Patents

Literature

40results about How to "Increase or decrease intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

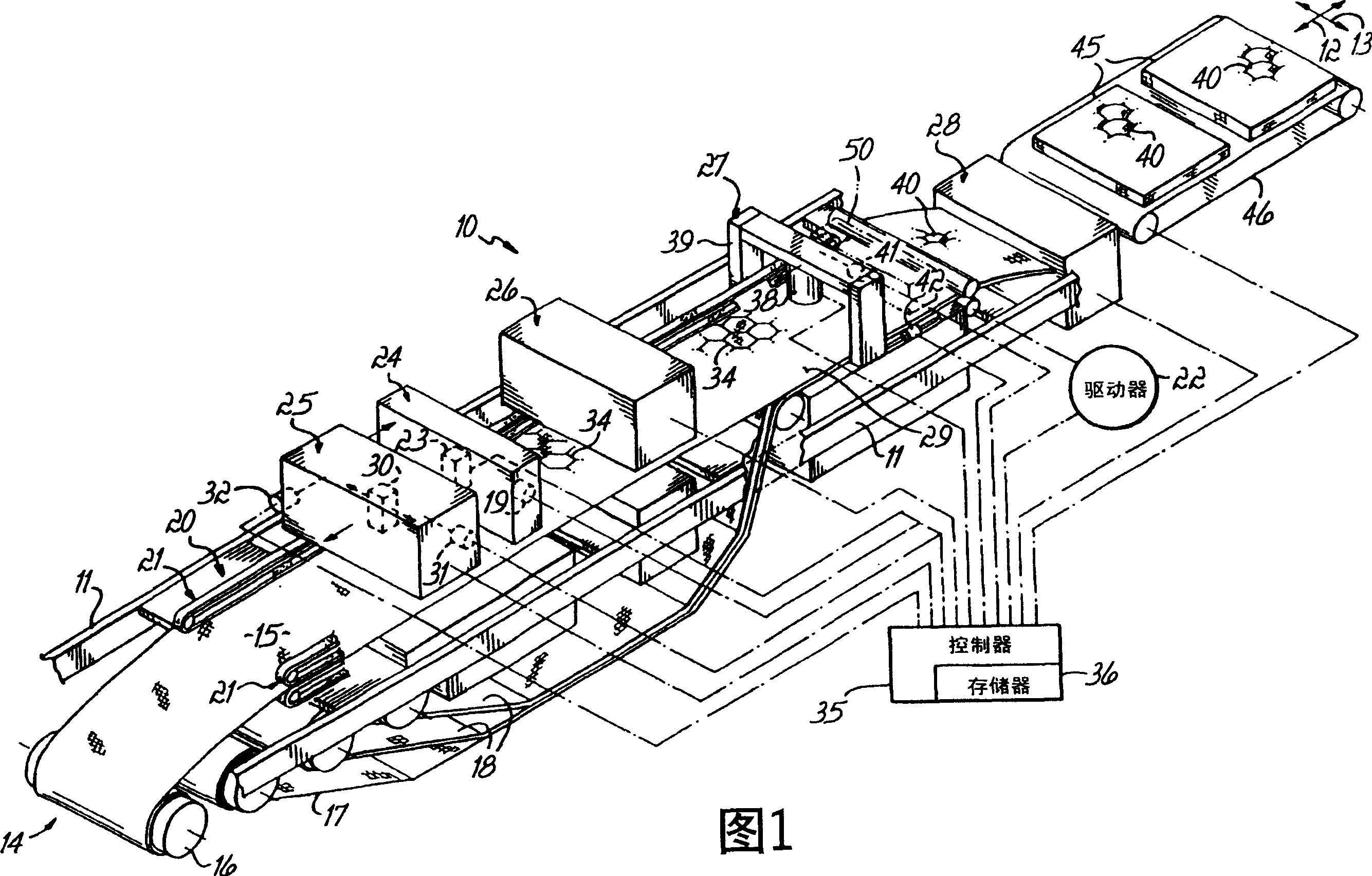

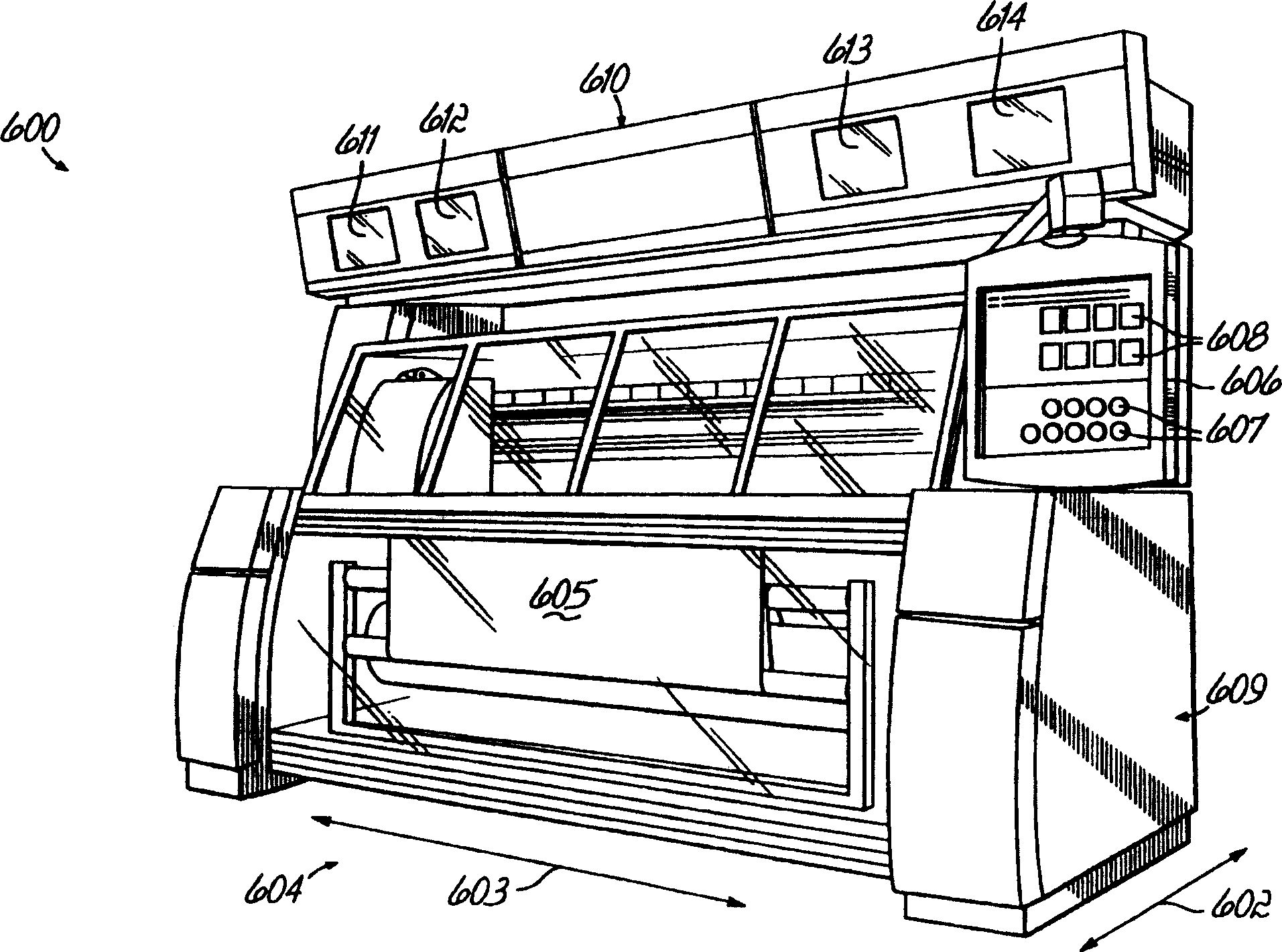

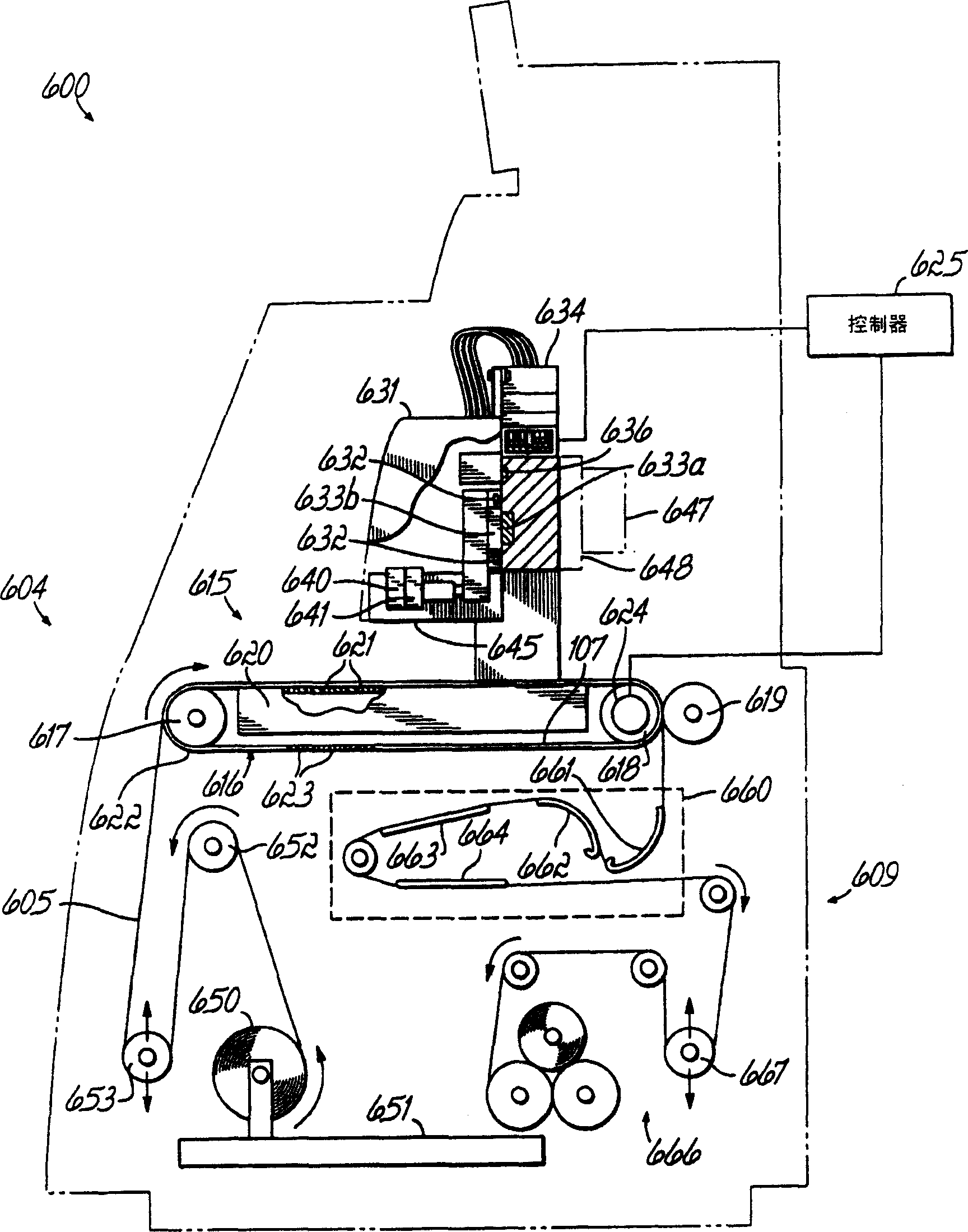

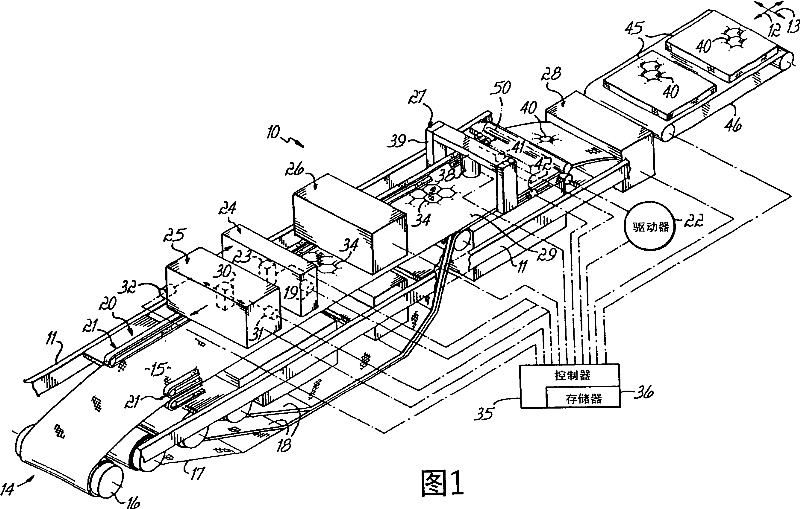

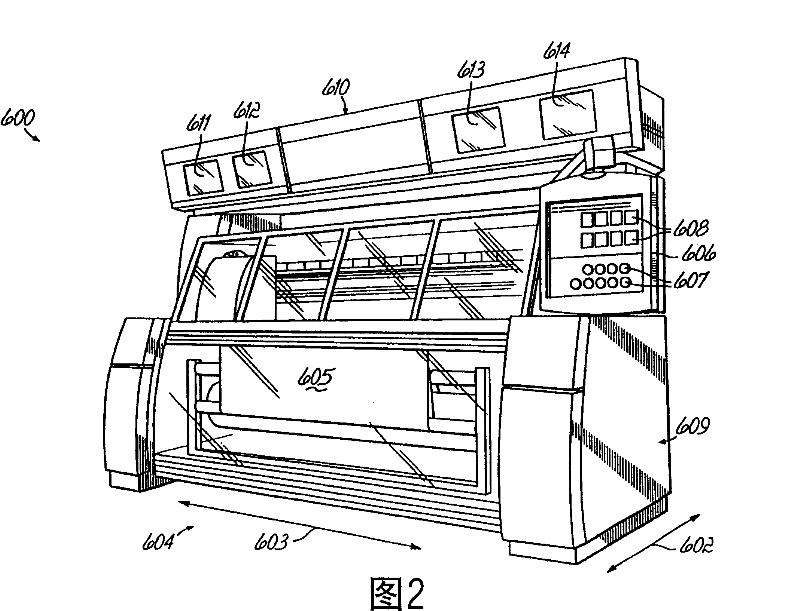

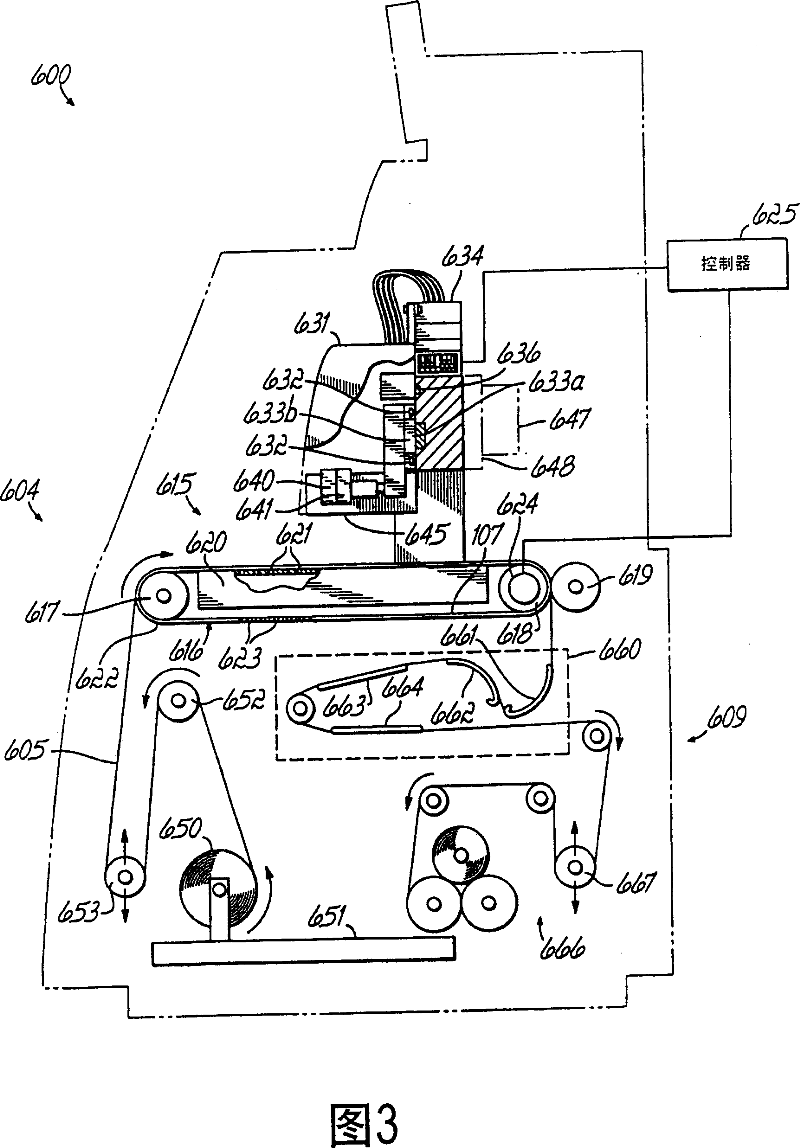

Method and apparatus for ink jet printing

InactiveCN1678458AEliminate cloggingImprove reliabilityDuplicating/marking methodsSpacing mechanismsPorous substratePolyester

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640, 641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645, 646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661, 662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702, 704) such as a TEFLON film or sheet, covers a substrate support (705, 706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material.

Owner:L & P PROPERTY MANAGEMENT CO

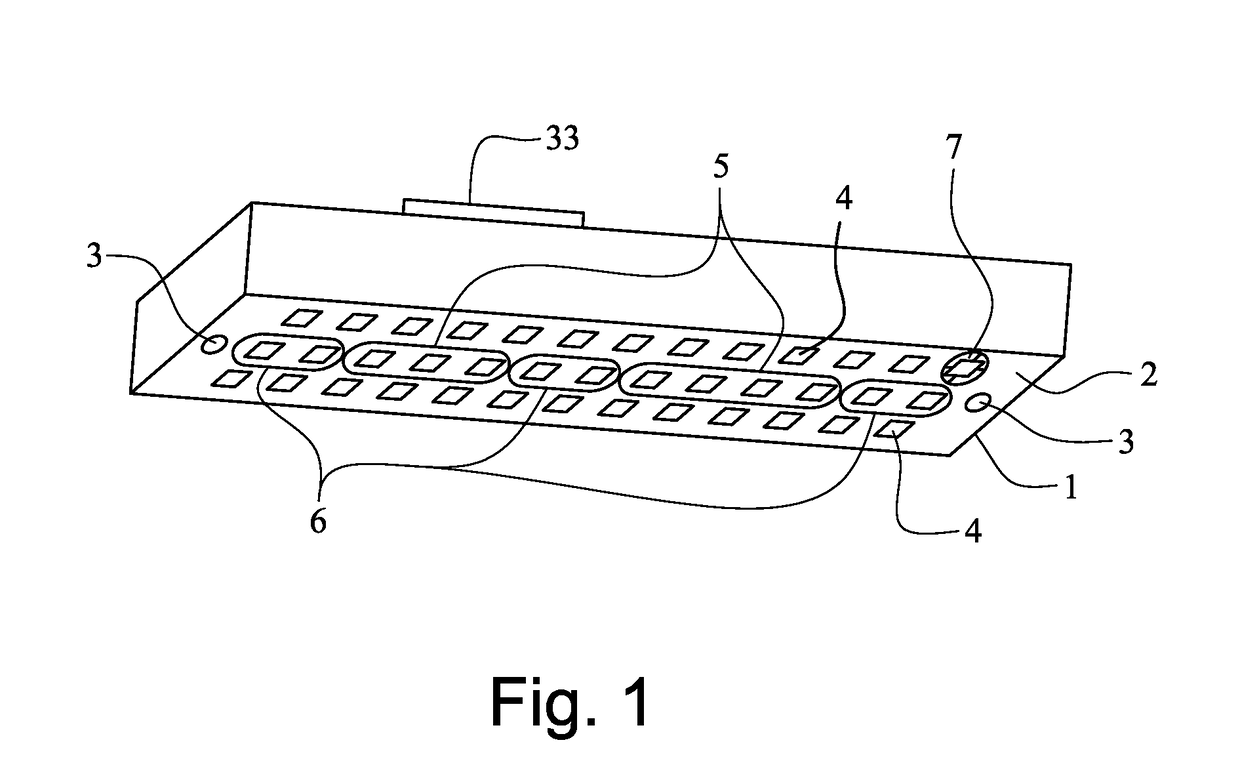

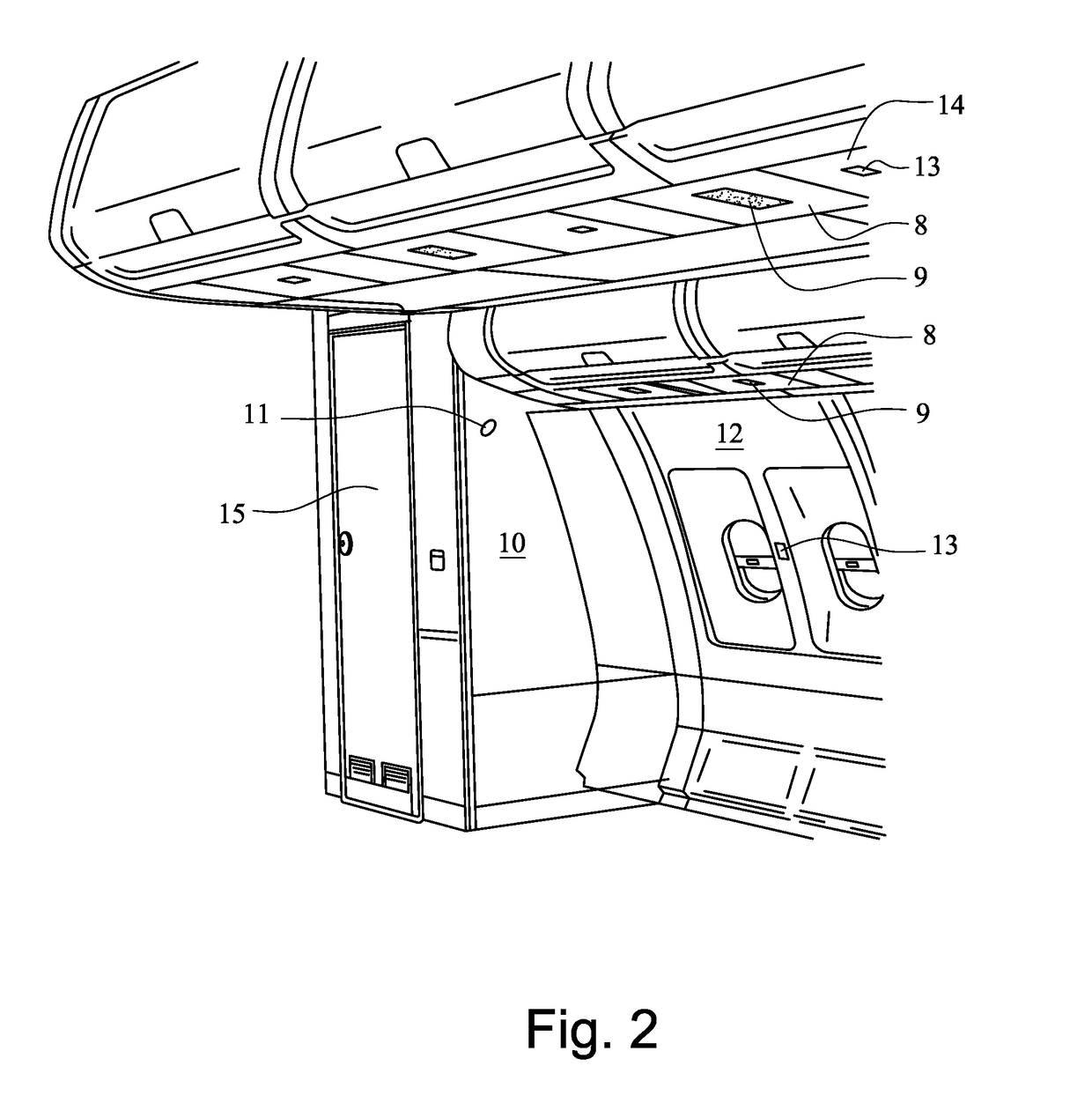

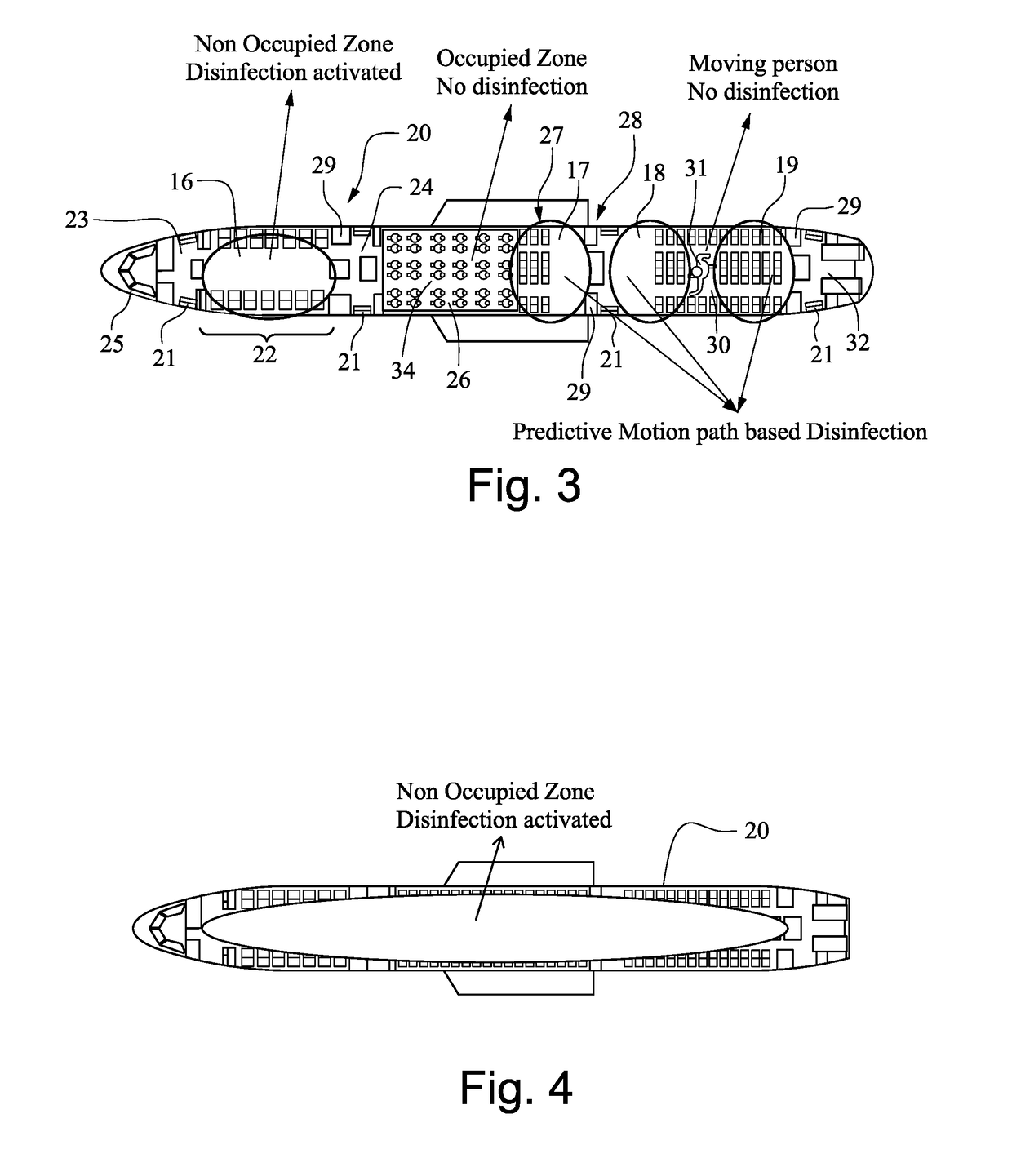

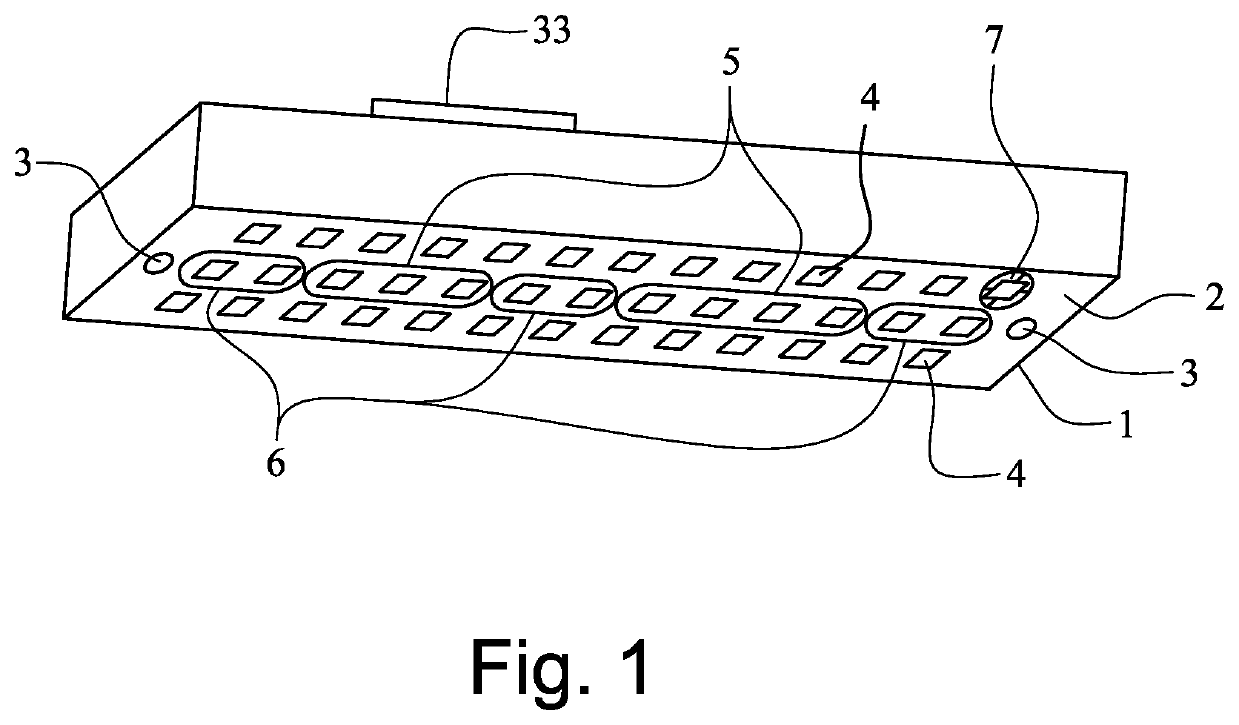

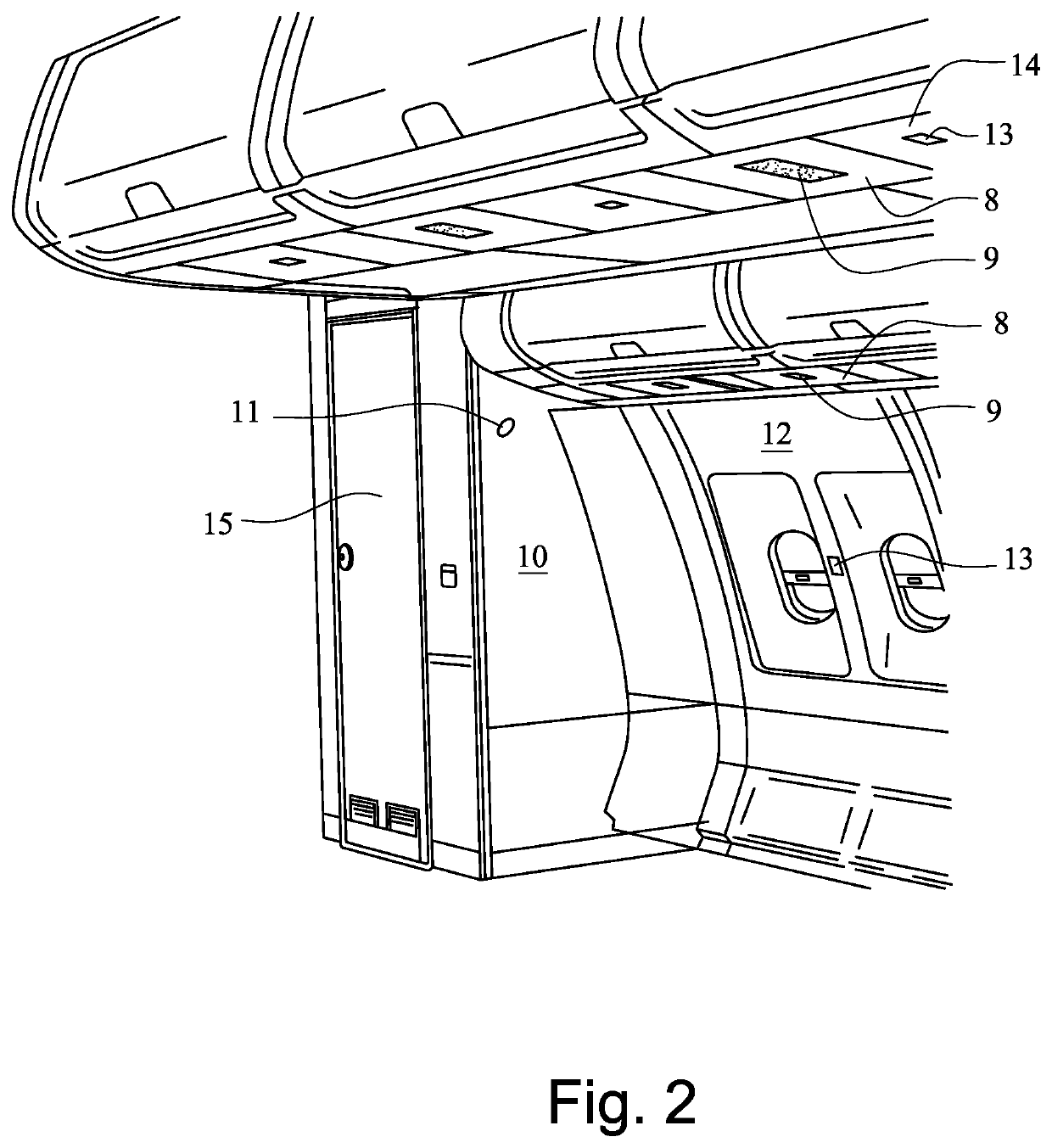

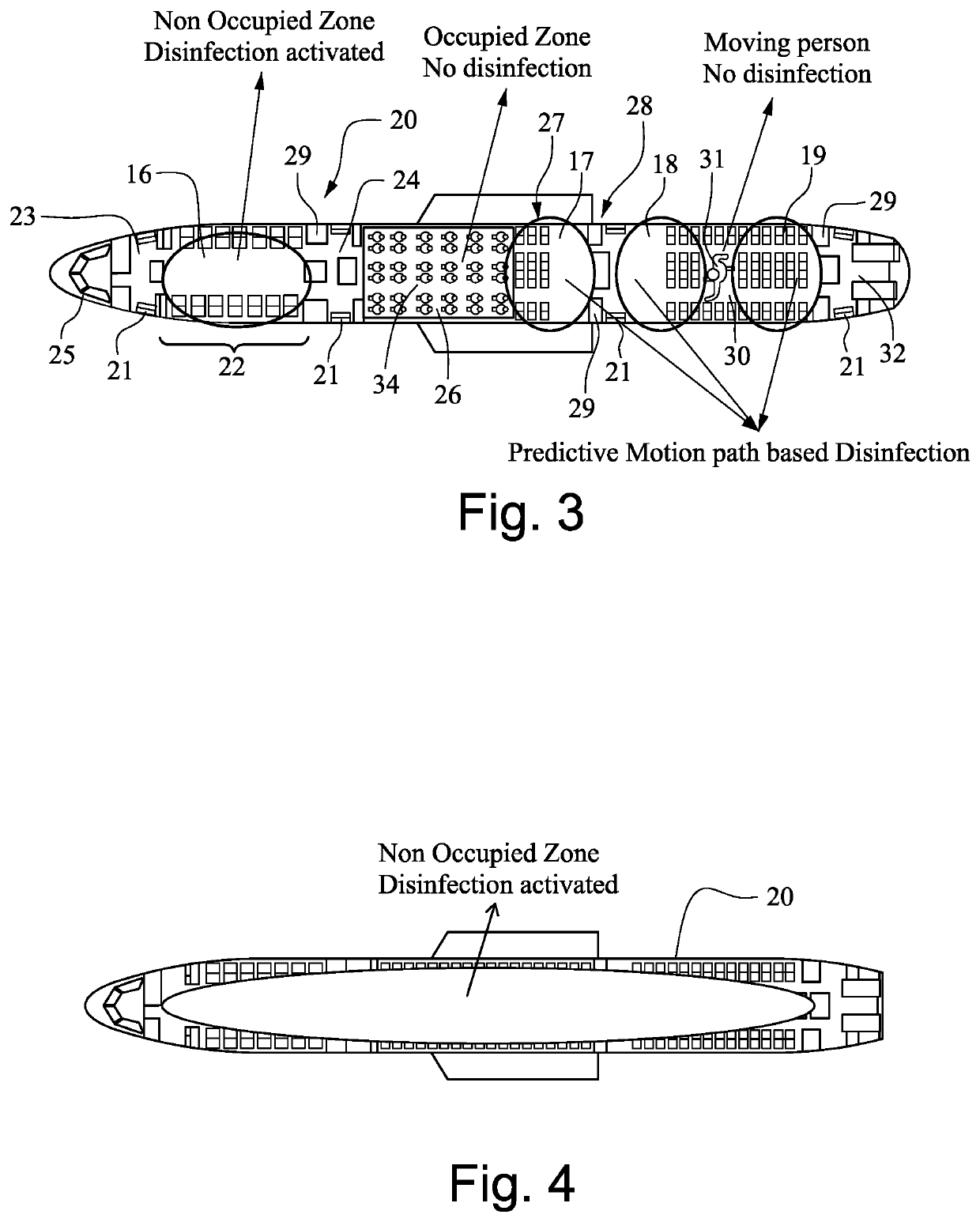

Aircraft cabin disinfection system

ActiveUS20190030195A1Lot of radiationAvoid less flexibilityLavatory sanitoryAircraft cleaningUVC RadiationEngineering

A cabin disinfection system for an aircraft, including: a sensing means (3, 11, 13) to sense the presence of personnel in one or more zones (16-19, 23-26, 28, 29, 30, 32), a predictive sensing means (3, 11, 13, 33) to sense the direction of motion of a person (31) and to predict whether that person will occupy a zone to be disinfected (18) during planned disinfection, one or more UVC radiation sources (4, 9) to disinfect the cabin, and a controller (33) to control operation of the UVC radiation sources (4, 9) dependent on sensing of personnel in that zone and the predictive sensing means (3, 11, 13, 33) predicting that a person (31) will occupy the zone (18) during the planned disinfection period.

Owner:AIRBUS SAS

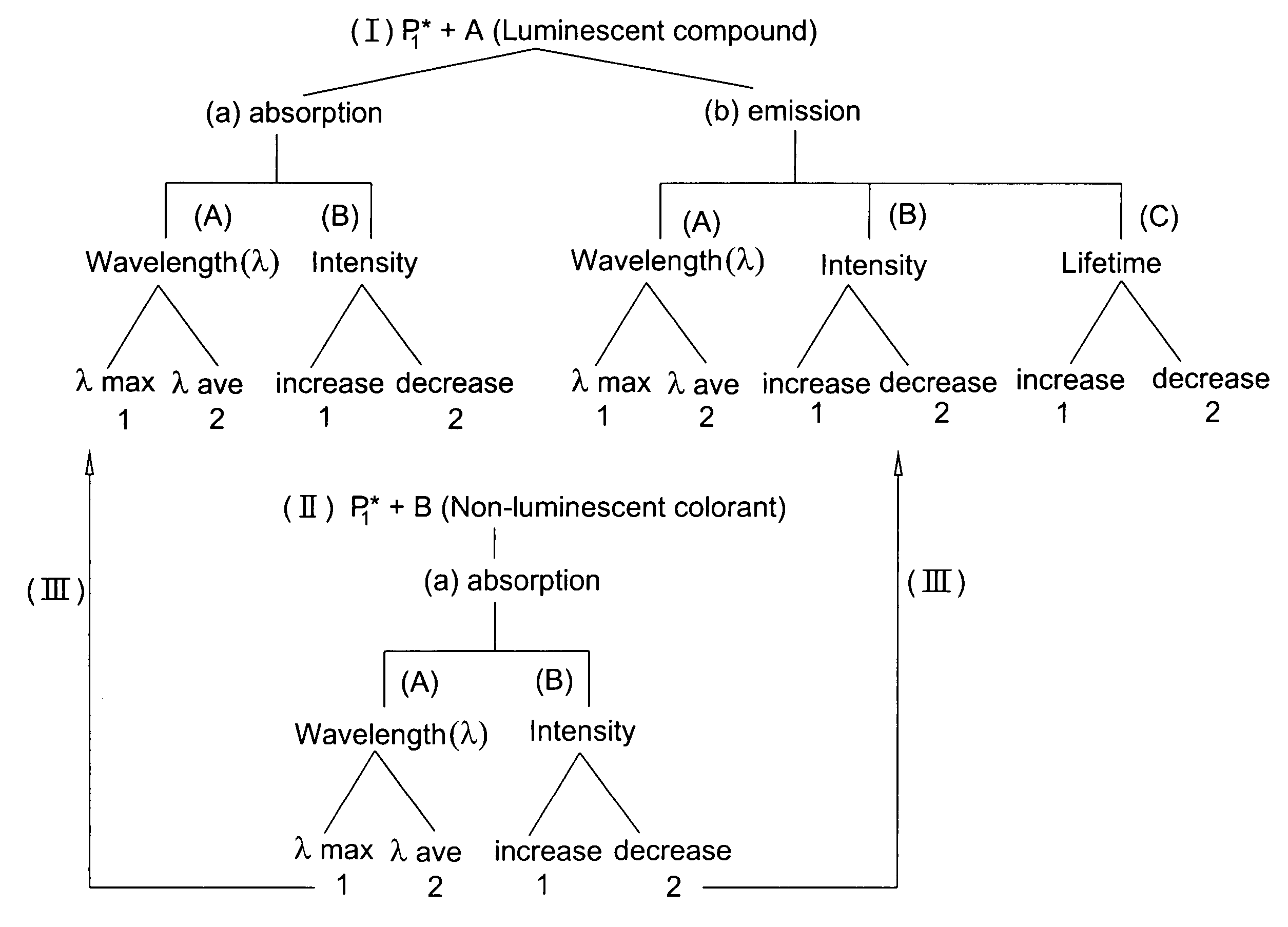

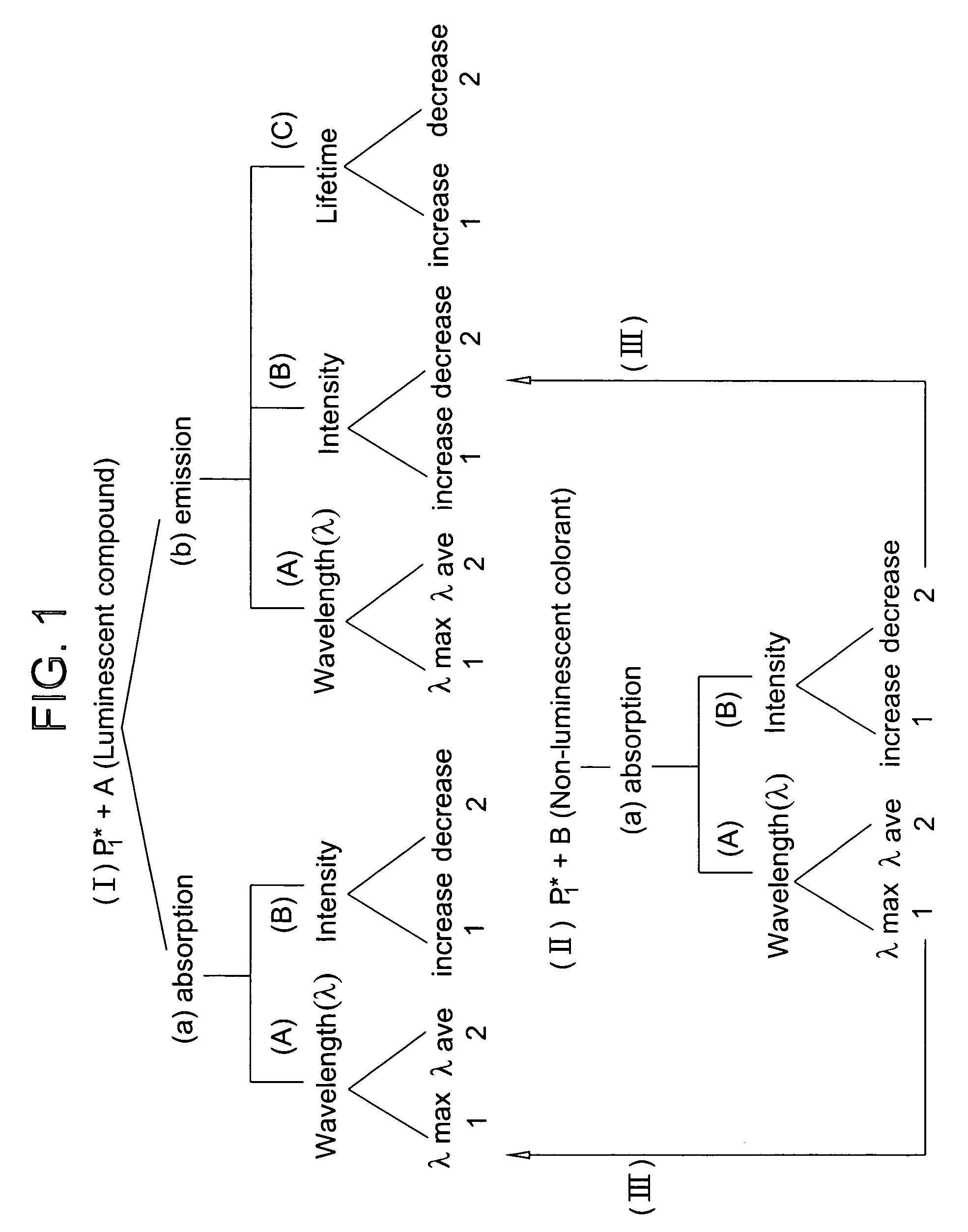

Ink jet ink composition and method for security marking

ActiveUS7147801B2Suitable for printingLuminescence quenchingNon-fibrous pulp additionLayered productsSolventLuminescence

Disclosed is an ink composition suitable for ink jet printing comprising a luminescent compound, a solvent, and an energy active compound, and optionally a non-luminescent colorant. The energy active compound, when exposed to energy, generates one or more active species that can react with the luminescent compound to alter one or more of the characteristics of the luminescent compound. The luminescent compound can be colored or colorless. Also disclosed is a method for marking substrates comprising providing a mark comprising a luminescent compound and an energy active compound. Further disclosed is a jet ink composition suitable for printing on substrates authentication or security marks which can be rendered unreadable. The luminescence of the mark is quenched and the visible color is changed when irradiated with a light.

Owner:VIDEOJET TECH INC

Fitness Board

InactiveUS20120329619A1Extended range of motionIncrease range of of exerciseSpace saving gamesStiltsEngineeringPhysical exercise

An exercise or fitness board having a deck adjustably attached to a base to adjust the angle of incline of the deck relative to the base, and a plurality of straps attached to the deck for the user to grasp for balance and exercise. The deck and / or base contains various contours, scallops, cutouts, and the like to facilitate comfortable and varied positioning of the body. A rail and / or channel may be placed on the underside and along the perimeter of the board to facilitate grip. A pad or mat may be placed on top of the board and / or base for comfort, stability, and protection.

Owner:JOHNNY G METHOD

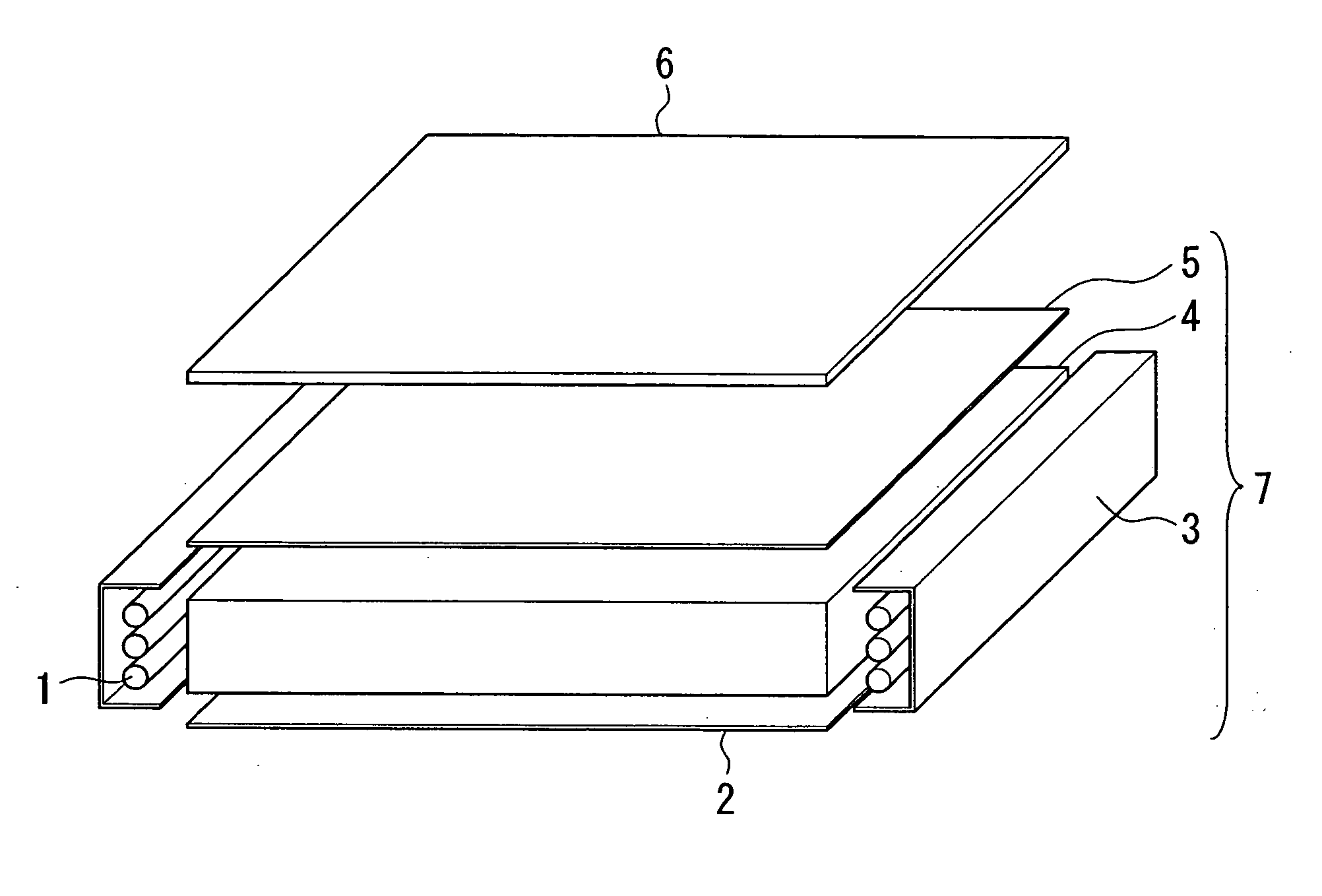

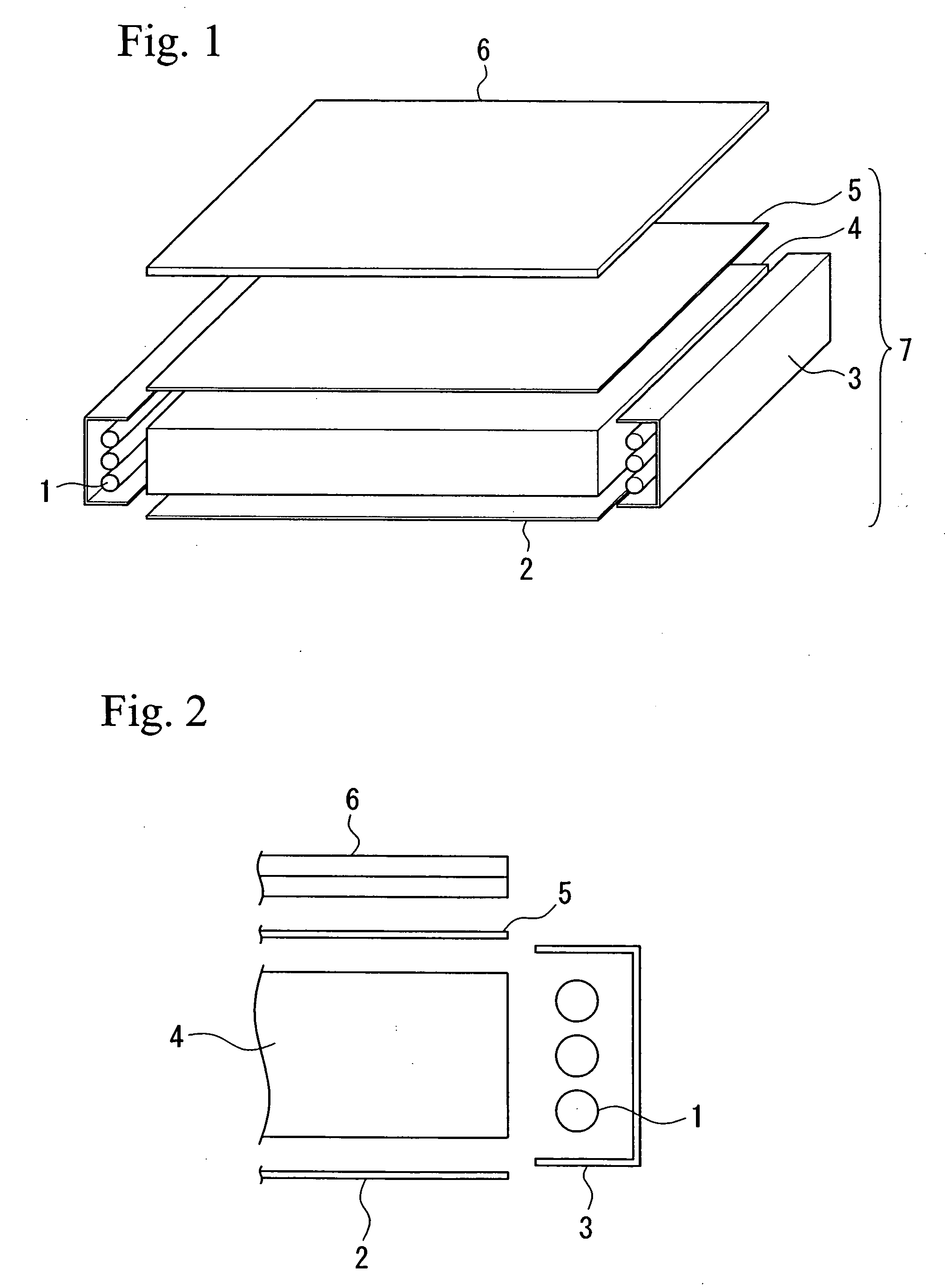

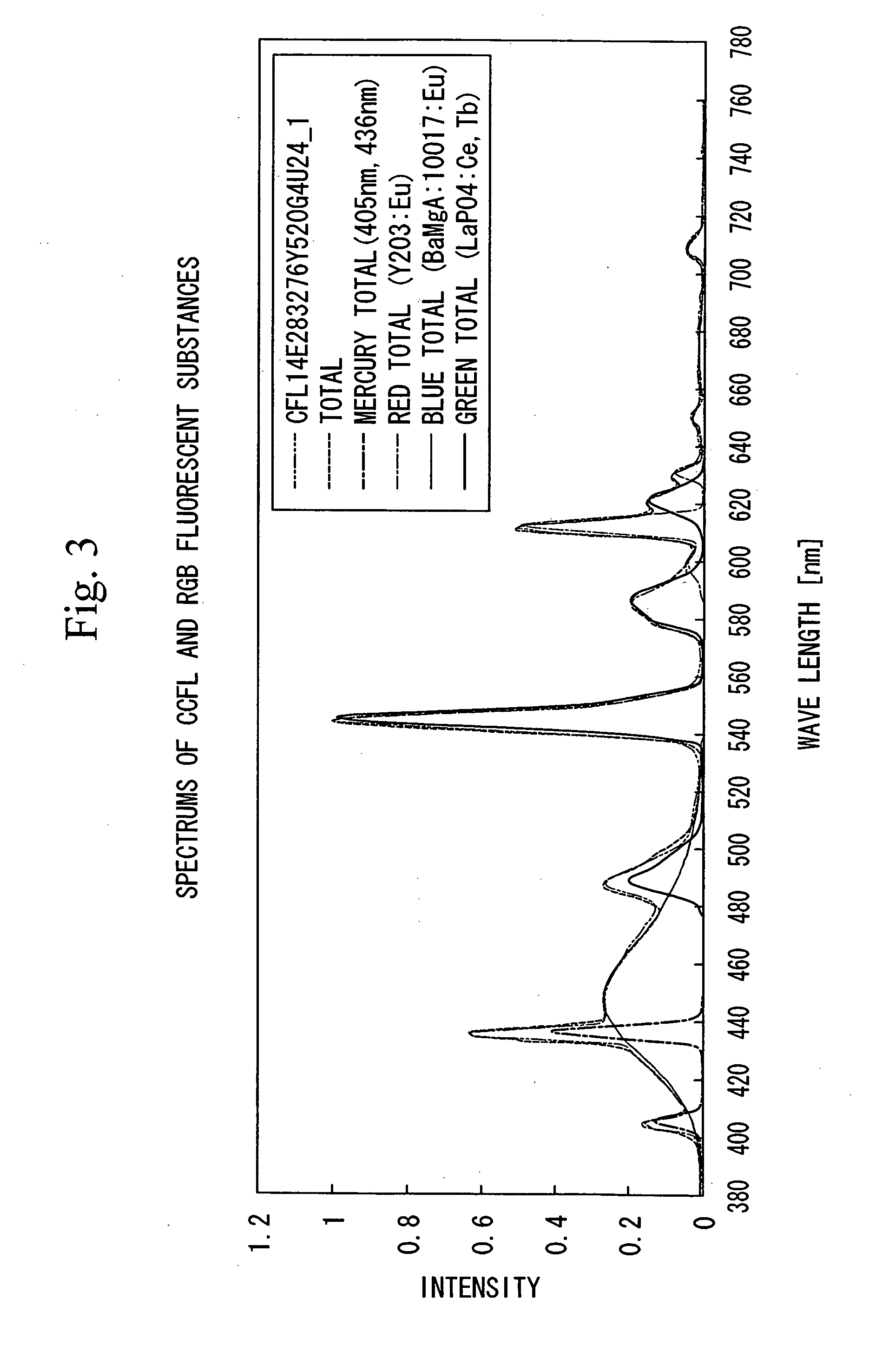

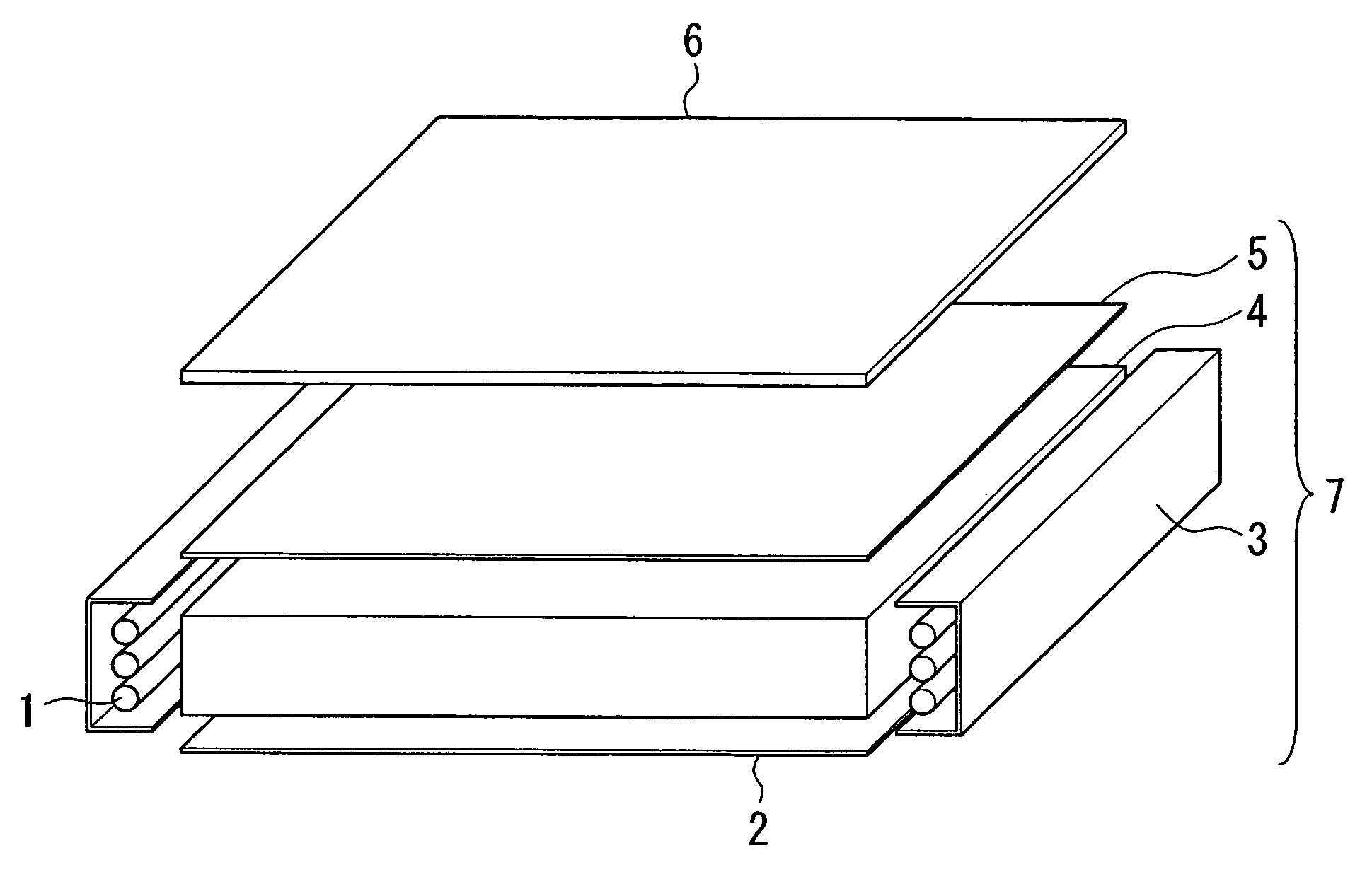

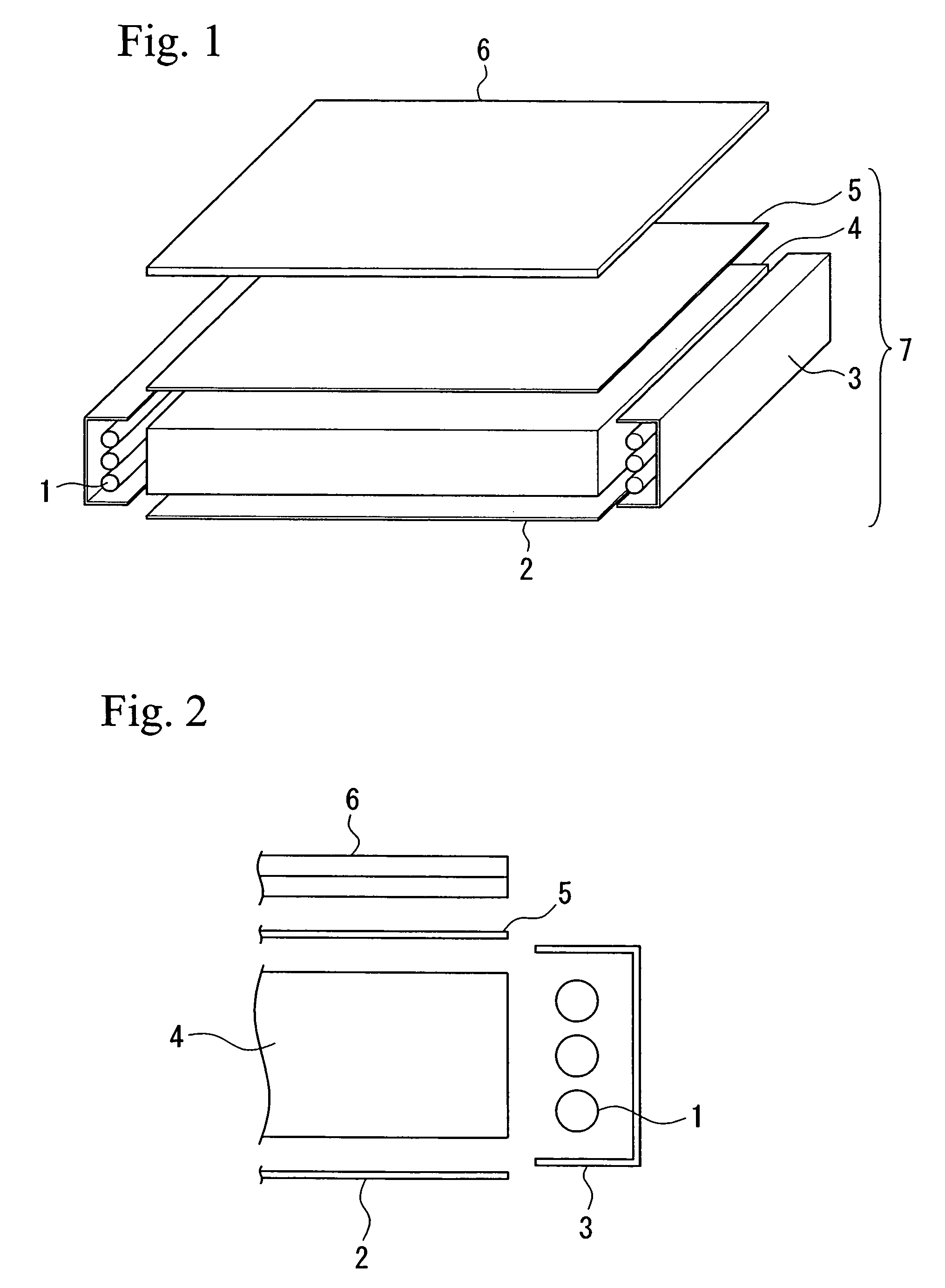

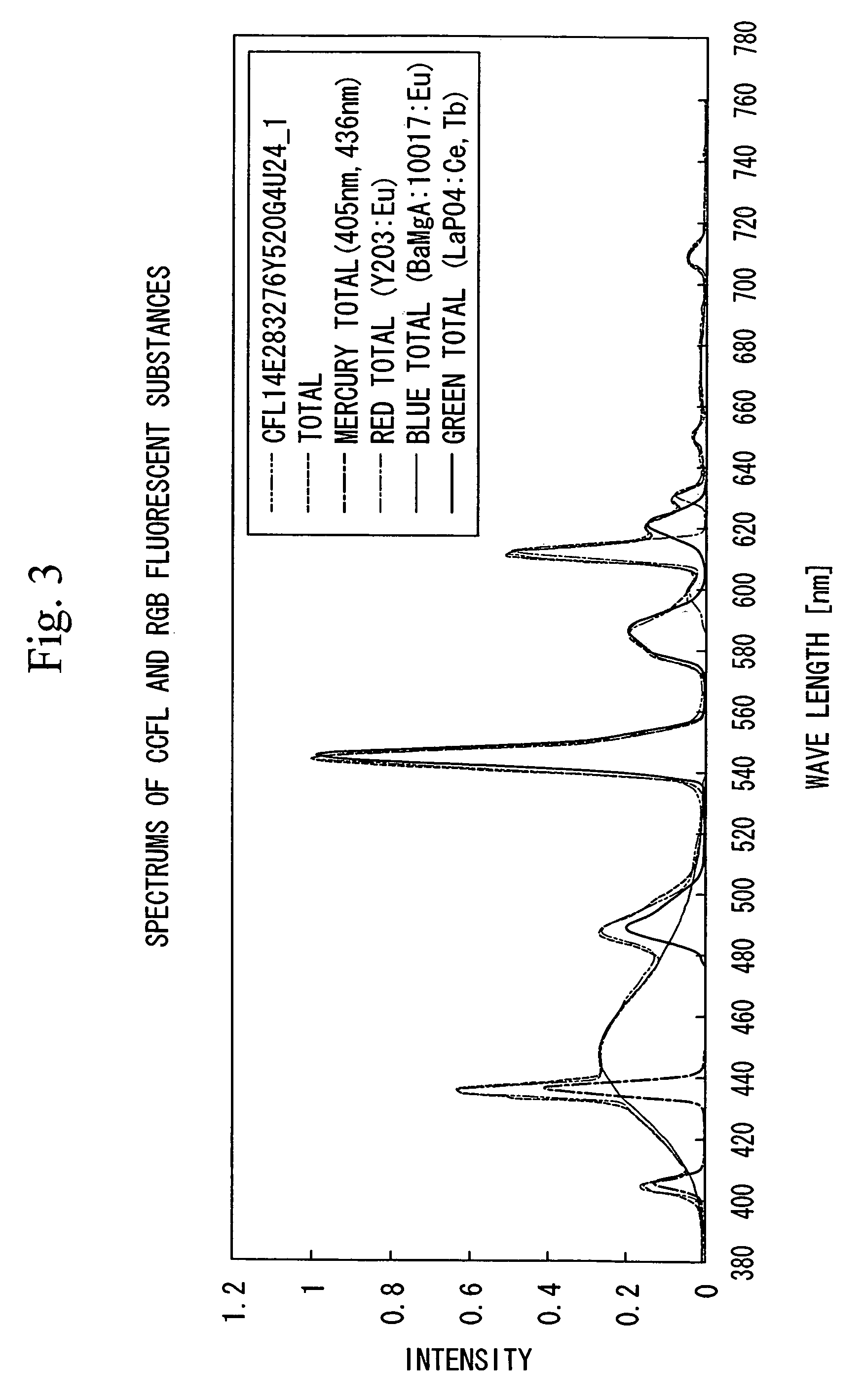

Image display apparatus

InactiveUS20050116609A1Constant chromaticityImprove color uniformityMechanical apparatusDischarge tube luminescnet screensLight sourceComputer graphics (images)

An image display apparatus is provided that enables the chromaticity of a display screen of a display apparatus to be adjusted to the chromaticity desired by a user. The image display apparatus is formed by a backlight unit that is provided with a plurality of light sources and by an image display panel that is placed at a front surface of the backlight unit. The image display apparatus performs a monochrome display. In the image display apparatus, the light sources have at least three different types of luminescent colors that surround a target color on a chromaticity diagram.

Owner:MITSUBISHI ELECTRIC CORP +1

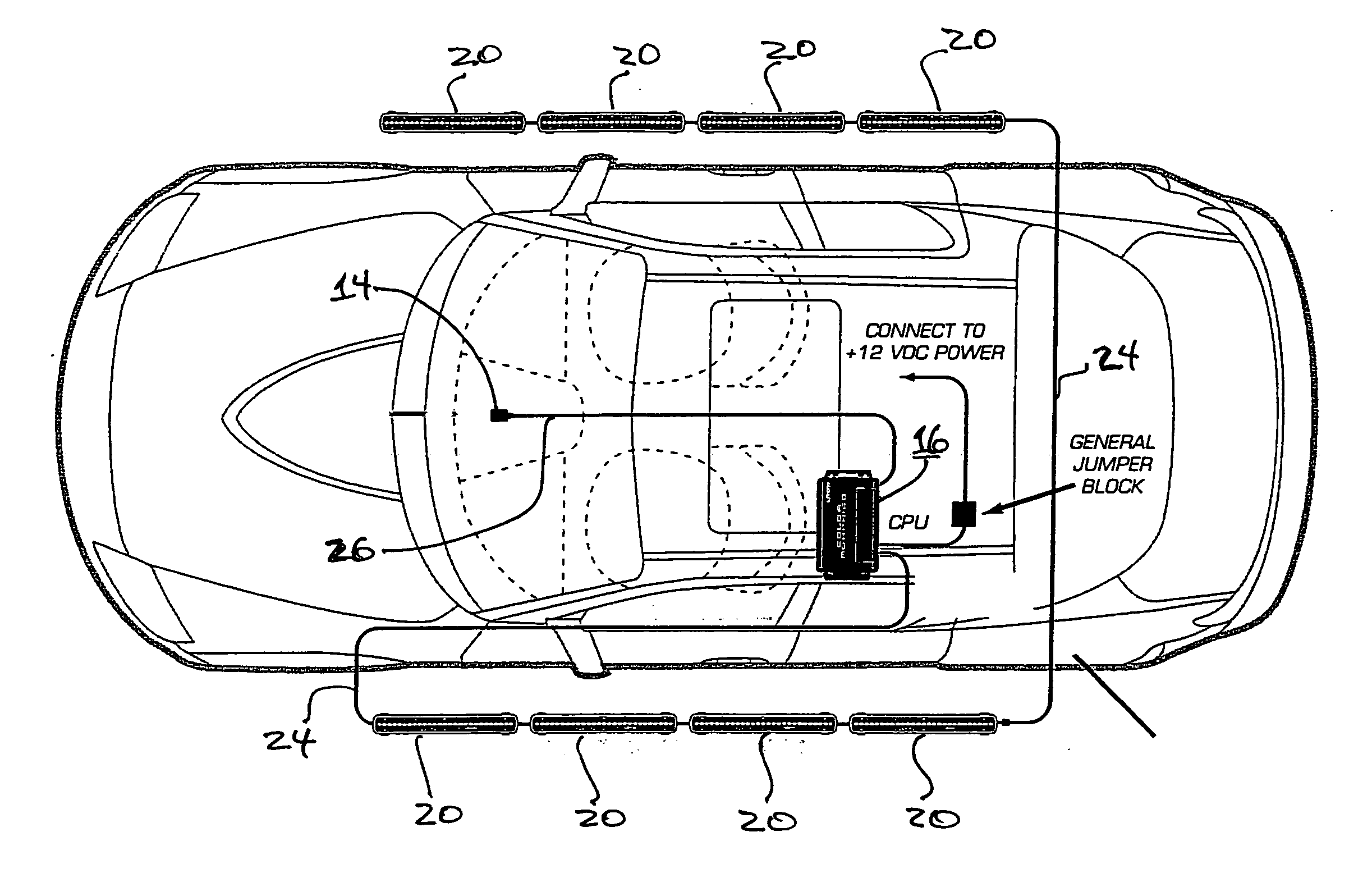

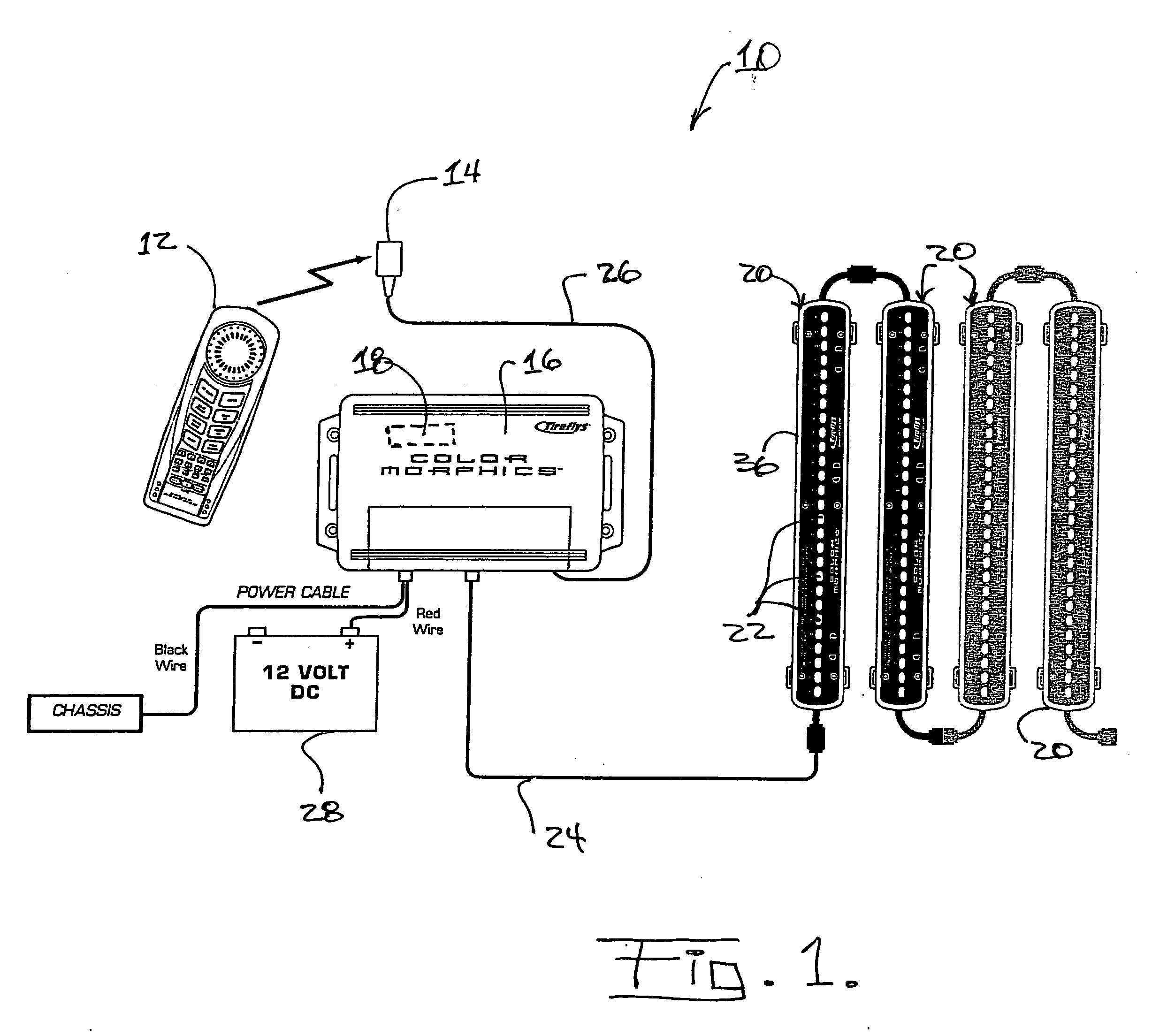

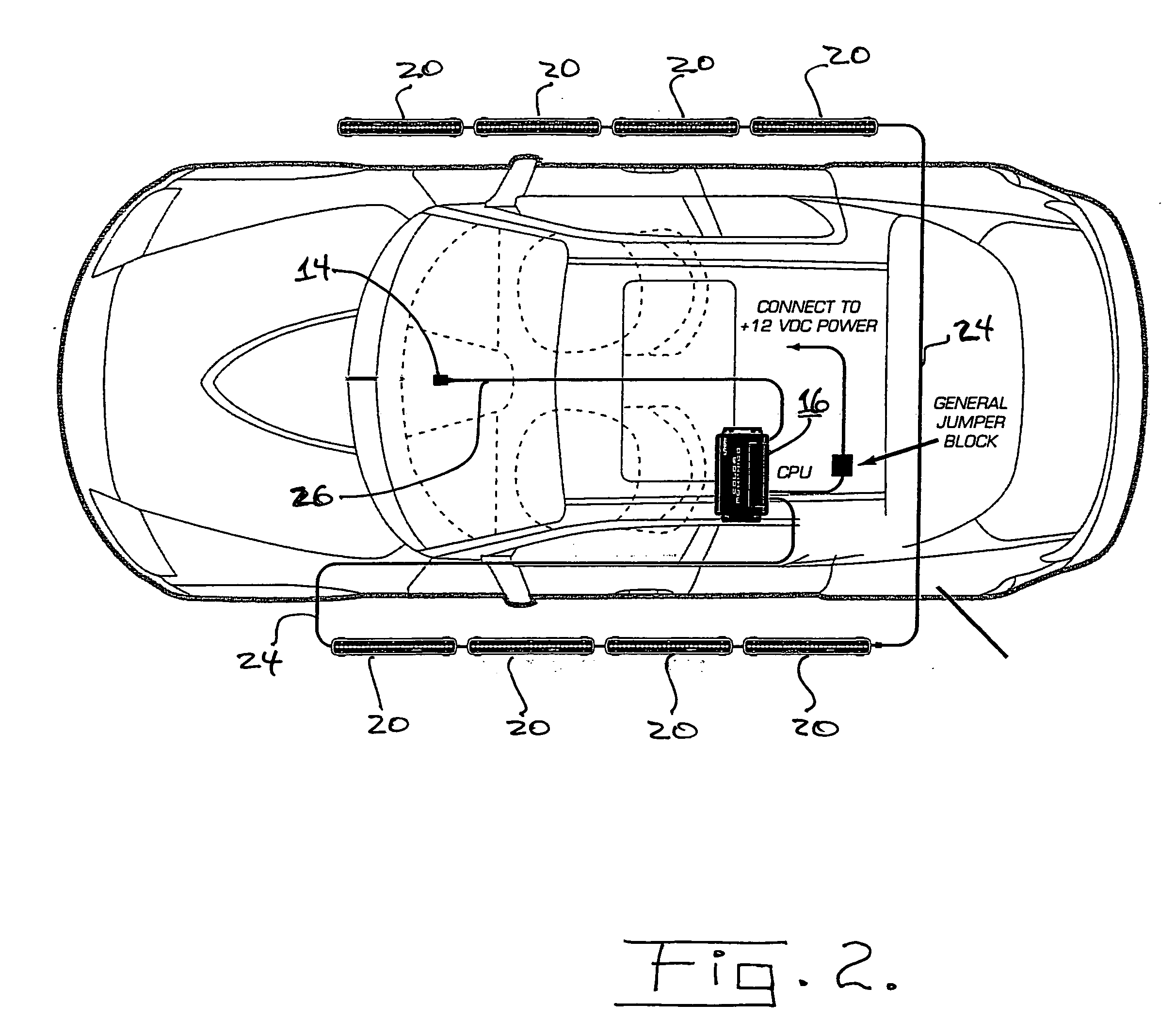

Decorative light system for motor vehicles

InactiveUS20050242969A1Increase and decrease intensity of light outputIncrease or decrease intensityVehicle interior lightingElectric/electromagnetic visible signallingMobile vehicleMicrocontroller

A light system for a motor vehicle includes a hand-held remote control unit is capable of generating a wireless or infrared signal containing one or more commands. A sensor is capable of recognizing the signal from the remote control and generates a sensor signal responsive thereto. A CPU is operable on direct current and contains a microcontroller and connected to said sensor to thereby generate a control signal responsive to said sensor signal. The CPU also has an input for receiving a signal containing sound information and is capable of coordinating the control signal with the sound information. A light unit has a substantially weather resistant housing made at least partially of light penetrable material and contains therein a plurality of LEDs operatively connected to said CPU, said plurality of LEDs being capable of generating light containing one or more wavelengths responsive to the control signal from the CPU.

Owner:THEORY3

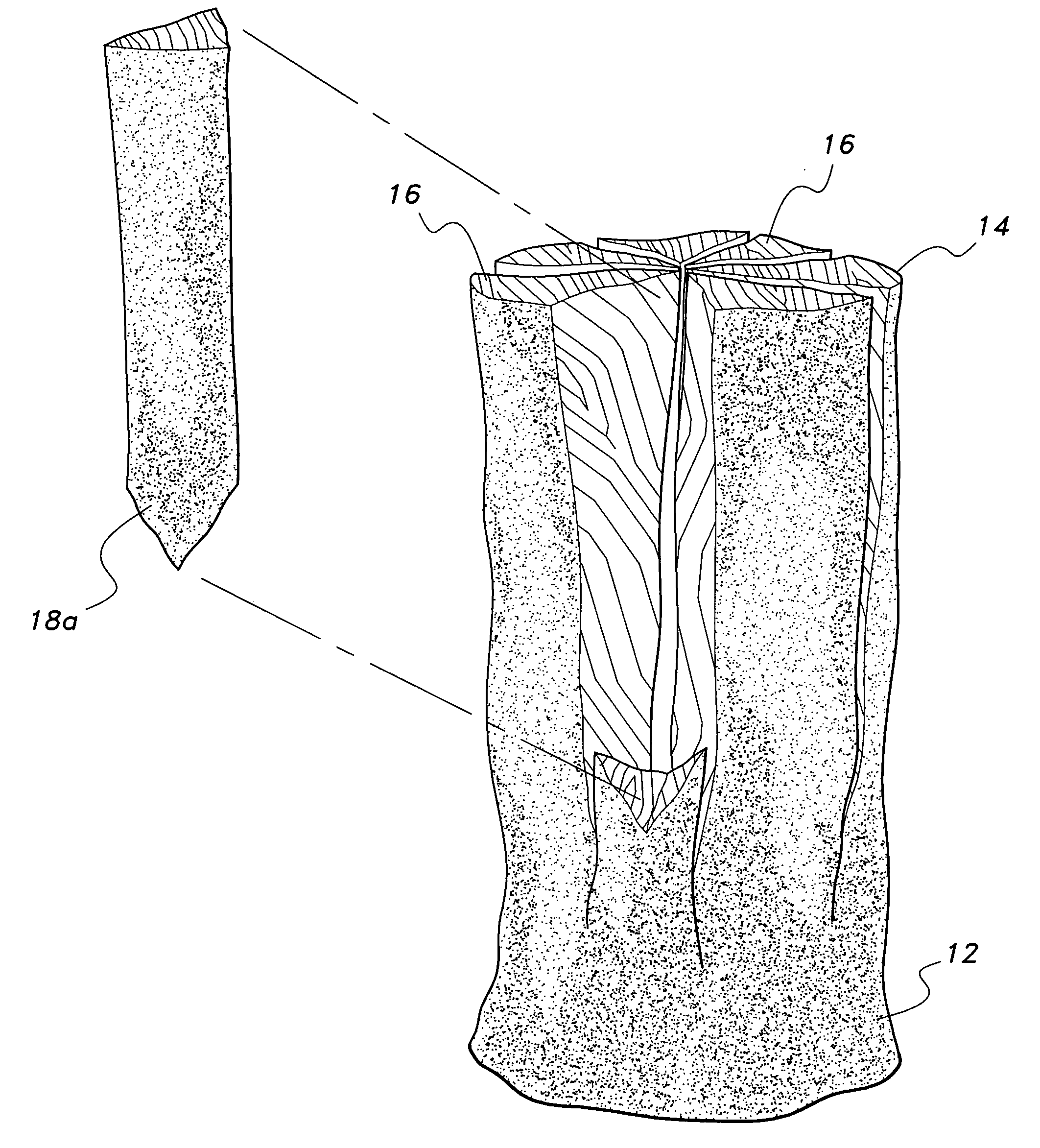

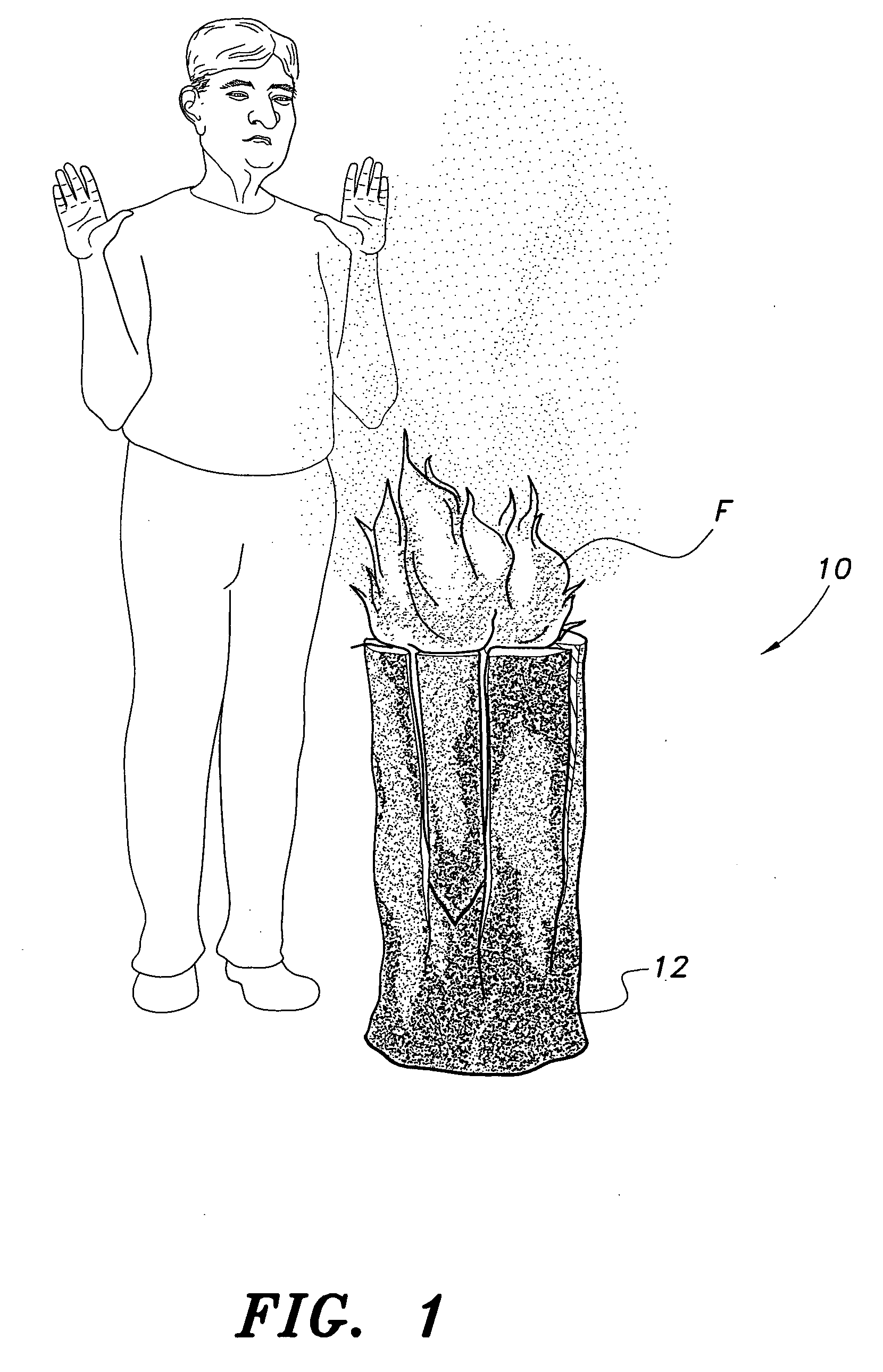

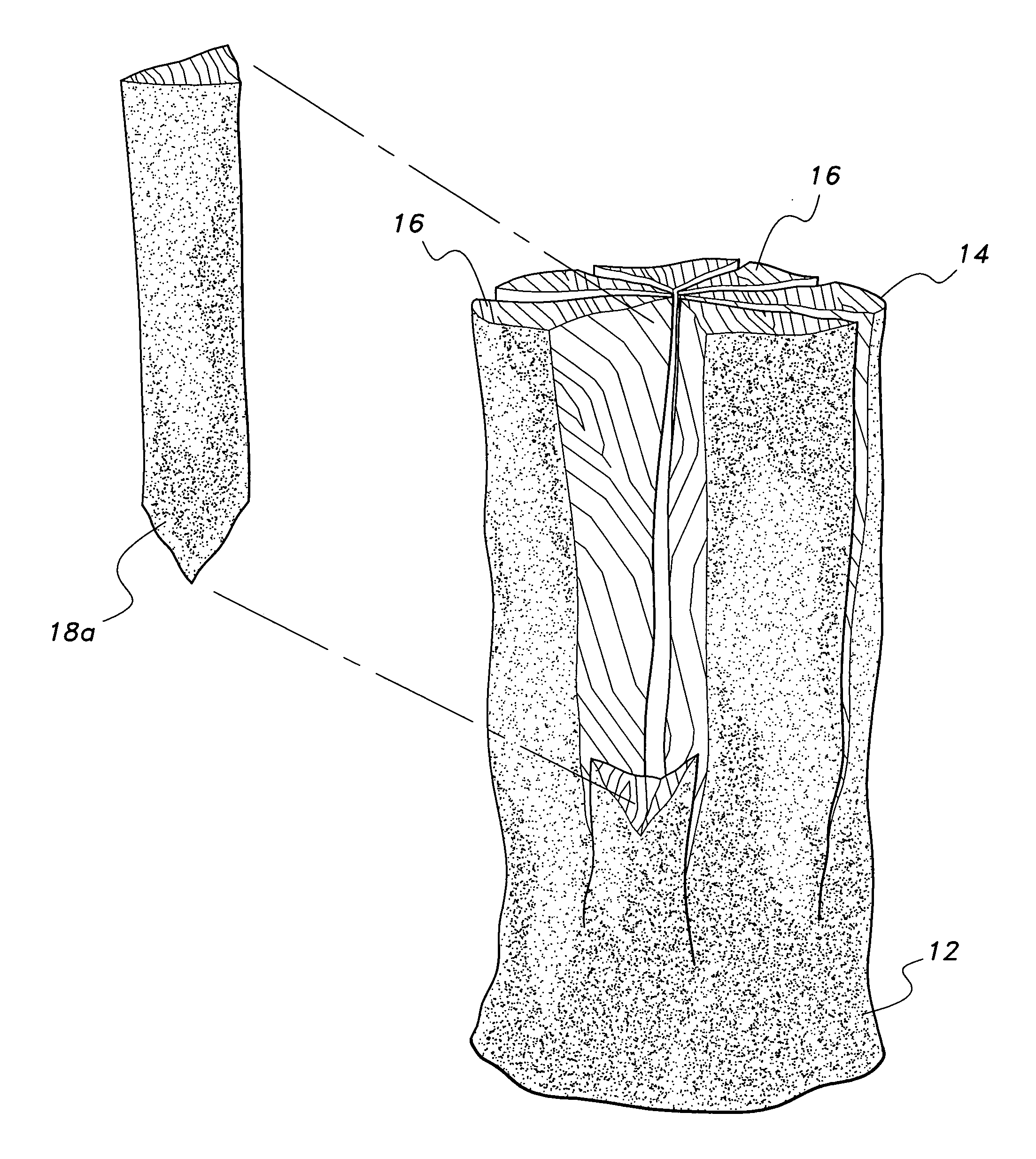

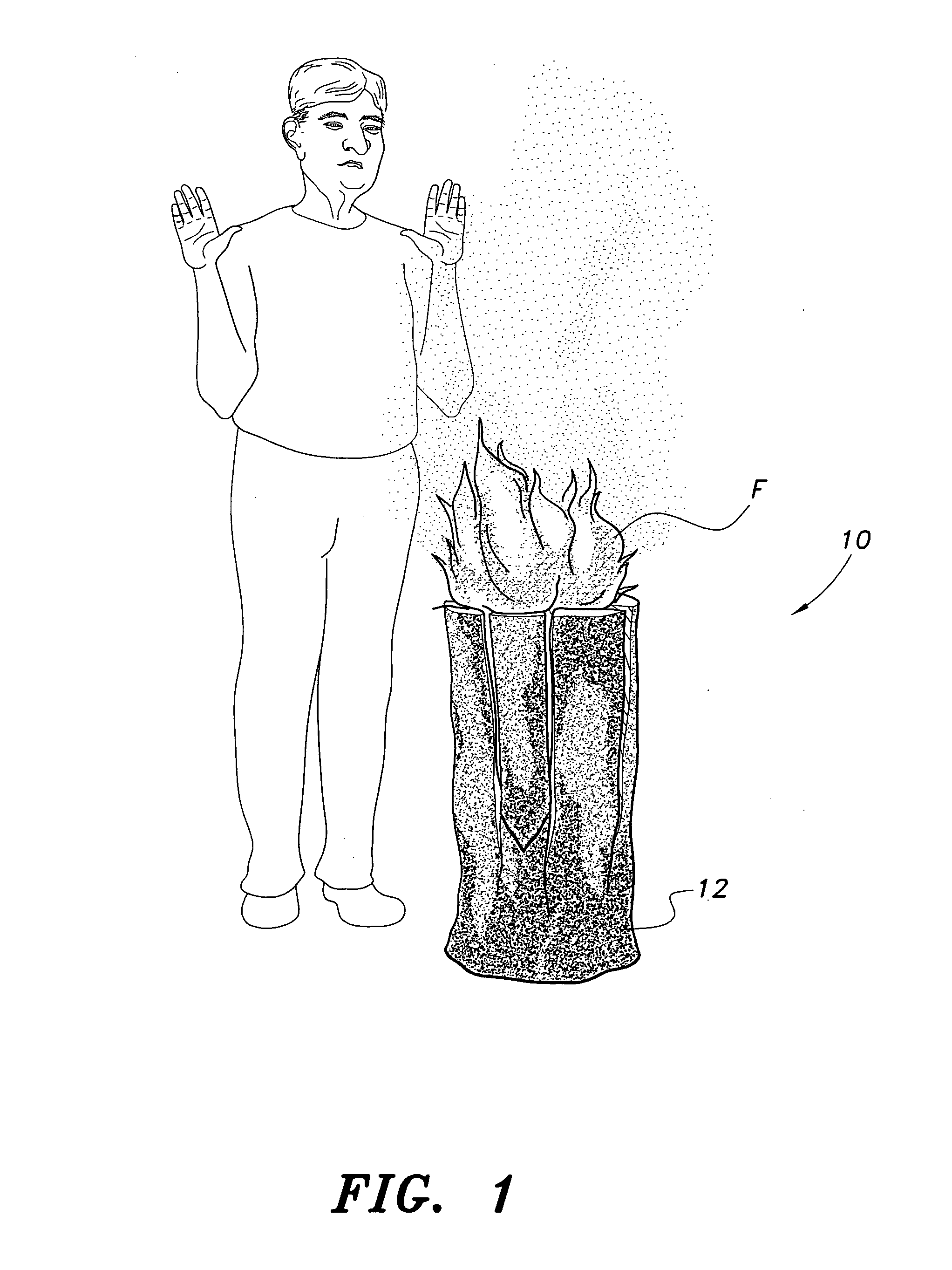

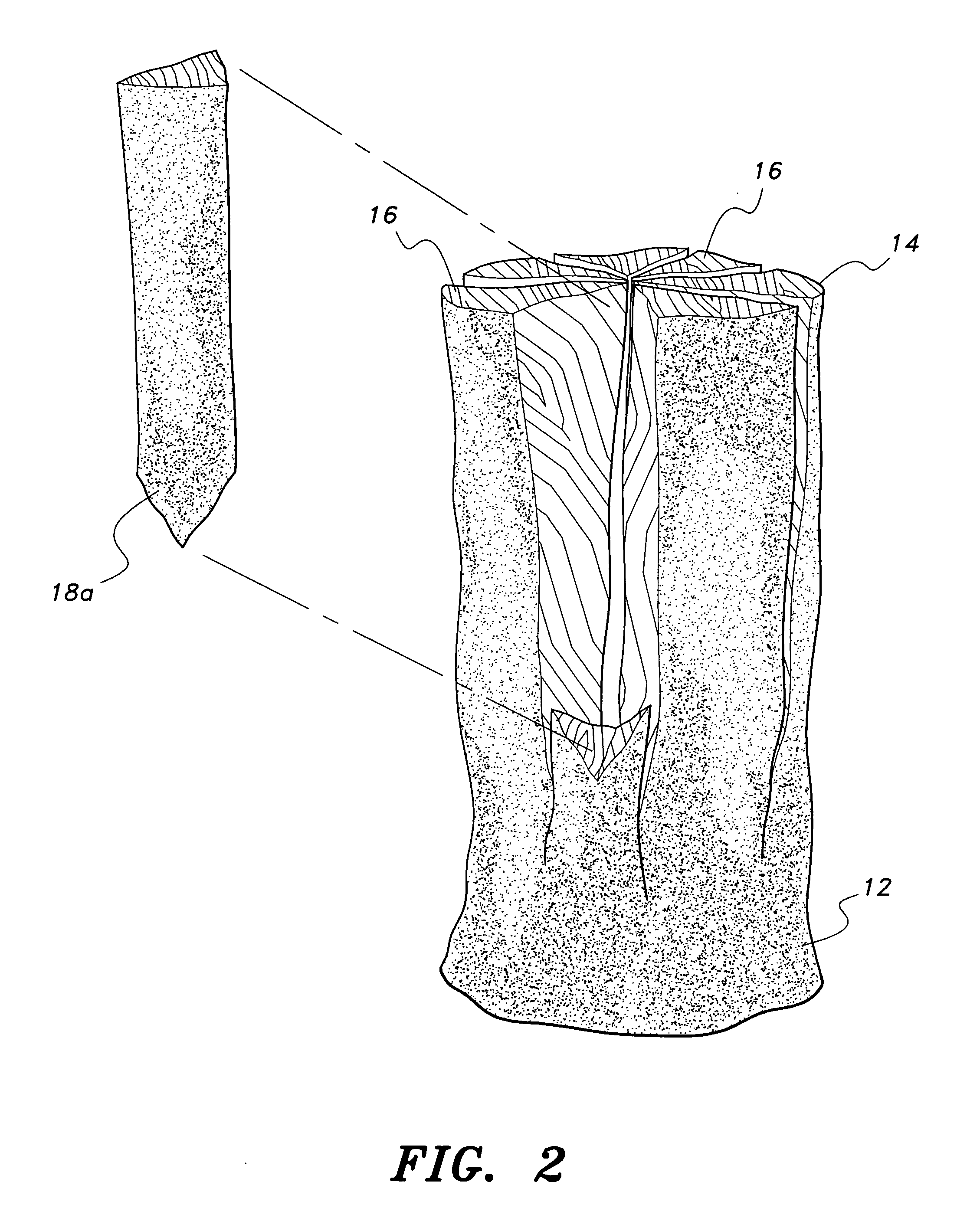

Fire log

InactiveUS20090307968A1Easy to igniteIncrease or decrease intensitySawing apparatusBiofuelsMostly TrueEngineering

A fire log includes a single fire log cut in a specific design to enable easy ignition and sustenance of a self-contained campfire. The single log is designed to stand vertically and may range from twenty-four to seventy-two inches in height depending on diameter. In most instances, four vertical, diametrical cuts are made in the log forming eight pie-slice segments. The cuts extend from the top surface of the log downward toward the base of the log. The vertical cuts stop short of the entire length of the log leaving approximately 25% of the length uncut. The uncut portion forms the base of the log. One of the segments is cut horizontally at its lower end adjacent the top of the base so that the segment can be removed from the log for air flow control.

Owner:PARKER WALTER Z

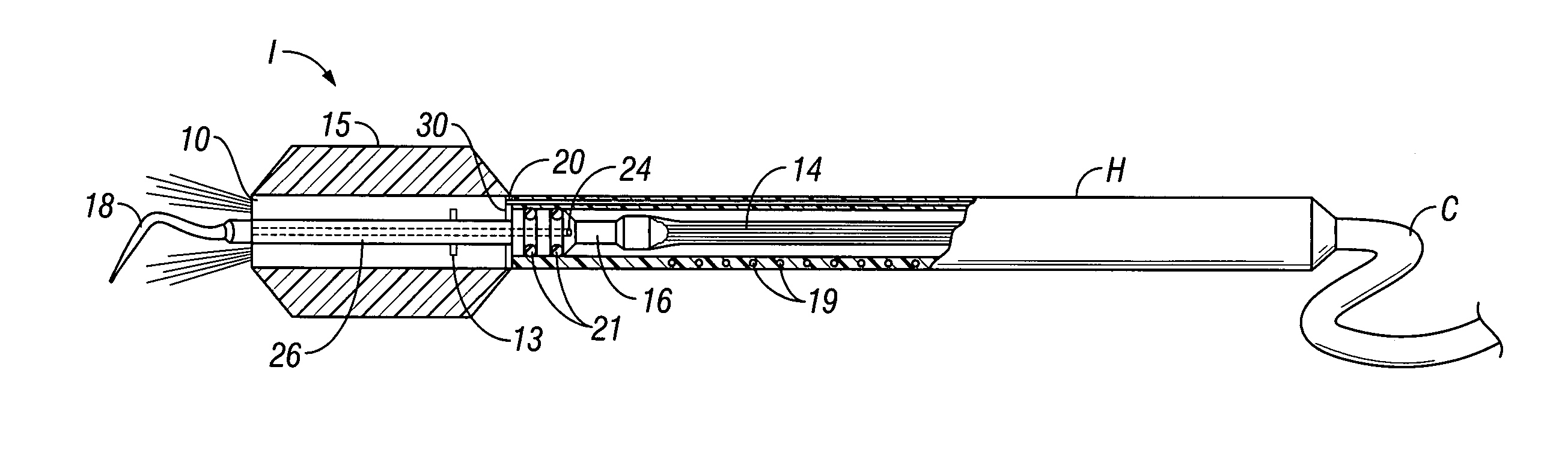

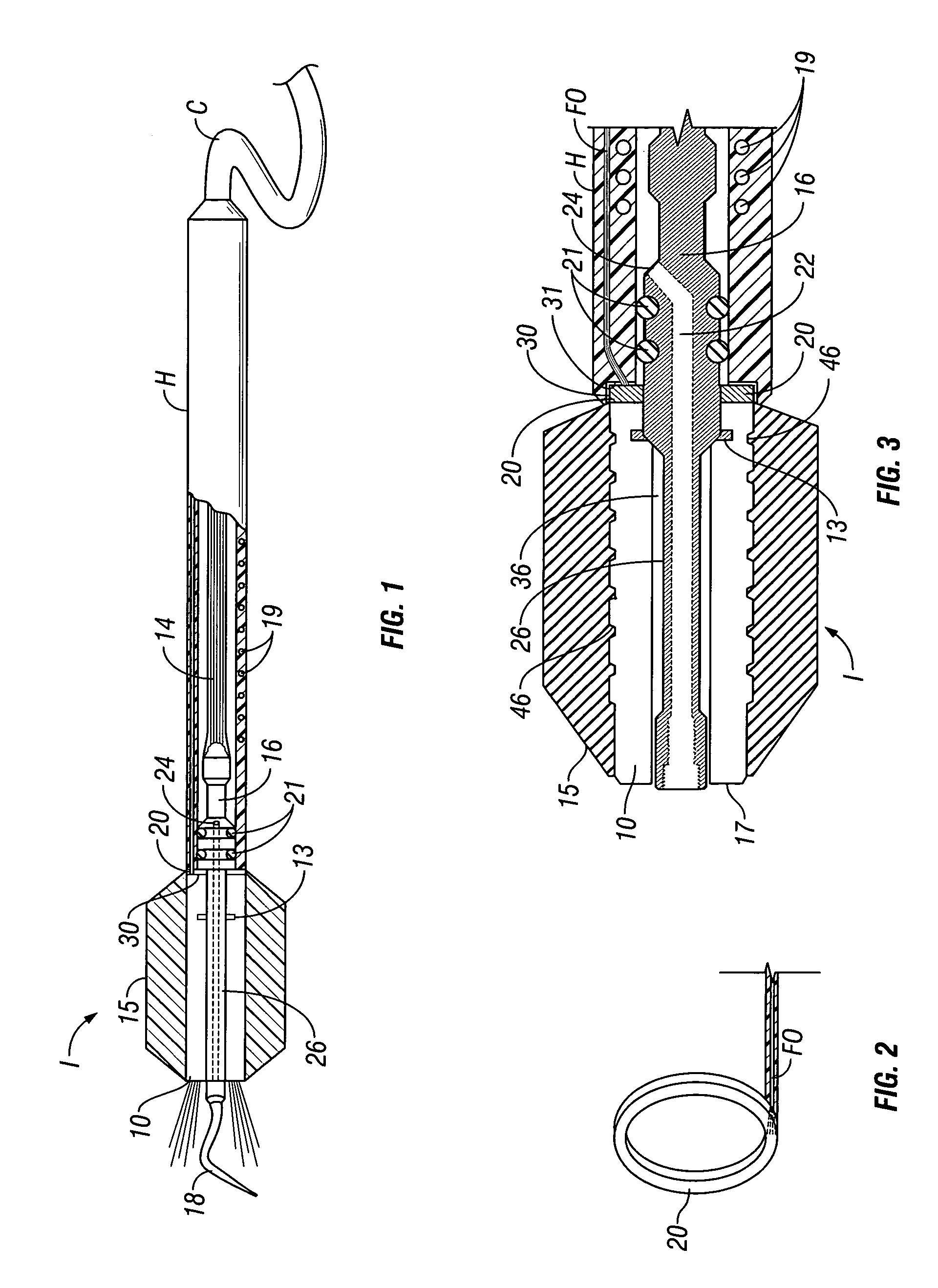

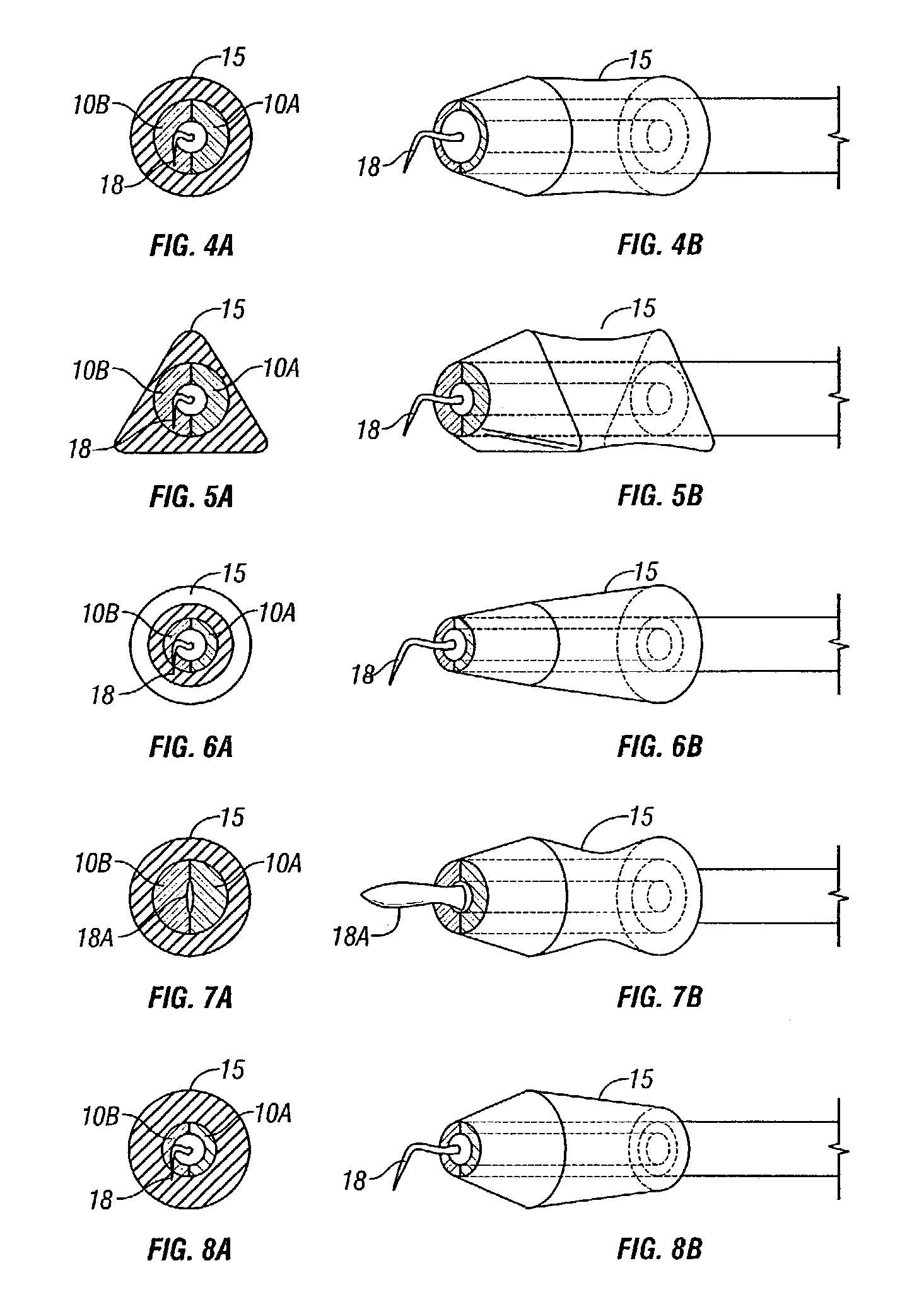

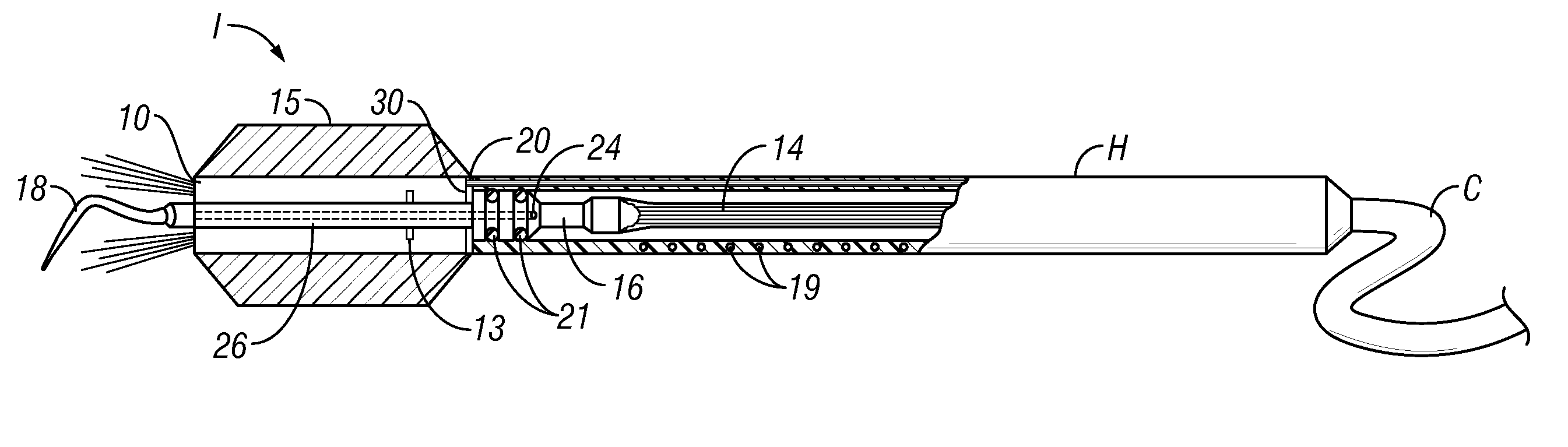

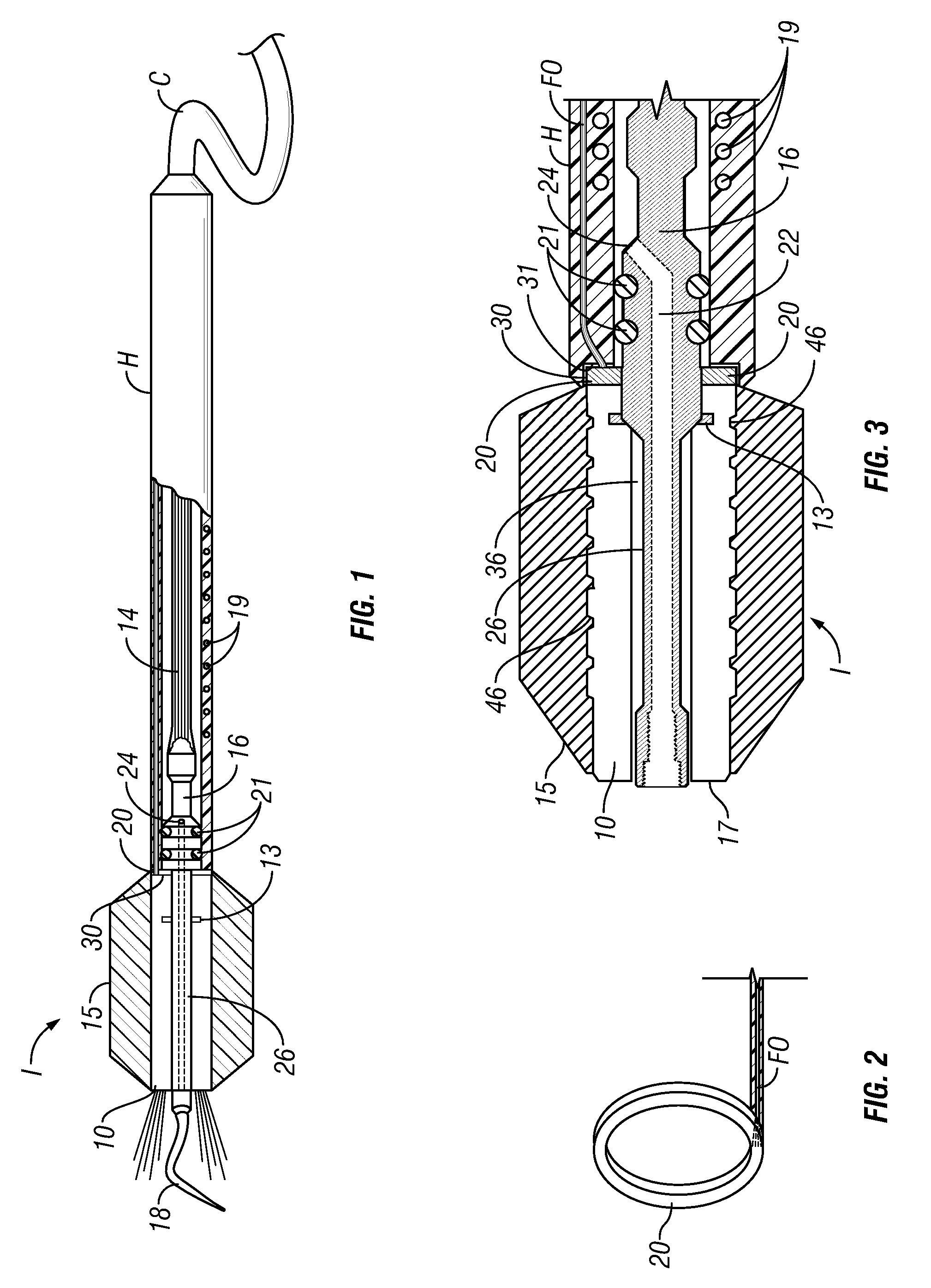

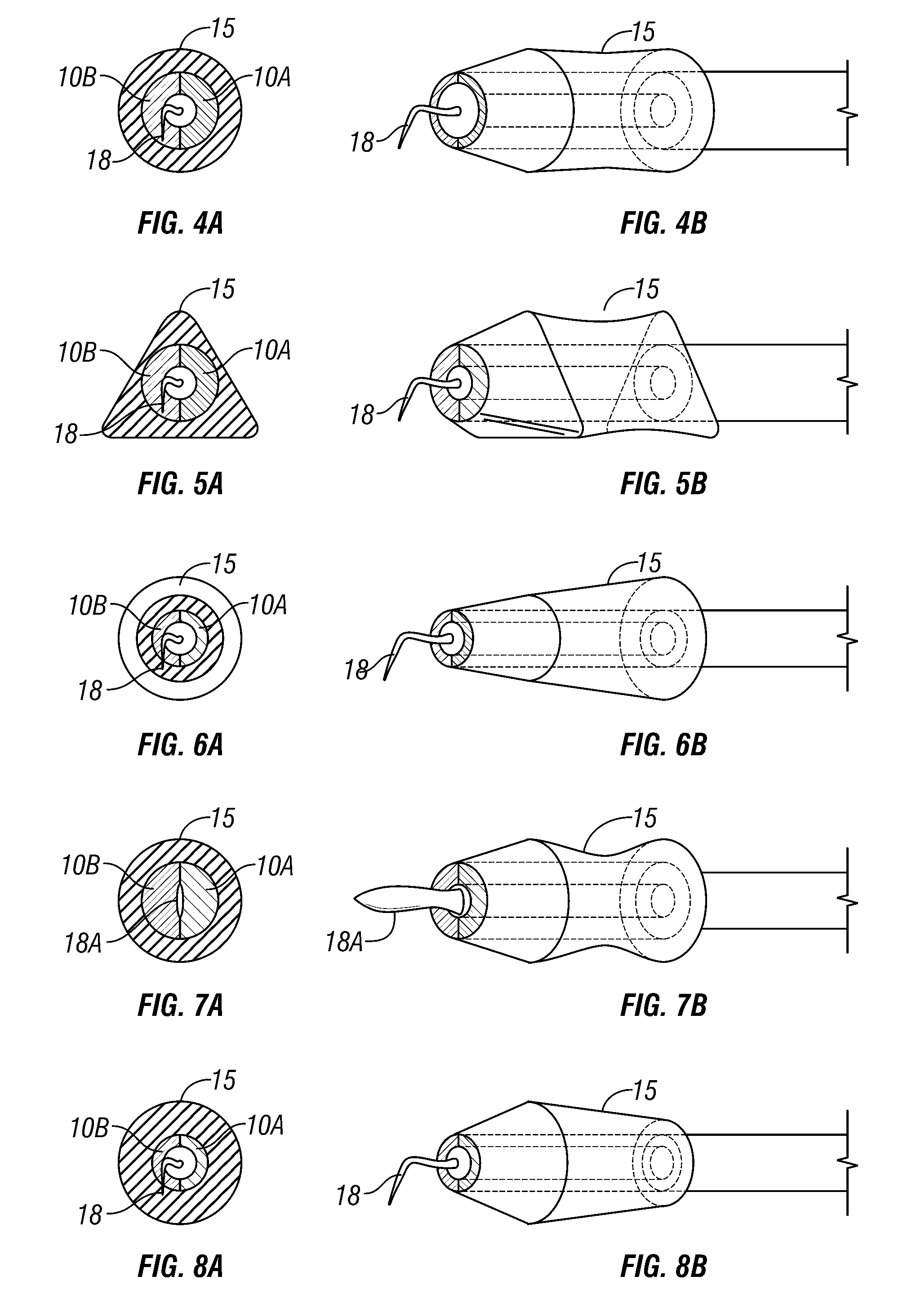

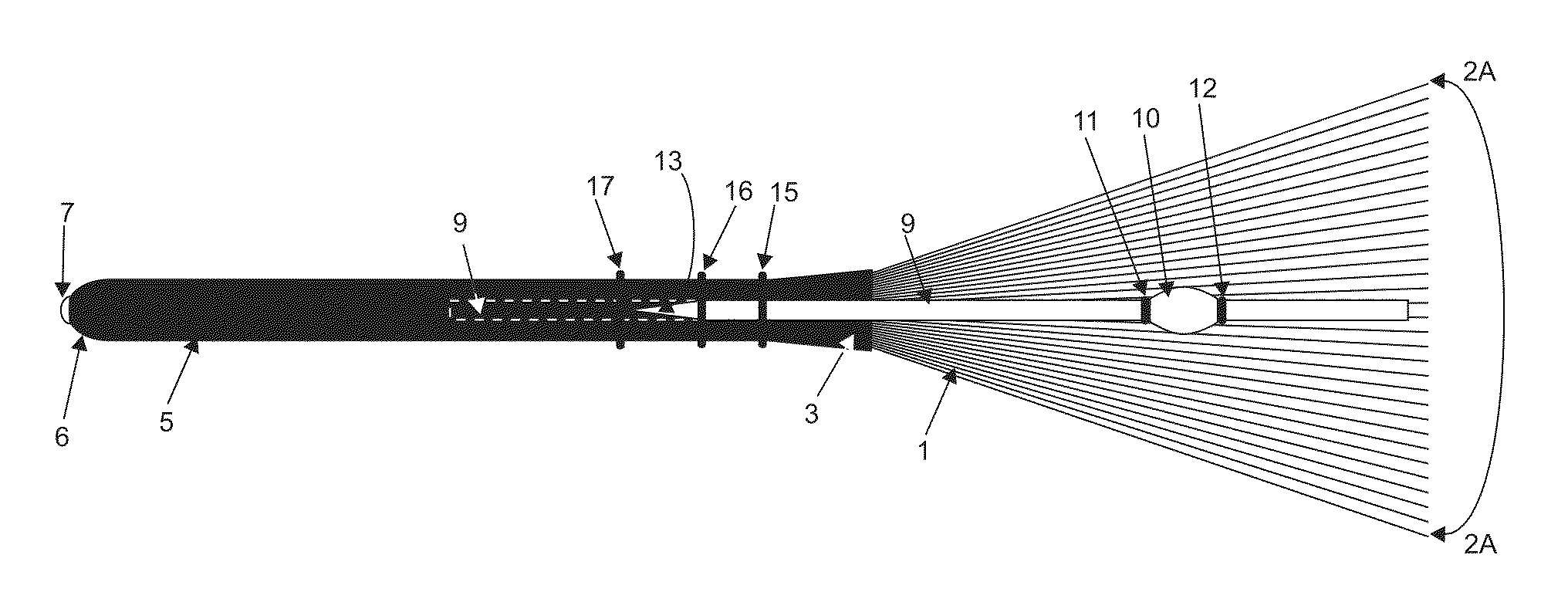

Lighted ultrasonic handpiece and color code grip system

InactiveUS7150629B2Easy to holdLess stressfulTooth pluggers/hammersCleaning using liquidsFiberDental Scaler

The present invention relates to a dental scaling translucent insert which provides a coaxially aligned light adjacent the distal end of such insert for illuminating the tip of the dental scaler which light may be provided by light emitting from a fiber optic light guide from a light source located remotely from the tip. The light provided can also be used to view through a camera lens system located in translucent insert to provide a clear unobstructed view of the work at the tip of the scaler on a remote screen or for recording.

Owner:FEINE JAMES MR

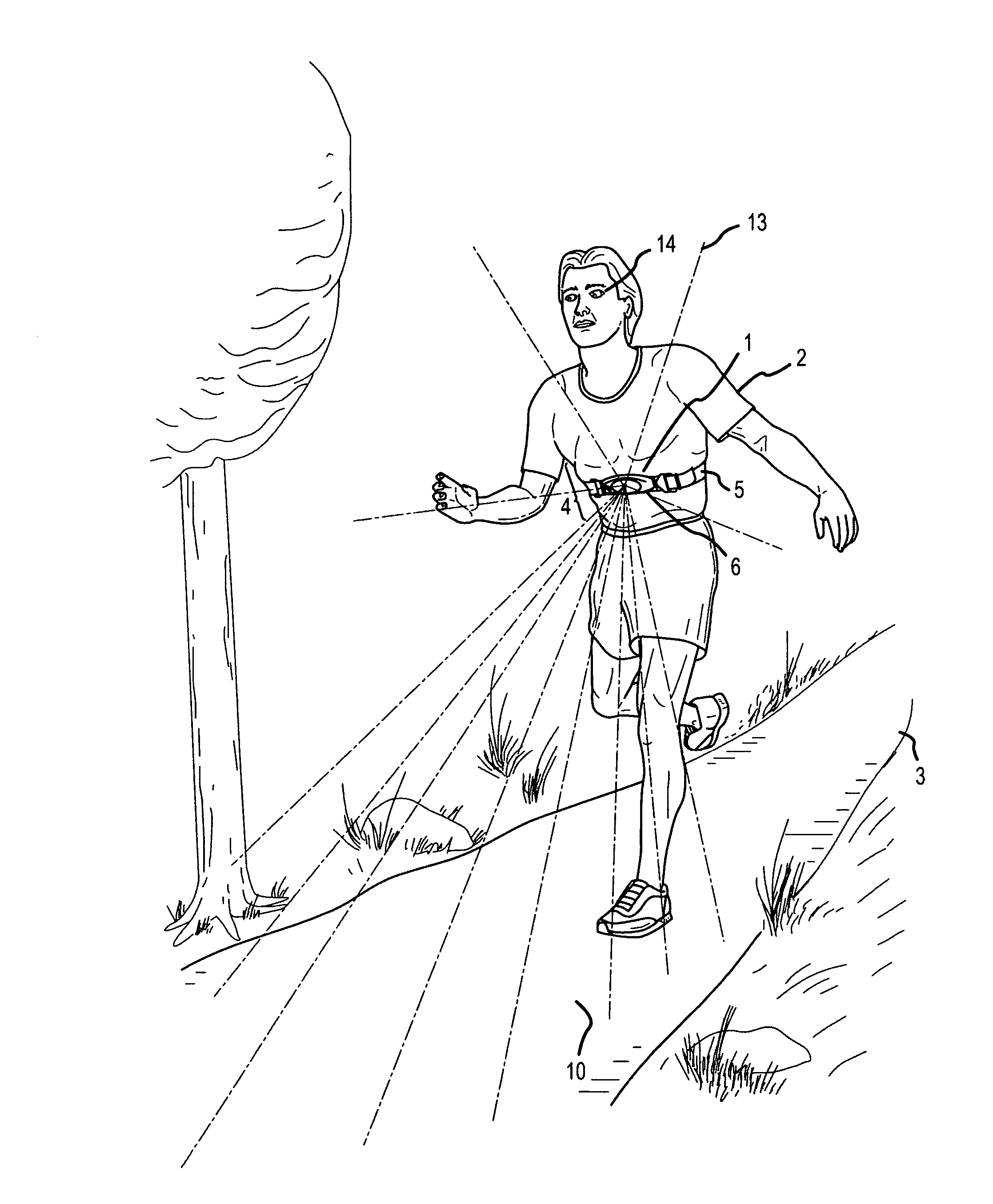

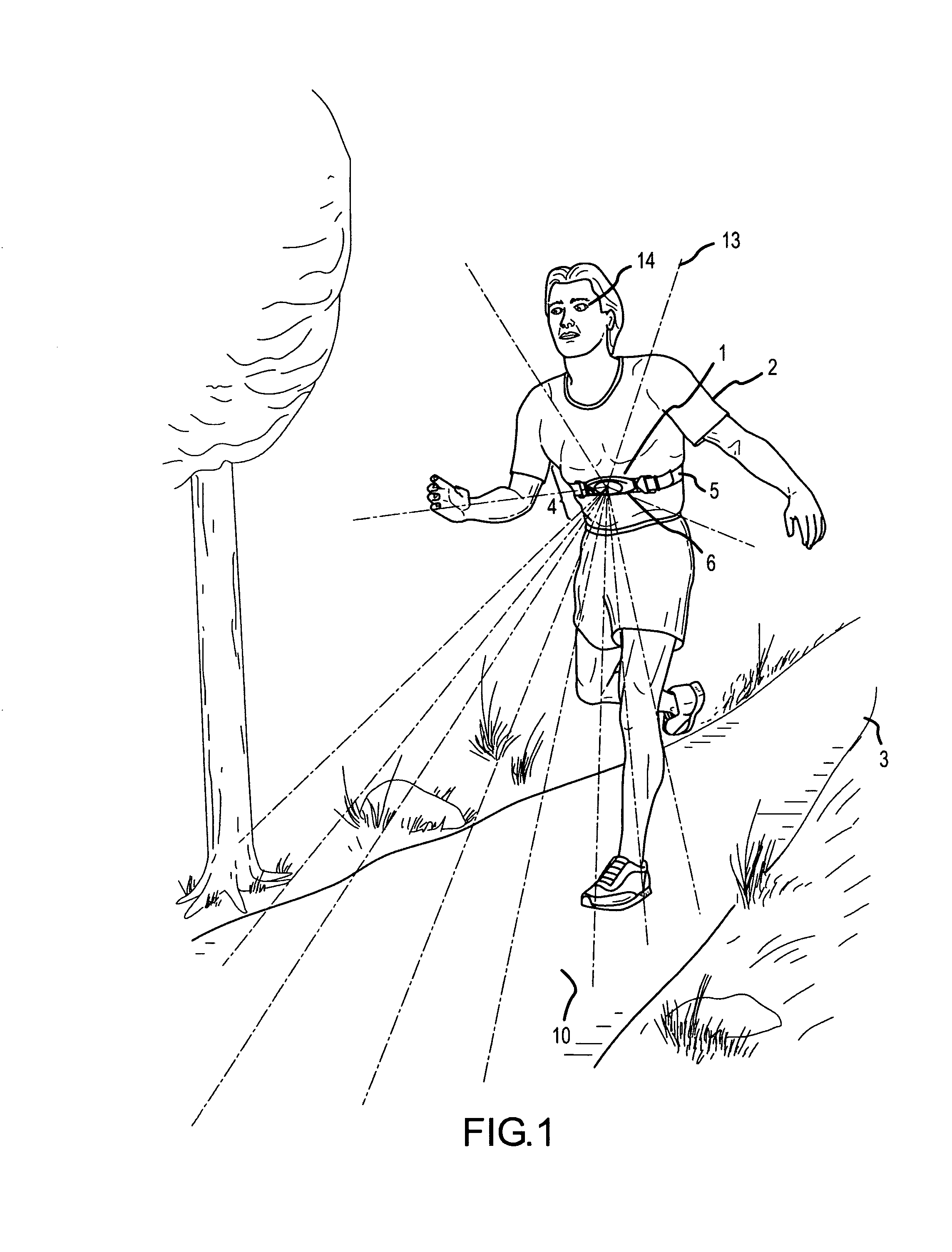

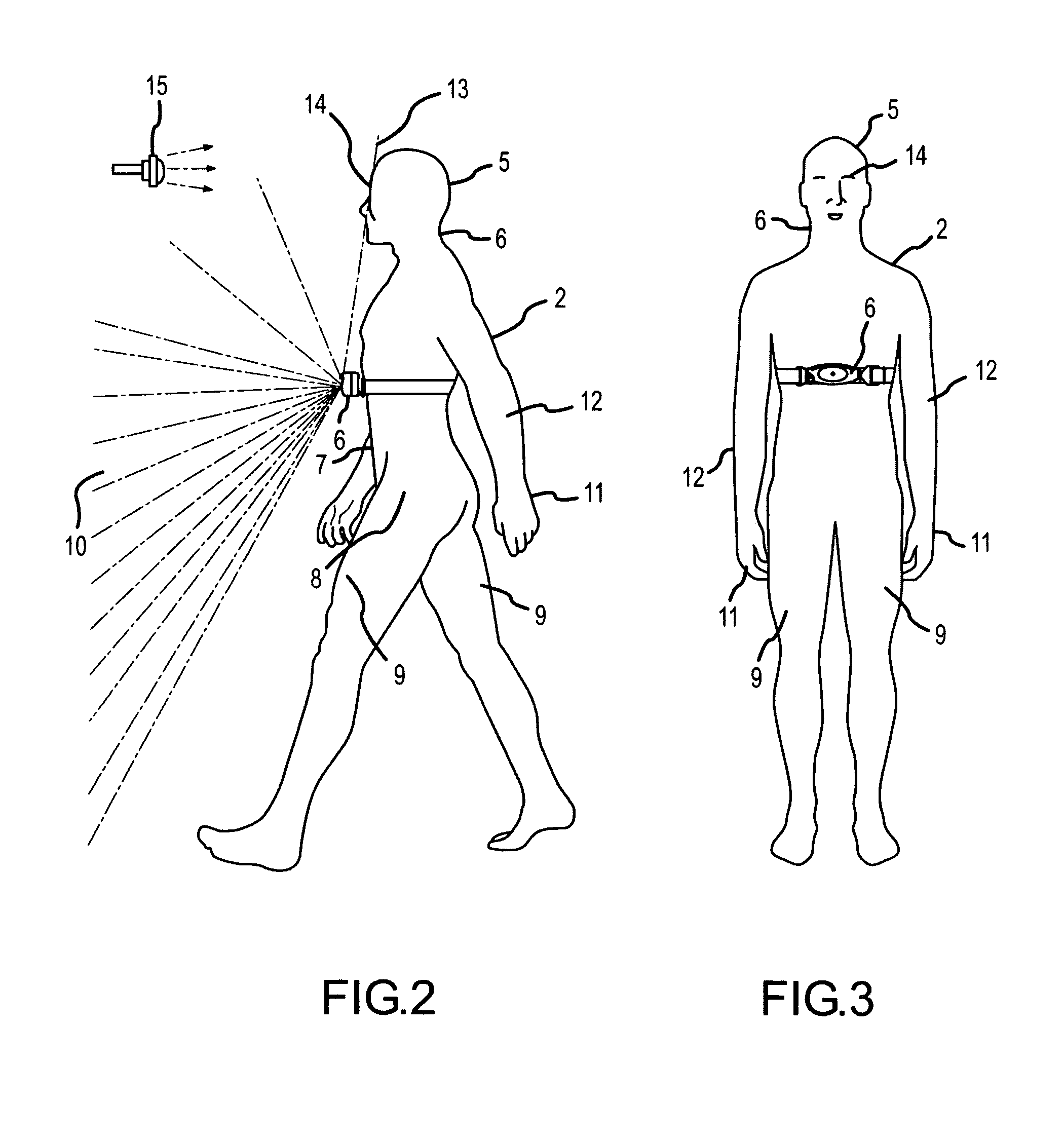

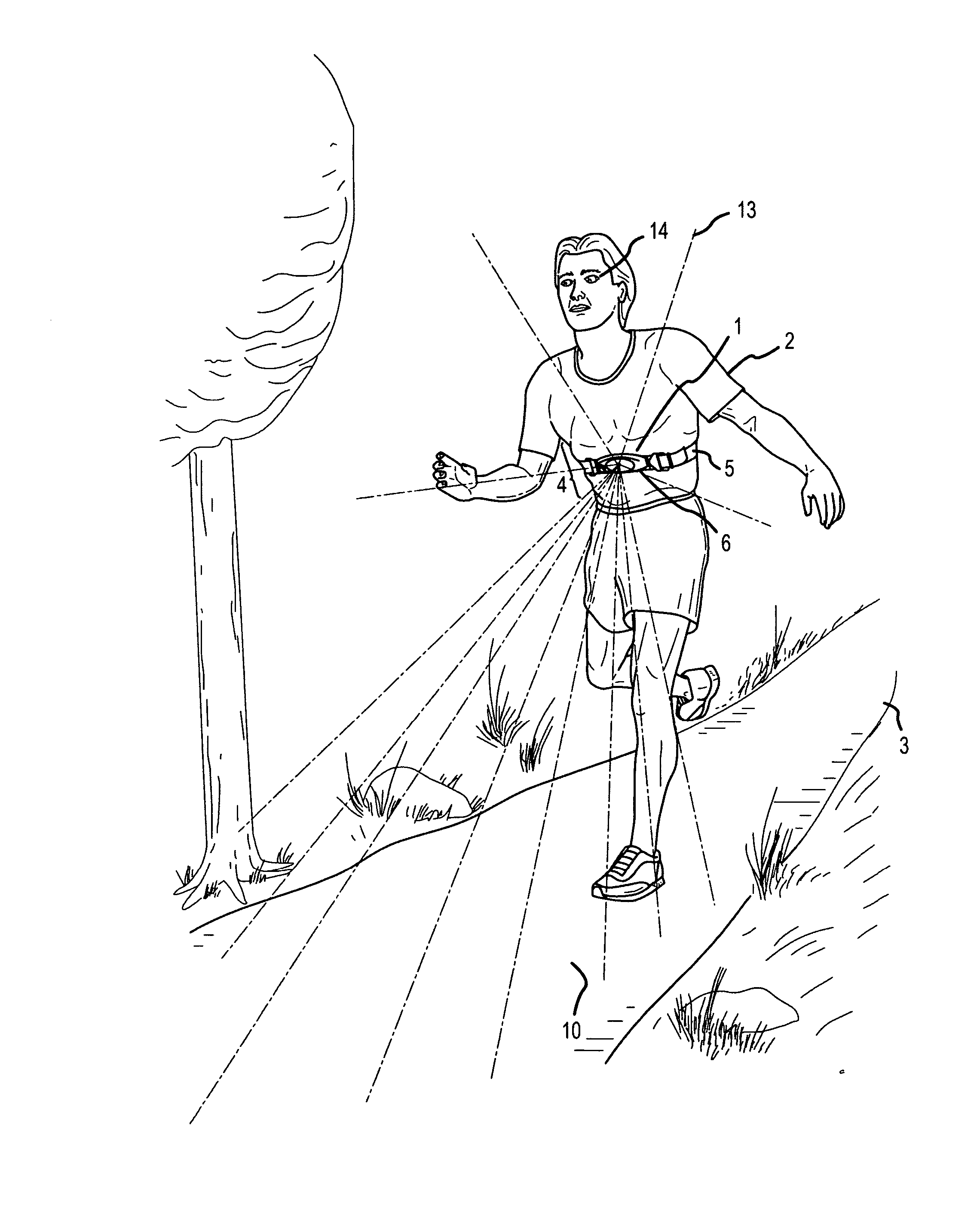

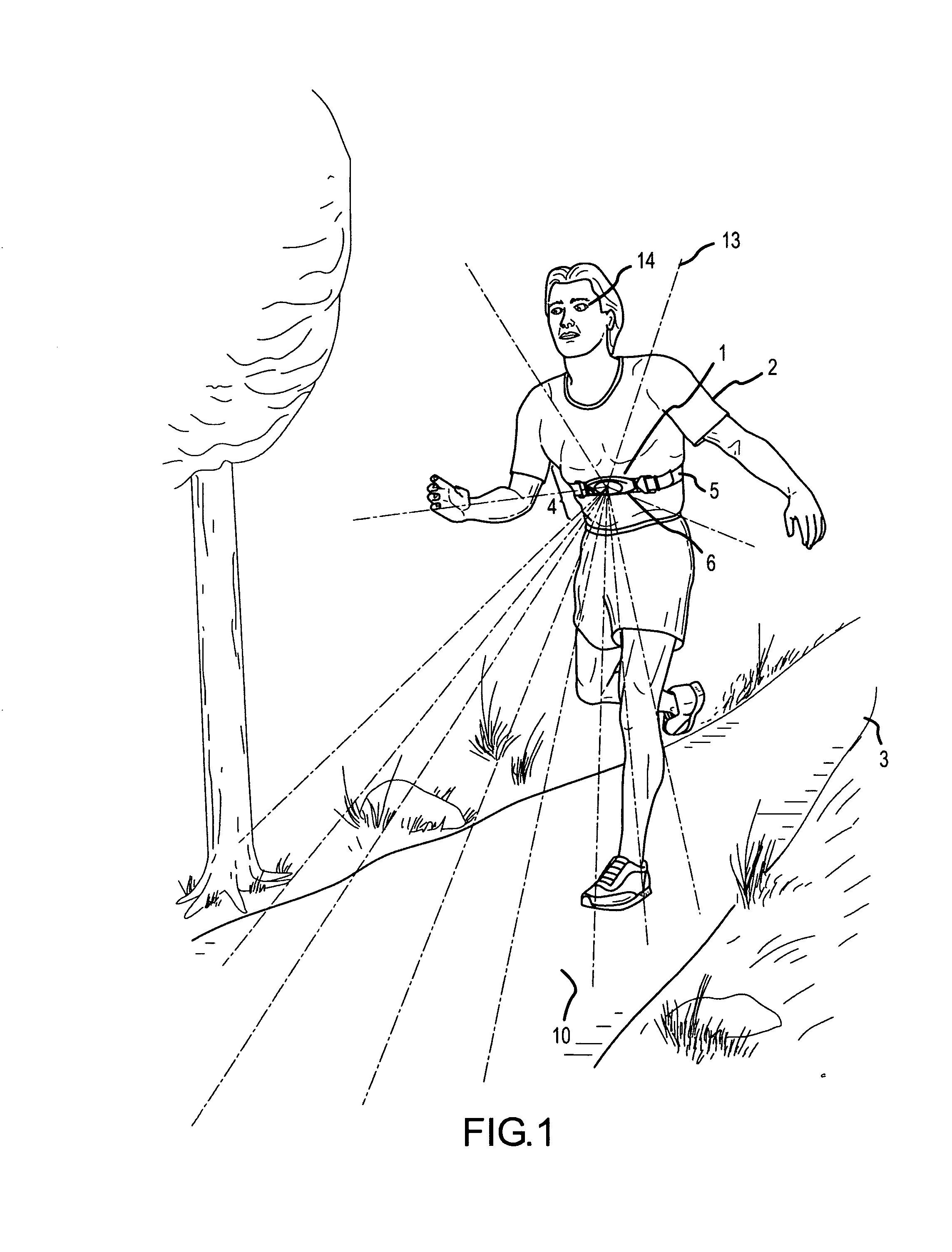

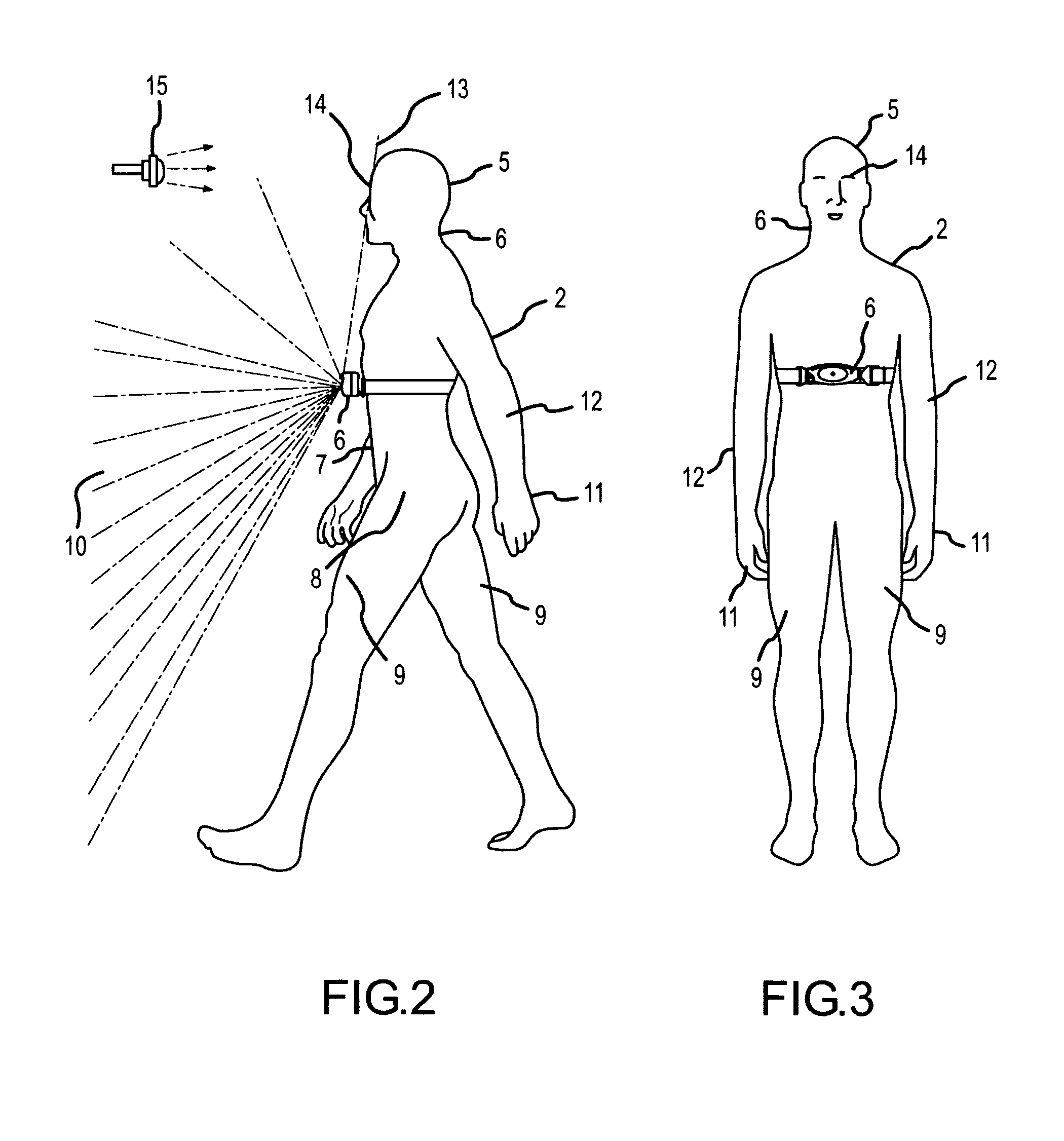

Chest height light emission system

InactiveUS7568813B2Relieve pressureAvoid contactLighting support devicesWith electric batteriesLight emissionPhysics

Owner:BARKER PAUL H

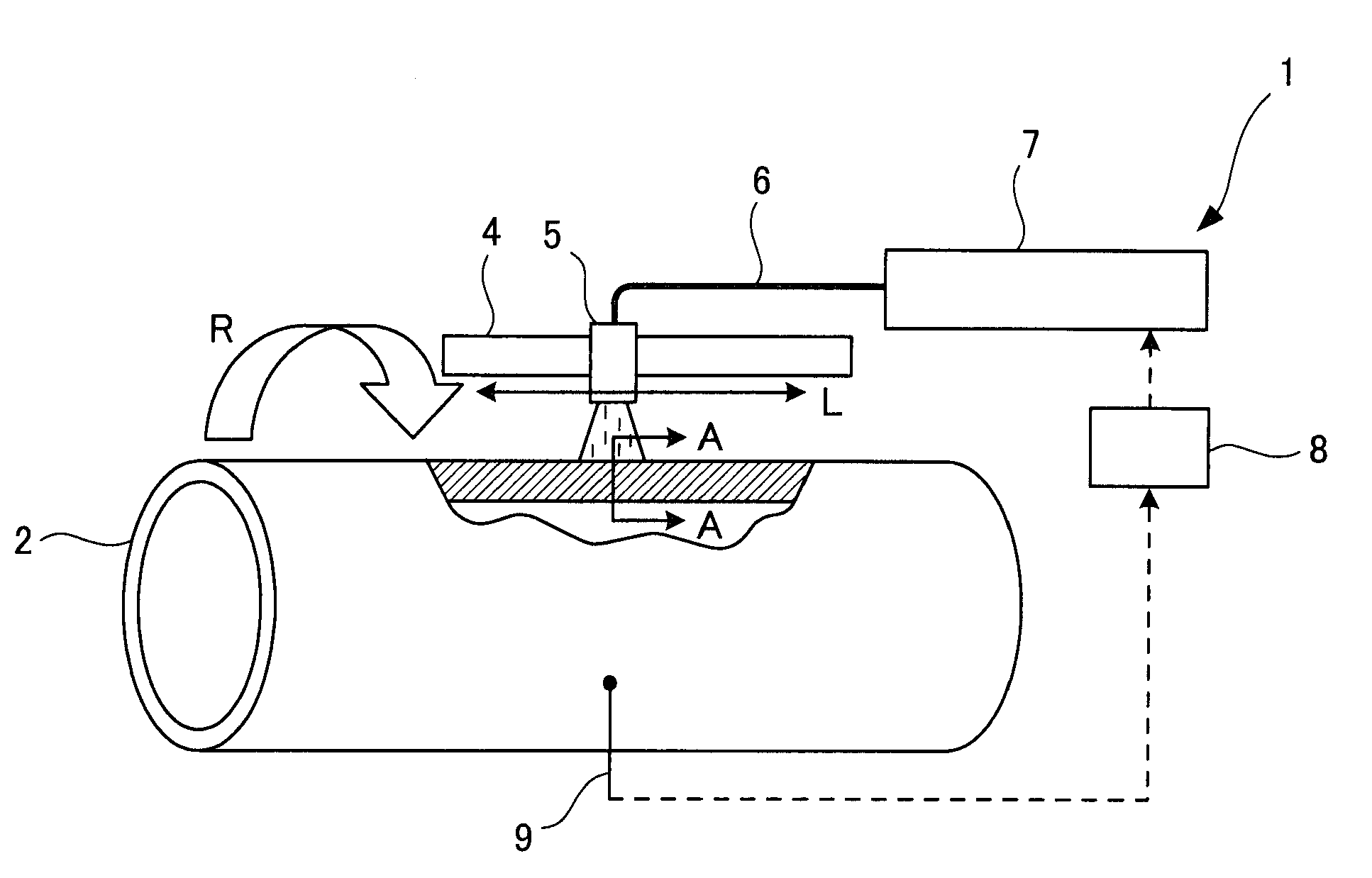

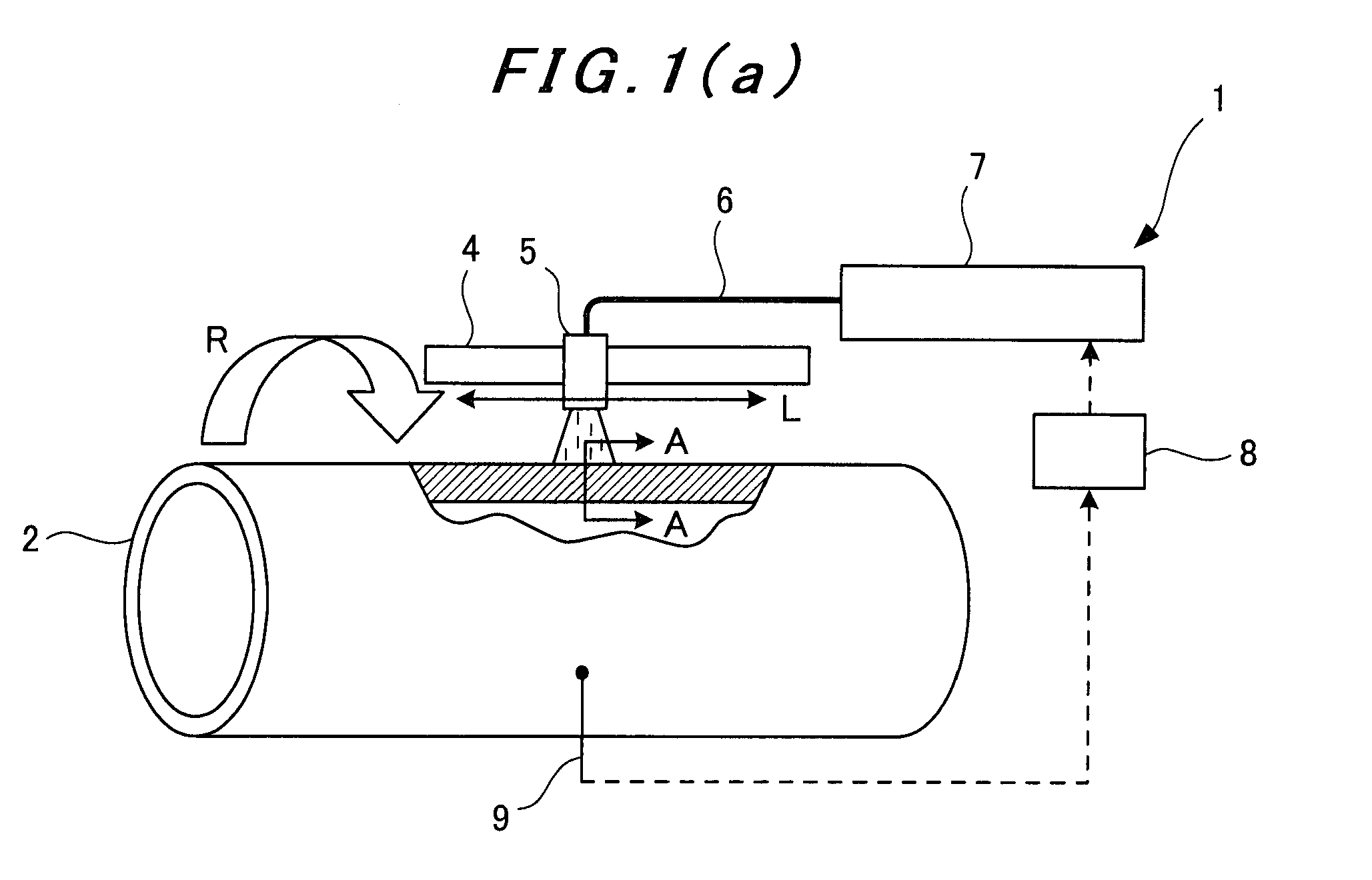

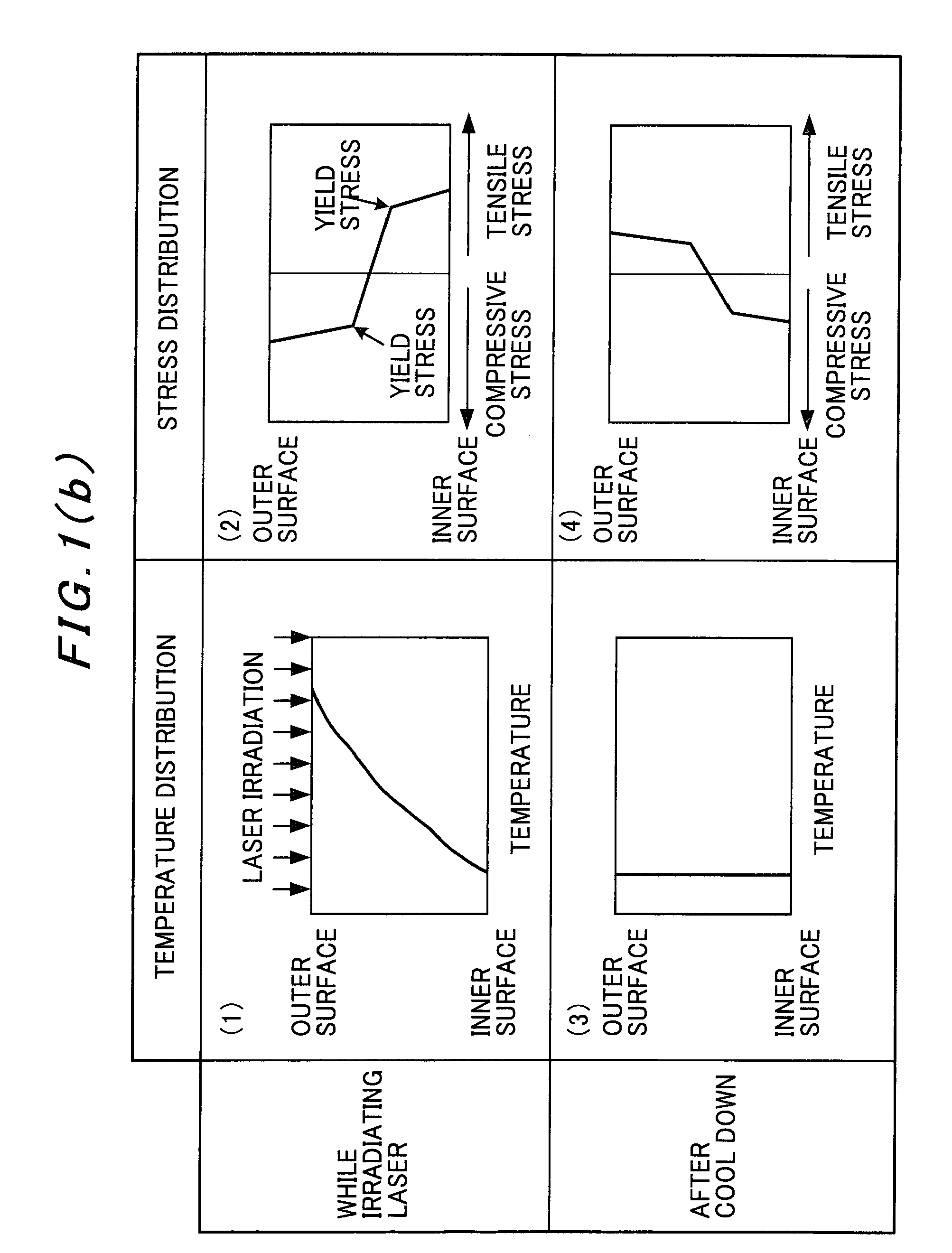

Method and system for improving residual stress in tube body

InactiveUS20090302012A1Avoid overall overheatingImprove residual stressFurnace typesMetal working apparatusClassical mechanicsUltimate tensile strength

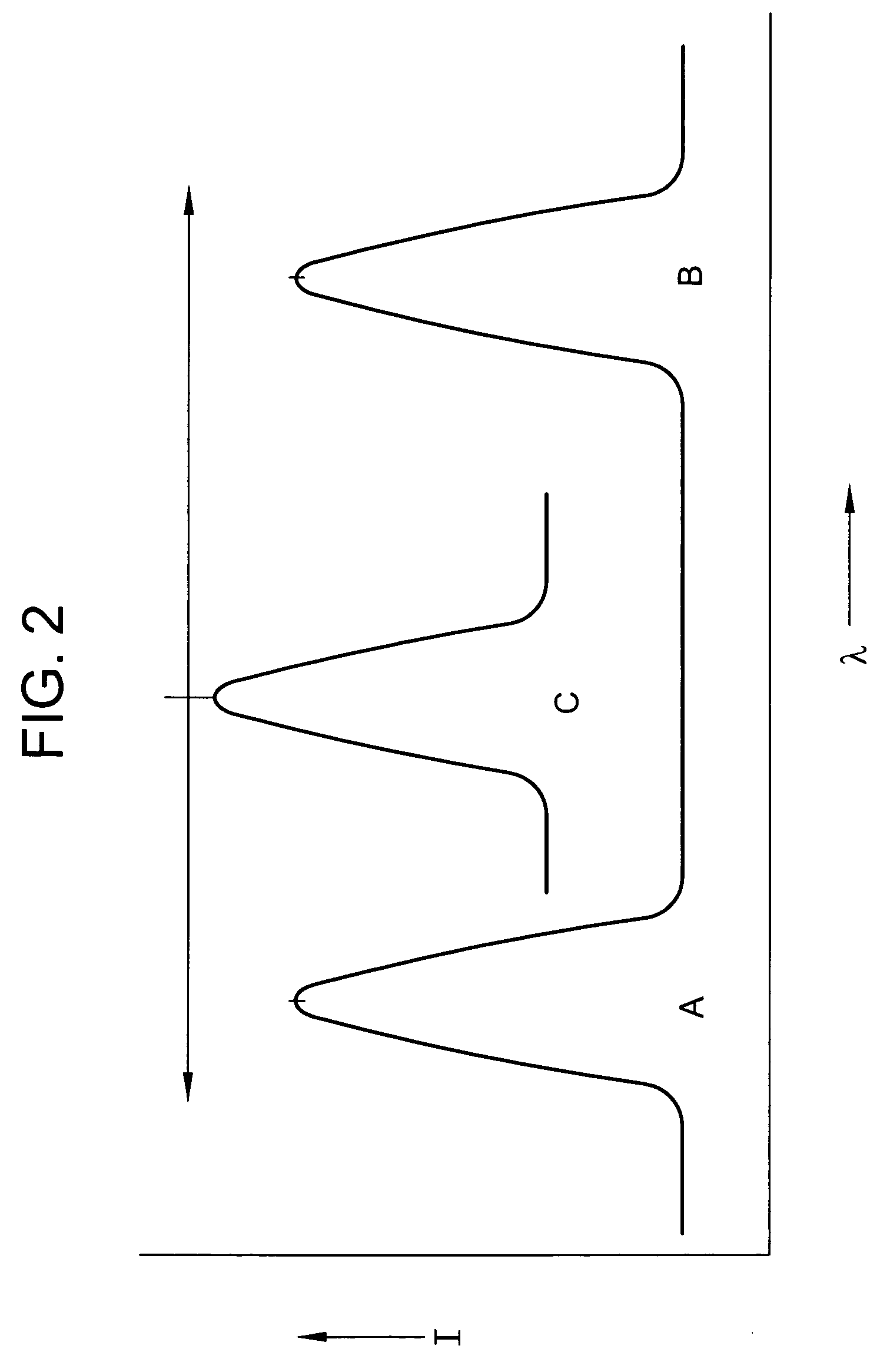

An object is to provide a method and a system for improving a residual stress in a tube body, with which the residual stress can reliably be improved without heating excessively. From an irradiation start angle θs to a first predetermined angle θ1 on the tube body, an intensity of a laser beam is gradually increased from 0.5 to the steady output of 1.0 output ratio; from the first predetermined angle θ1 to a second predetermined angle θ2, the intensity of the laser beam is set at 1.0 output ratio; from the second predetermined angle θ2 to an irradiation end angle θe, the intensity of the laser beam is gradually decreased from the 1.0 output ratio to 0.5; and at the irradiation end angle θe, the intensity of the laser beam is set to 0. All these steps are performed at one turn of rotation in the method and the system for improving residual stress in the tube body.

Owner:MITSUBISHI HEAVY IND LTD

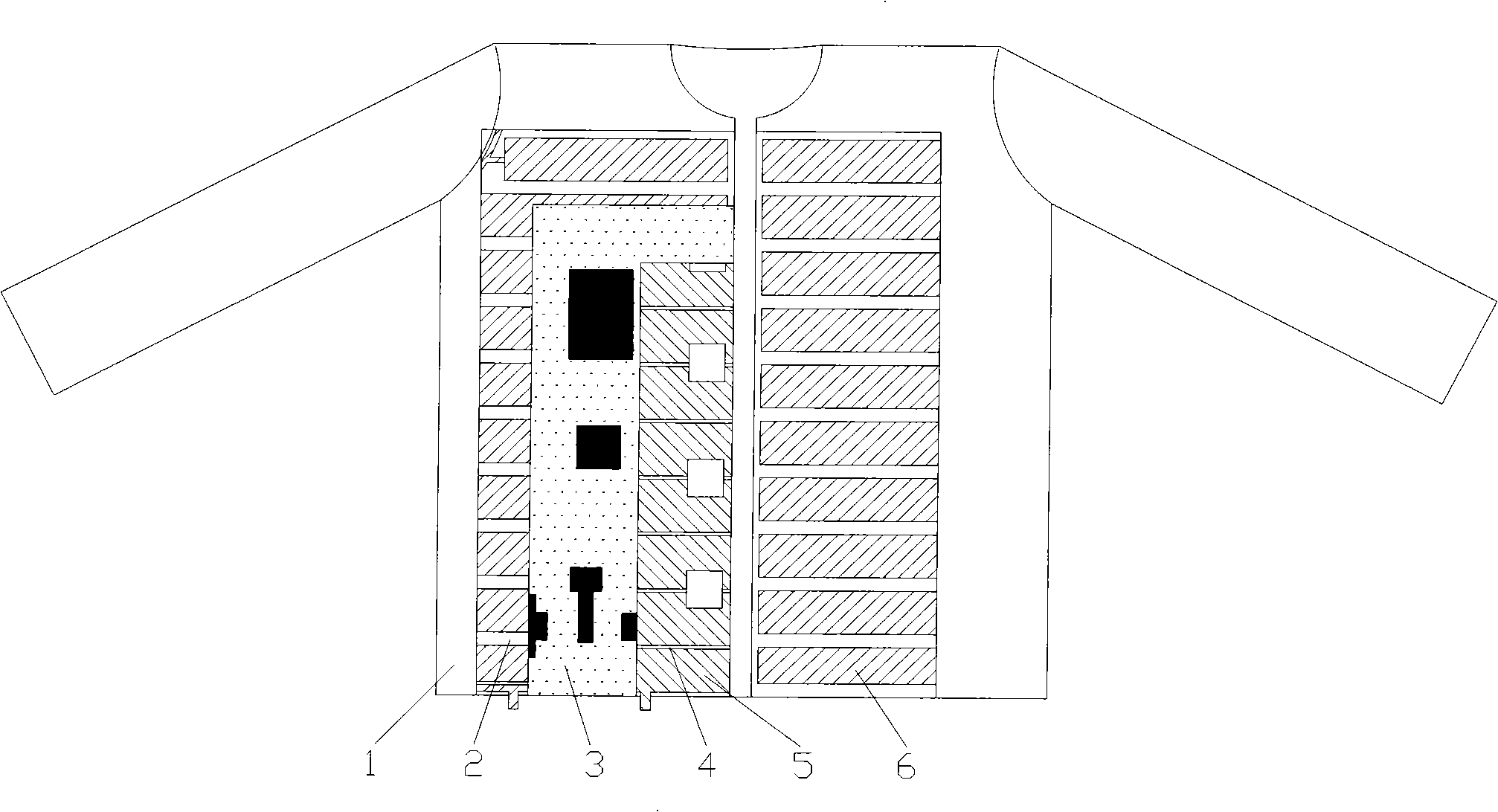

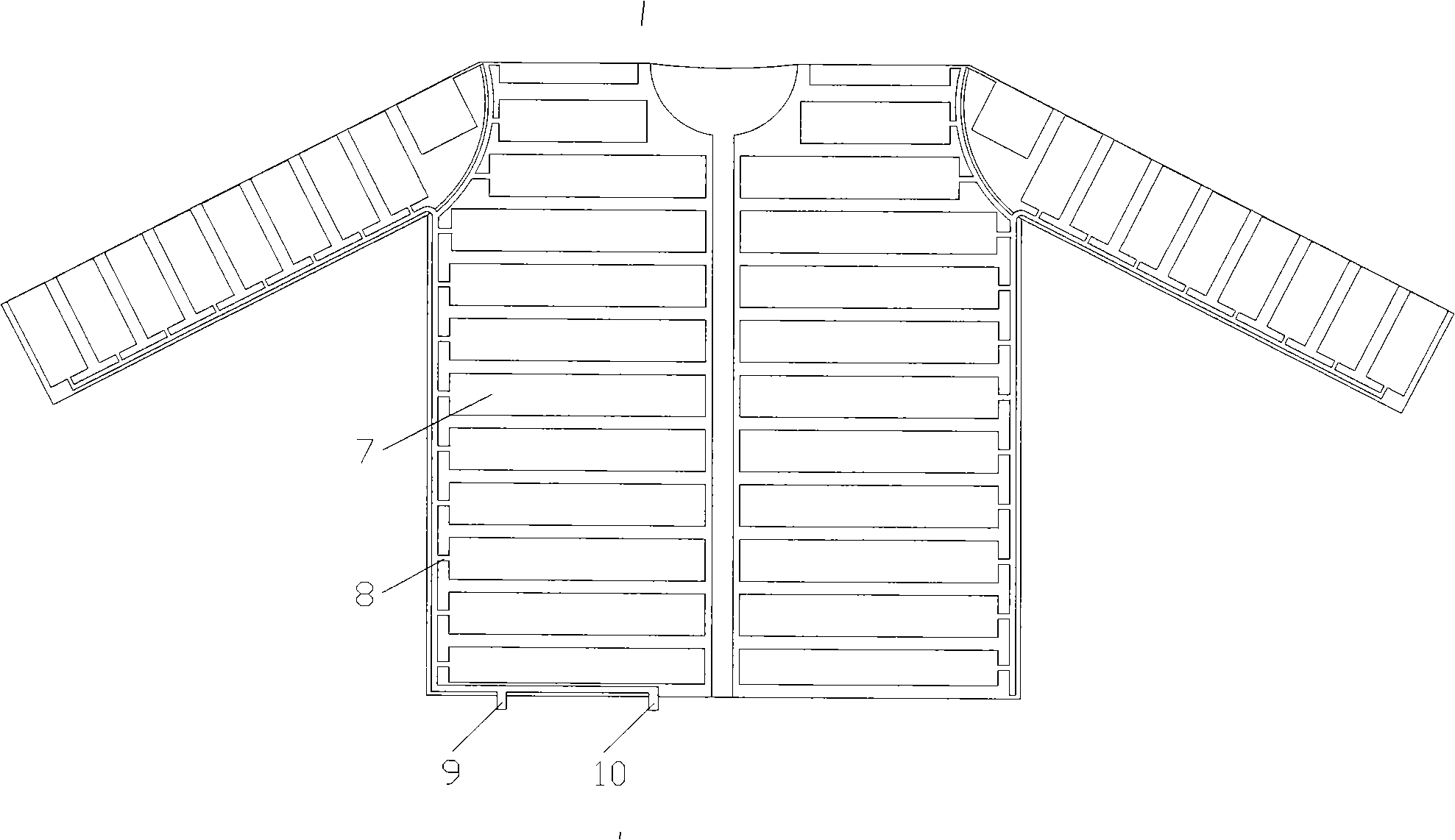

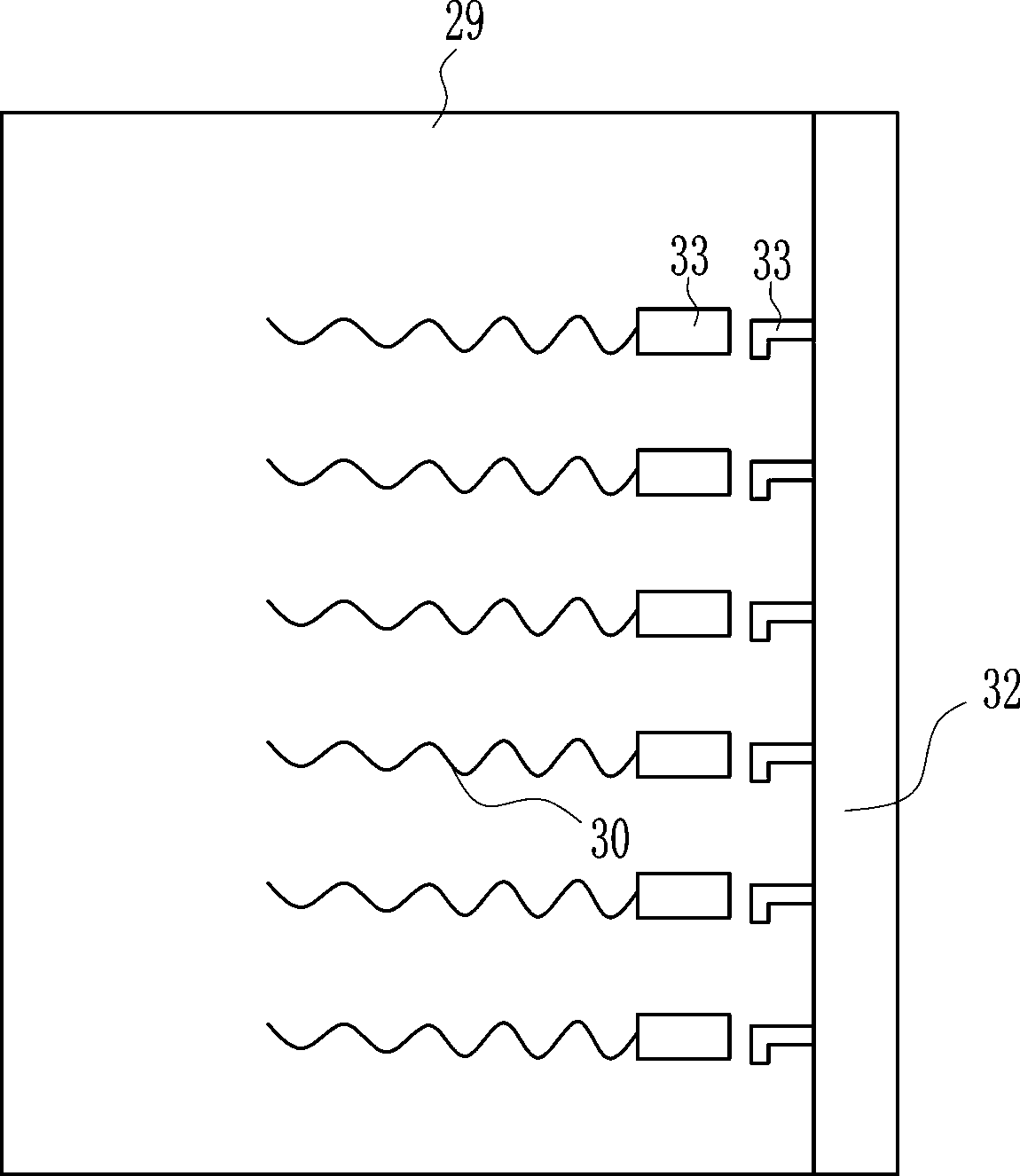

Intelligently controlled air inflation cold protective clothing

InactiveCN101292781ANo air tightness requirementAdjust the size of the output airflowOvergarmentsProtective garmentPerspirationMicrocomputer control

The invention provides an intelligently controlled inflatable cold protective clothing to overcome the defect that the prior art fails to realize the automatic adjustment of warm keeping performance. The cold protective clothing realizes the functions of warm keeping, temperature adjustment, perspiration and dewetting through the intelligent control. The intelligently controlled inflatable cold protective clothing comprises three layers of interlayer structure, which are an outer layer, a middle layer, an inner layer and the three layers are integrated by fabrics; the outer layer is a sealed insulative layer with the charge / deflation adjustable and is provided with a sealed air bag; the middle layer is internally provided with an embedded microcomputer control device; the inner layer is provided with an air passage; the embedded microcomputer control device of the middle layer is connected with the sealed air bag of the outer layer and the air passage of the inner layer. The outer layer is provided with a plurality of parallel air passages each of which is filled with a strip-shaped air column sealed pocket; all the sealed pockets are connected mutually into a sealed air bag through an air passage header pipe and an air passage branch pipe. The two ends of the sealed bag are provided with soft windpipe connections which are mutually connected with the header pipe of the air passage and each branch pipe of the air passage into a sealed air bag.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

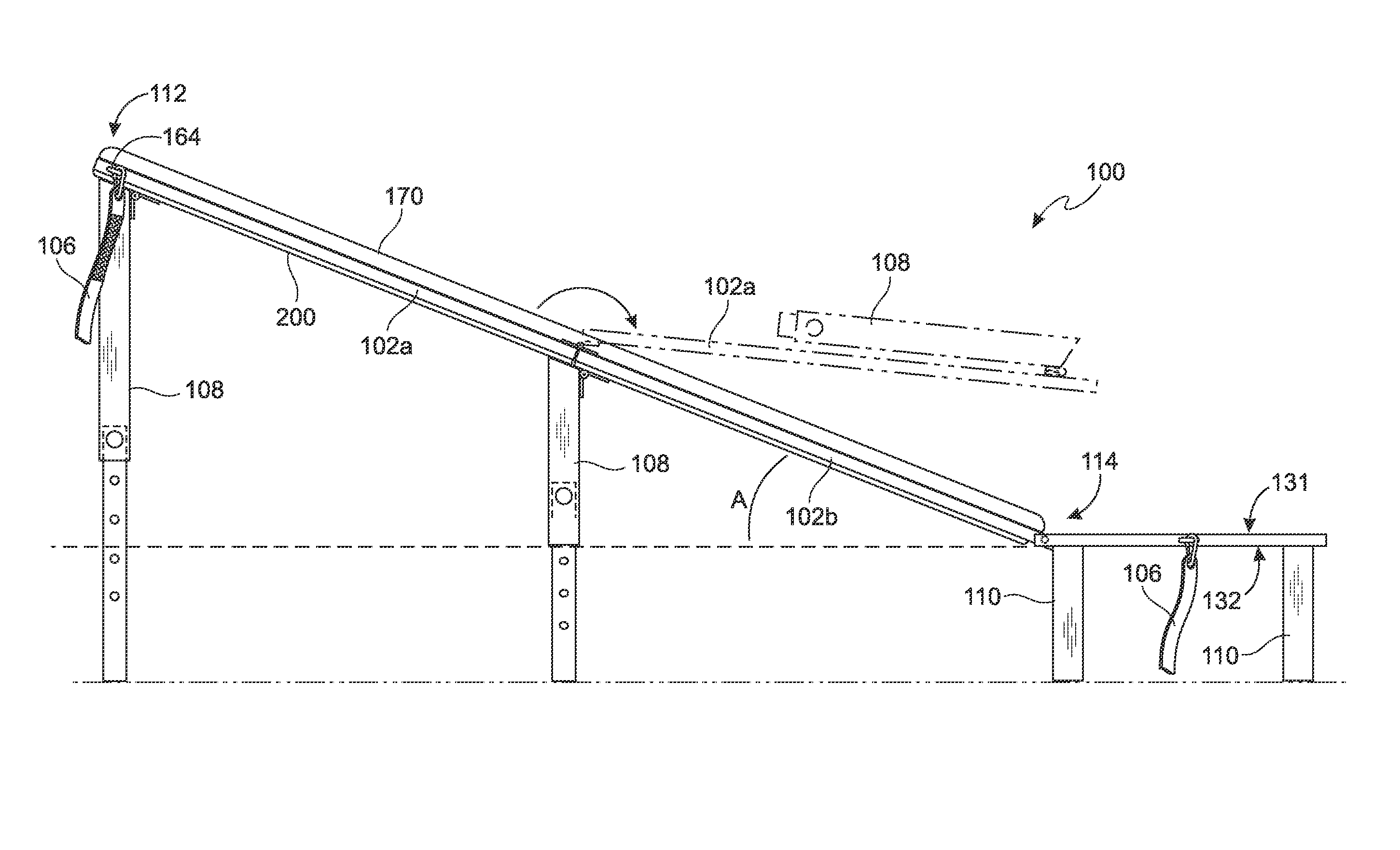

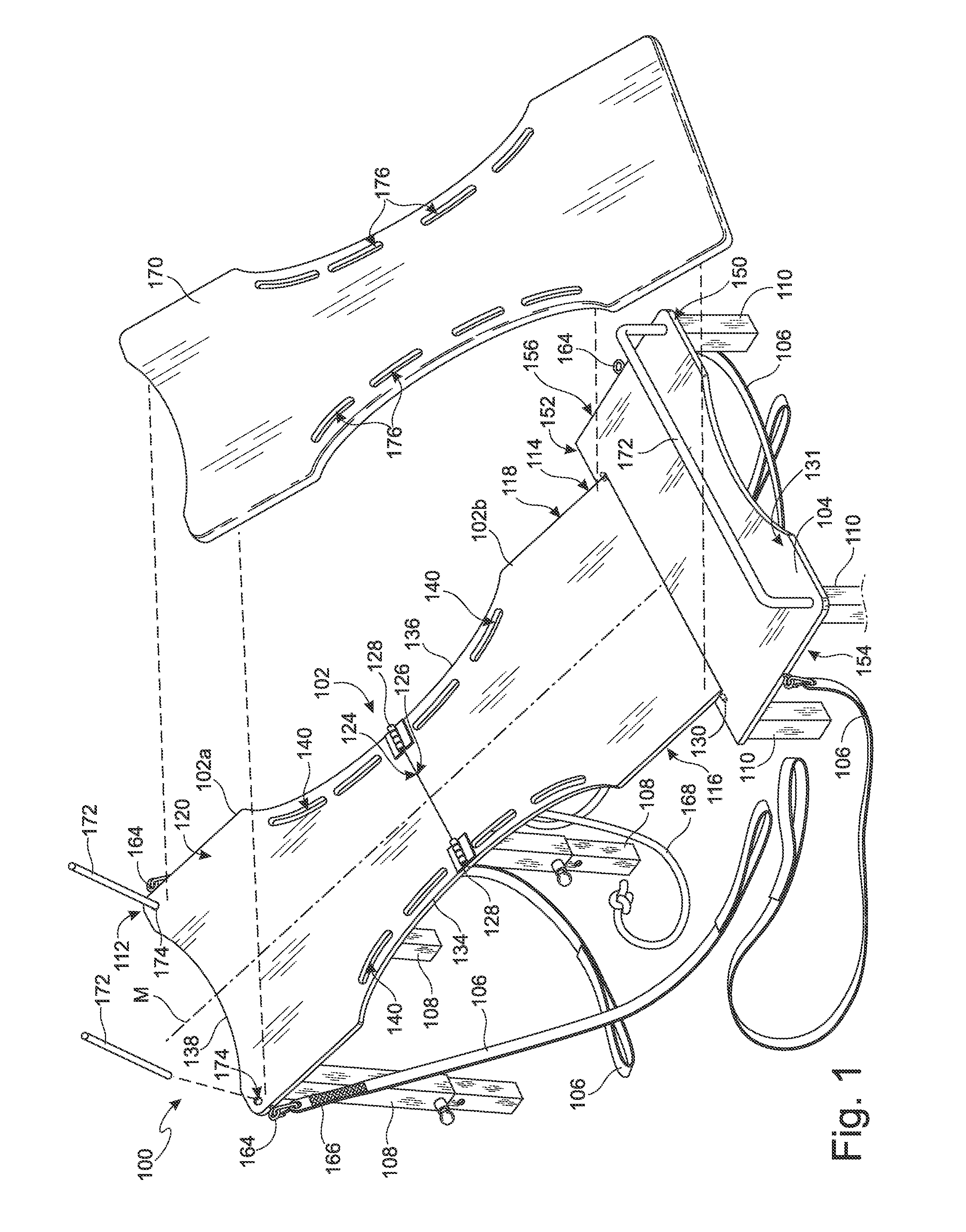

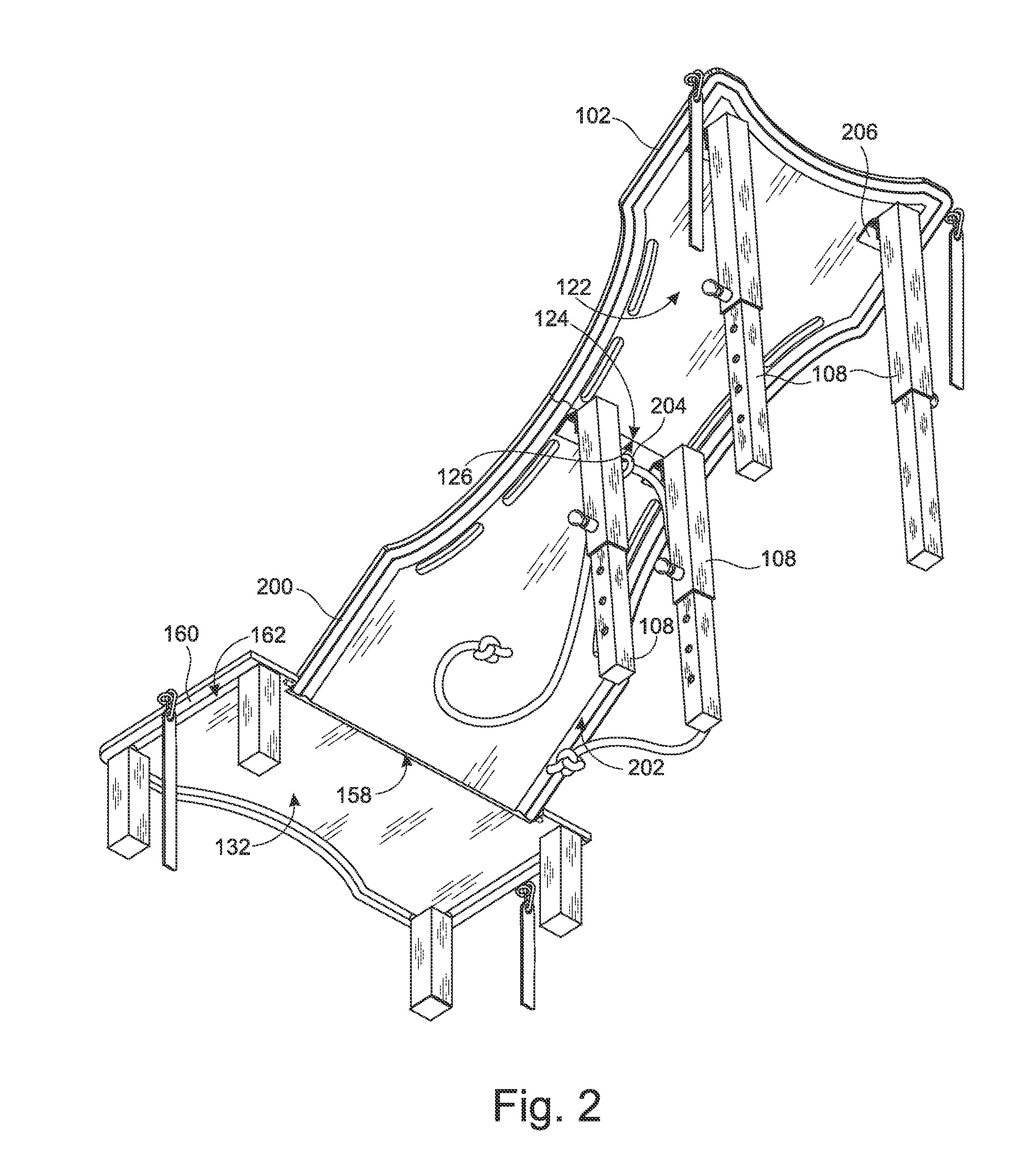

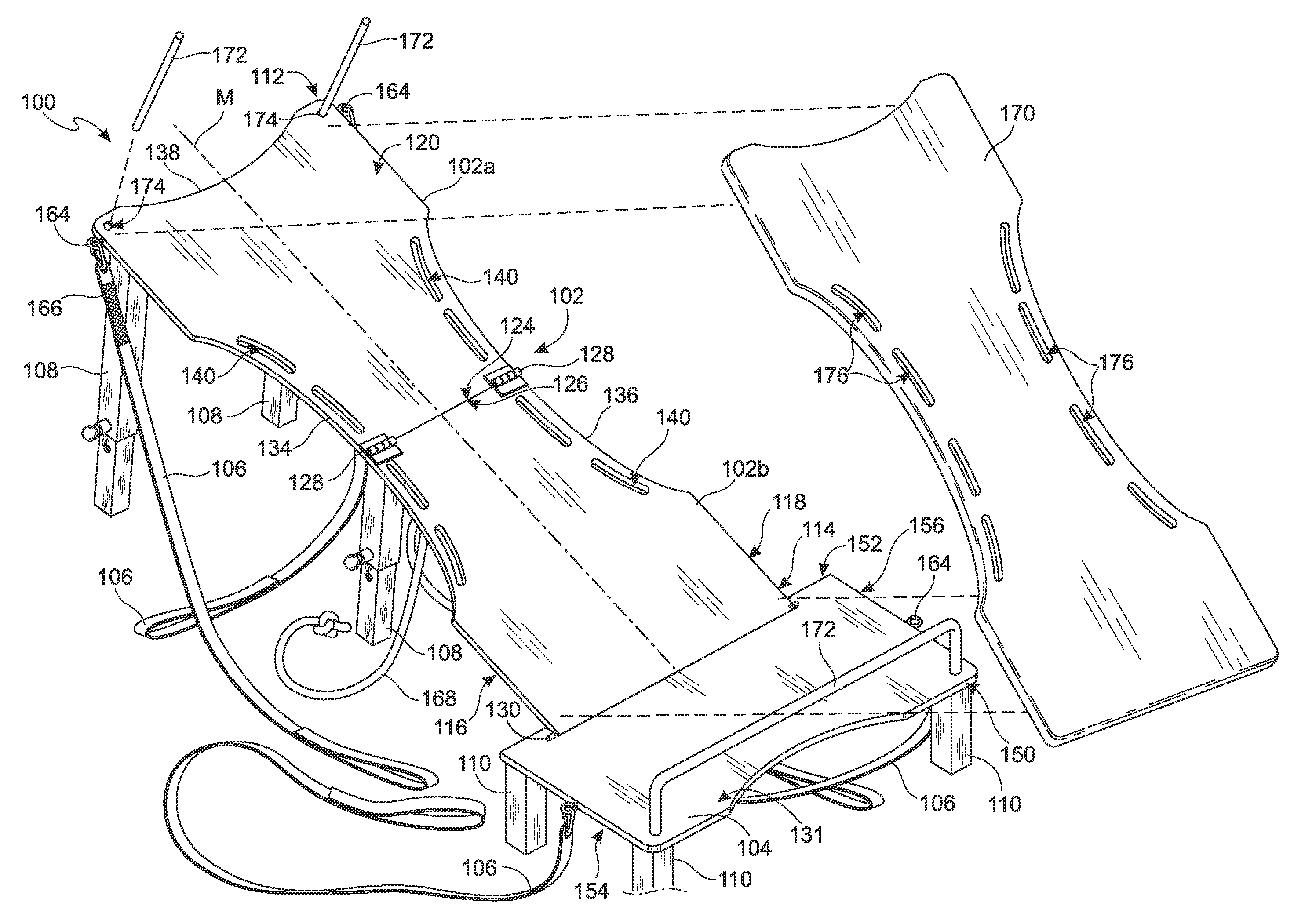

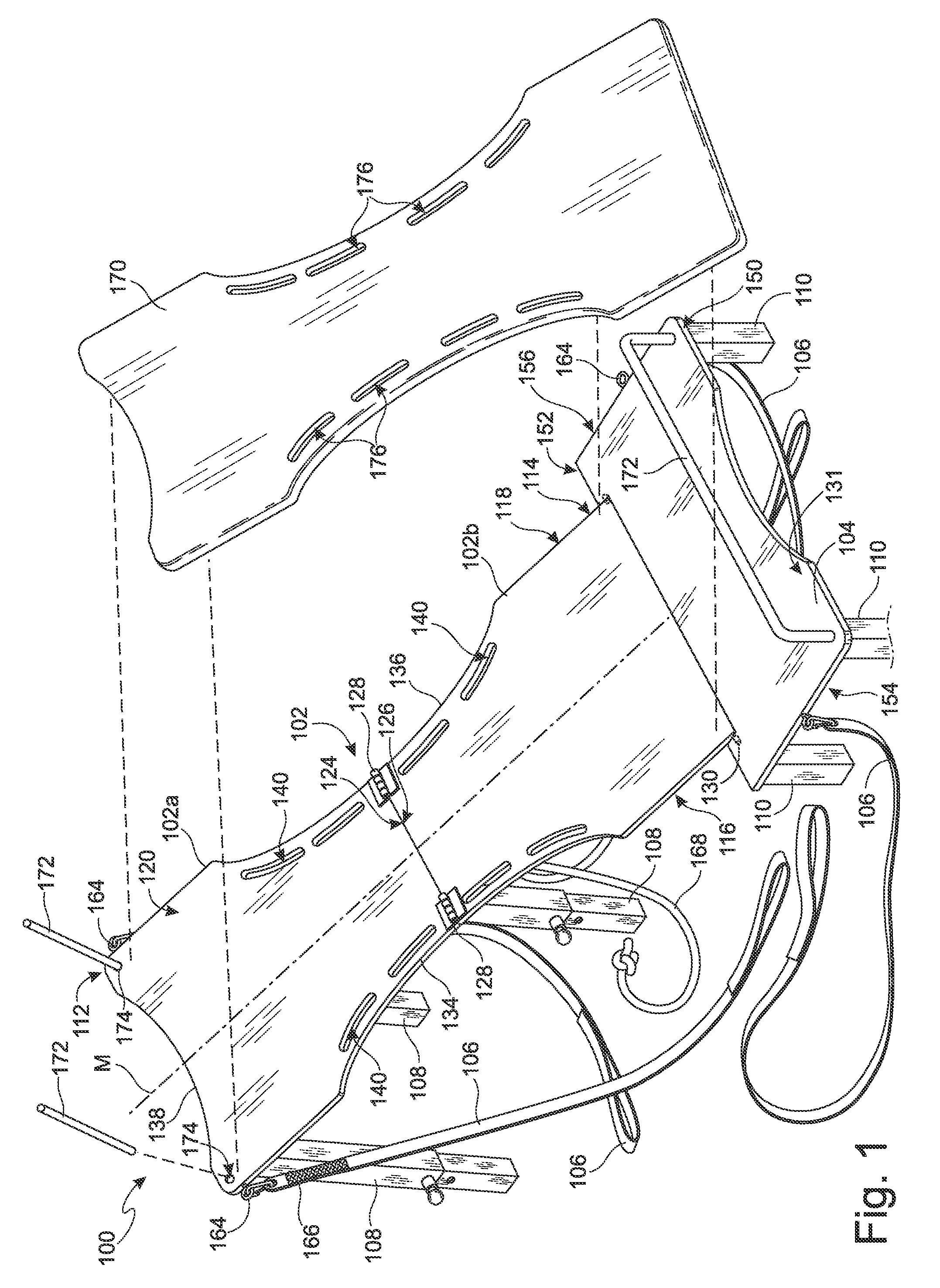

Fitness board

InactiveUS9022911B2Extended range of motionChange intensityResilient force resistorsSpace saving gamesEngineeringPhysical exercise

An exercise or fitness board having a deck adjustably attached to a base to adjust the angle of incline of the deck relative to the base, and a plurality of straps attached to the deck for the user to grasp for balance and exercise. The deck and / or base contains various contours, scallops, cutouts, and the like to facilitate comfortable and varied positioning of the body. A rail and / or channel may be placed on the underside and along the perimeter of the board to facilitate grip. A pad or mat may be placed on top of the board and / or base for comfort, stability, and protection.

Owner:JOHNNY G METHOD

Image display apparatus

InactiveUS7193356B2Improve color uniformityIncrease or decrease intensityMechanical apparatusDischarge tube luminescnet screensComputer graphics (images)Monochrome

Owner:MITSUBISHI ELECTRIC CORP +1

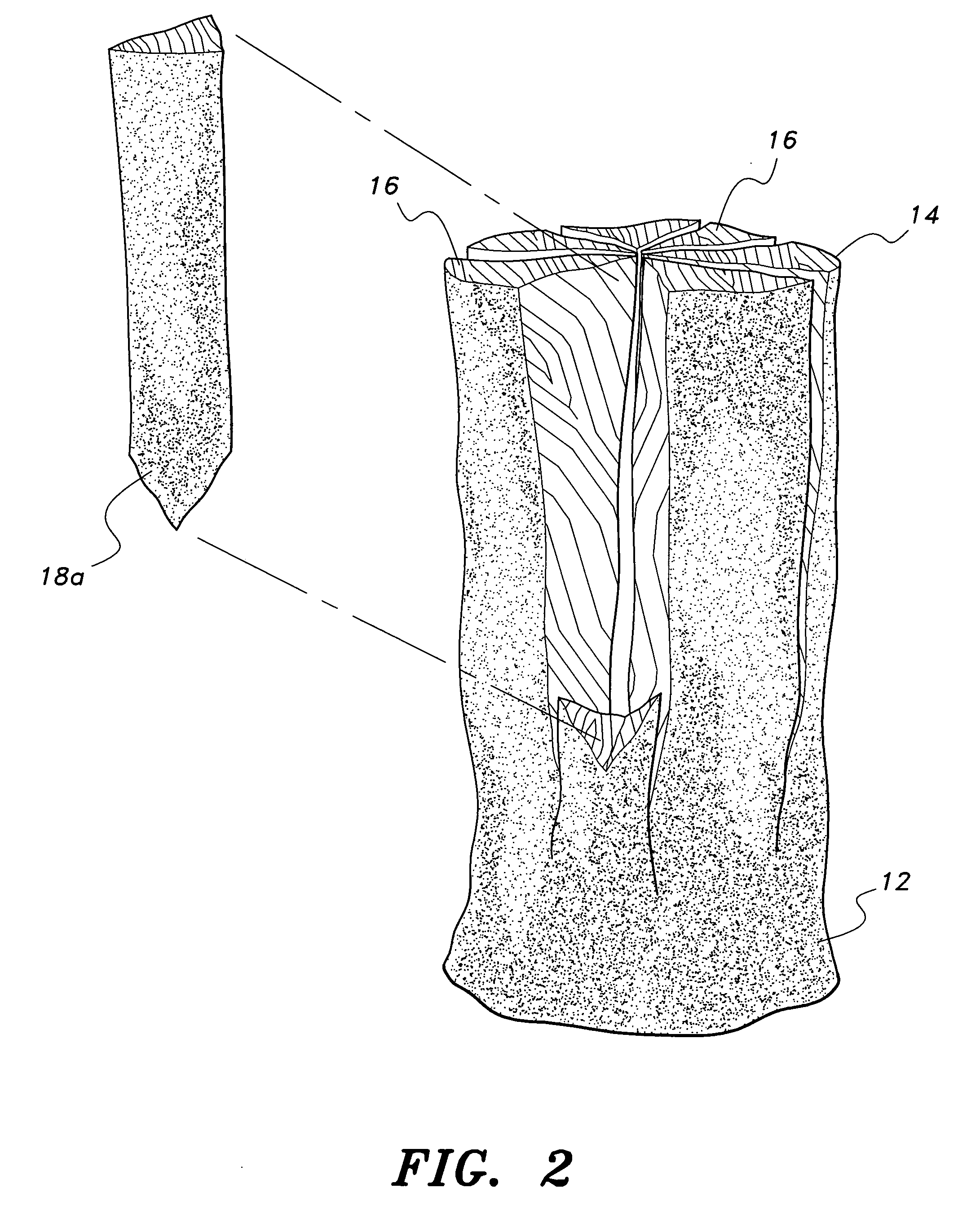

Fire log

InactiveUS8425634B2Easy to igniteIncrease or decrease intensitySawing apparatusBiofuelsMostly TrueEngineering

A fire log includes a single fire log cut in a specific design to enable easy ignition and sustenance of a self-contained campfire. The single log is designed to stand vertically and may range from twenty-four to seventy-two inches in height depending on diameter. In most instances, four vertical, diametrical cuts are made in the log forming eight pie-slice segments. The cuts extend from the top surface of the log downward toward the base of the log. The vertical cuts stop short of the entire length of the log leaving approximately 25% of the length uncut. The uncut portion forms the base of the log. One of the segments is cut horizontally at its lower end adjacent the top of the base so that the segment can be removed from the log for air flow control.

Owner:PARKER WALTER Z

Chest height light emission system

InactiveUS20060285314A1Relieve pressureAvoid contactLighting support devicesWith electric batteriesLight emissionPhysics

Owner:BARKER PAUL H

Lighted Ultrasonic Handpiece and Color Code Grip System

InactiveUS20070148618A1Easy to holdLess stressfulTooth pluggers/hammersCleaning using liquidsFiberCamera lens

The present invention relates to a dental scaling translucent insert which provides a coaxially aligned light adjacent the distal end of such insert for illuminating the tip of the dental scaler which light may be provided by light emitting from a fiber optic light guide from a light source located remotely from the tip. The light provided can also be used to view through a camera lens system located in translucent insert to provide a clear unobstructed view of the work at the tip of the scaler on a remote screen or for recording.

Owner:FEINE JAMES

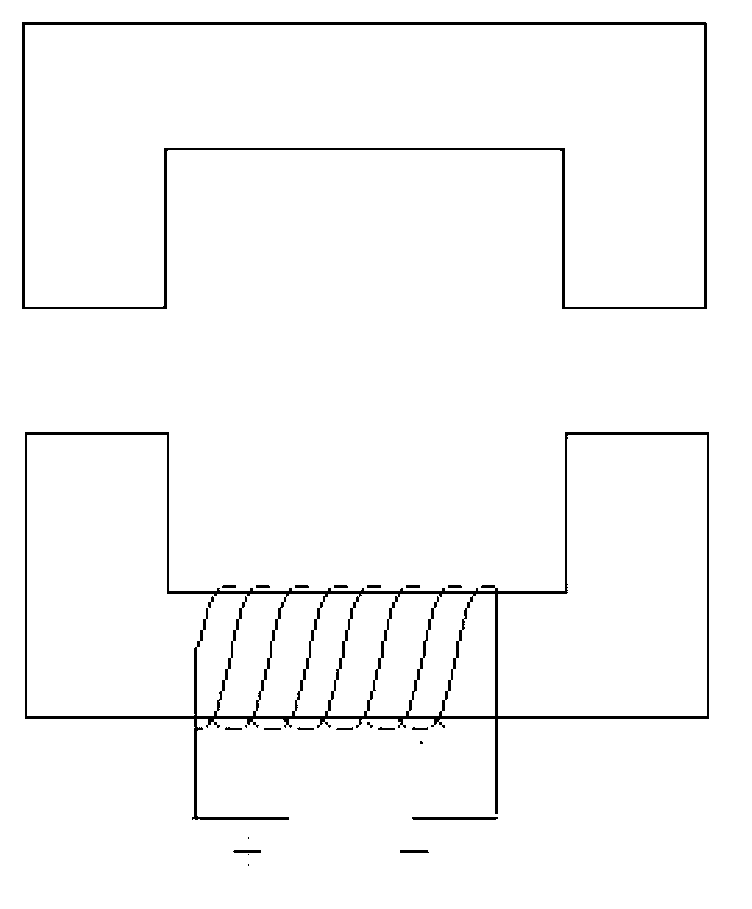

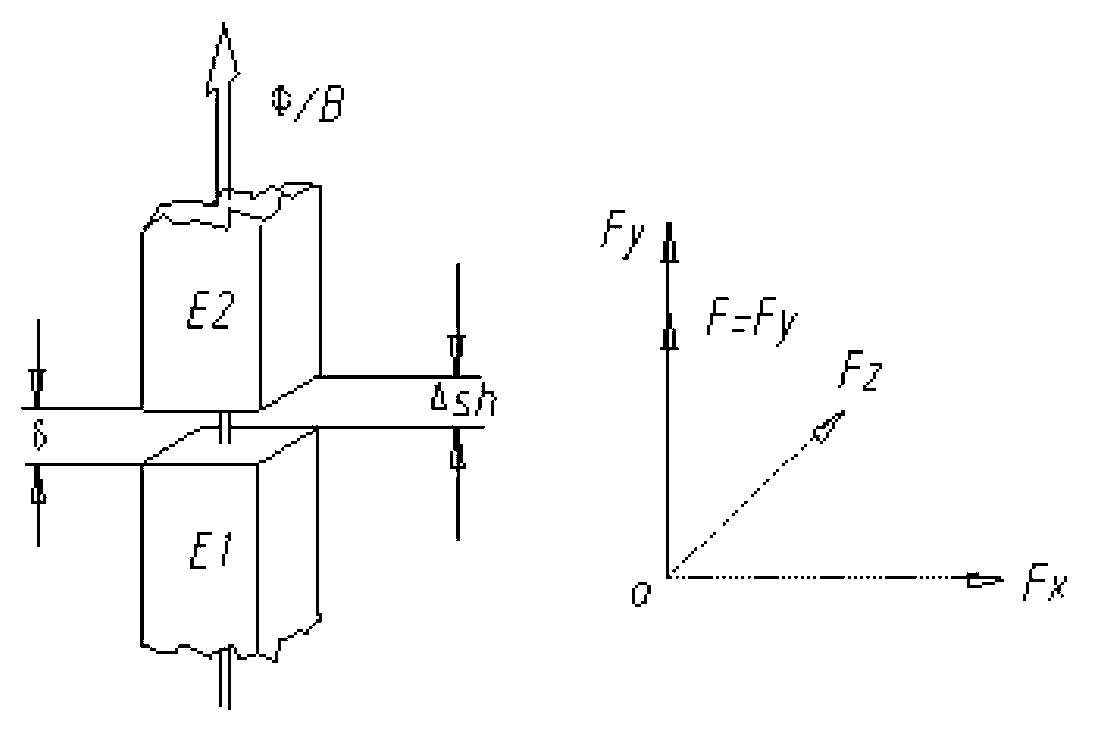

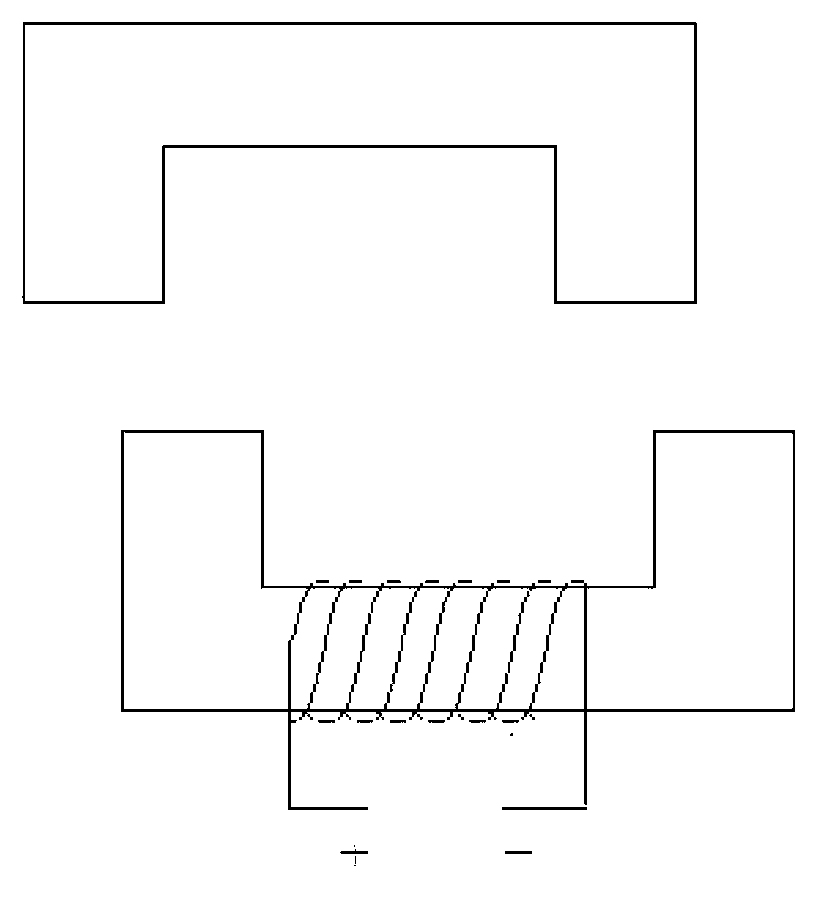

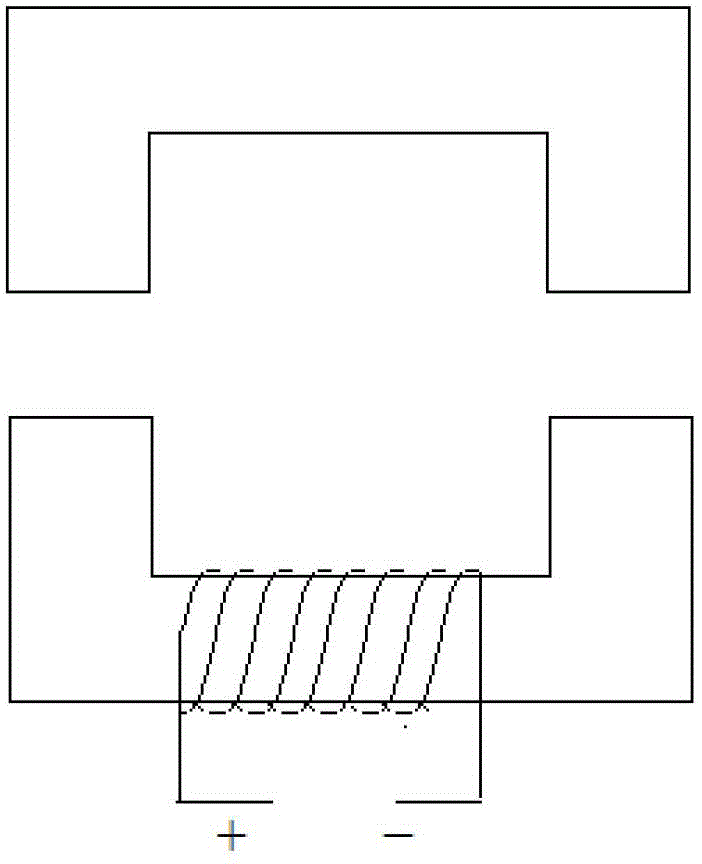

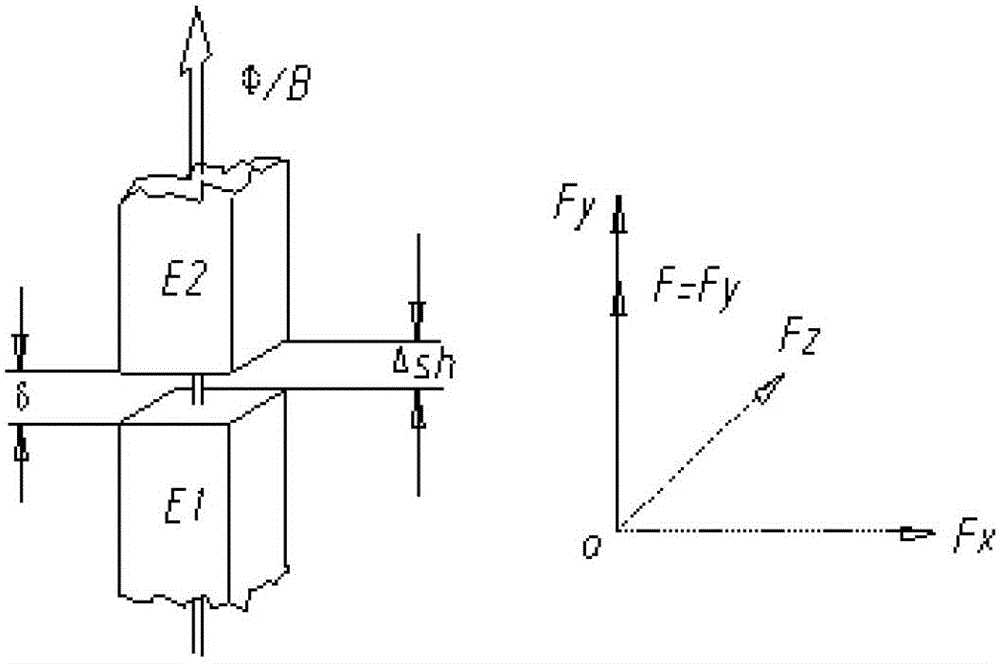

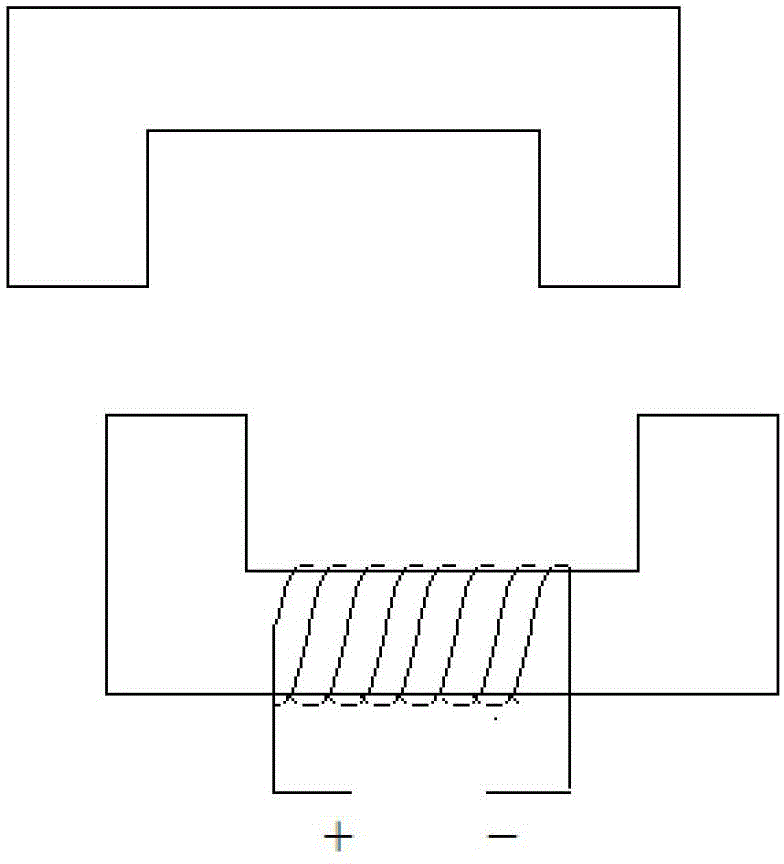

Vector magnetic fluid motor based on phase angle controlling

InactiveCN103178659AImprove energy conversion efficiencyOptimized magnetic circuitSingle motor speed/torque controlStructural associationPhysicsElectric energy

A vector magnetic fluid motor based on phase angle controlling comprises a stator, a rotor and a coil. The stator is arranged opposite to the rotor; the stator is fixed; and the rotor can move relatively to the stator. At least one stator magnetizer is arranged in the stator; and at least one rotor magnetizer is arranged in the rotor. An air gap is arranged between the stator magnetizer and the rotor magnetizer. The coil is wound on the stator magnetizer and the rotor magnetizer. A position sensor and a controller are arranged, and the position sensor is connected with the controller; and the coil is connected with a power source through the controller. Totally different working principles and working manners are adopted on the vector magnetic fluid motor; two working manners of magnetic field rotating and phase shifting of traditional motors are completely abandoned; inductive reactance is basically eliminated; impedance is drastically reduced; and remarkable energy-saving effect is achieved. The vector magnetic fluid motor has fire-new structure and working manners.

Owner:江苏飞马动力科技有限公司

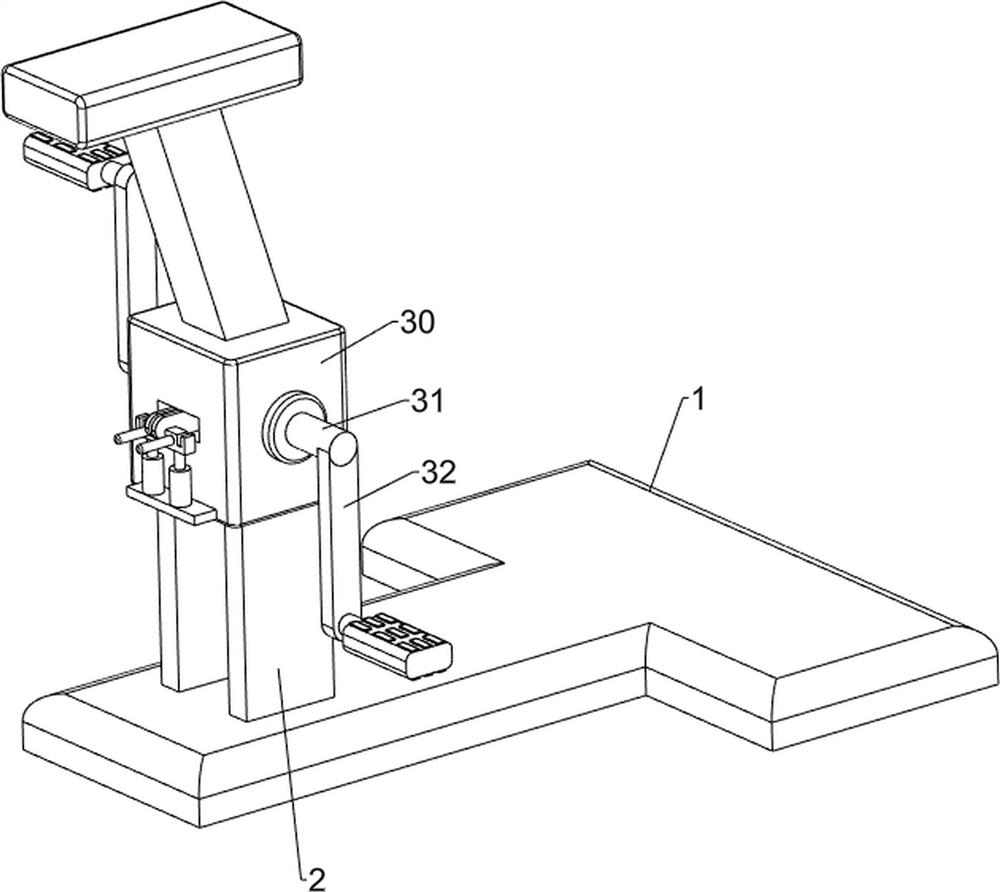

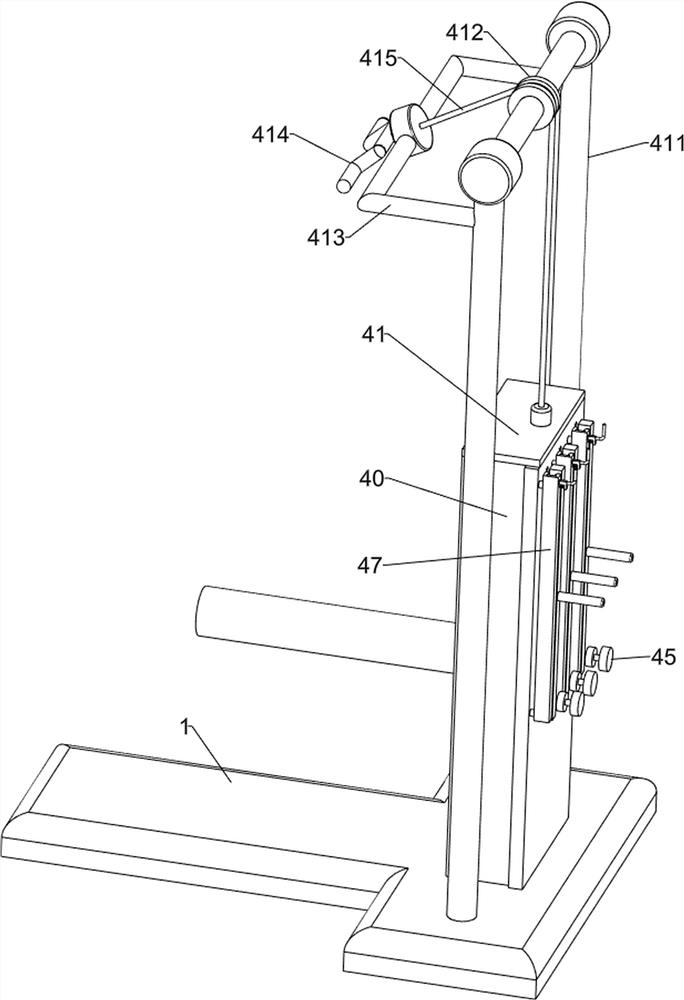

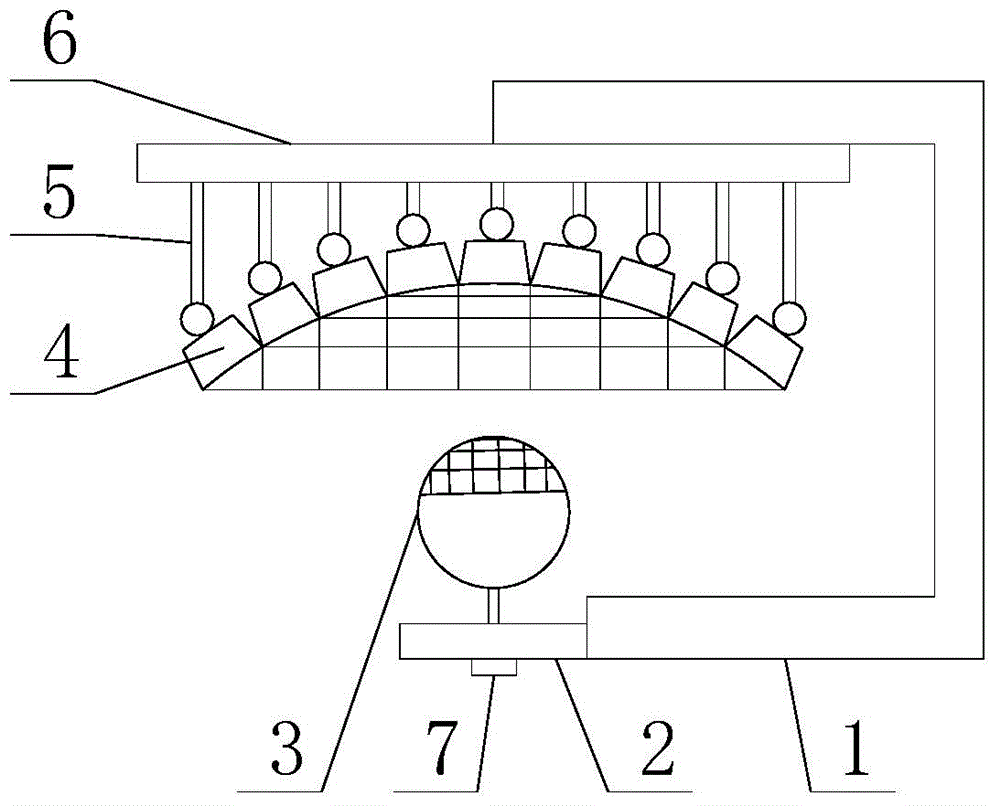

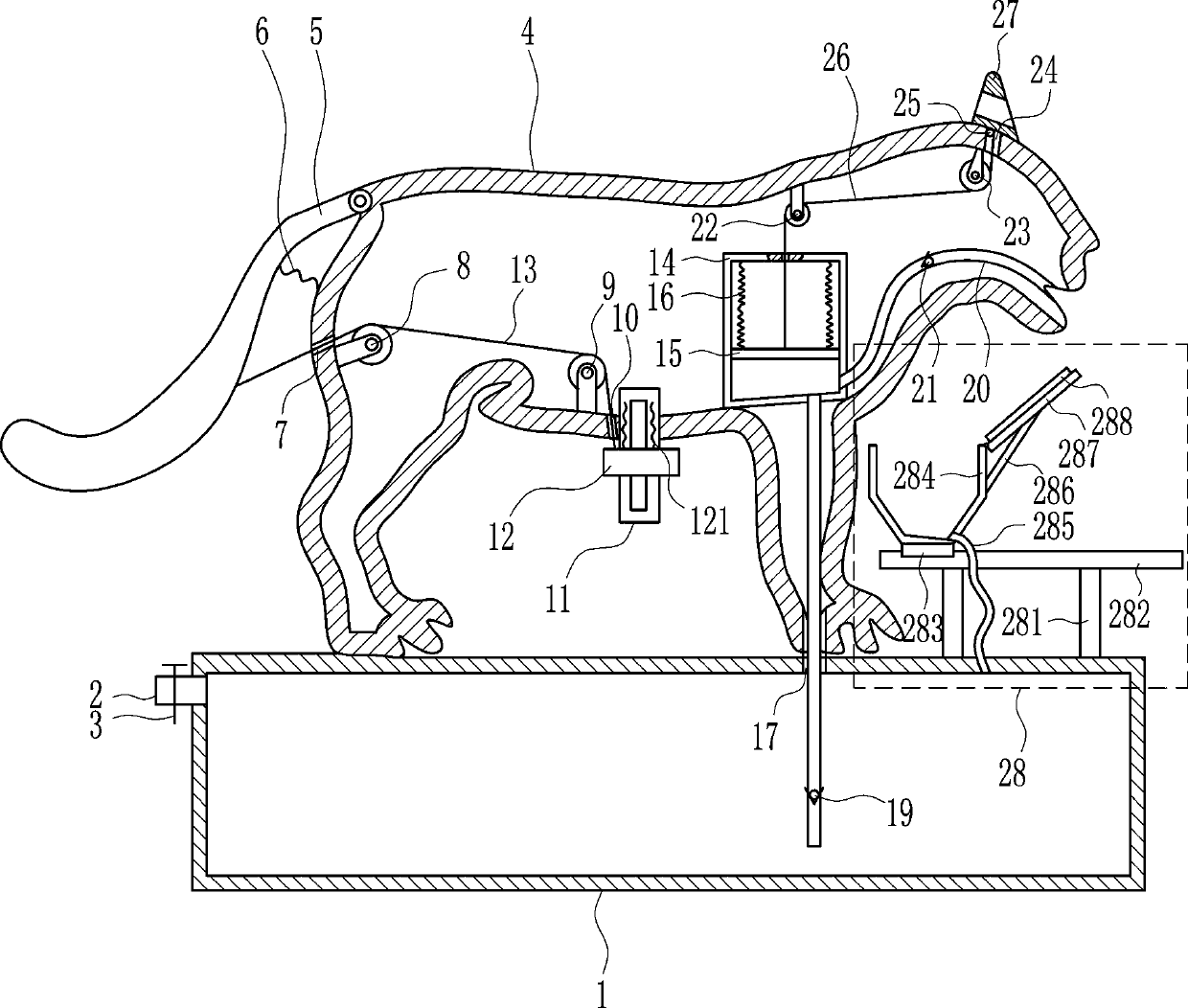

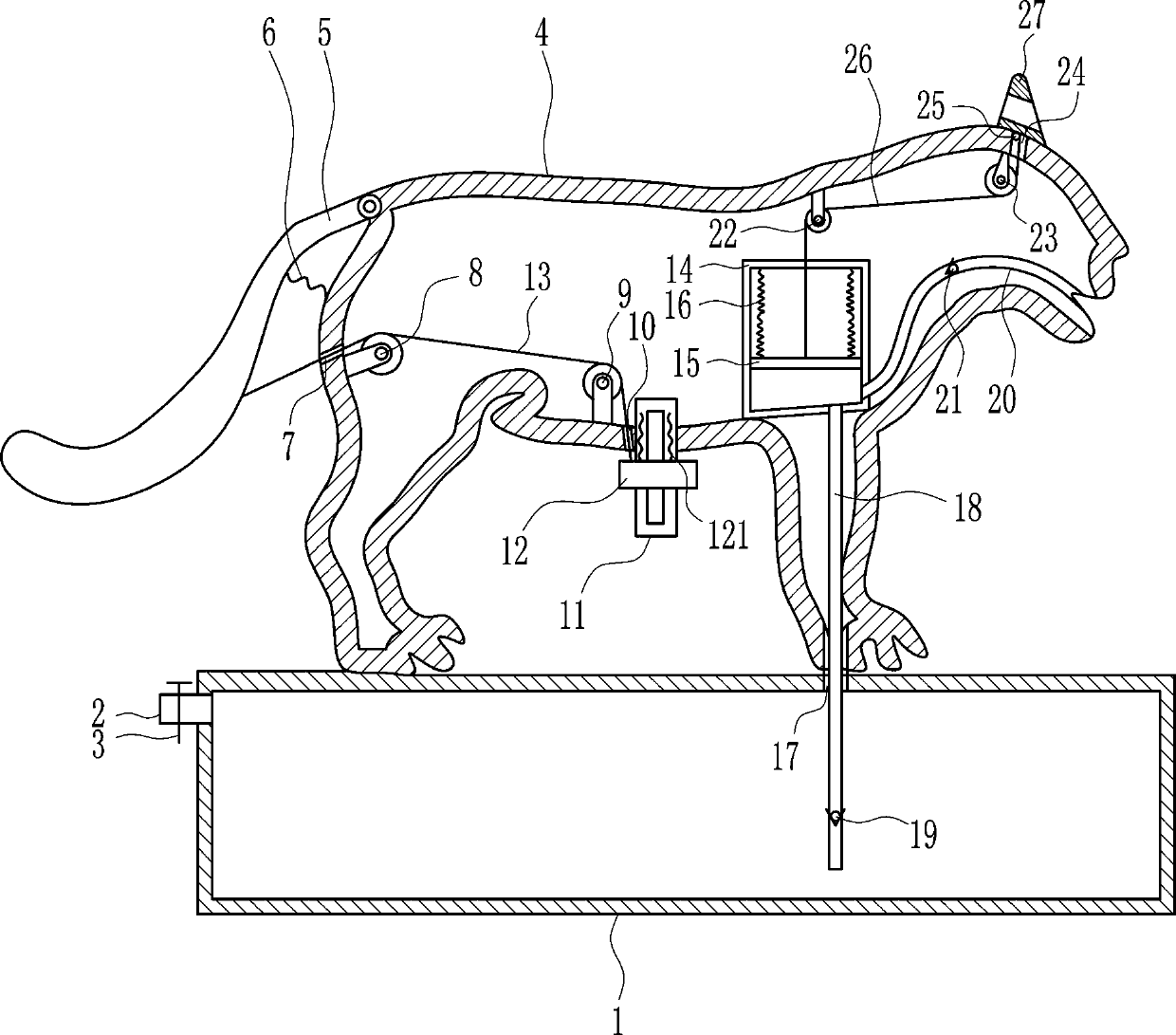

Exercise equipment suitable for old people

ActiveCN111973935AConvenient exerciseAdjust exercise intensityMovement coordination devicesMuscle exercising devicesExercise equipmentOlder people

The invention relates to exercise equipment, in particular to exercise equipment suitable for old people. According to the exercise equipment suitable for the old people, leg exercising and stretchingexercising of the old people can be met at the same time, the exercise intensity can be adjusted, and the angle of a backup plate can be adjusted. The exercise equipment suitable for the old people comprises a base, a supporting plate, a treading mechanism and a stretching mechanism; the supporting plate is arranged on one side of the top of the base; the treading mechanism is arranged at the topof the supporting plate; and the stretching mechanism is arranged on the side, away from the supporting plate, of the top of the base. By means of the exercise equipment, the requirements of the oldpeople for leg exercising and stretching exercising can be met, the exercise intensity of leg exercising and stretching exercising is adjusted, meanwhile, the angle of the backup plate can be adjusted, and the old people can feel more comfortable during exercising.

Owner:山东沂南园区开发建设有限公司

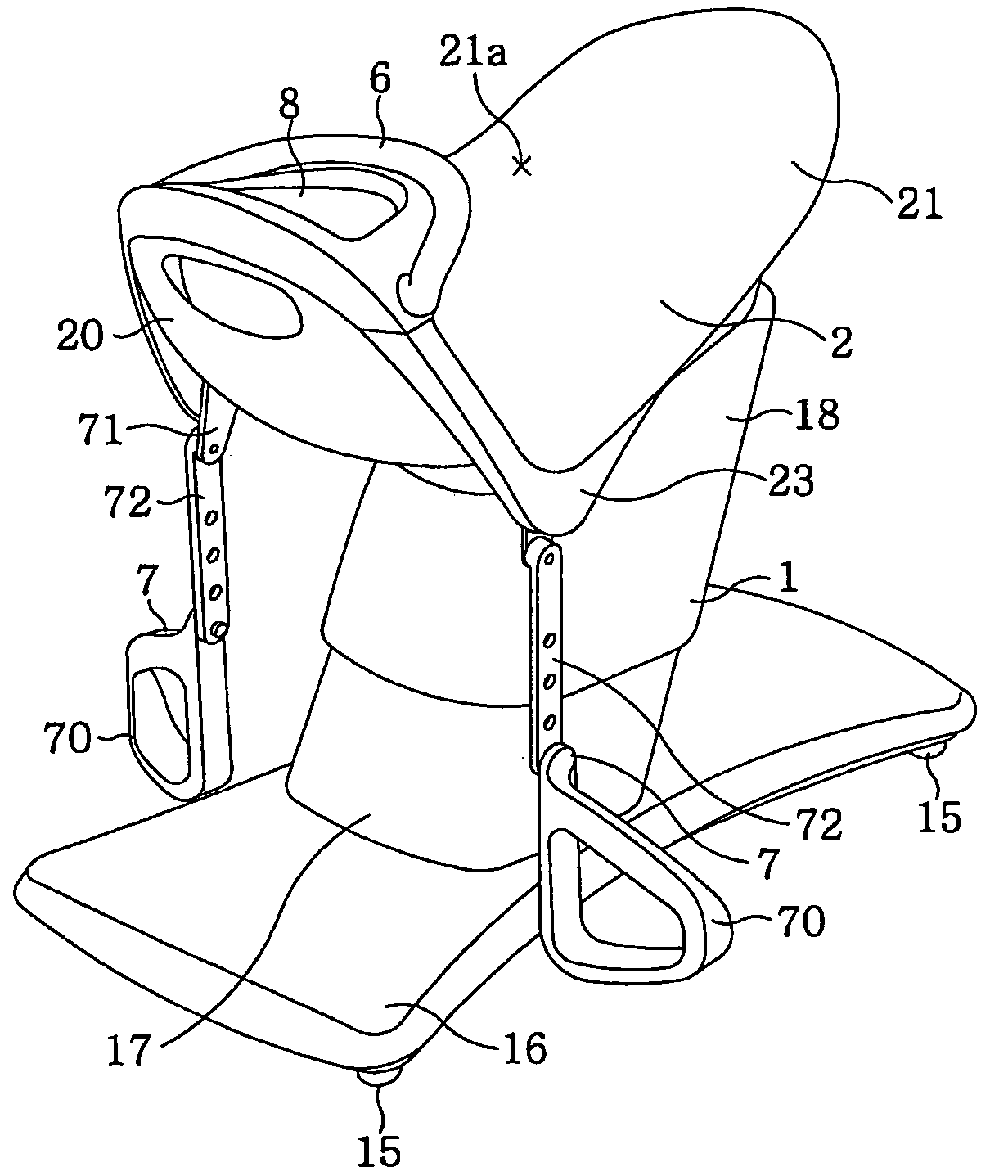

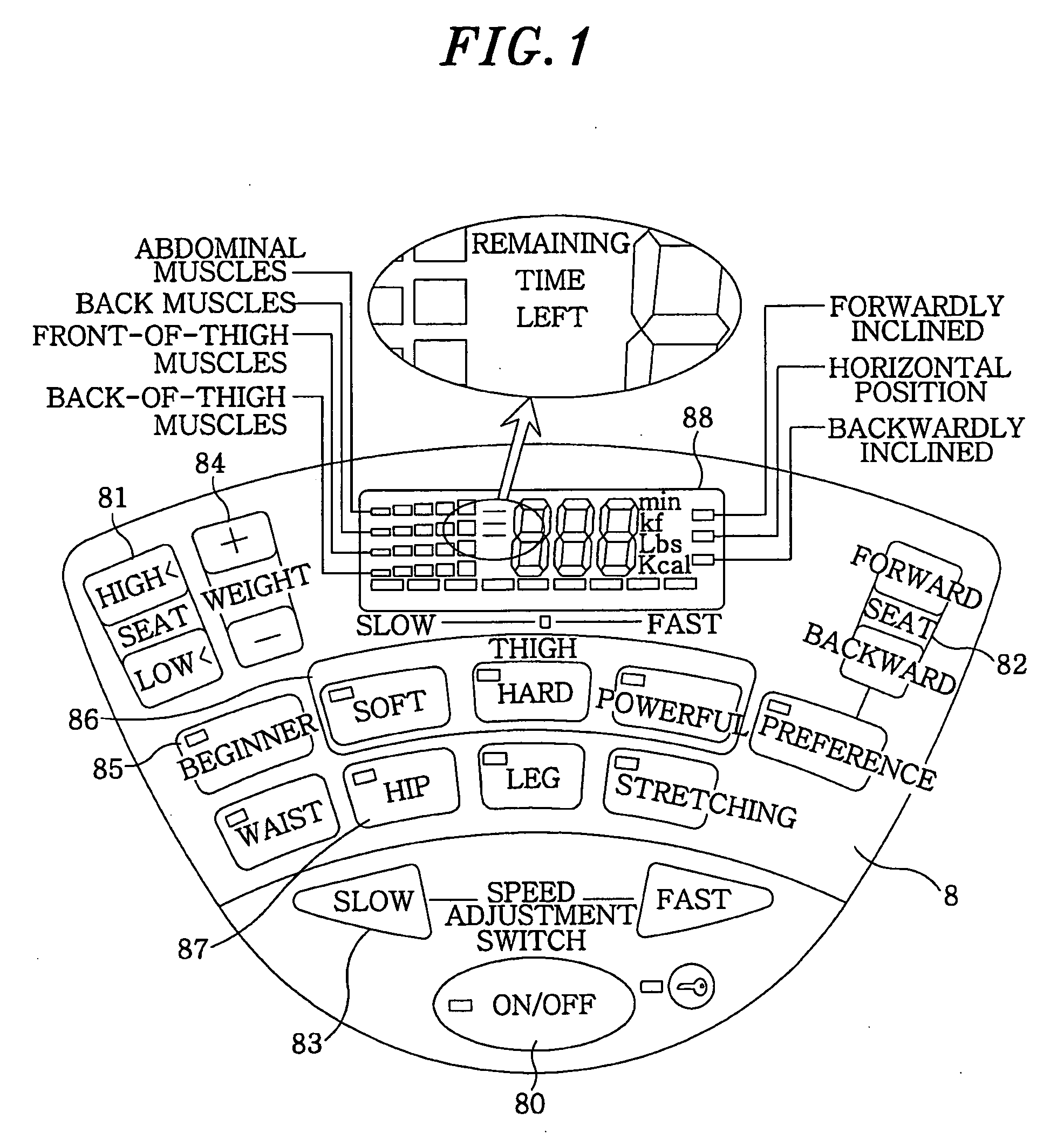

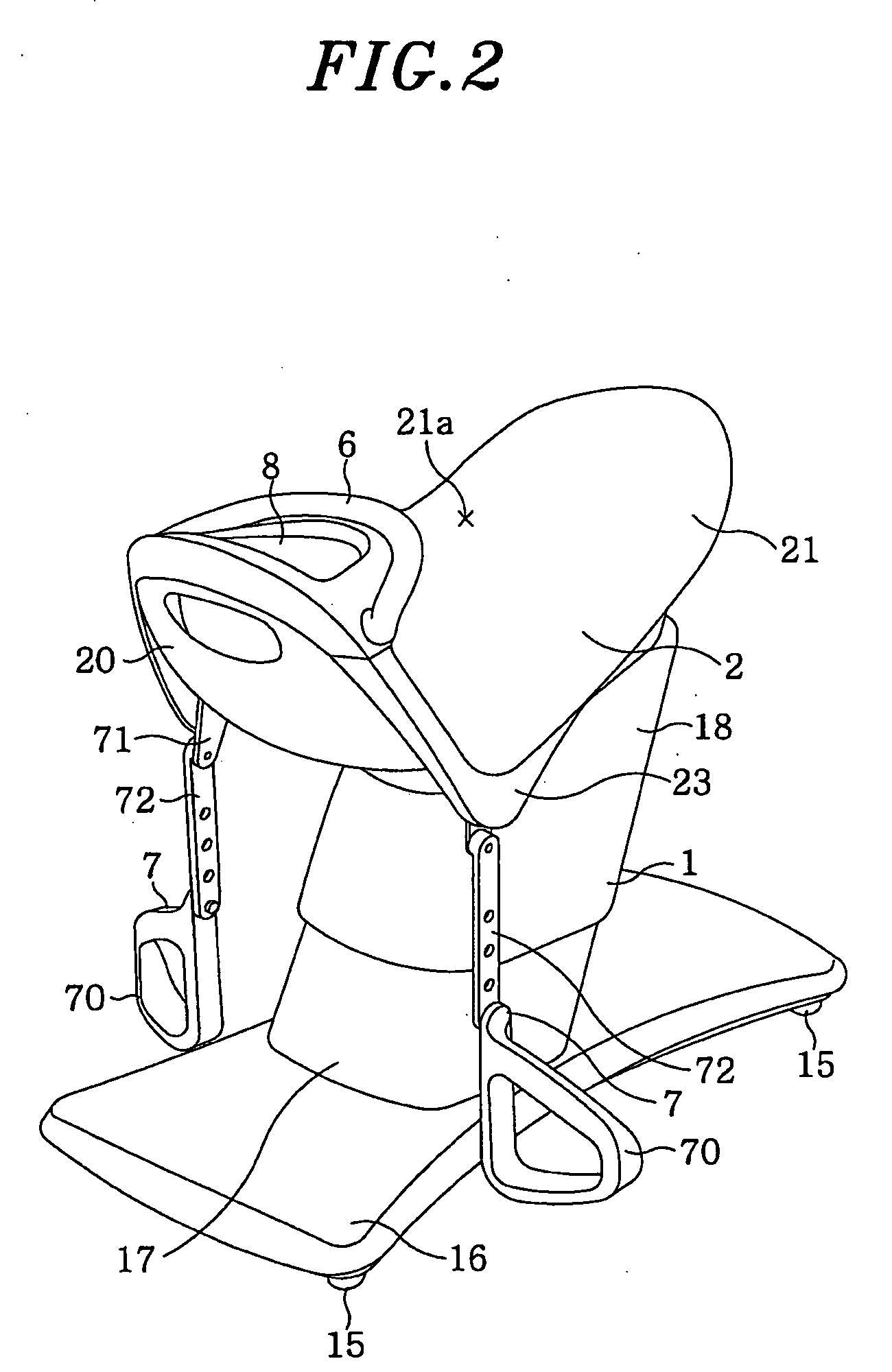

Rocking type exercising apparatus

InactiveUS20090062075A1Increase or decrease intensityIncrease the relative amount of exerciseStiltsMuscle exercising devicesEngineeringMultiple body regions

A rocking type exercising apparatus includes a movable unit on which a user rides, a driving unit for causing the movable unit to perform a rocking motion, and a rocking motion changing unit for changing the rocking motion of the movable unit driven to rock by the driving unit. The rocking type exercising apparatus also includes a display unit, responsive to the change in the rocking motion caused by the rocking motion changing unit, for displaying loads to be applied to a plurality of body regions of the user.

Owner:MATSUSHITA ELECTRIC WORKS LTD

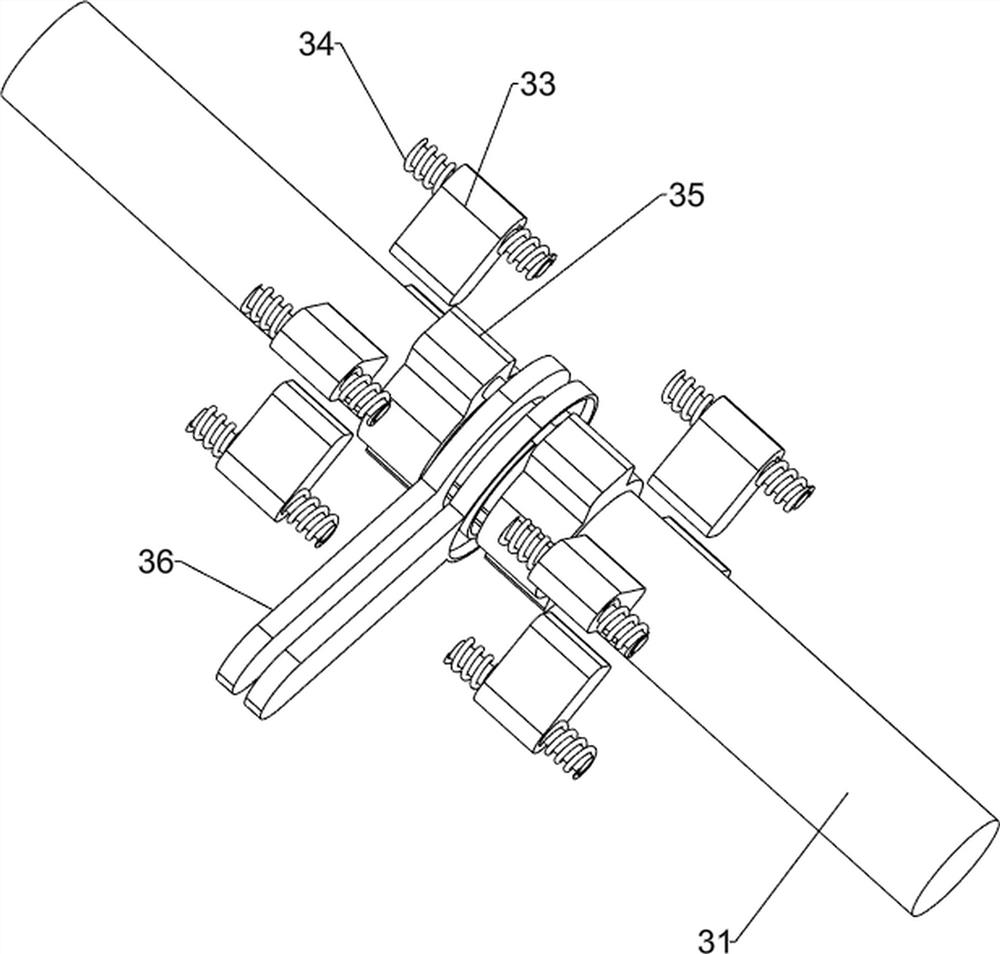

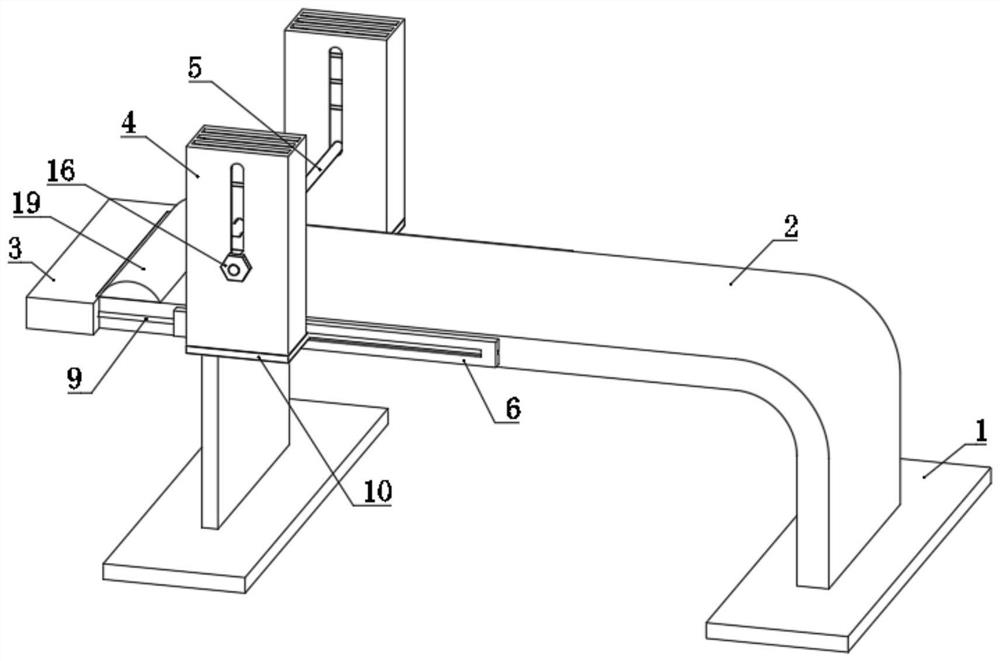

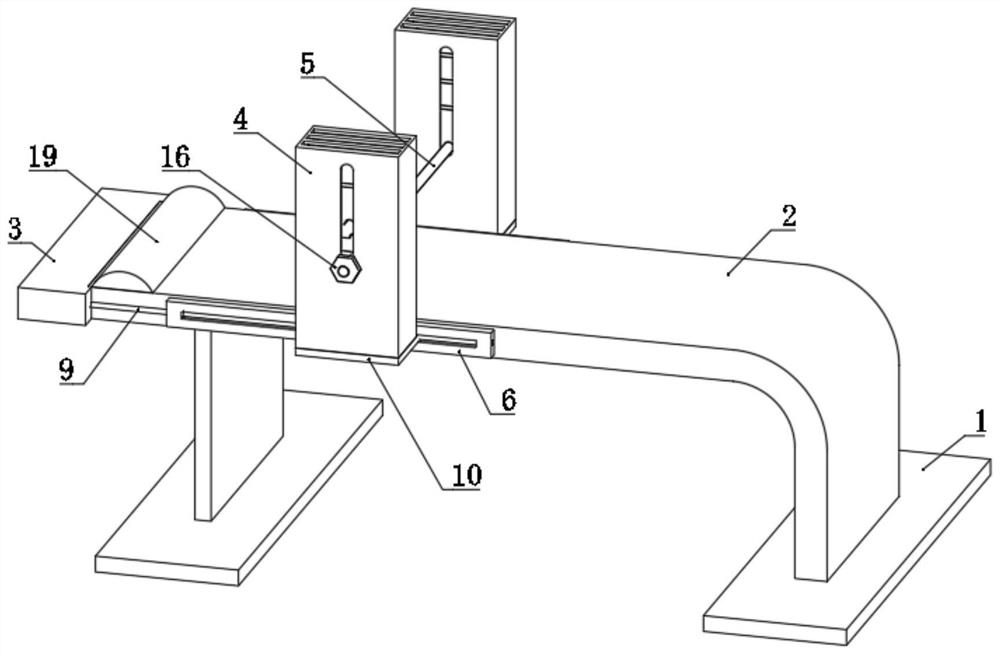

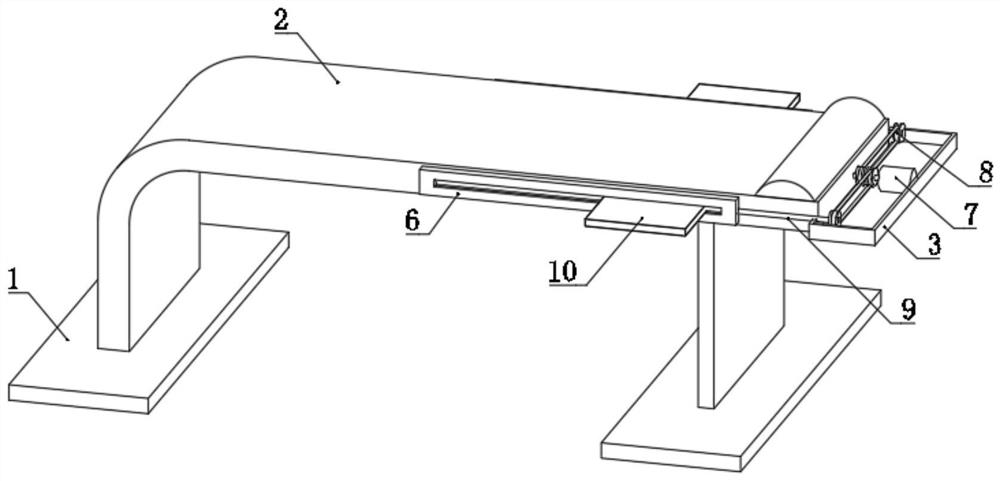

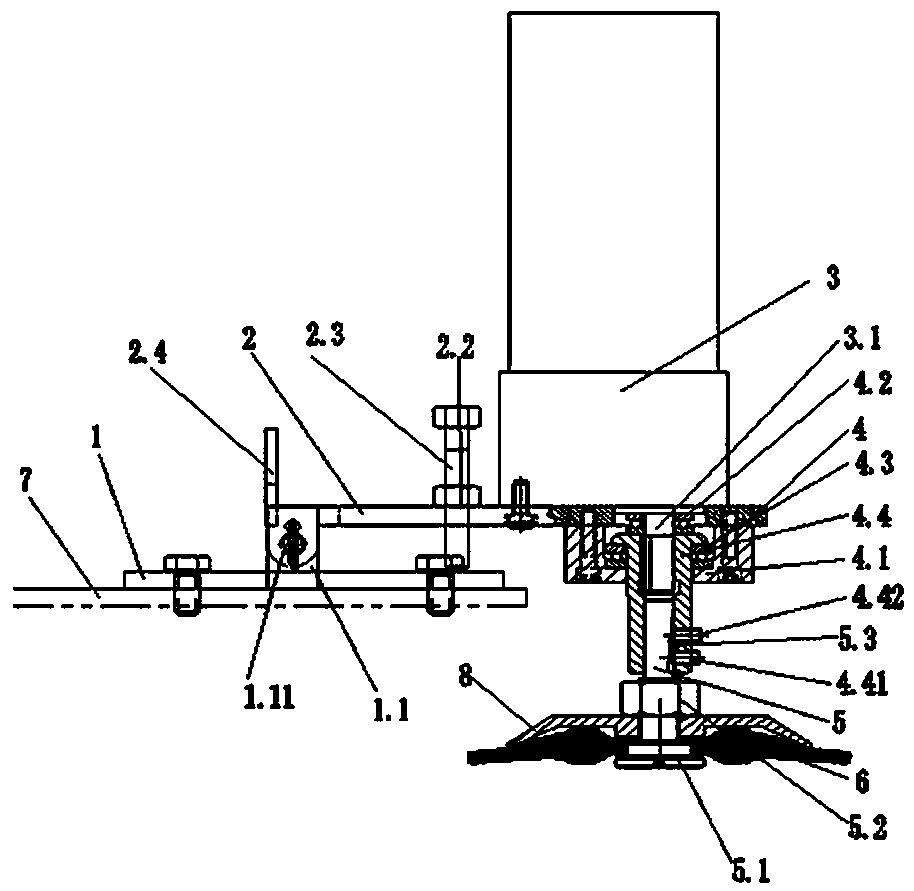

Barbell stand capable of conveniently adjusting counter weight

ActiveCN113521648AEasy to move and adjustAvoid cumbersomenessDumb-bellsMuscle strainsElectric machinery

The invention discloses a barbell stand capable of conveniently adjusting counter weight, and belongs to the field of physical fitness equipment. The barbell stand comprises a lying plate, the lying plate is placed on the ground through a base, one end of the lying plate is an arc-shaped section, the other end of the lying plate is a horizontal section, a transmission box is installed on the horizontal section of the lying plate, and a motor is installed in the transmission box; sliding rails are installed on the two sides of the end, close to the transmission box, of the lying plate, threaded rods are rotationally installed in the sliding rails, supporting plates are installed on the sliding rails through the threaded rods in a threaded mode, and ends of the threaded rods extend into the transmission box. According to the barbell stand, diversified training modes can be provided for trainees, the complexity of increasing and decreasing the balancing weights can be well solved during training, potential safety hazards are eliminated, suitable training intensity can be provided for trainees with different strength, the training intensity is increased and decreased step by step, and muscle strain is not likely to be caused.

Owner:YANTAI UNIV

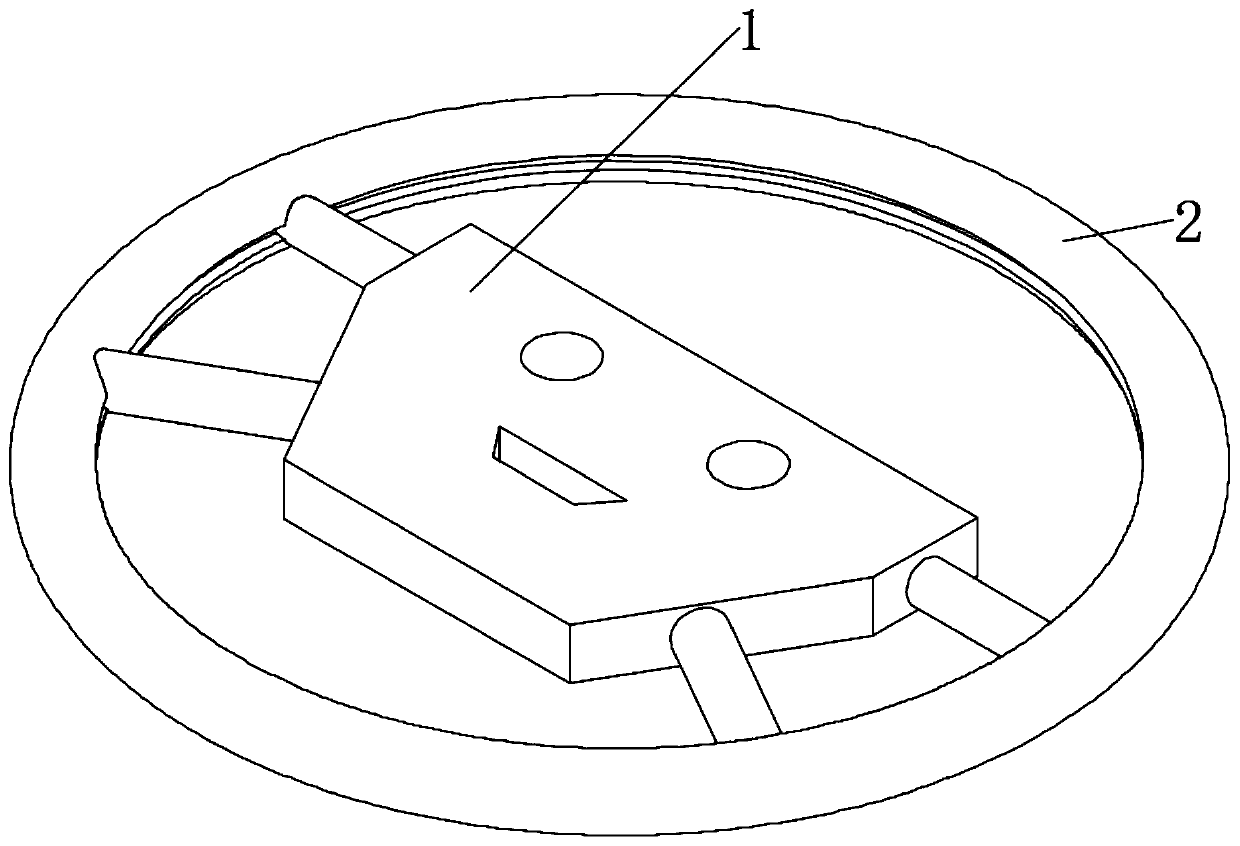

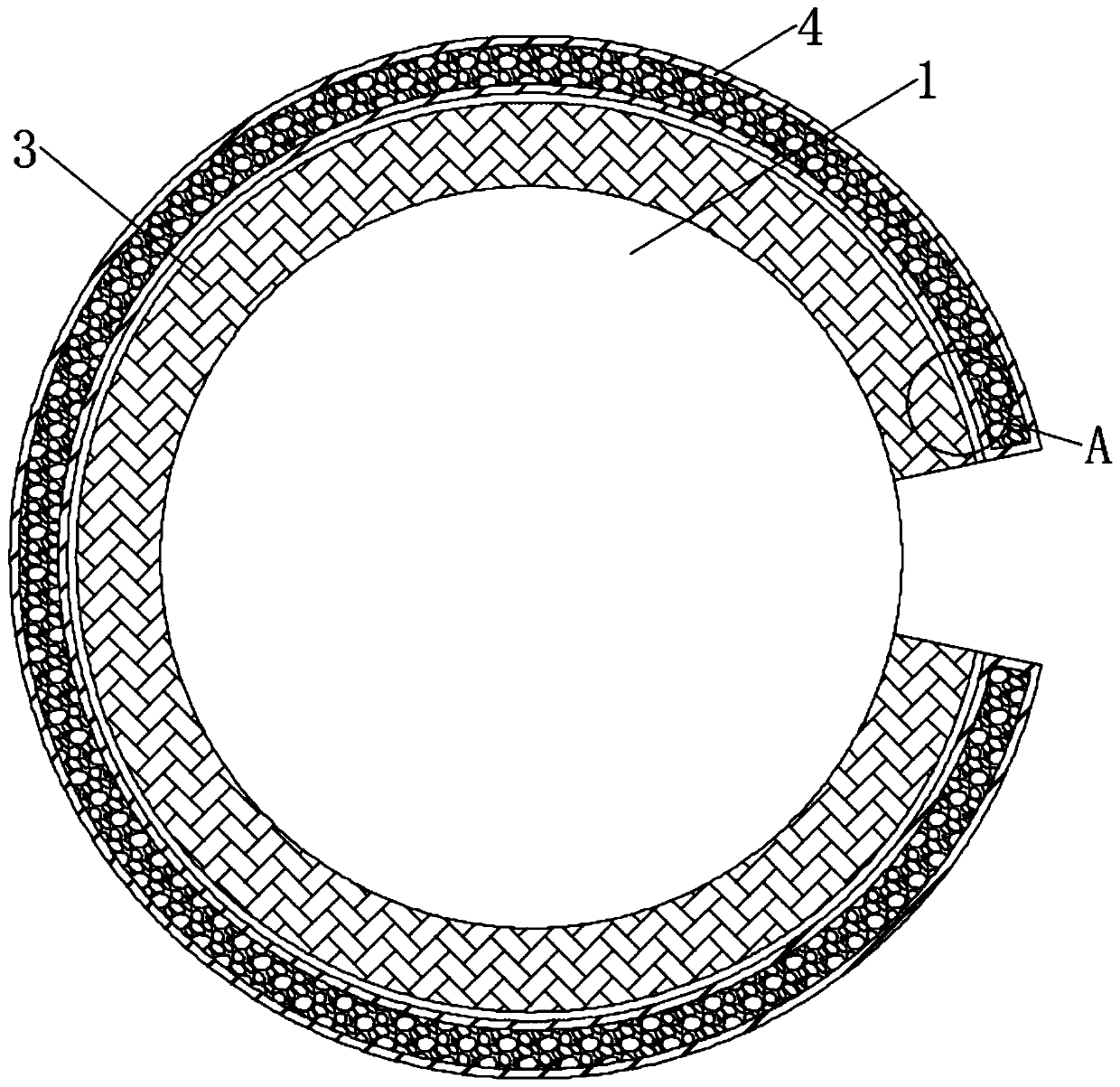

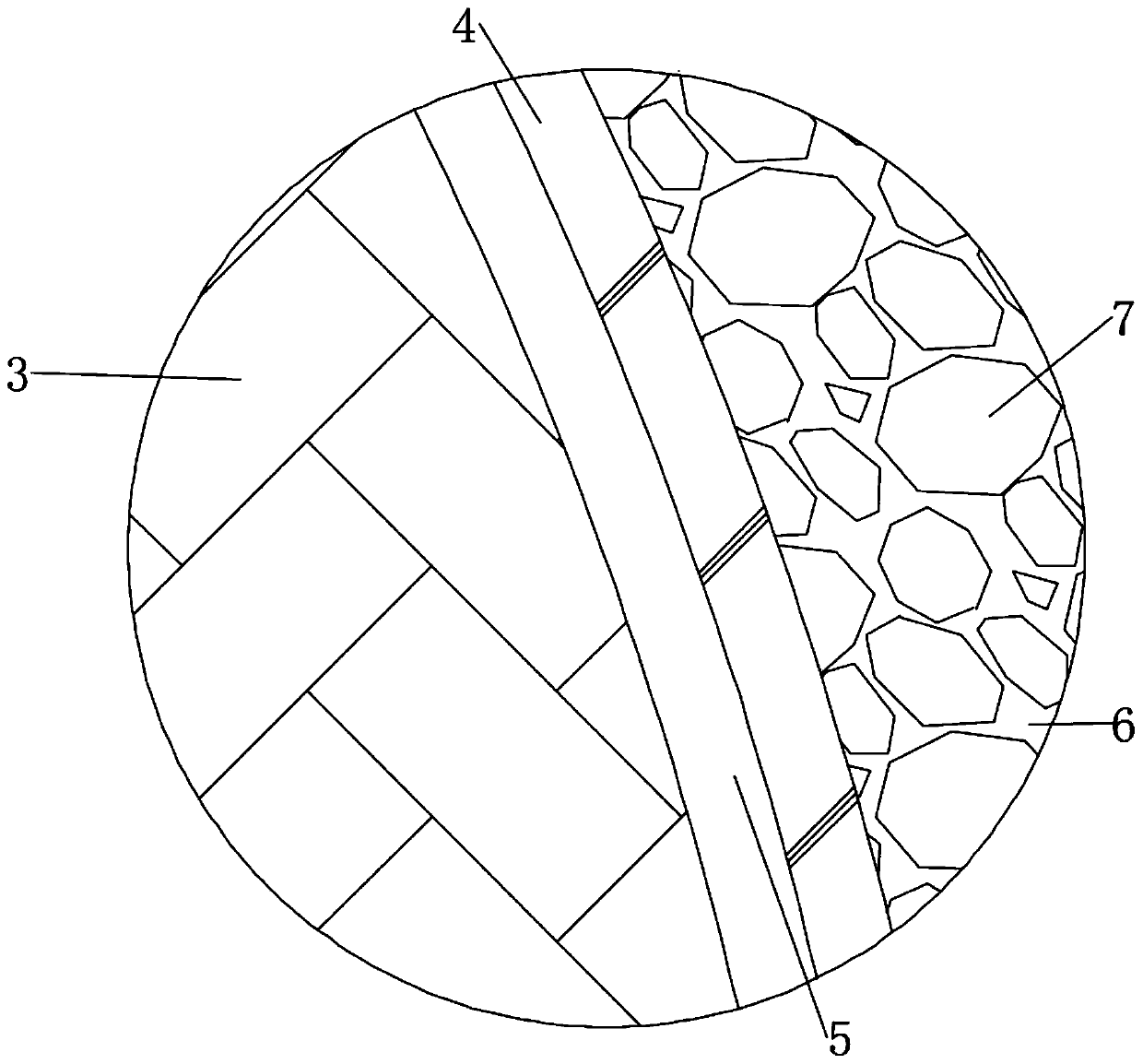

Heating pad for automobile steering wheel and processing technology of heating pad

The invention discloses a heating pad for an automobile steering wheel and a processing technology of the heating pad, and belongs to the field of steering wheel heating pads. According to heating padfor the automobile steering wheel and the processing technology of the heating pad, an electric heating wire is embroidered on the surface of a textile fabric main body through an embroidering process, and a corresponding energy supply unit is provided for the electric heating wire, so that a textile heating sheet integrally becomes a heat supply unit of the heating pad; then, an outer protectivesleeve is additionally arranged on the outer wall of the textile heating sheet, and a solid silica gel block and a liquid silica gel in the outer protective sleeve are utilized to realize the uniformheat dissipation of the textile heating sheet, so that the overall temperature difference of the outer side of the heating pad main body is small, the great influence on a driver due to the non-uniform heating of the outer side part of the heating pad main body is not easy to generate; and finally, a plurality of grating plates are additionally arranged in the outer protective sleeve, so that thestrength of the outer protective sleeve body can be effectively increased and decreased, the phenomenon that the outer protective sleeve slips off during the process that the driver holds the outer protective sleeve for driving is not likely to happen, and the safety performance of the outer protective sleeve is greatly improved.

Owner:海安荣民汽车配件有限公司

Aircraft cabin disinfection system

ActiveUS10918749B2Increase or decrease intensitySolve the slow scanning speedLavatory sanitoryAircraft cleaningNacelleUVC Radiation

A cabin disinfection system for an aircraft, including: a sensing means (3, 11, 13) to sense the presence of personnel in one or more zones (16-19, 23-26, 28, 29, 30, 32), a predictive sensing means (3, 11, 13, 33) to sense the direction of motion of a person (31) and to predict whether that person will occupy a zone to be disinfected (18) during planned disinfection, one or more UVC radiation sources (4, 9) to disinfect the cabin, and a controller (33) to control operation of the UVC radiation sources (4, 9) dependent on sensing of personnel in that zone and the predictive sensing means (3, 11, 13, 33) predicting that a person (31) will occupy the zone (18) during the planned disinfection period.

Owner:AIRBUS SAS

Intelligent-dimming energy-saving wall lamp

InactiveCN104864308AIncrease or decrease intensityShort lifeElectrical apparatusPoint-like light sourceEngineeringLED lamp

The invention discloses an intelligent-dimming energy-saving wall lamp. According to the wall lamp, a user can select a high-brightness mode or a low-brightness mode as required, a controller controls reflector driving mechanisms to drive reflectors to move to adjust reflecting surfaces of the reflectors, so that directions of lights emitted by all LED lamp beads are changed, and lights reflected by the plurality of reflectors interfere to increase or decrease the light intensity, and the purpose of changing lighting intensity can be realized as required without adjusting power; meanwhile, the controller is used for controlling the reflector driving mechanisms to carry out fine adjustment on the reflection directions on the reflectors in real time according to ambient brightness detected by a brightness detector, so that the ambient brightness can reach a standard threshold value. Through adoption of the intelligent-dimming energy-saving wall lamp, electric energy is saved, the lighting intensity can be adjusted as required, and the condition that the service life of a light source is shortened due to the change of the lighting power is avoided.

Owner:FANCHANG BOTONG E COMMERCE CO LTD

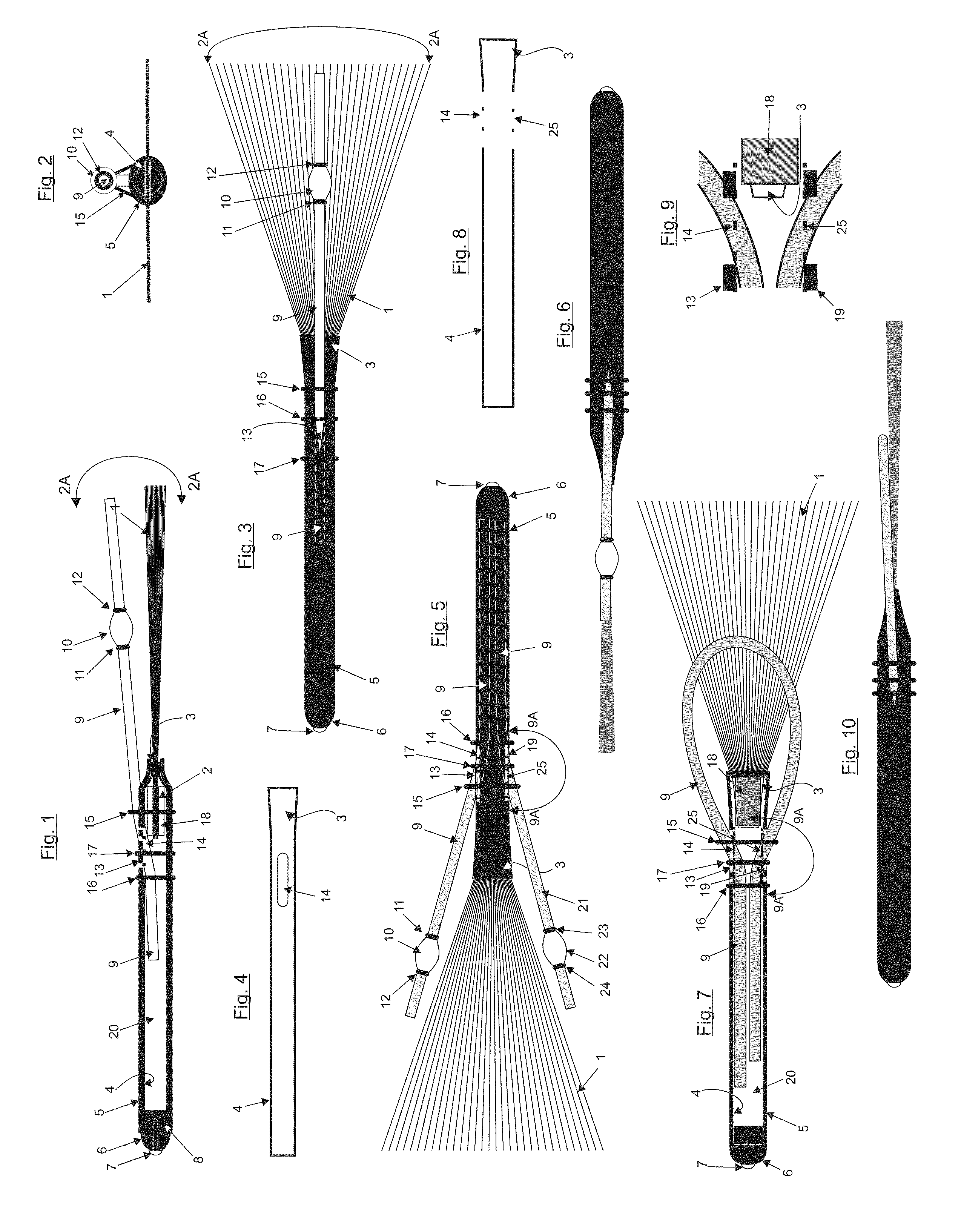

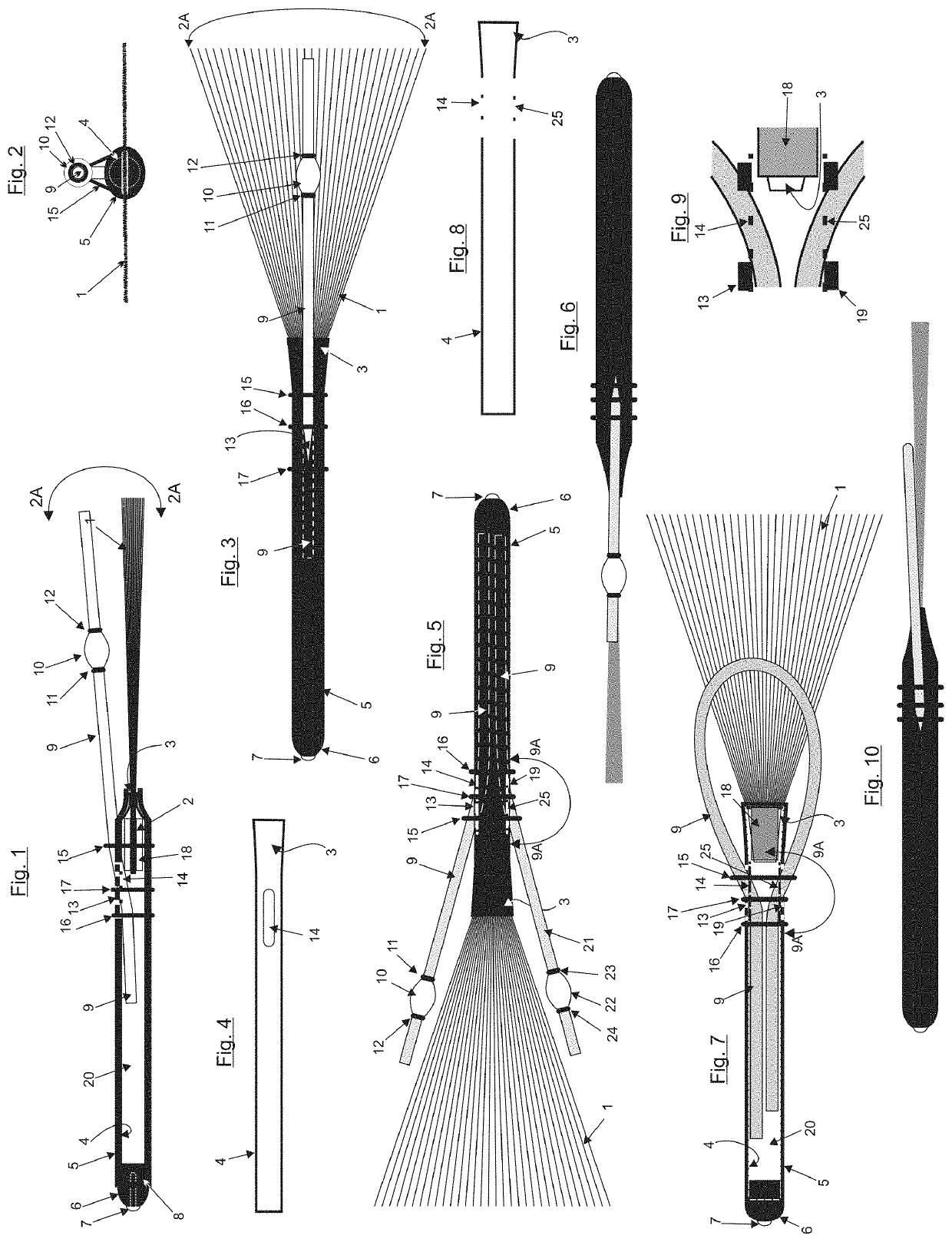

Drum Brush with Rod

ActiveUS20150170620A1Increased and decreased in intensityEasy to reboundPercussion musical instrumentsBristleEngineering

A drum brush comprising a tube with slot, a plurality of wire bristles, a rod and O-ring, where the said bristles are at least partially within said tube in which portions of bristles extend outwardly from one end of tube, the end of casing from which the bristles extend is partially flattened to hold the bristles in position. The tube has a slot, its relative position is perpendicular and near to the end from which the bristles extend. A rod of a diameter such that when inserted into the said slot is held in position and adjustable in length by sliding in and out of the tube. The said O-ring is slid over the tube and rod, its function is used to adjust the height or relative distance of the said rod to that of the bristles.

Owner:RUNDLE DAVID CHAPPELL

Method and apparatus for ink jet printing

InactiveCN100354134CIncrease or decrease timeChange the final compositionDuplicating/marking methodsSpacing mechanismsPorous substratePolyester

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640, 641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645, 646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661, 662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702, 704) such as a TEFLON film or sheet, covers a substrate support (705, 706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material.

Owner:L & P PROPERTY MANAGEMENT CO

Drum brush with rod

A drum brush comprising a tube with slot, a plurality of wire bristles, a rod and O-ring, where the said bristles are at least partially within said tube in which portions of bristles extend outwardly from one end of tube, the end of casing from which the bristles extend is partially flattened to hold the bristles in position. The tube has a slot, its relative position is perpendicular and near to the end from which the bristles extend. A rod of a diameter such that when inserted into the said slot is held in position and adjustable in length by sliding in and out of the tube. The said O-ring is slid over the tube and rod, its function is used to adjust the height or relative distance of the said rod to that of the bristles.

Owner:RUNDLE DAVID CHAPPELL

A kind of arm strength training equipment for children in parks for municipal engineering

ActiveCN108686344BAvoid streamingAvoid enteringMuscle exercising devicesEnvironmental resource managementWater resources

The invention relates to child arm strength exercising equipment, in particular to child arm strength exercising equipment for municipal engineering in a park. The invention aims at providing the child arm strength exercising equipment which can attract a child to exercise and is used for municipal engineering in the park. According to the technical scheme, the child arm strength exercising equipment for municipal engineering in the park comprises a box body, a first water inlet pipe, a valve, a tiger model, a tiger tail, a first spring, a first fixed pulley, a second fixed pulley, a first slide rail, a first slide block and the like; the first water inlet pipe is connected to the upper portion of the left wall of the box body and communicated with the left wall of the box body, the valveis arranged on the first water inlet pipe, and the tiger model is connected to the top of the box body. By means of the exercising equipment, the arm strength of the child is exercised by pulling earsof the tiger model; meanwhile, in the exercising process, water can be ejected out of the mouth of the tiger model to attract the child to exercise; a water reflux device can prevent water from flowing everywhere, the water can also be recycled, and then water resources are saved.

Owner:郑于兵

Vector magnetic fluid motor based on phase angle controlling

InactiveCN103178659BEliminate inductive reactanceLower impedanceSingle motor speed/torque controlStructural associationMagnetic currentElectric machine

Owner:江苏飞马动力科技有限公司

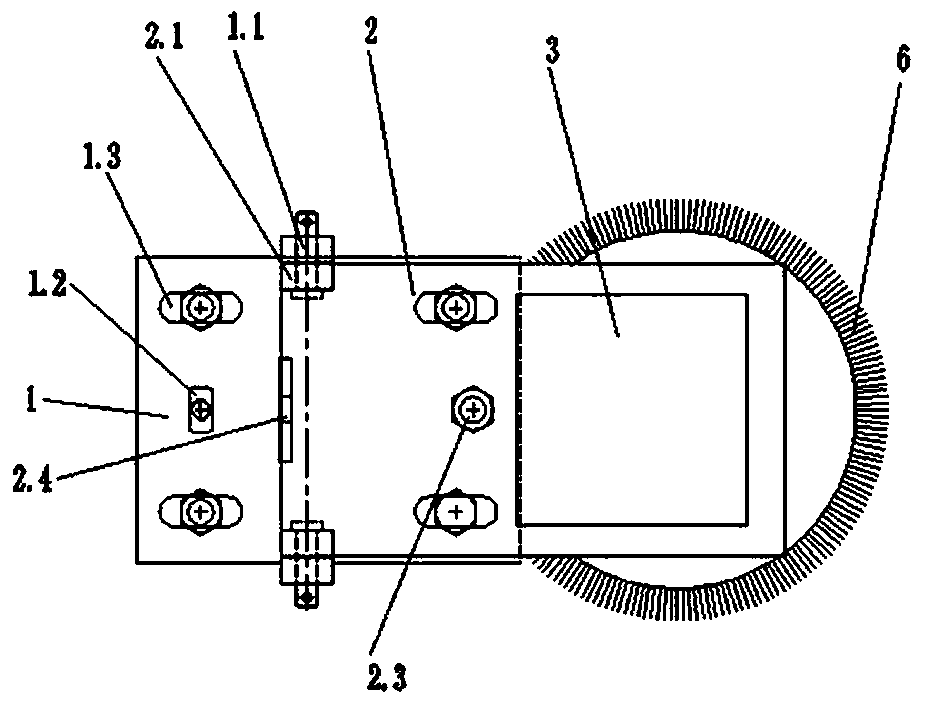

Cloth clip cutter plate surface cleaning device for setting machine

PendingCN109365340APrevent sticking clipsDoes not affect normal workCleaning using toolsSurface cleaningEngineering

The invention provides a cloth clip cutter plate surface cleaning device for a setting machine. The cloth clip cutter plate surface cleaning device is characterized in that the device comprises an installation base, a connection bracket, an electric gear motor, a bearing assembly, a dowel bar and a brush wheel; the installation base is connected to a cover plate located at the semicircle positionof the outer side of the tail of the setting machine; one end of the connection bracket is connected to the installation base, and the other end of the connection bracket stretches out of the cover plate located at the semicircle position of the outer side of the tail of the setting machine; one end, stretching out of the cover plate located at the semicircle position of the outer side of the tailof the setting machine, of the connection bracket is provided with a through hole, the electric gear motor is fixed to the upper portion of the connection bracket, and an output shaft of the electricgear motor penetrates the through hole; the bearing assembly is fixed to the lower portion of the connection bracket and is in transmission connection with the output shaft; the dowel bar is connected to the lower portion of the bearing assembly; and the brush wheel is connected to the bottom of the dowel bar. Through the cloth clip cutter plate surface cleaning device, the problem that filled cloth adheres to a clip can be effectively solved, and normal working of the setting machine is not influenced when the cloth clip cutter plate surface cleaning device conducts cleaning work.

Owner:JIANGSU LITTLE SUN TECH DEV CO LTD

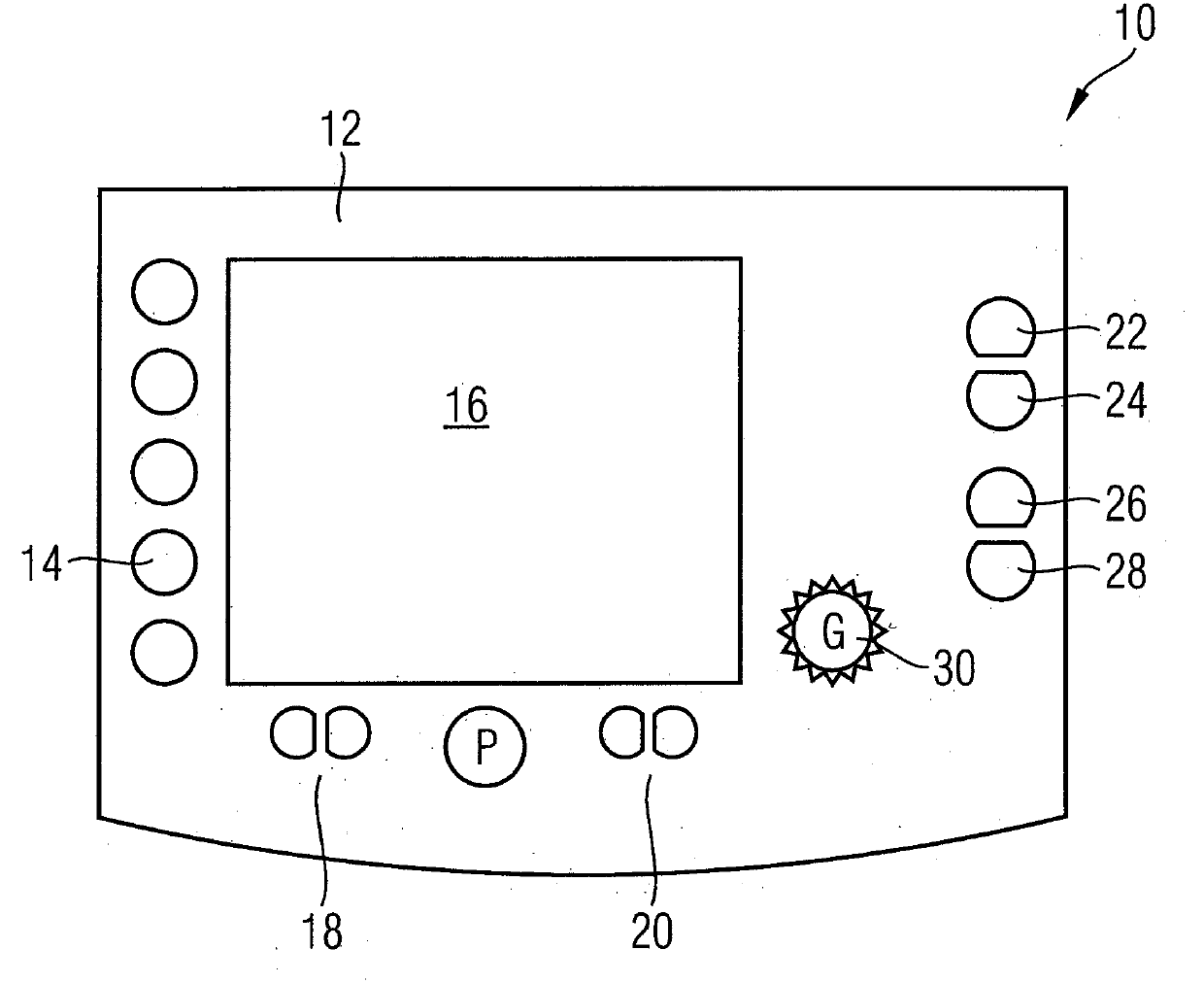

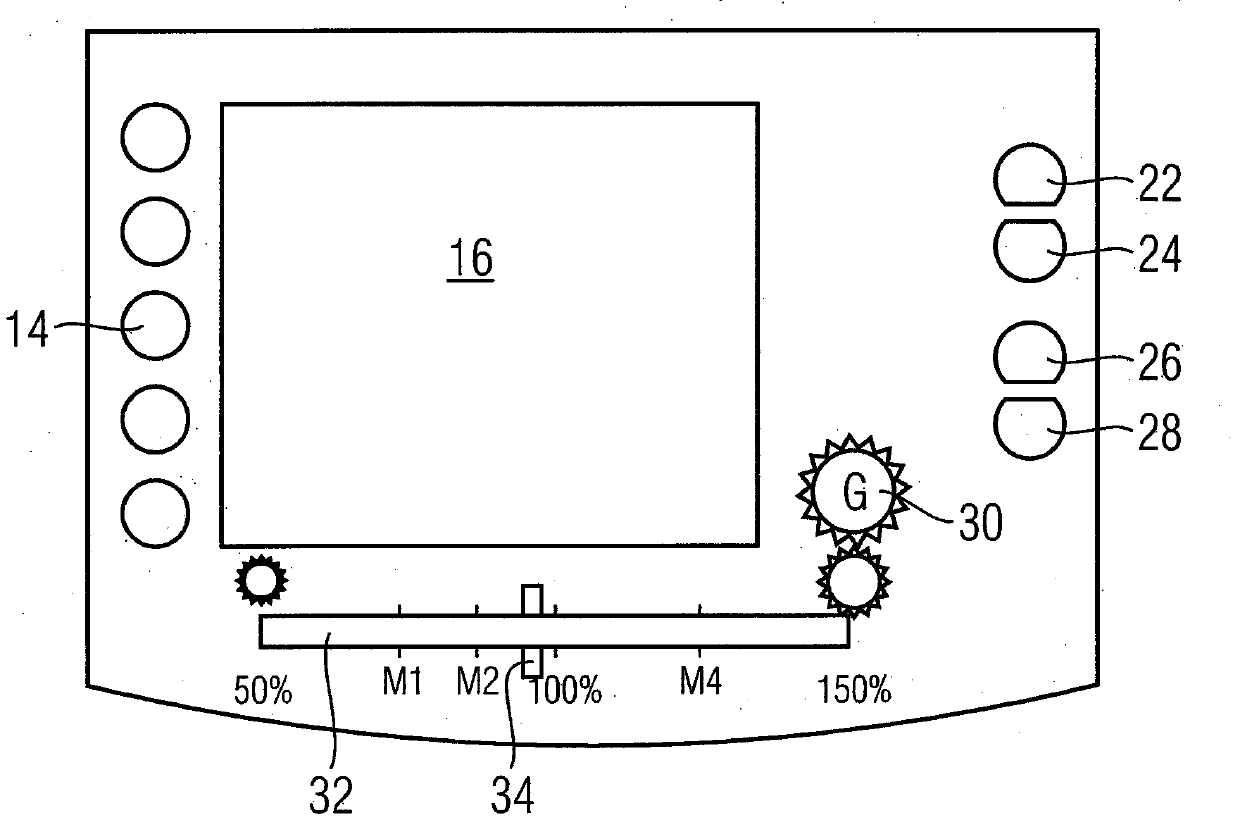

Dental furnace and method for operating a dental furnace

InactiveCN103994659AReduce complexityIncrease or decrease intensityFurnace typesControl devices for furnacesDisplay deviceEngineering

A dental furnace having a display device and an operating device (10) for the dental furnace, is provided, the operating device being integrated in particular in the display device by forming a touch screen (12), and the operating device (10) facilitating the selection of programs for the firing of dental restoration parts in the dental furnace. The operating device (10) allows in particular the input of further parameters for a firing cycle. An operating element (30, 32, 34) facilitates the control of a final firing program of the dental furnace, namely with different values for the temperature as well as for the duration of the final firing, the operating element (30, 32, 34) making possible the simultaneous adjusting of temperature and duration parameters of the final firing.

Owner:IVOCLAR VIVADENT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com