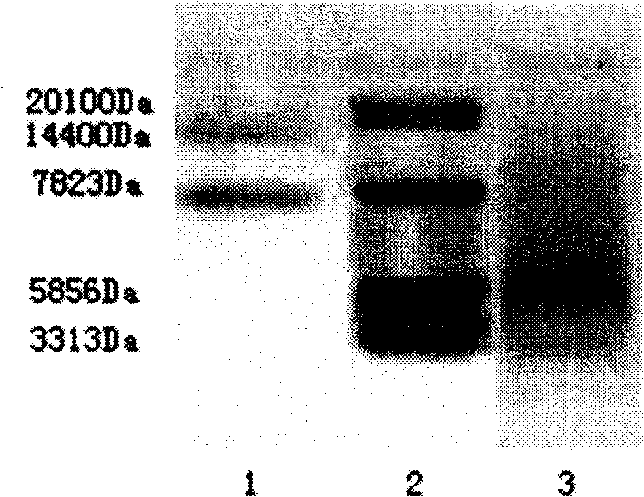

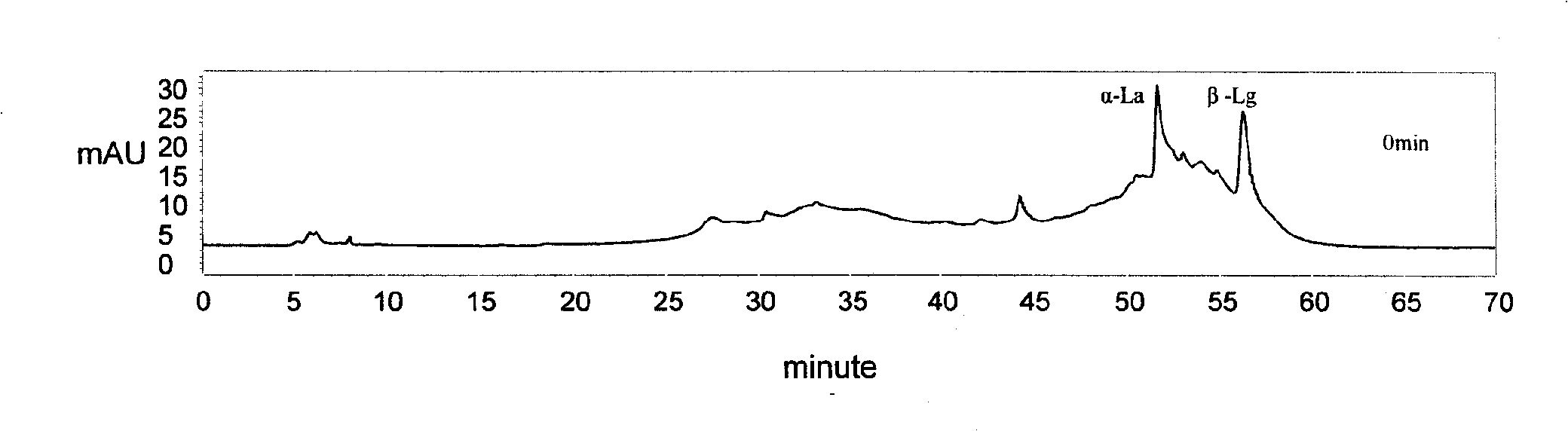

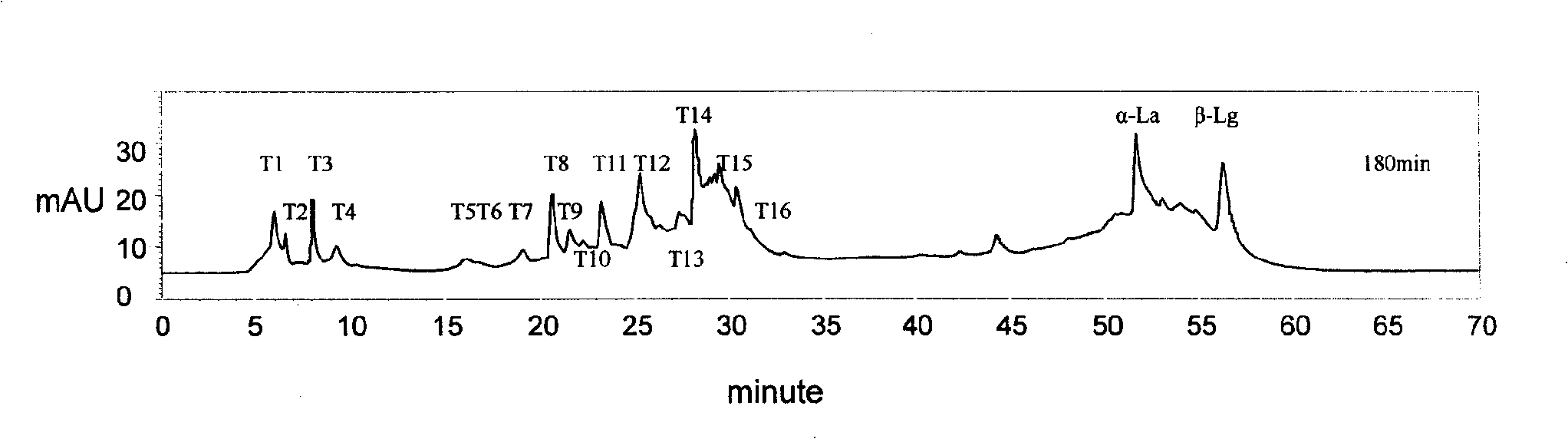

[0035] Preparation of Hypoallergenic Whey Protein Hydrolyzate

[0036] Weigh 8g of concentrated whey protein (WPC-8000) and dissolve it in 100ml of water, fully dissolve it on a magnetic stirrer, heat at 85°C for 15min to denature the protein, and cool down to 45°C; dilute the milk with 1mol / L NaOH or HCl The pH value of albumin solution is adjusted to 7.5, then add 0.1g compound protease (composition and ratio of compound protease: alkaline protease, papain, flavor protease ratio is 1: 1: 1), and shake in constant temperature water bath Hydrolyze at 55°C and pH 7.5 for 3 hours; then keep at 90°C for 15 minutes to inactivate the enzyme. Then the whey protein hydrolyzate was desalted through a cation exchange resin column at a flow rate of 50 r / min, the flow rate was controlled by a countercurrent pump, the effluent was collected, and dried to obtain 6.5 g of low-sensitivity whey protein hydrolyzate.

Embodiment 2

[0038] Preparation of Hypoallergenic Whey Protein Hydrolyzate

[0039] Weigh 6g of concentrated whey protein (WPC-8000) and dissolve it in 120ml of water, fully dissolve it on a magnetic stirrer, heat at 90°C for 10min to denature the protein, and cool down to 48°C; use 1mol / L NaOH or HCl to dissolve the milk The pH value of the albumin solution is adjusted to 7.6, then add 0.096g composite protease (composition and ratio of composite protease: alkaline protease, papain, flavor protease ratio is 1: 1.2: 1), and shake in constant temperature water bath Hydrolyze at 52°C and pH 7.6 for 2 hours; then keep at 90°C for 15 minutes to inactivate the enzyme. Then the whey protein hydrolyzate was desalted through a cation exchange resin column at a flow rate of 50 r / min, the flow rate was controlled by a countercurrent pump, the effluent was collected, and dried to obtain 5.0 g of low-sensitivity whey protein hydrolyzate.

Embodiment 3

[0041] Preparation of Hypoallergenic Whey Protein Hydrolyzate

[0042] Weigh 3g of concentrated whey protein (WPC-8000) and dissolve it in 50ml of water, fully dissolve it on a magnetic stirrer, heat at 85°C for 15min to denature the protein, and cool down to 45°C; dilute the milk with 1mol / L NaOH or HCl The pH value of the albumin solution is adjusted to 7.8, then add 0.045g composite protease (composition and ratio of composite protease: alkaline protease, papain, flavor protease ratio is 1: 1: 1.5), and shake in constant temperature water bath Hydrolyze at 50°C and pH 7.8 for 3 hours; then keep at 100°C for 10 minutes to inactivate the enzyme. Then the whey protein hydrolyzate was desalted through a cation exchange resin column at a flow rate of 50 r / min, the flow rate was controlled by a countercurrent pump, the effluent was collected, and dried to obtain 2.5 g of low-sensitivity whey protein hydrolyzate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com