Special multiple-spot spot welding machine for oil baffle plate

A multi-point welding and oil baffle technology, applied in welding equipment, resistance welding equipment, resistance electrode bases, etc., to eliminate inductive reactance, make the surface beautiful, and ensure the welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

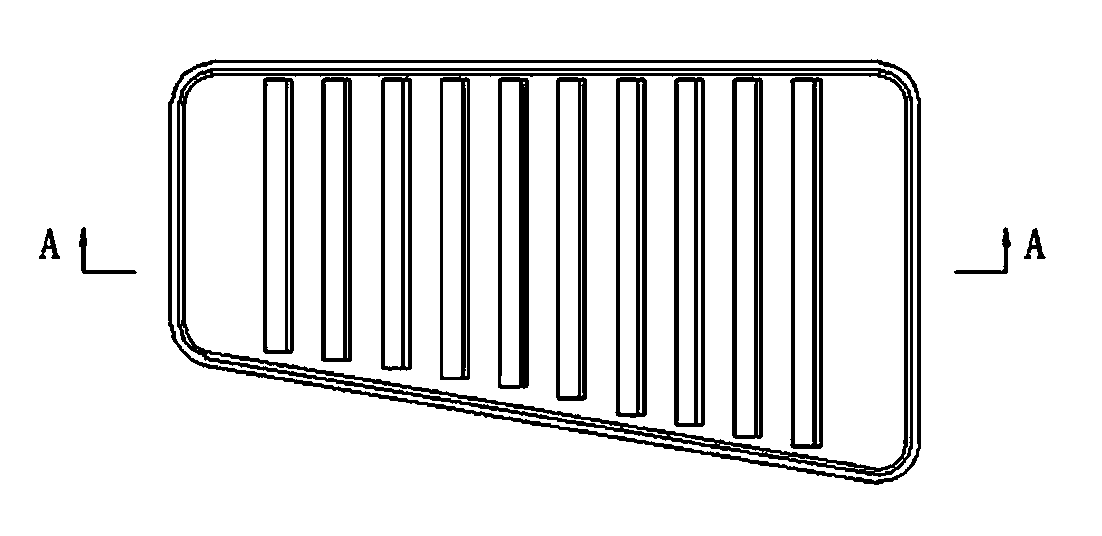

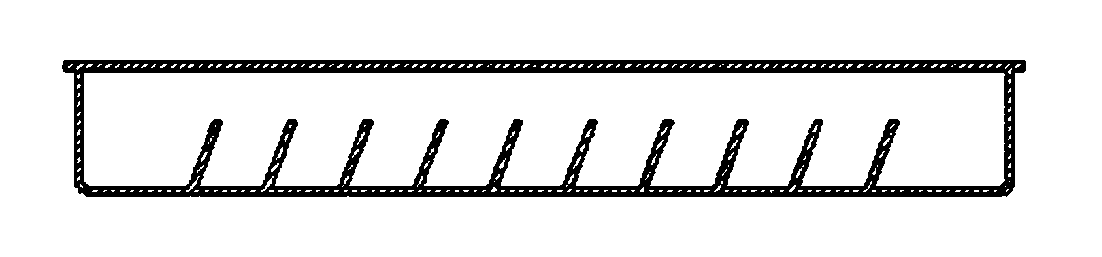

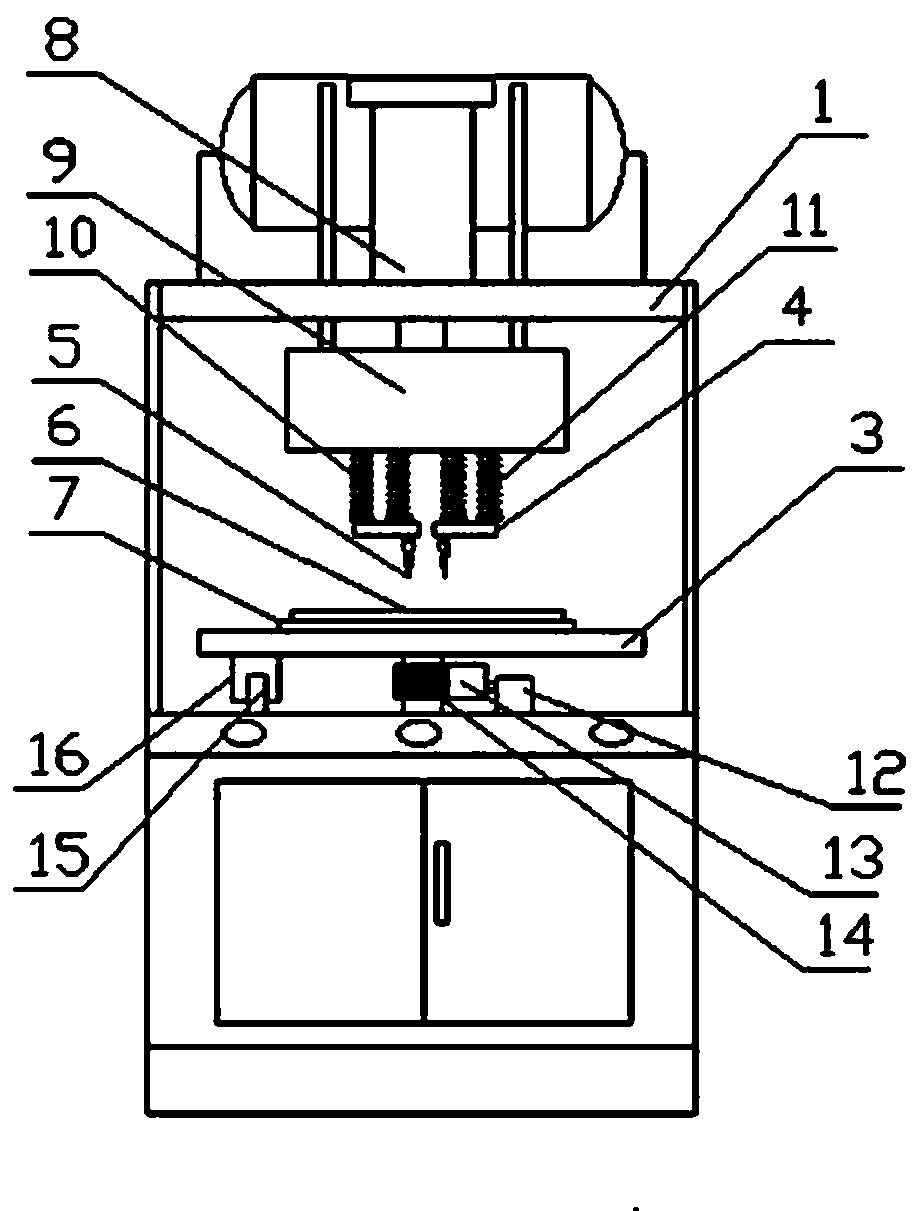

[0015] Embodiment: A special multi-point spot welding machine for oil baffle, including a frame 1, a case 2, a welding device, and a workbench 3. The case 2 is set on the frame 1, and the case 2 is provided with a transformer, a welding device and a workbench. The longitudinal position of the table 3 is correspondingly set on the frame 1. The welding device includes a lifting mechanism and an electrode arm 4. The lifting mechanism can drive the electrode arm 4 to move longitudinally. The lower end of the electrode arm 4 is provided with a number of electrode heads 5, and the workbench is provided with The positioning frame 6 and the lower electrode plate 7 are arranged on the lower electrode plate 7. The lower electrode plate 7 is connected to the transformer, and the transformer is connected to the power supply. The transformer includes three one-way transformers. The three-phase full-wave rectifier circuit forms a three-phase full-wave rectifier circuit, and the three-phase fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com