Vector magnetic fluid motor based on phase angle controlling

A phase angle control and vector technology, which is applied in the direction of single motor speed/torque control, electrical components, electromechanical devices, etc., can solve the problems of the overall conversion efficiency loss of electrical energy and mechanical energy, so as to improve the output effect of mechanical energy and energy conversion efficiency , Optimize the effect of the magnetic circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

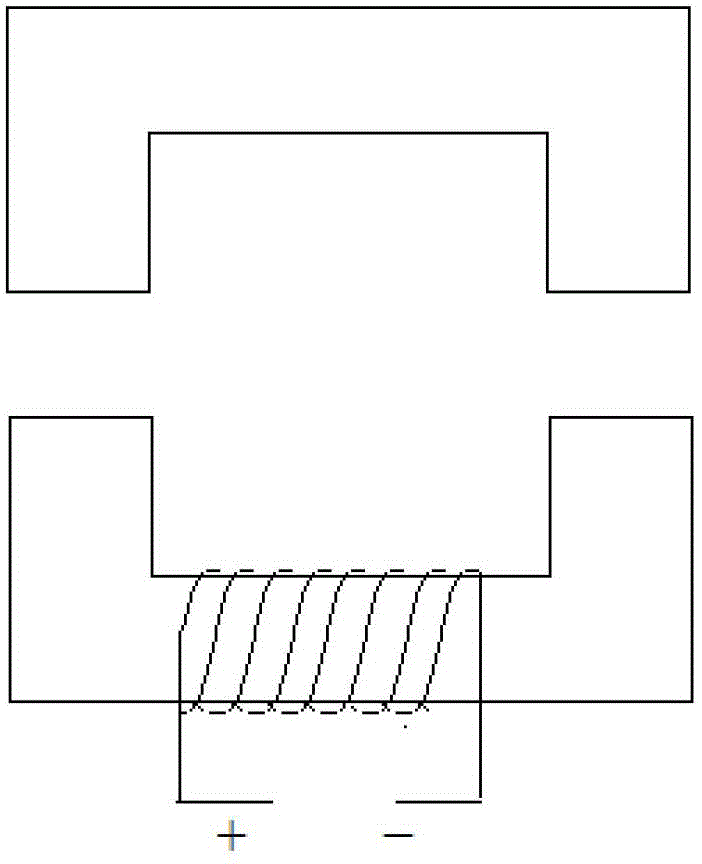

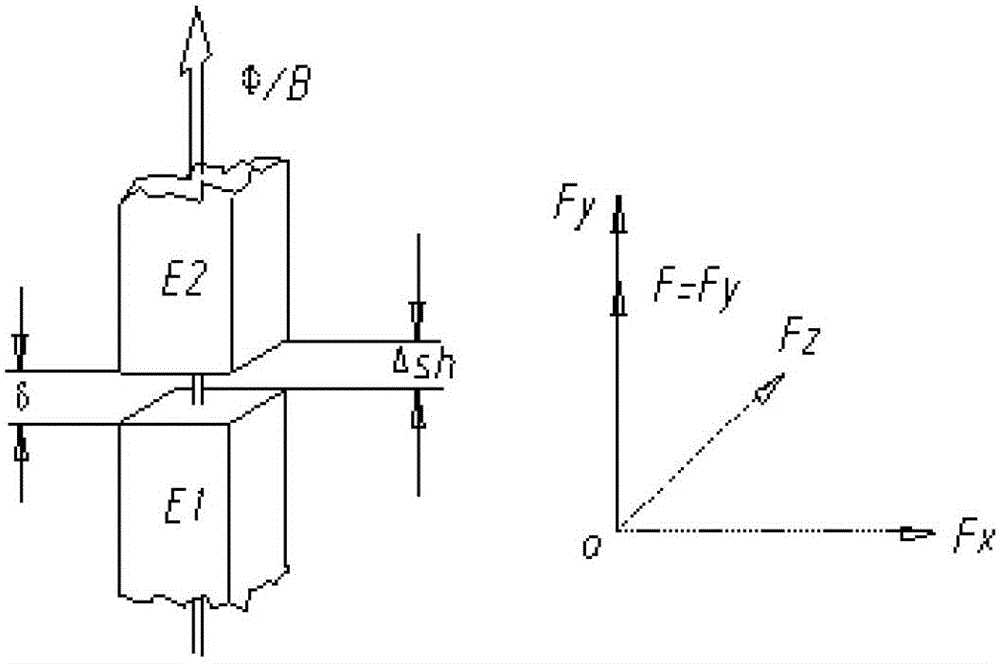

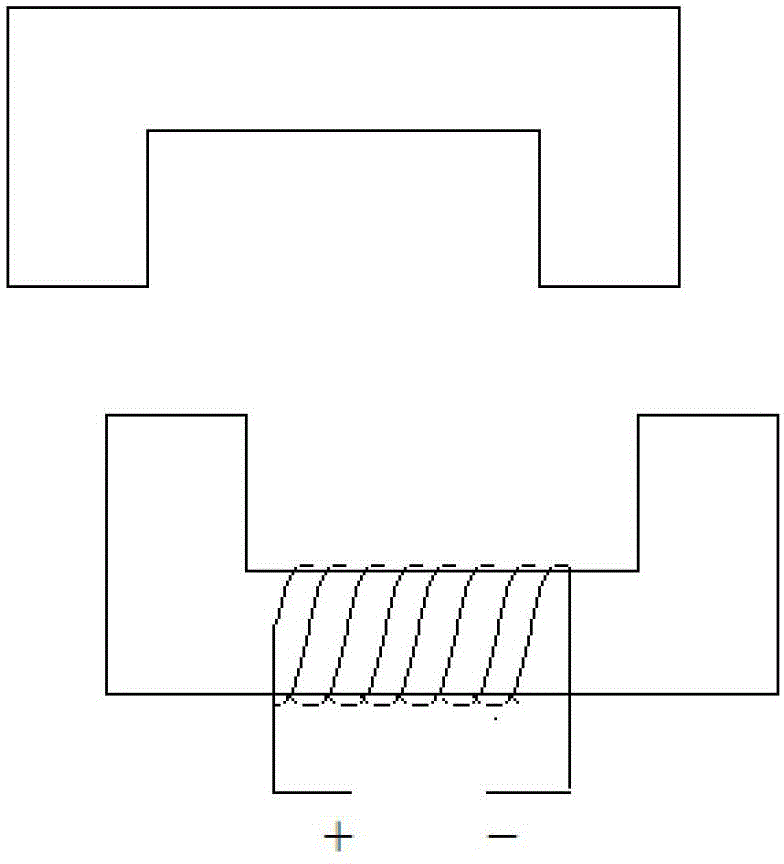

[0124] Such as Figure 1a , The stator magnet E1 and the mover magnet E2 are coaxially arranged, there is an air gap δ between the stator magnet E1 and the mover magnet E2, the stator magnet E1 is fixed, the mover magnet E2 can be in the y-axis direction To move, the controller only needs to input electrical energy to the closed coil in the stator magnetizer E1 or the mover magnetizer E2 mechanism to move the mover magnetizer E2 upward by Δs h . When the mover magnetizer E2 has completed Δs h During the stroke, the controller cuts off the input current, and the mover magnetizer E2 returns to the initial position, ready for the next mechanical movement and work cycle, until the controller sends out work instructions and input electrical energy again. The mechanical movement feature of the mover magnetizer E2 mechanism is a simple, linear, reciprocating mechanical movement.

[0125] Refer to Figure 1a , 1b And 2a, 2b: When the current is input to the closed coil, the magnetic flux...

Embodiment 2

[0132] See attached Figure 5A , A vector magnetic current motor based on phase angle control, composed of stator 6, mover 7 and controller 5. A stator magnet 1 is provided on the stator 6, a winding coil 2 is provided on the stator magnet 1, a mover magnet 3 is provided on the mover 7, and an air gap is provided between the stator guide 6 and the mover magnet 3. δ4, stator magnet 1, mover magnet 3 and air gap δ4 constitute a magnetic flux circuit 8. The stator 6 is in a fixed position, and the mover magnetizer 3 is a mechanical movement that can rotate and move along the circle center O and the radius R. The controller 5 is connected to the winding coil 2, and the winding coil 2 is connected to the controller 5. The controller 5 controls the on / off of the connection between the winding coil 2 and the main power supply. The stator 6 is provided with a position sensor 9, and the position sensor 9 outputs the current change amount ΔS of the winding coil 2 to the controller 5.

[...

Embodiment 3

[0139] Such as Figure 7 As shown, the difference between this embodiment and the second embodiment is that the mover 7 is provided with the first to fourth four mover magnetizers 3a, 3b, 3c, 3d, and the controller 5 controls the energization frequency of the winding coil 2. , Control the speed of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com