Cloth clip cutter plate surface cleaning device for setting machine

A technology of cleaning device and setting machine, which is applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc. The effect of sizing cloth sticking, improving production efficiency and reducing the strength of brushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

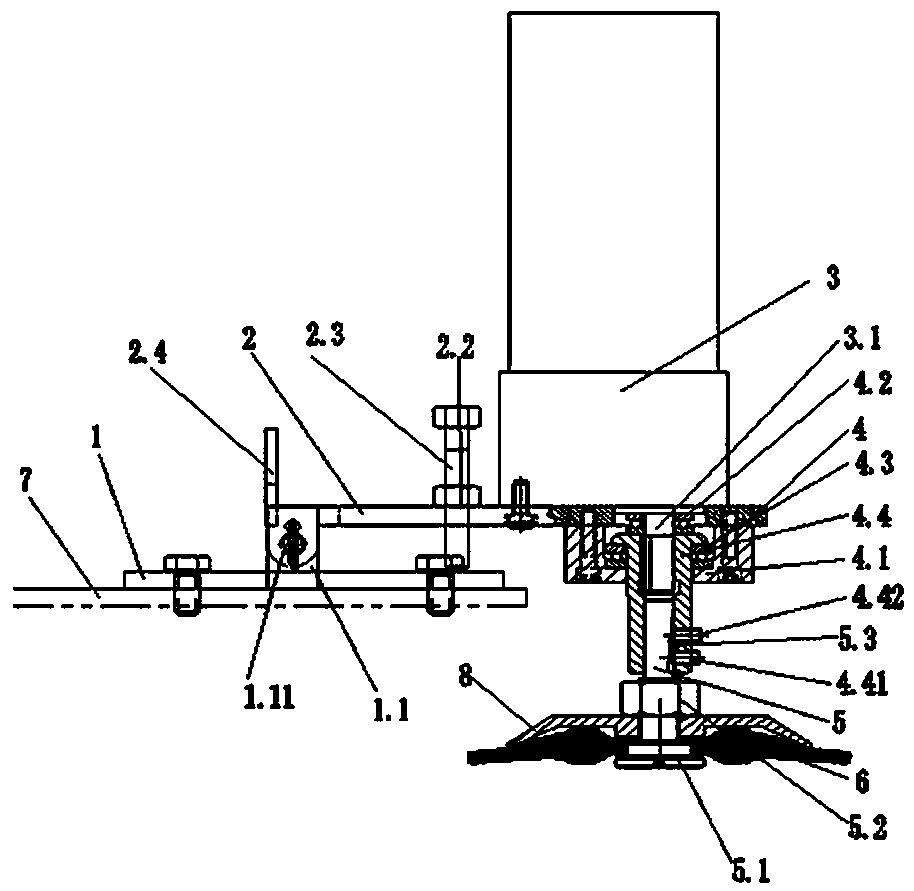

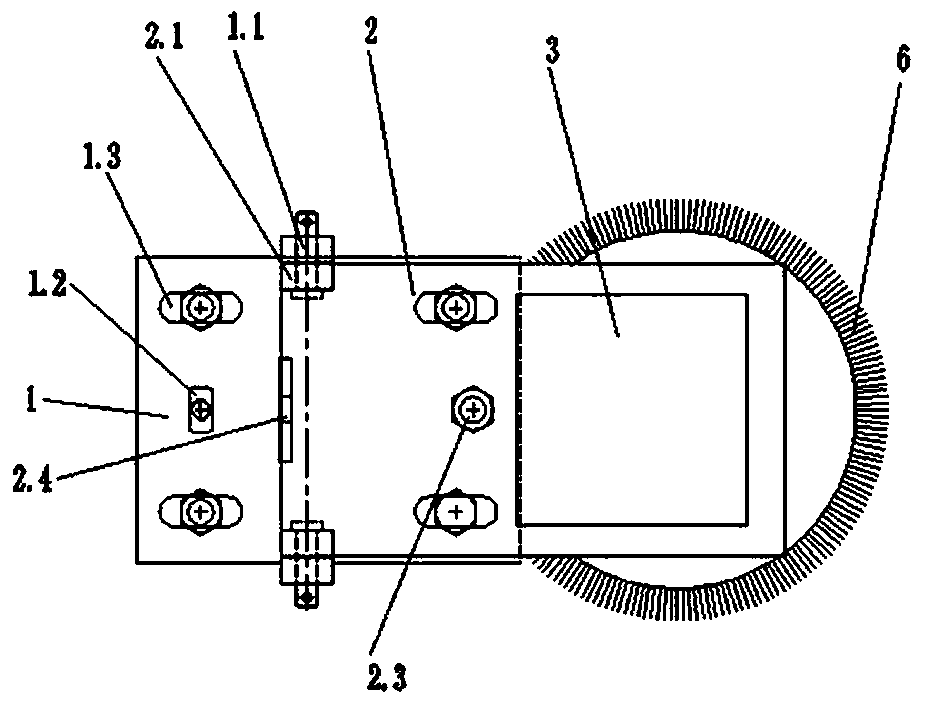

[0021] Embodiment 1: as figure 1 As shown, a device for cleaning the surface of a cloth clip knife for a shaping machine includes a mounting base 1, a connecting bracket 2, an electric deceleration motor 3, a bearing assembly 4, a dowel 5, and a brush wheel 6. The mounting base 1 is connected to the On the cover plate 7 at the outer semicircle of the machine tail; one end of the connecting bracket 2 is connected to the installation base 1, and the other end extends out of the cover plate 7 at the outer semicircle of the shaping machine tail; the connecting bracket 2 extends out of the outer semicircle of the shaping machine tail One end of the cover plate 7 at the place is provided with a through hole, the electric deceleration motor 3 is fixed above the connecting bracket 2 and the output shaft 3.1 of the electric decelerating motor 3 passes through the through hole; the bearing assembly 4 is fixed under the connecting bracket 2, the bearing assembly 4 and the output The shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com