Dental furnace and method for operating a dental furnace

A technology for dentistry and operating devices, which is applied in the field of operating dental furnaces and can solve problems such as discarding dental restorations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

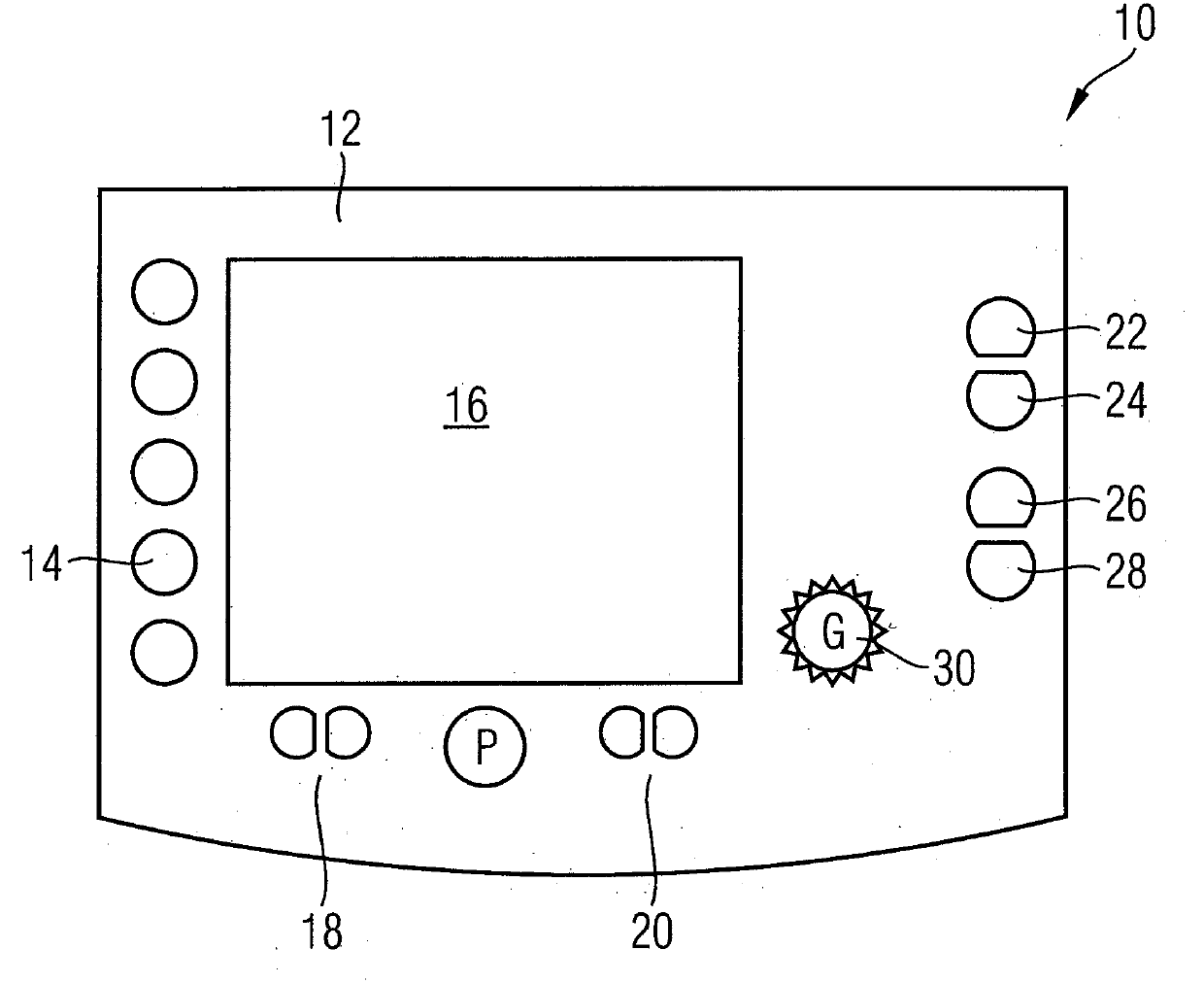

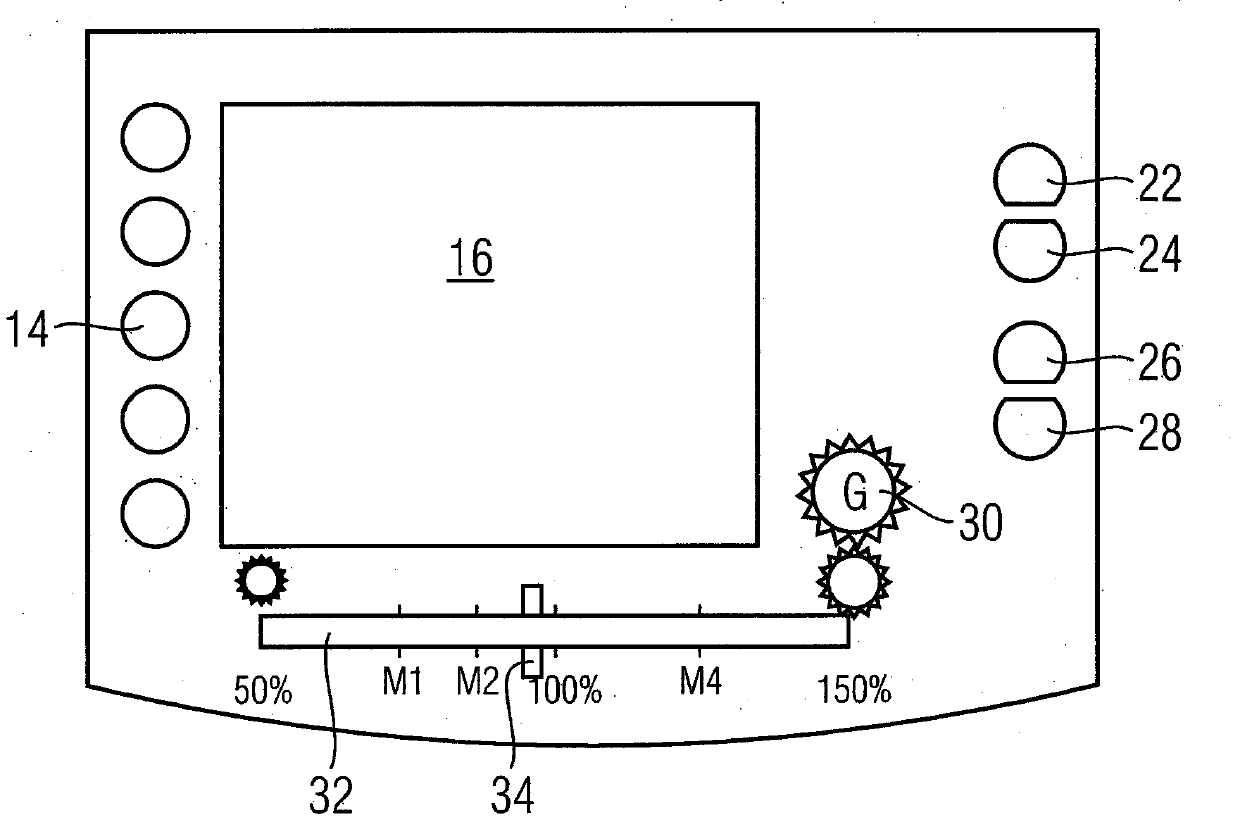

[0023] in figure 1 In, the display and operation device 10 of the creative dental oven combination is shown. The dental furnace includes a controller (not shown), which can respond to the program parameters input through the keys P on the display and operating device 10 to control the firing cycle for the dental restoration component, which is placed in the dental In the furnace.

[0024] The display and operation device includes a touch screen 12, which includes a plurality of panels, such as a plurality of keys 14, if each key is touched, a function will be triggered. The buttons 14 and the remaining operating elements are only arranged in the form of symbols, as known in the art, and can trigger corresponding required functions if touched.

[0025] In addition, the screen 12 includes a display panel 16, which displays the experienced firing curve, the corresponding existing temperature at the corresponding existing measurement point of the dental furnace, or the remaining firin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com