Lighted Ultrasonic Handpiece and Color Code Grip System

a technology of ultrasonic handpieces and color code grips, applied in the field of medical or dental handpieces, can solve the problem that no prior art provides a light path through the insert grip to guide remotely generated light to the tip of the scaler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

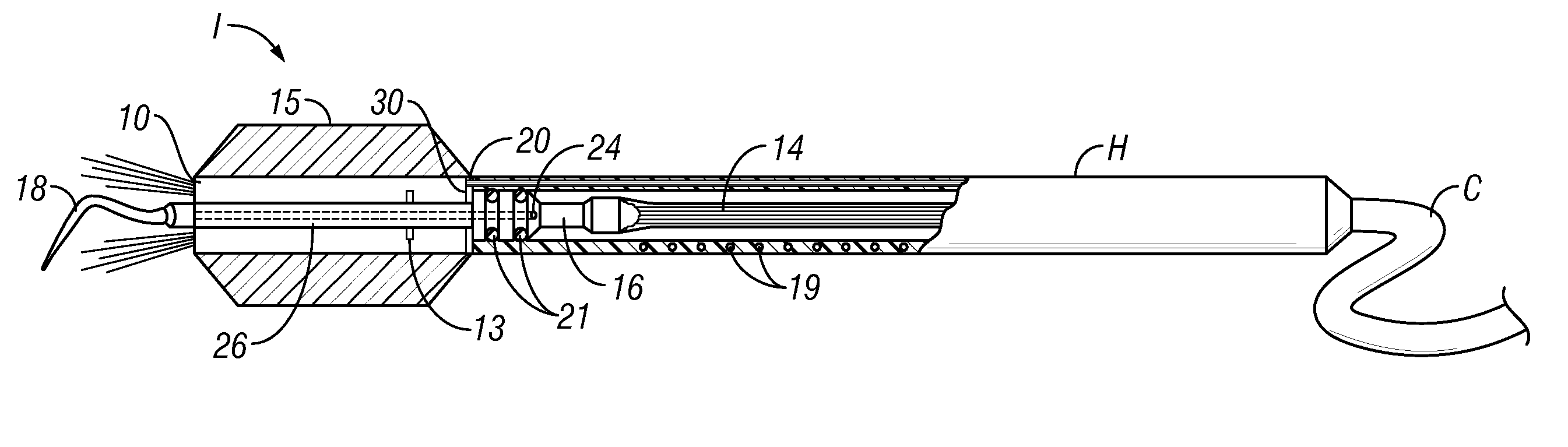

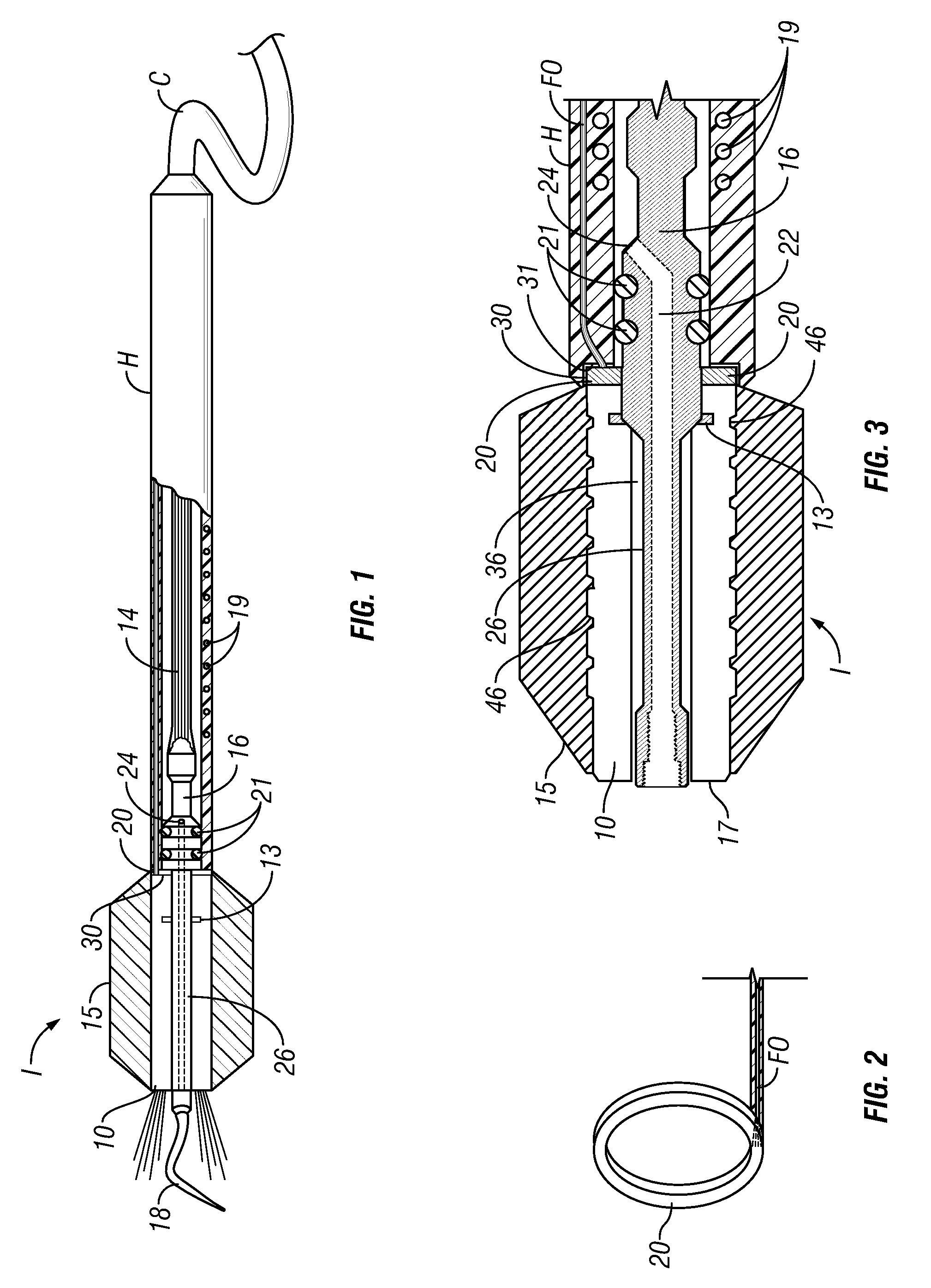

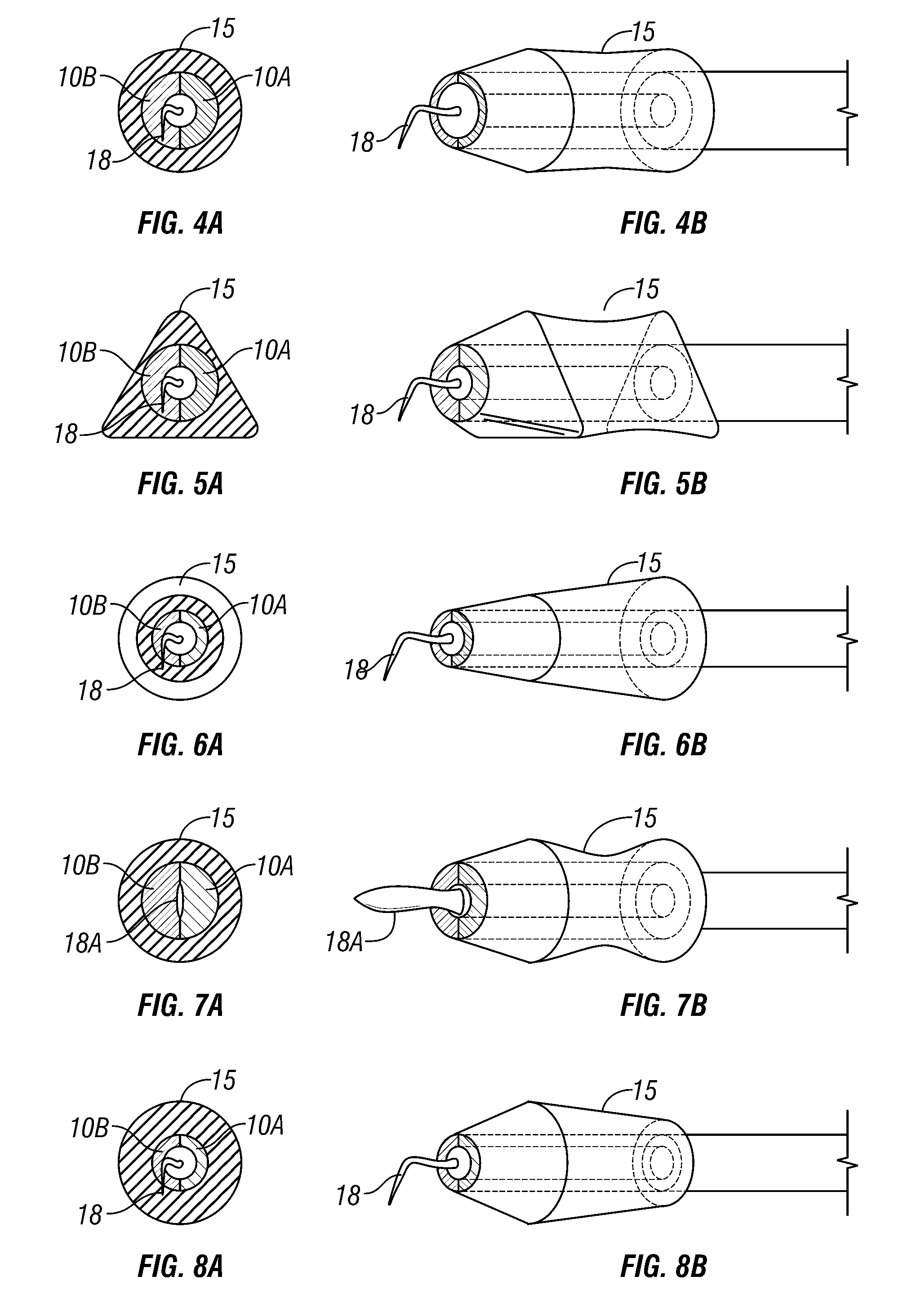

[0036] The present invention relates to a dental scaling insert providing a translucent path from a light source to the end of the handpiece through a translucent grip covered by an ergonomically designed resilient sheath. In a preferred embodiment shown in FIG. 1, insert system I is comprised of a magnetostrictive stack 14 typically formed of nickel or nickel alloy plates in a manner well known to those skilled in this art, which are soldered together and which respond to electrical energy supplied by coil 19 encircling stack 14 in the handpiece H. Stack 14 is connected to a velocity transducer 16 which is connected to a scaling tip 18 and which is covered with grip 10. Grip 10 is formed from two segments or pieces of high grade plastic, for example, such as a polycarbonate, that provide a profile on their interior surface to retain the velocity transducer 16. In this embodiment, one or more teeth 13 are provided on the exterior lateral surfaces of the velocity transducer 16 to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com