Patents

Literature

33results about How to "Strong solder joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

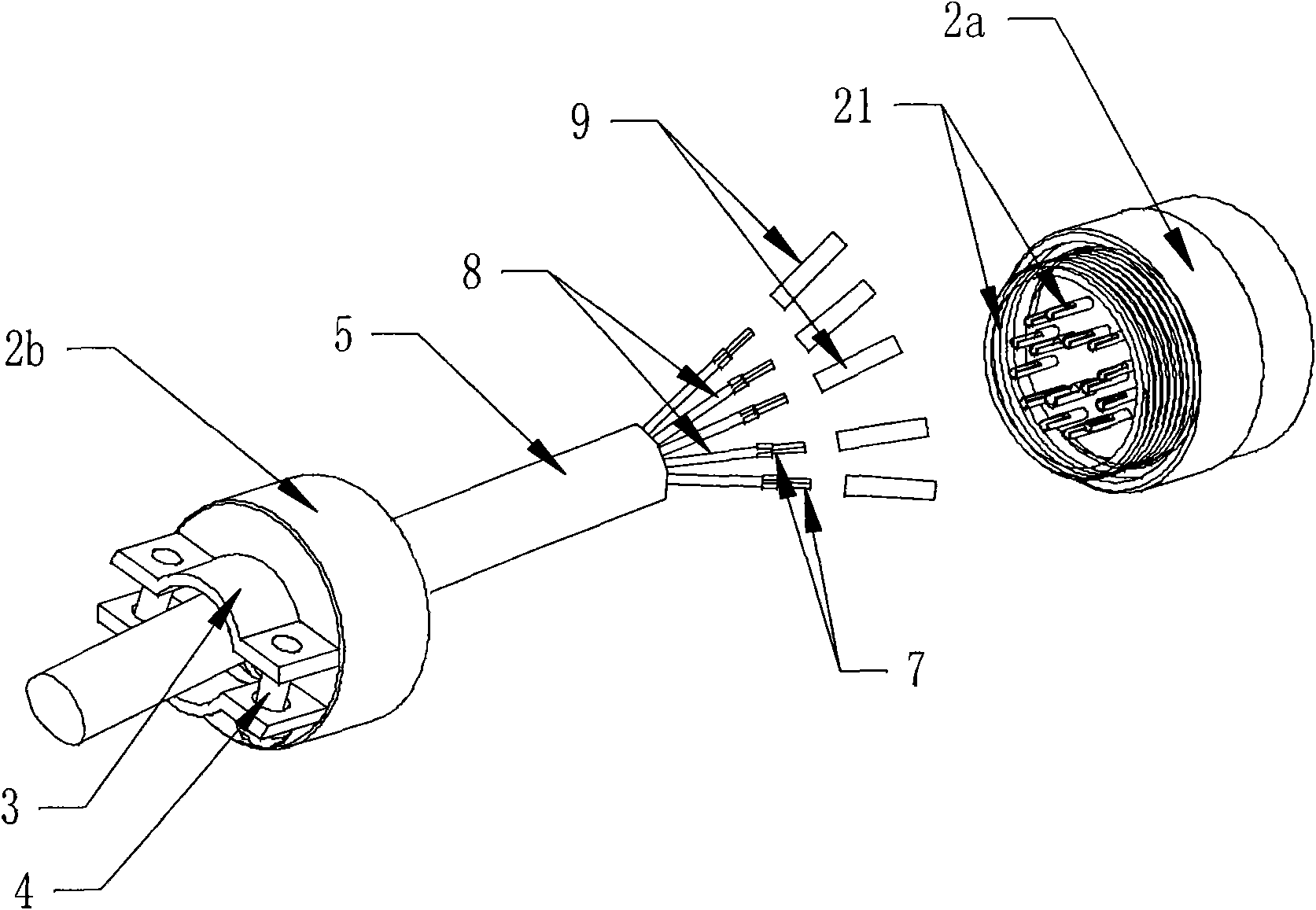

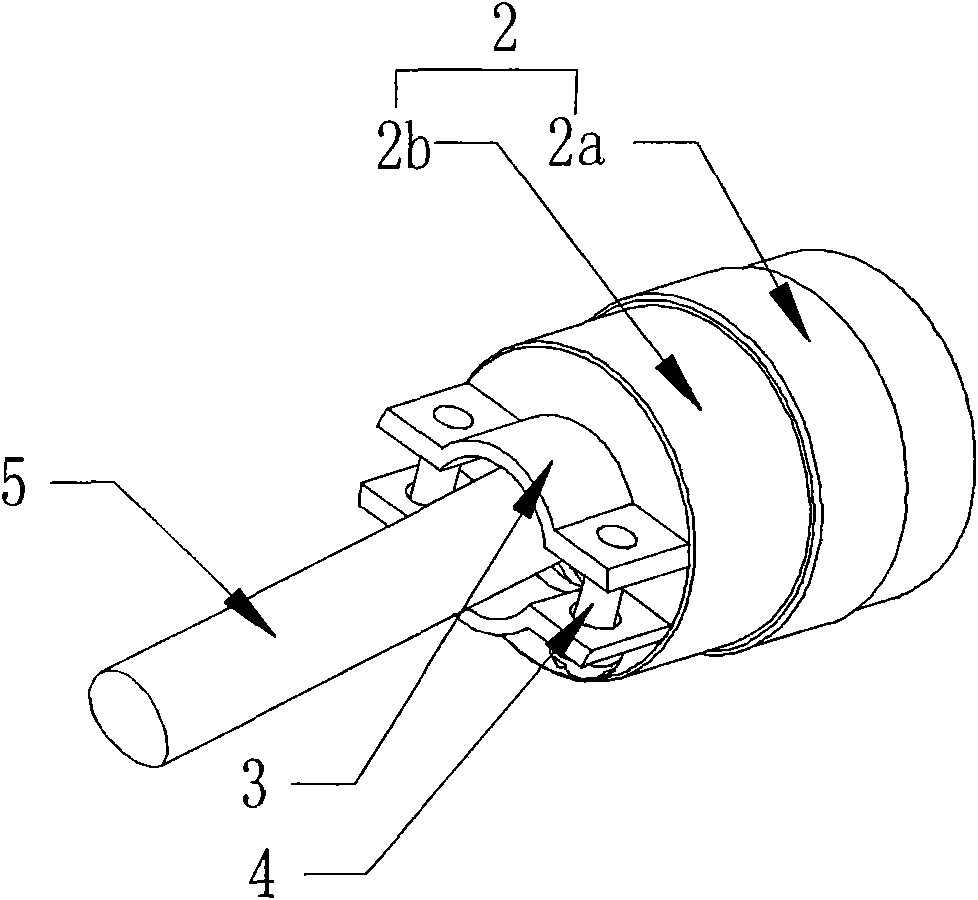

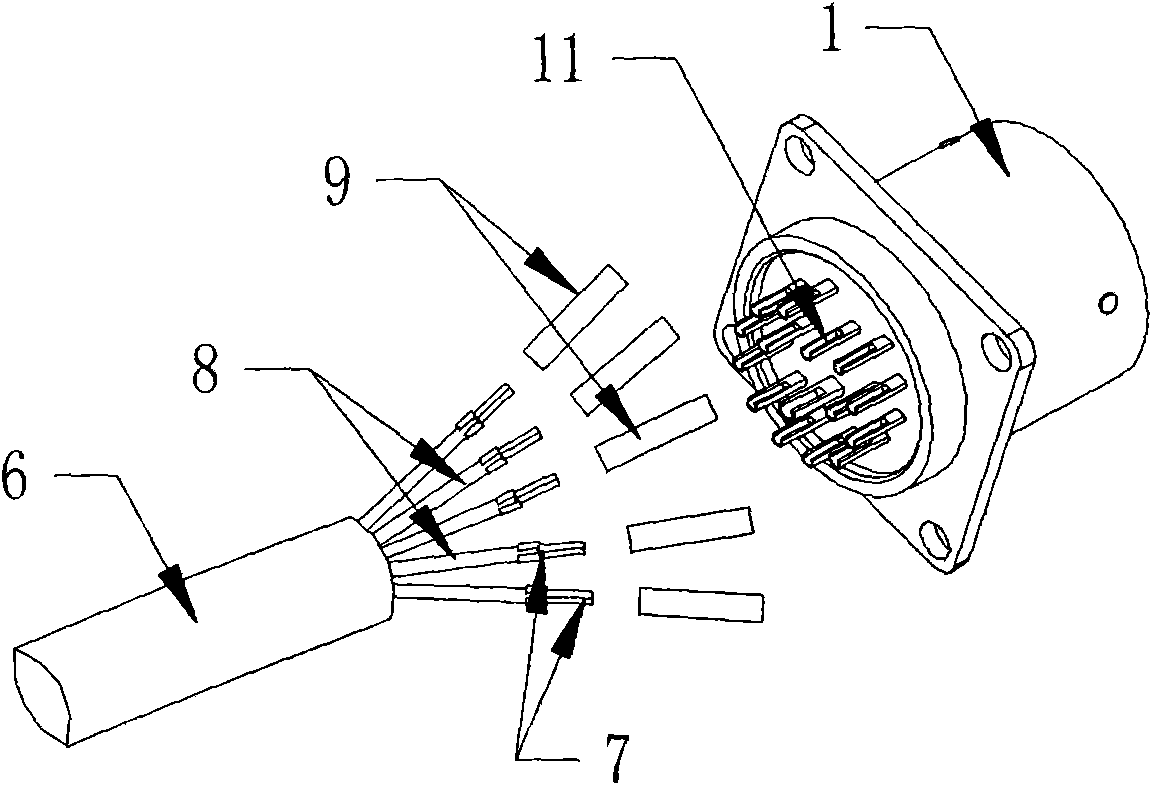

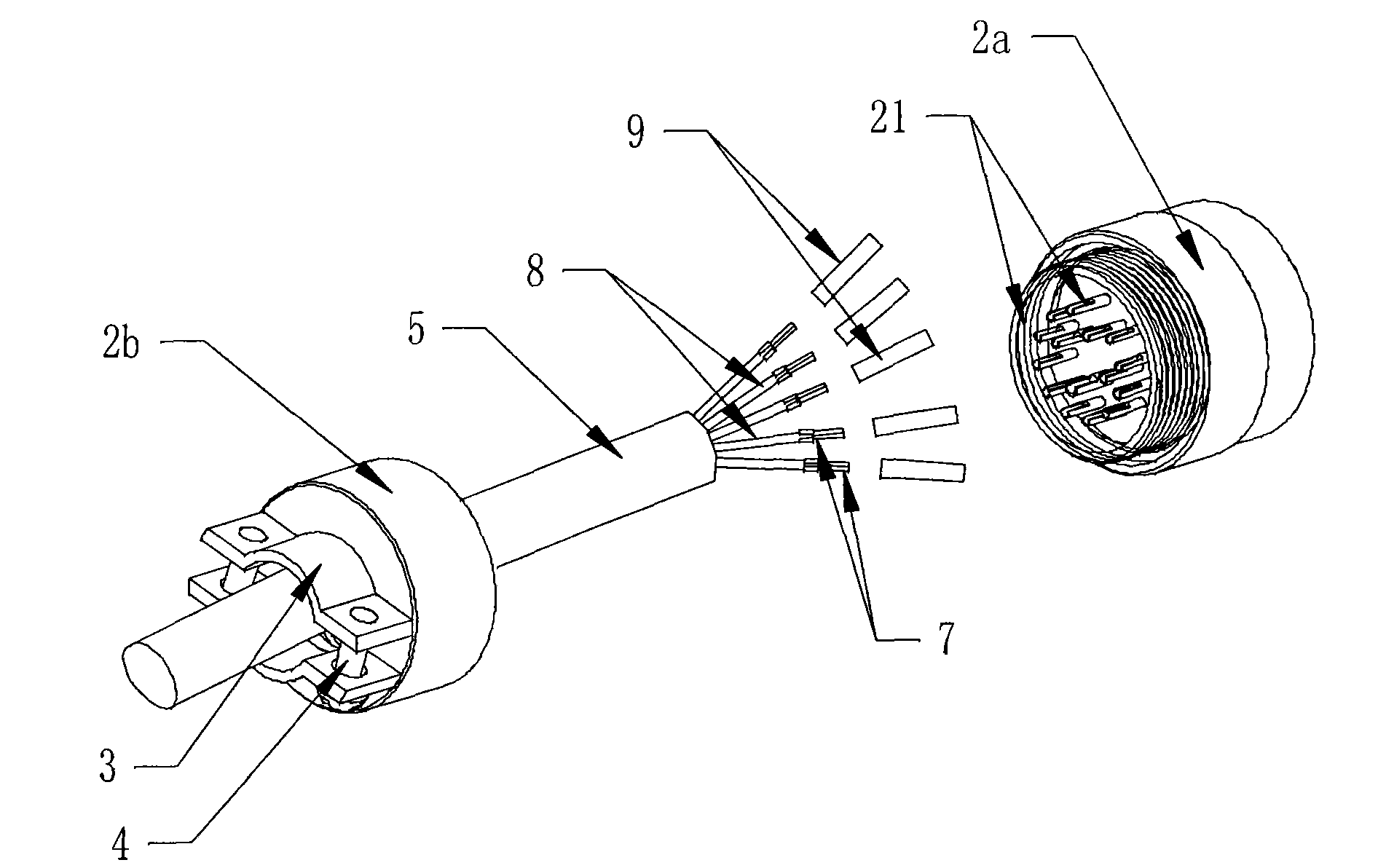

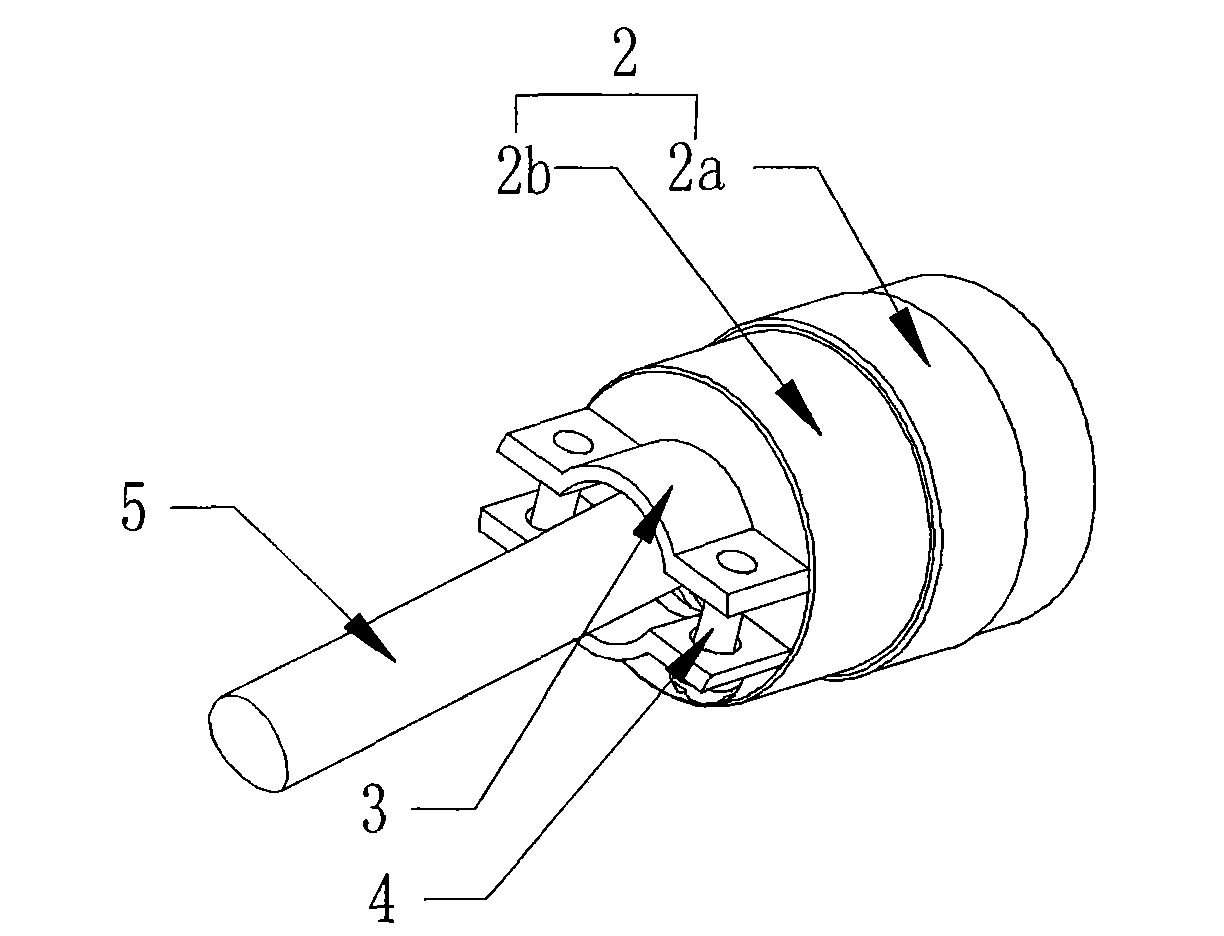

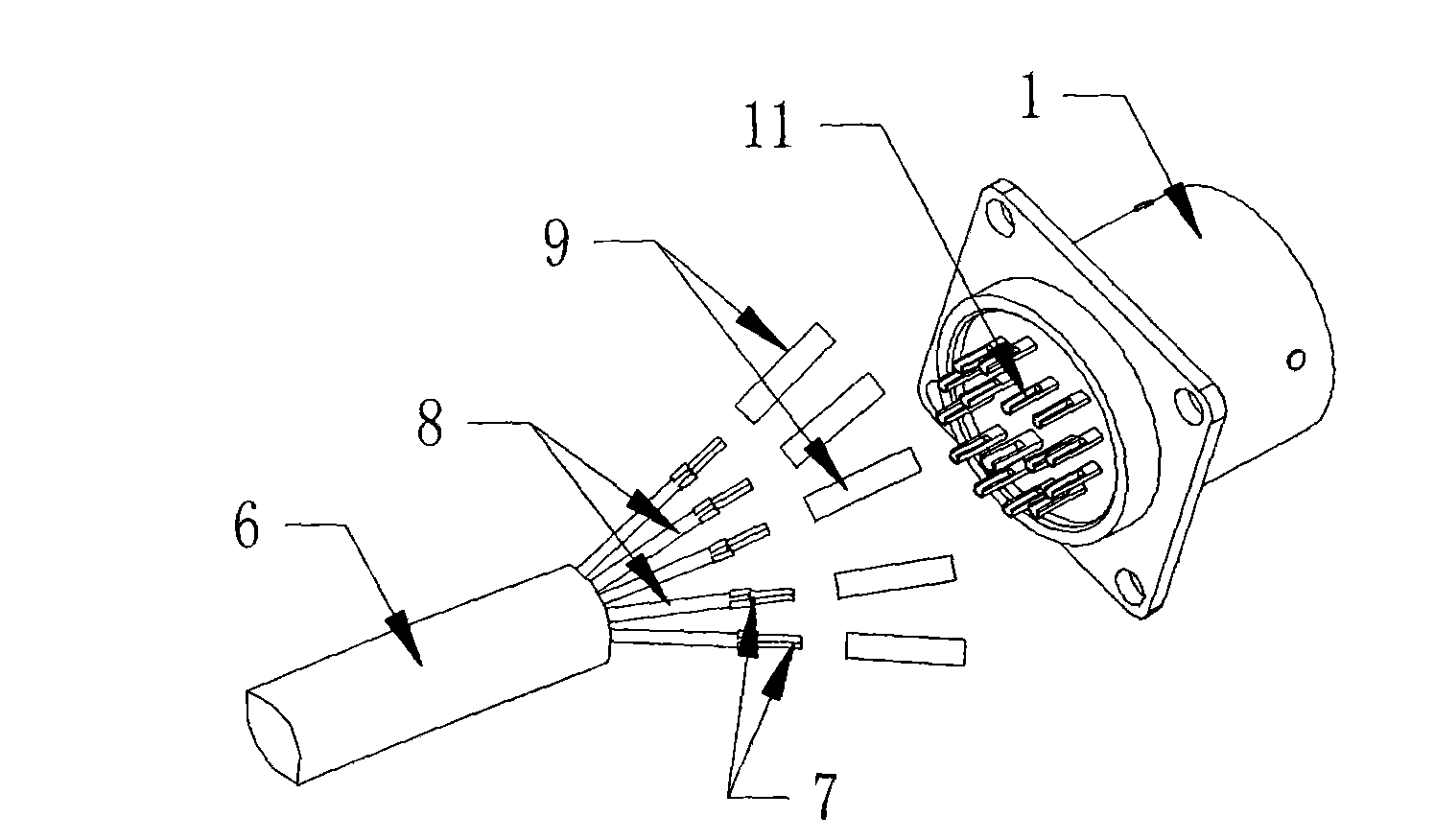

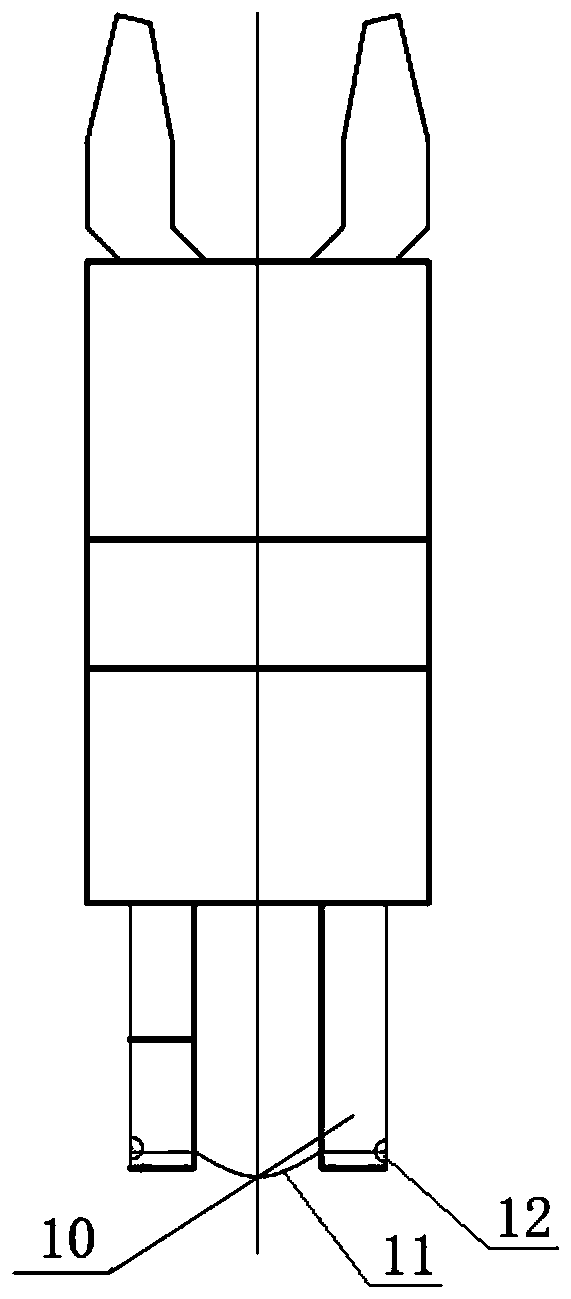

Electric connector and wire connecting method thereof

ActiveCN101989726AAvoid breakingEasy connection strengthLine/current collector detailsSoldered/welded conductive connectionsElectricityEngineering

The invention discloses an electric connector and a wire connecting method thereof. The connecting method comprises the step of connecting socket wires or plug wires and comprises the following concrete steps: strengthening the end parts of wires; welding and protecting each wire after the end parts of the wires are welded with a socket or a plug; and protecting the integrated wires connected with the socket or the plug. The electric connector comprises a socket, a plug, a first wire cable and a second wire cable, wherein the first wire cable and the second wire cable are respectively connected with the plug or the socket; metal terminals are fixed at the end parts of the wires and are welded together with pins on the plug or the socket; a small thermal shrinkable sleeve is sleeved at thewelding part of the wires; a big thermal shrinkable sleeve is sleeved outside the second wire cable; and the sheath of the first wire cable is clamped by a tail clamp of the plug. The connecting method of the invention can enhance the connecting strength, can enhance the tensile resistance and the torsion resistance, and completely can ensure the reliability requirement of a reinforced computer. The electric connector of the invention has high connecting strength, tensile resistance and torsion resistance, and the wires can not be broken easily.

Owner:深圳市研祥智慧科技股份有限公司

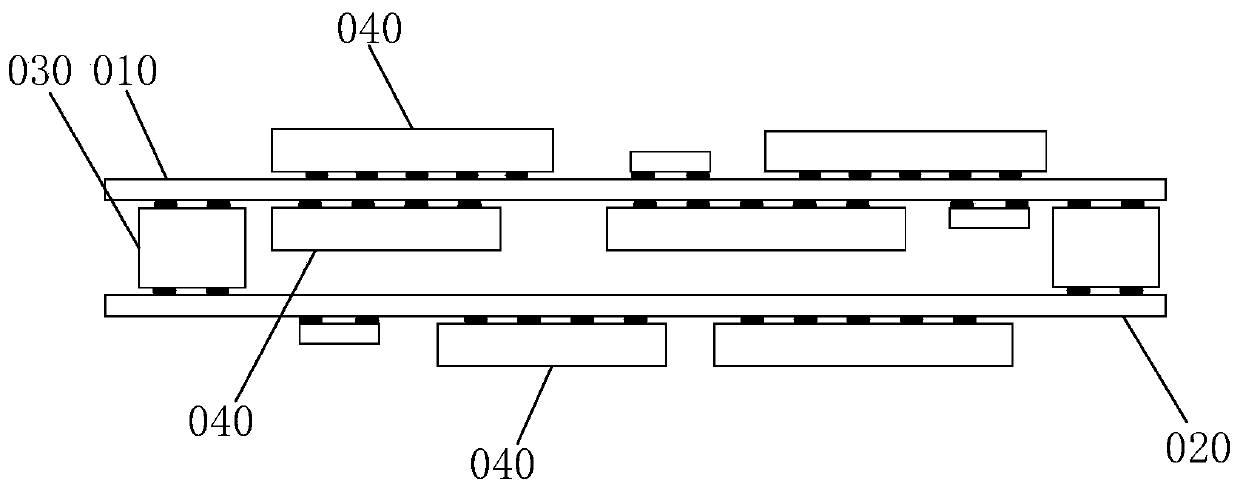

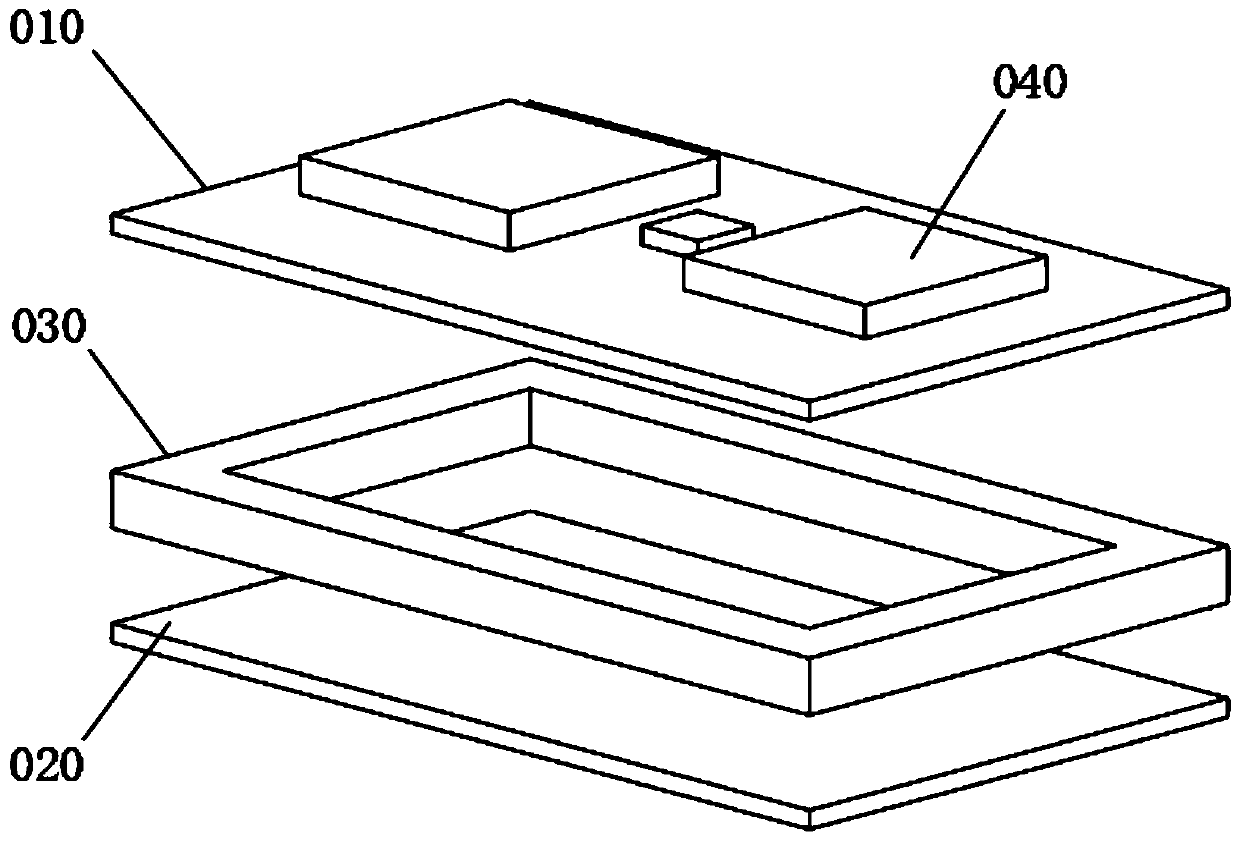

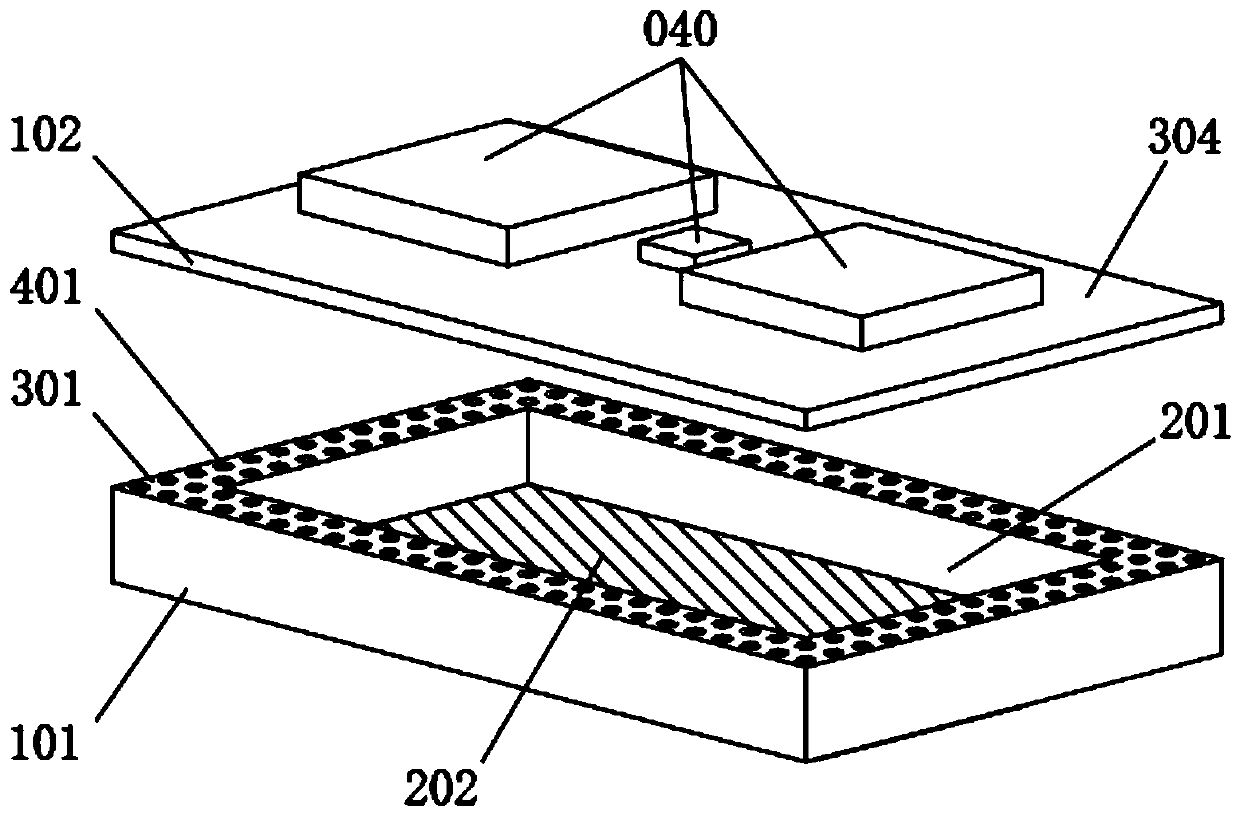

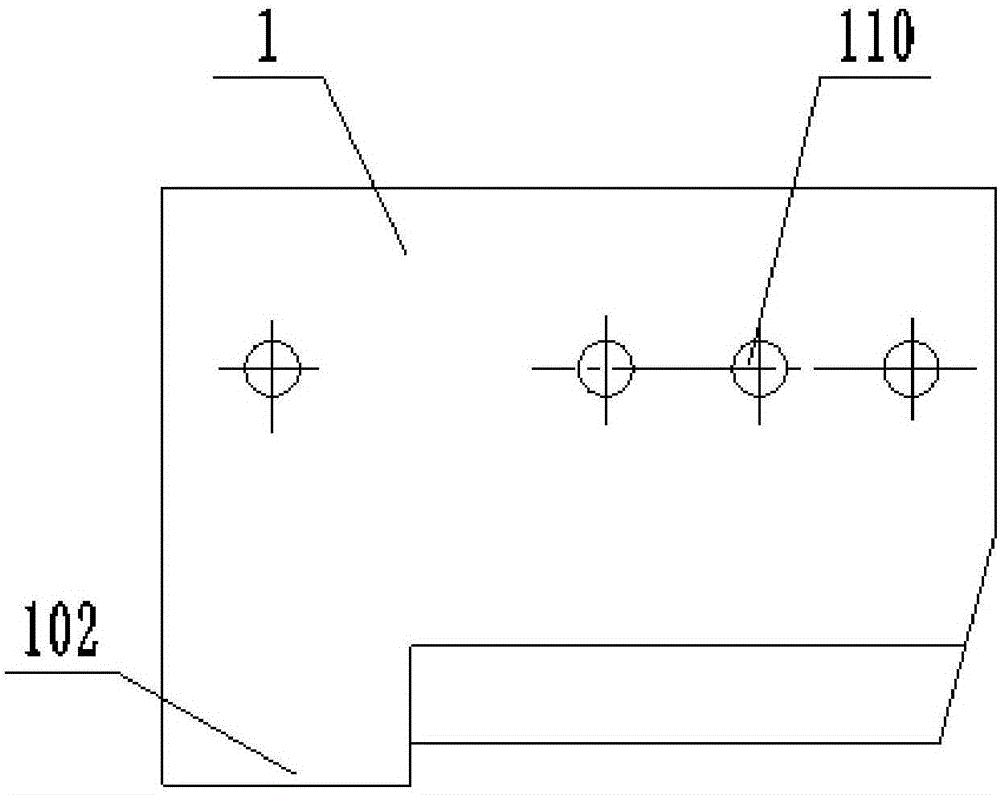

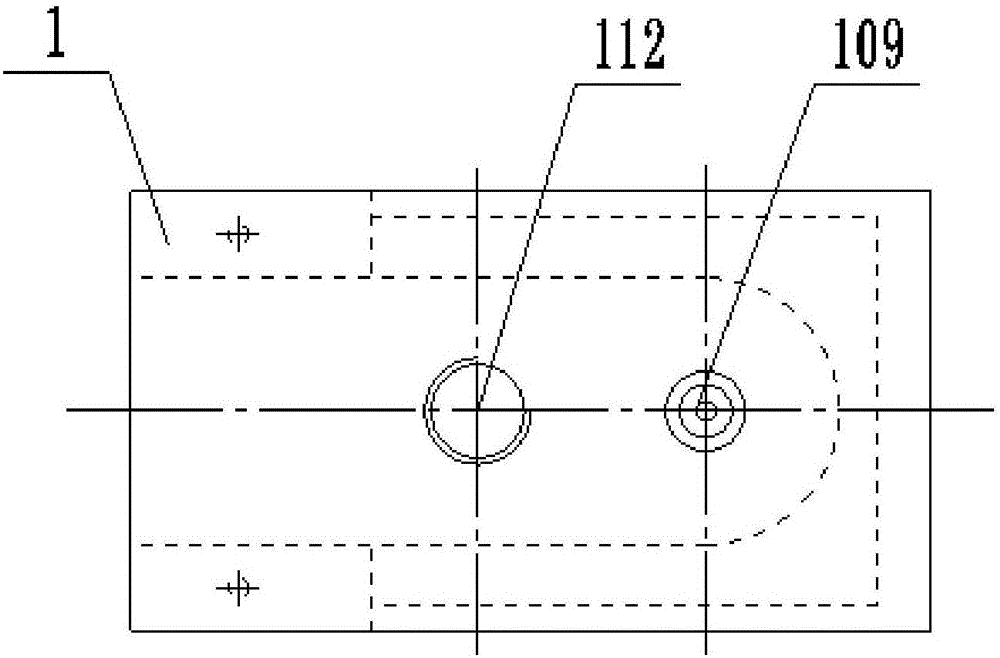

Printed circuit board, manufacturing method thereof and electronic equipment

InactiveCN110149762AAvoid warpingAvoid the consequences of electrical connection failuresPrinted circuit assemblingPrinted circuits structural associationsSurface mountingEngineering

The embodiment of the invention provides a printed circuit board, a manufacturing method thereof and electronic equipment. The printed circuit board comprises a first printed circuit board. The firstprinted circuit board comprises a first surface and a second surface, and the first surface and the second surface are opposite in direction. The first printed circuit board is provided with a first groove, and an opening of the first groove faces the first surface. The first surface is provided with a first bonding pad. An electronic element is mounted on the second surface. The printed circuit board also comprises a second printed circuit board which comprises a third surface and a fourth surface, and the third surface and the fourth surface are opposite in direction. The third surface is provided with a second bonding pad, and the second bonding pad corresponds to the first bonding pad in position. The third surface and the fourth surface are respectively provided with electronic elements. The first printed circuit board and the second printed circuit board are welded through the first bonding pad and the second bonding pad to form a stacked structure. The printed circuit board provided by the invention is not likely to warp, has stronger stress deformation resistance, and can prolong the service life of electronic equipment.

Owner:HUAWEI TECH CO LTD

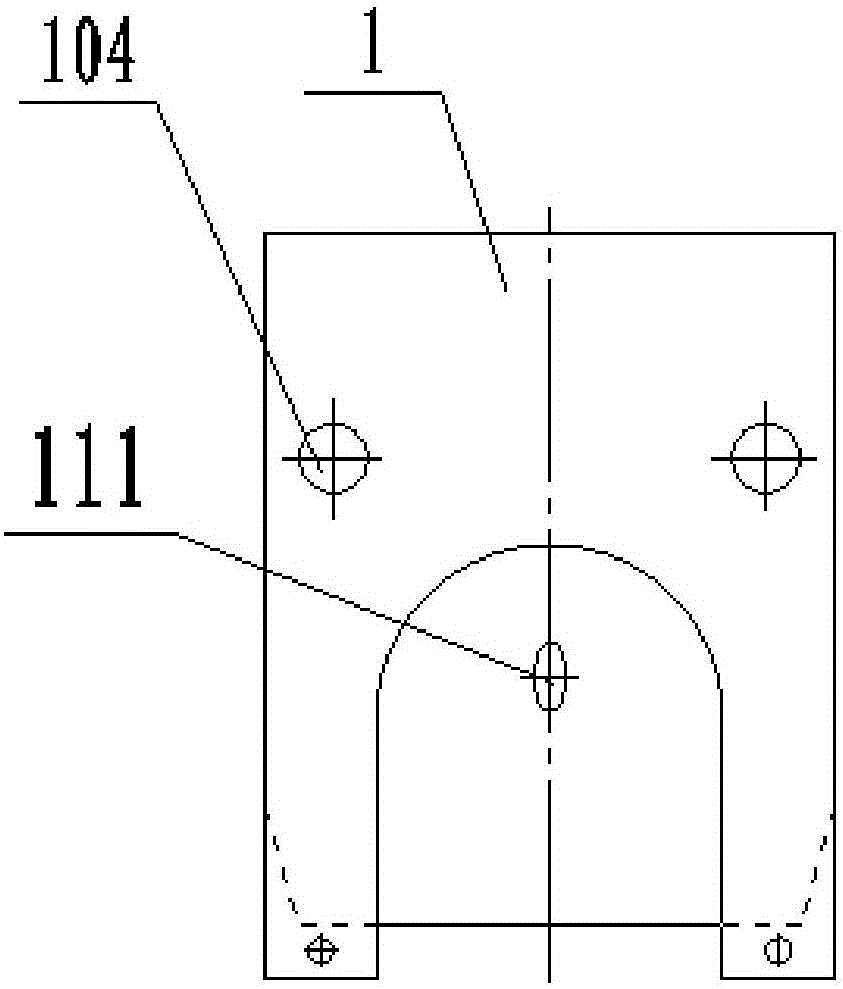

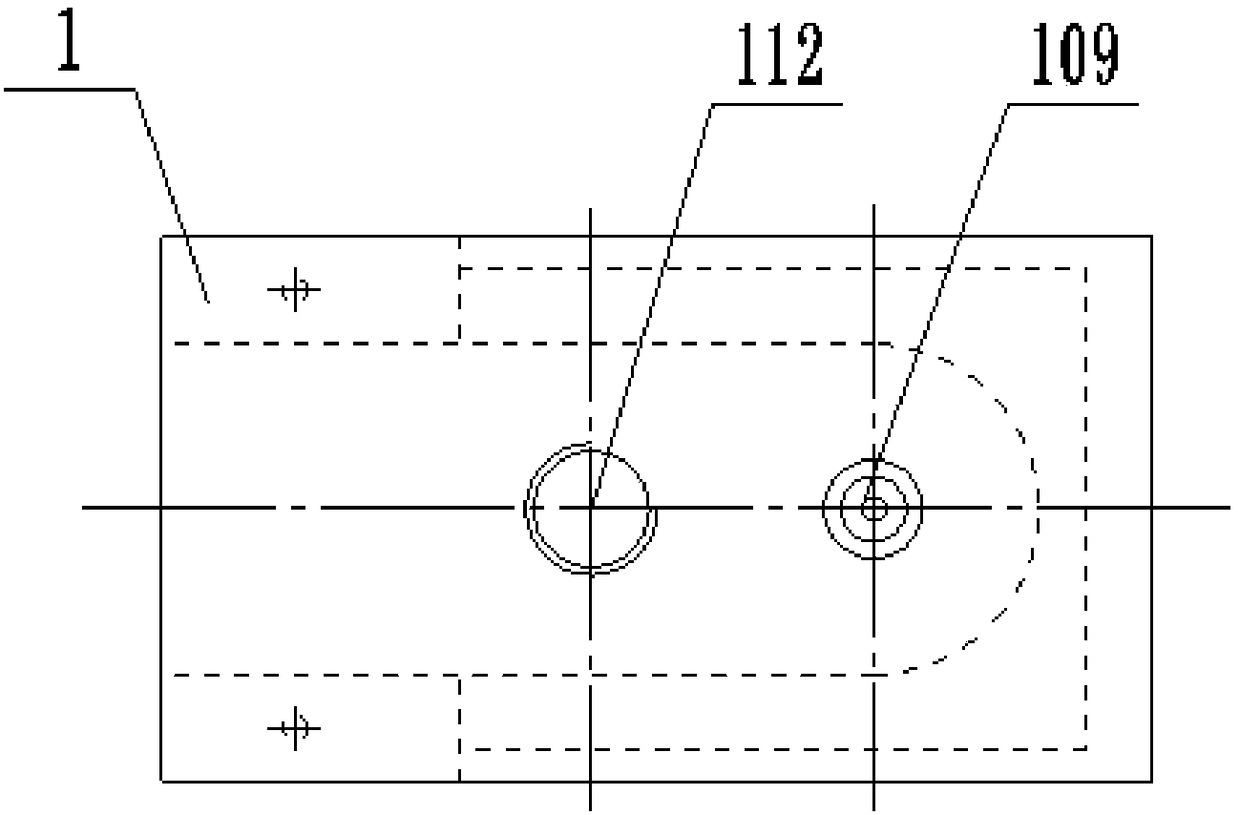

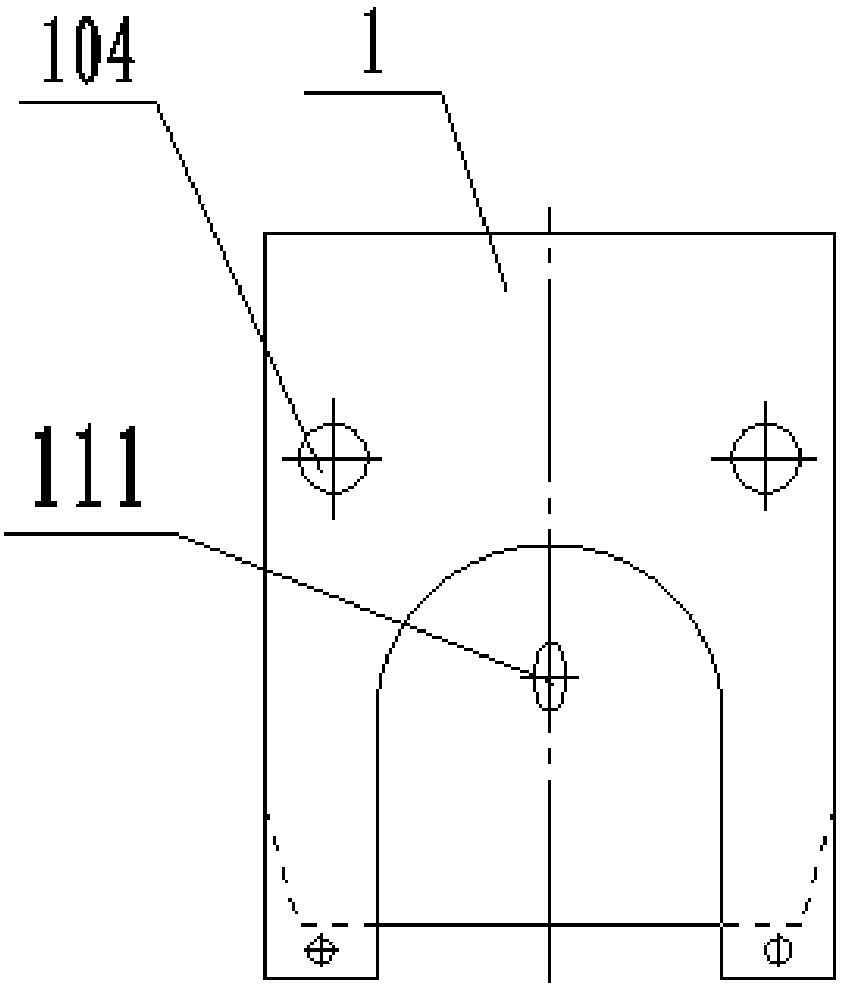

Air conditioner liquid storage device welding protection device and application method thereof

ActiveCN106270915AAvoid oxidation and blackeningAvoid contactGas flame welding apparatusSurface oxidationEngineering

The invention discloses an air conditioner liquid storage device welding protection device and an application method thereof, and belongs to the technical field of welding. The air conditioner liquid storage device welding protection device comprises an outer ventilation block and an inner ventilation block. The outer ventilation block is of a rectangular block-shaped structure and is provided with a transverse air blowing hole and longitudinal air blowing holes and connected with an air source through an outer ventilation connecting hole. An inner air blowing hole is formed in the inner ventilation block and connected with the air source through an inner ventilation connecting hole. According to the method, a cylinder is inflated with protection air through the inner ventilation block in the welding process, the welding position is immediately inflated with the protection air through the outer ventilation block after welding is finished, and air is prevented from making contact with a welding line. By means of the air conditioner liquid storage device welding protection device and the application method thereof, the surface of a welded part can be prevented from being oxidized during liquid storage device welding, the connecting strength of the welding line is improved, the quality of a finished product is improved, and the production cost is reduced.

Owner:ANHUI ZHONGHUI REFRIGERATION

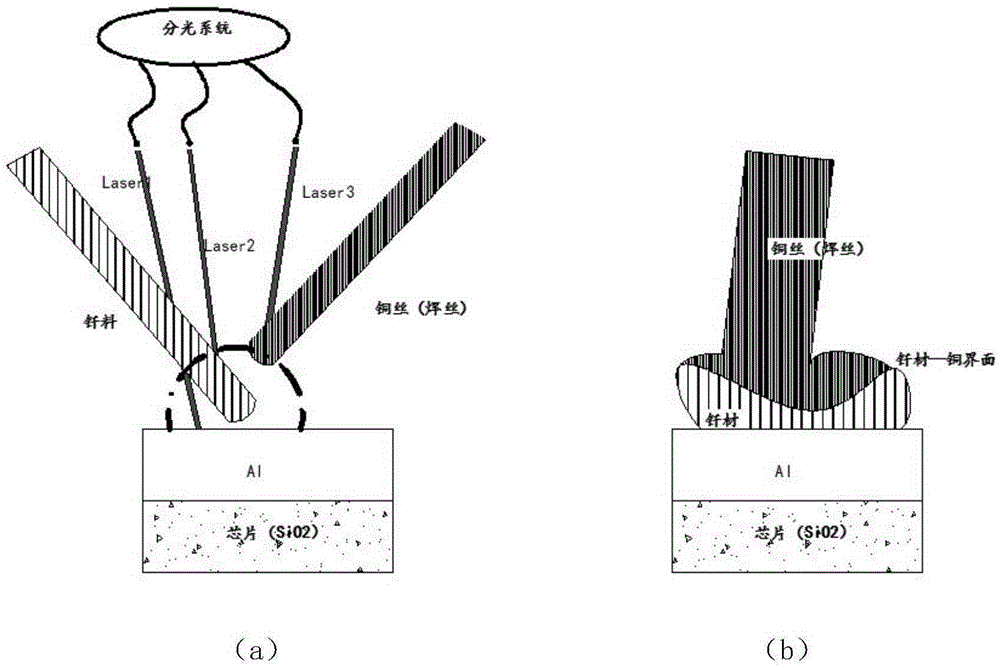

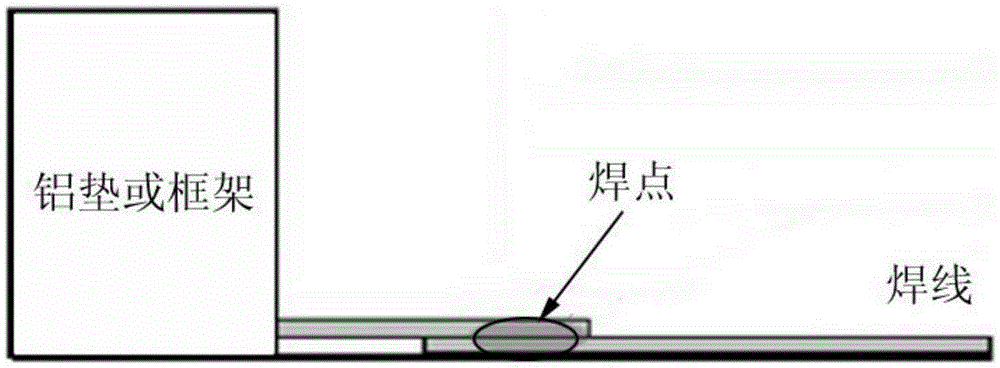

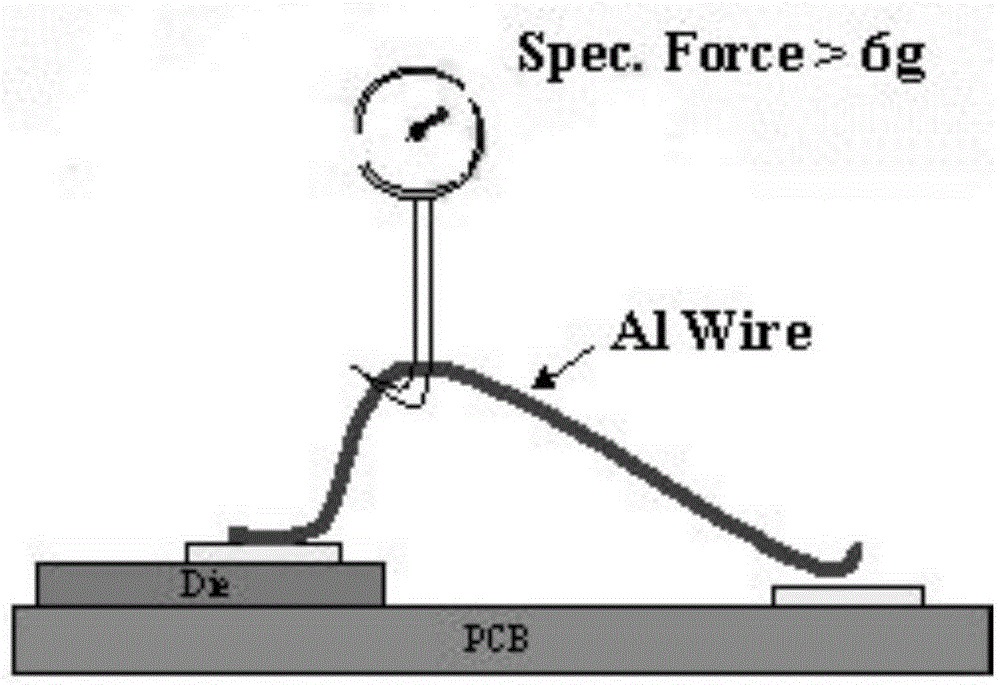

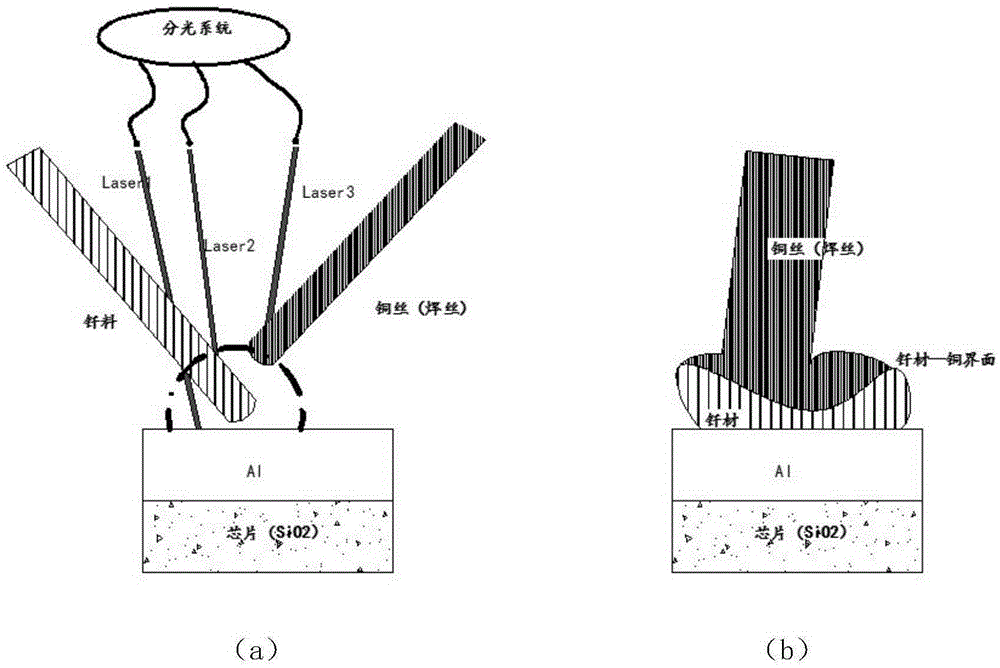

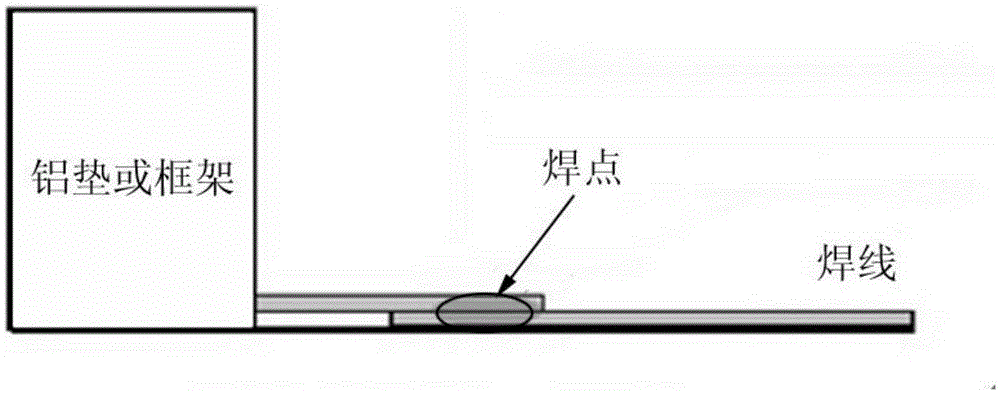

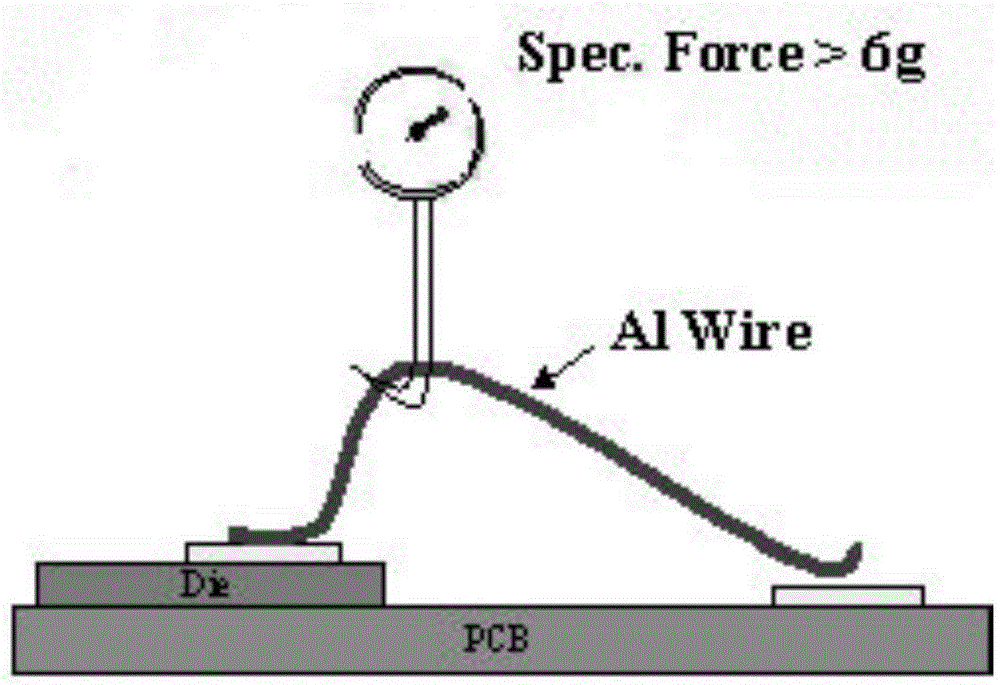

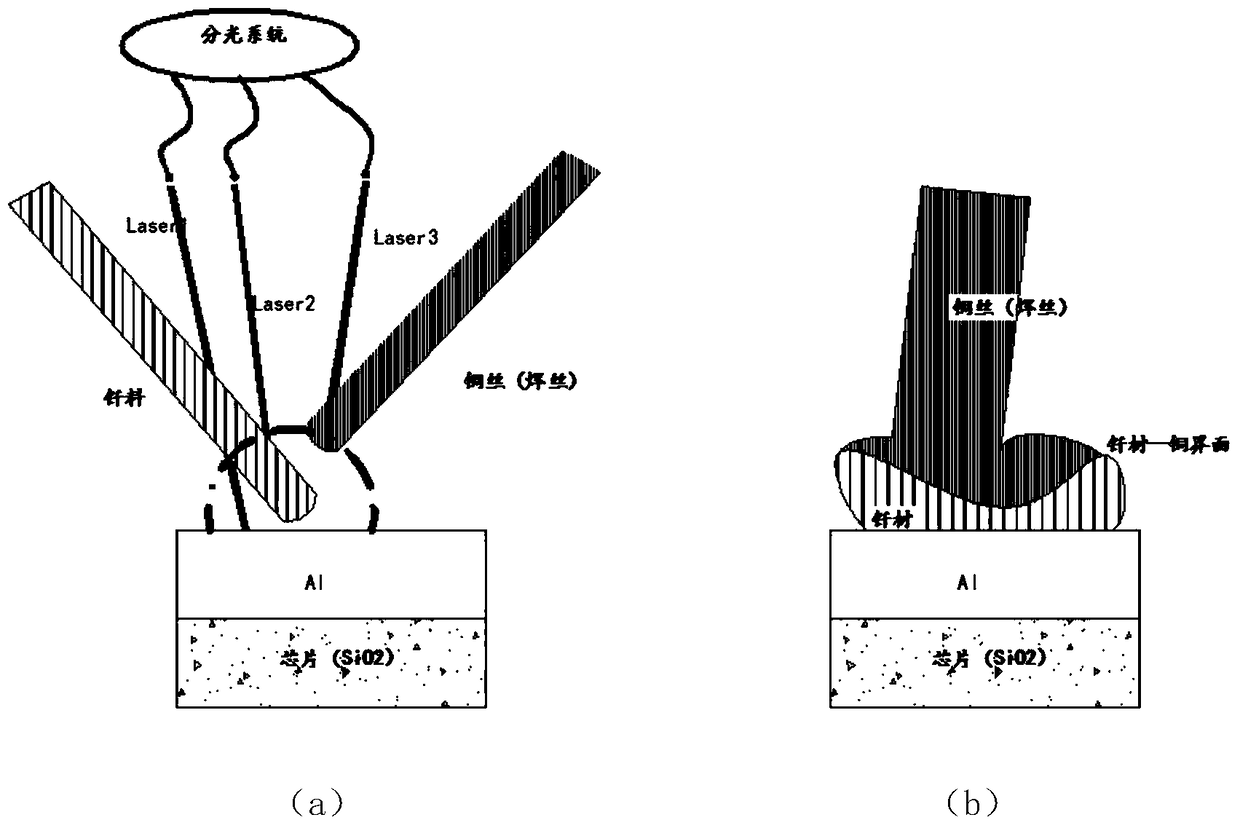

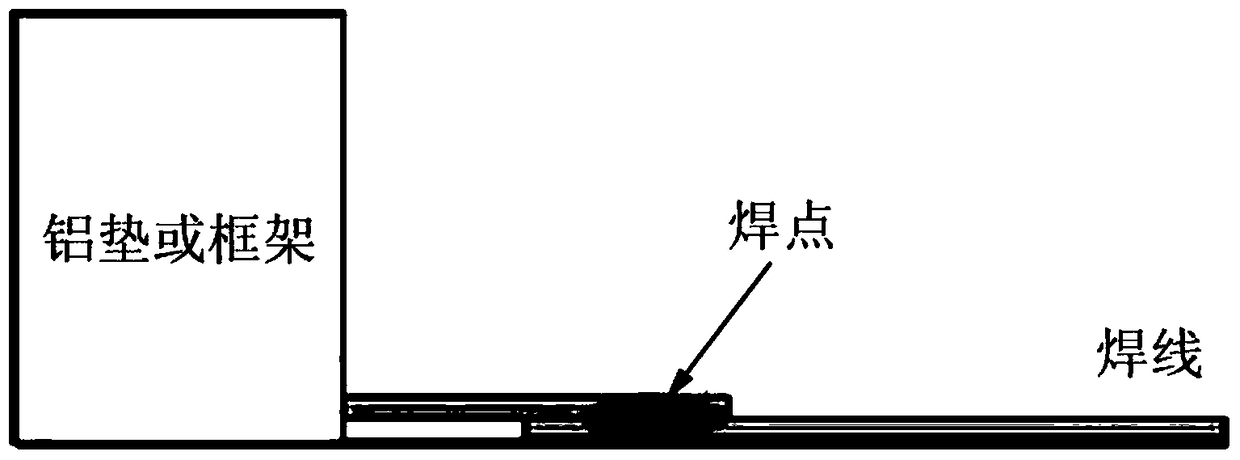

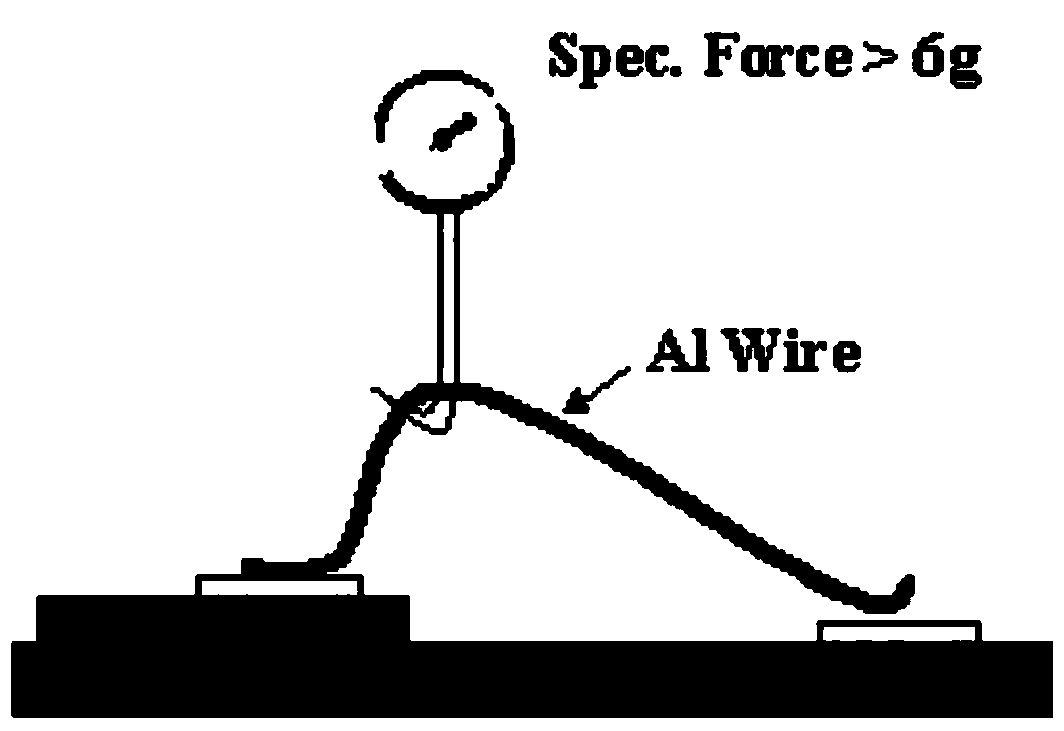

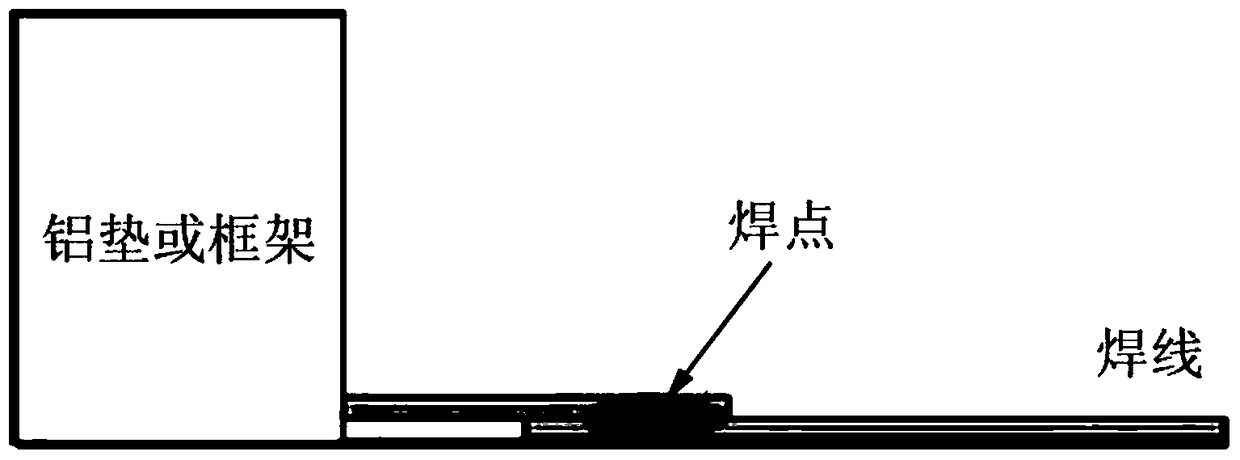

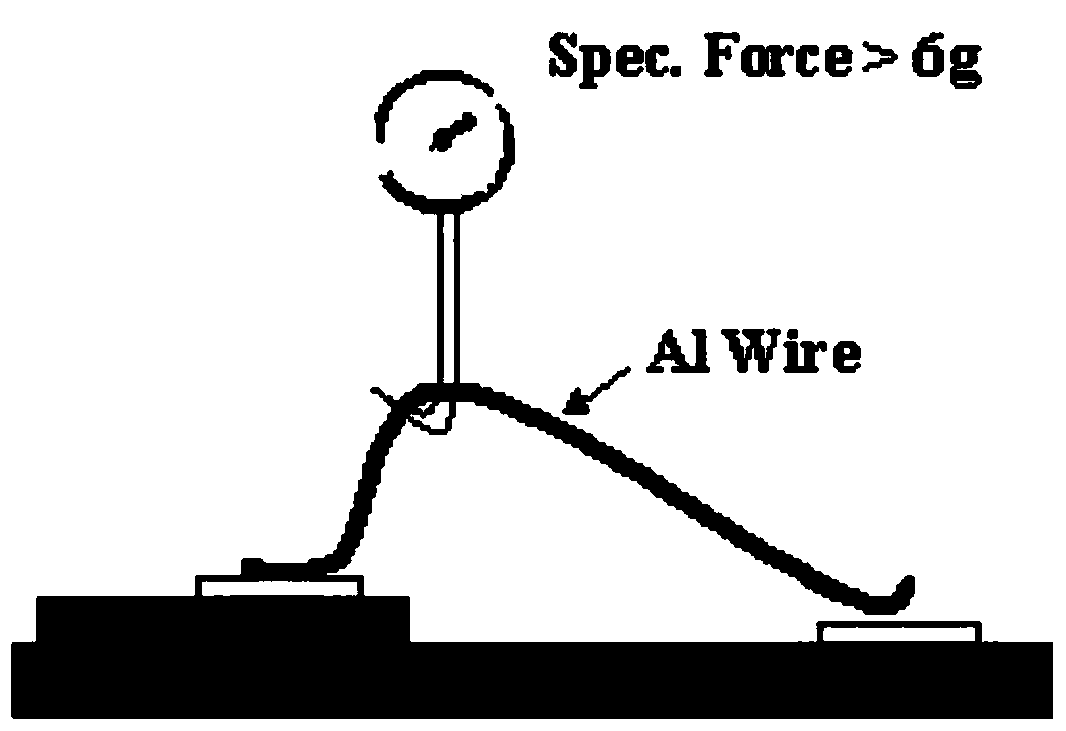

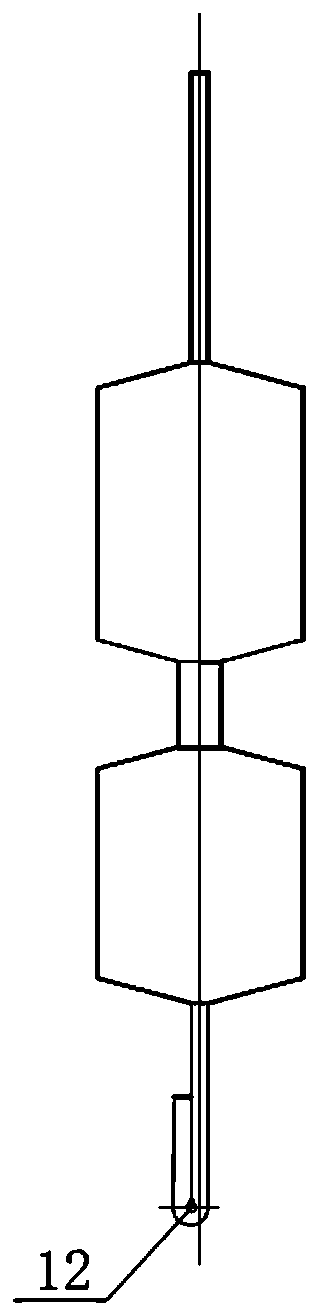

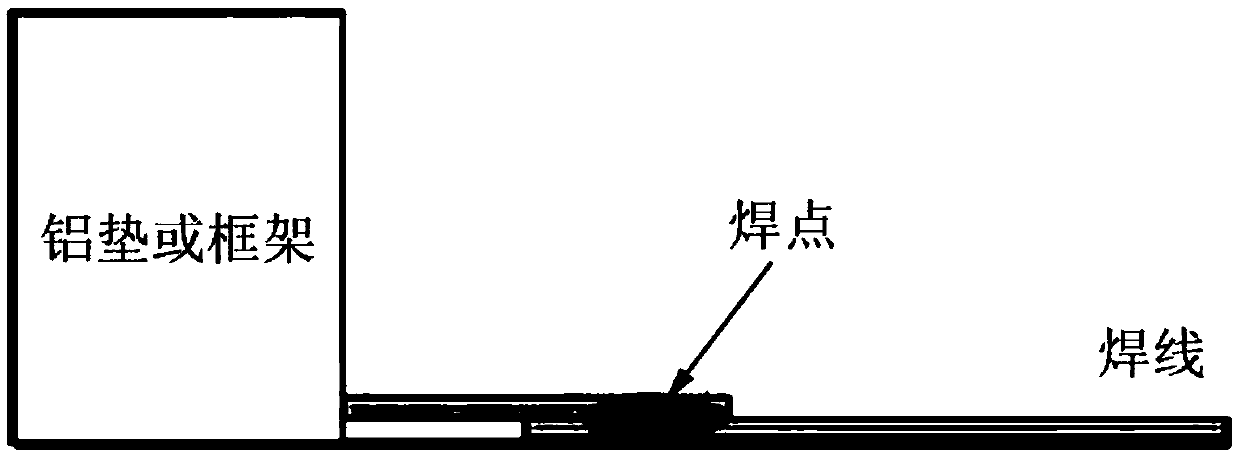

Lead welding technique for packaging semiconductor power device

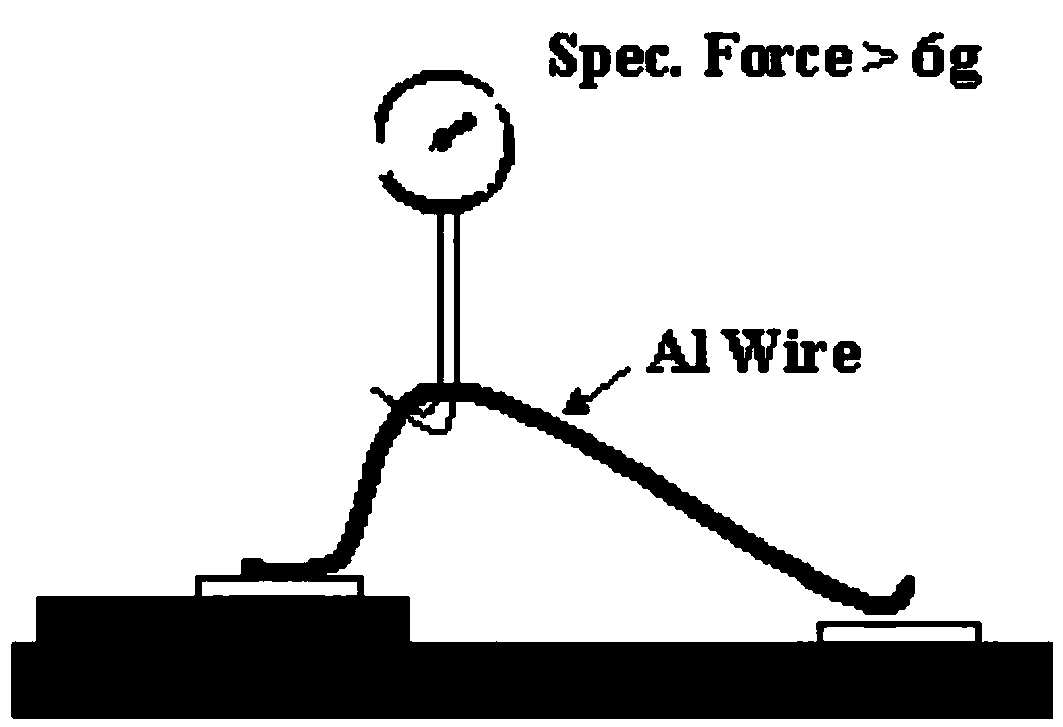

ActiveCN105458434ANo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

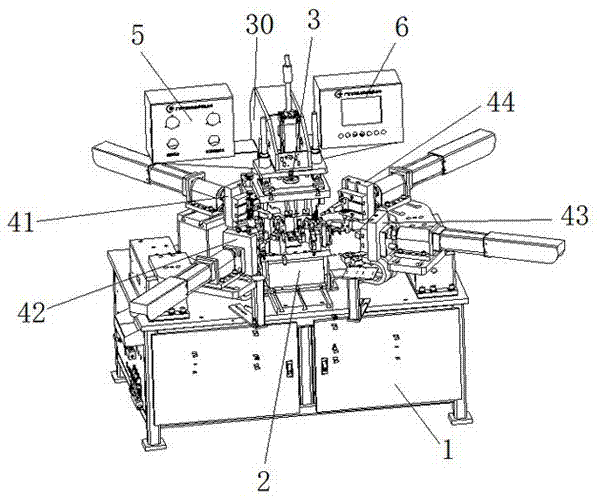

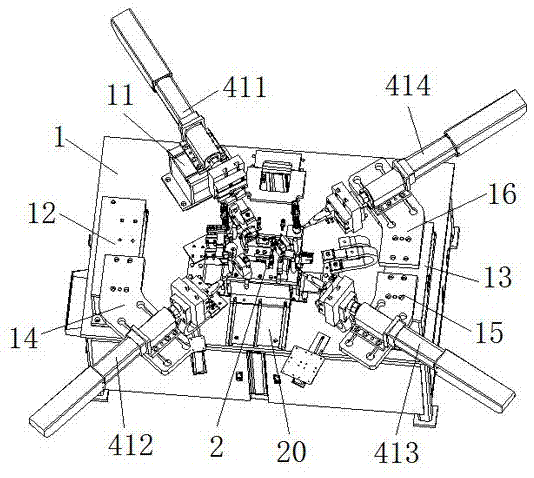

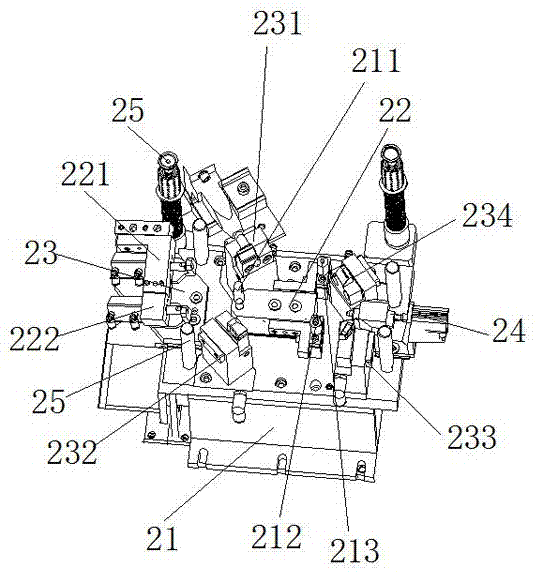

Fuel filler cap welder

ActiveCN105436731AHigh precisionSmall heat rangeWelding/cutting auxillary devicesAuxillary welding devicesScaling dimensionSoldering gun

The invention discloses a fuel filler cap welder which comprises a machine table, a first welding set, a second welding set, a third welding set, a fourth welding set, an upper mould bracket, an upper mould set, an operation box and a display screen. According to the fuel filler cap welder, a fuel filler cap can be positioned by virtue of an upper mould, so that the fuel filler cap welder can be suitable for positioning fuel filler caps with different scale dimensions; a fuel cap bracket is subjected to positioning and fine turning by fixing a conductive electrode base by virtue of four fuel cap brackets , so that the fuel filler cap welder can be suitable for positioning the fuel cap brackets with different scale dimensions, and also can be suitable for positioning fuel cap rotary plates with different scale dimensions, and therefore, precise mould closing of the upper mould set and a lower mould set is realized; a plurality of welding guns can be used for simultaneously welding a fuel cap, so that the efficiency is high; a fuel filler cap welding workpiece is small in heating range, so that the fuel filler cap is small in deformation and even is not deformed, and therefore, a workpiece welding position is high in precision, a welding spot is free of an insufficient welding phenomenon, a welding spot is firm, a yield is high, a rate of defective products is lower than 1 / 10000, the cost is low, and the intelligent degree is high.

Owner:HERON INTELLIGENT EQUIP CO LTD

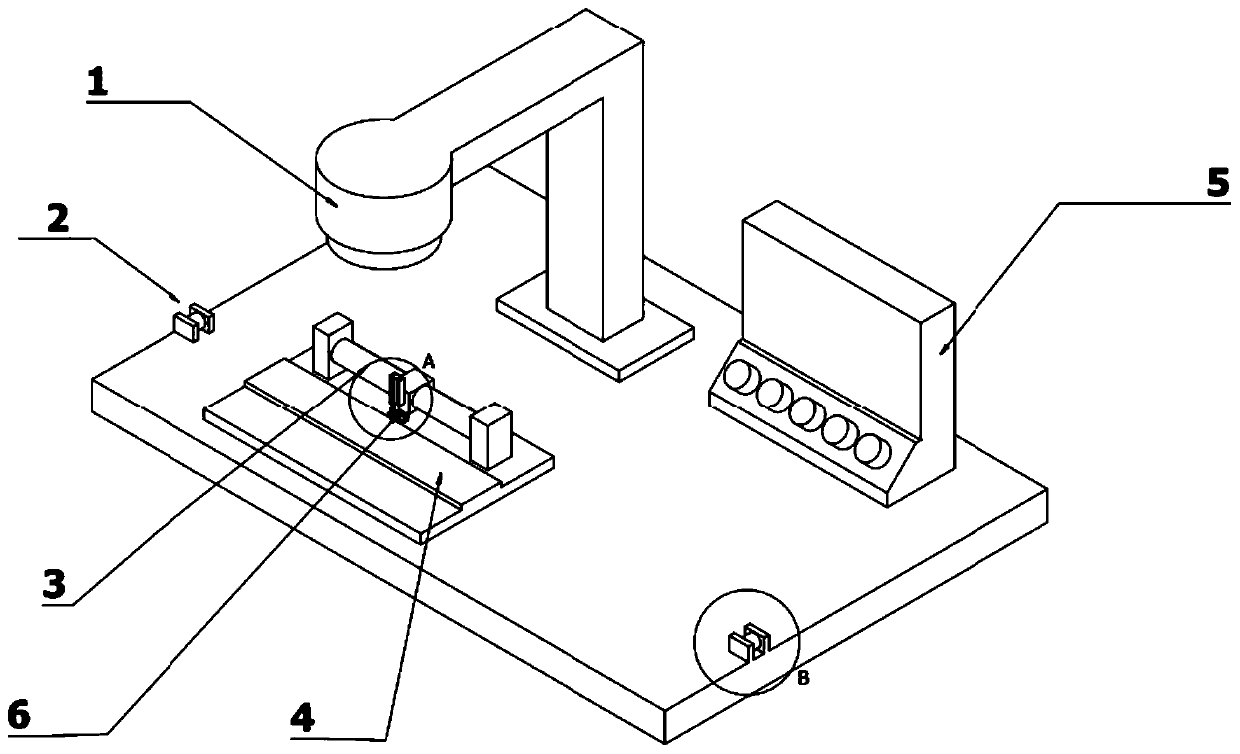

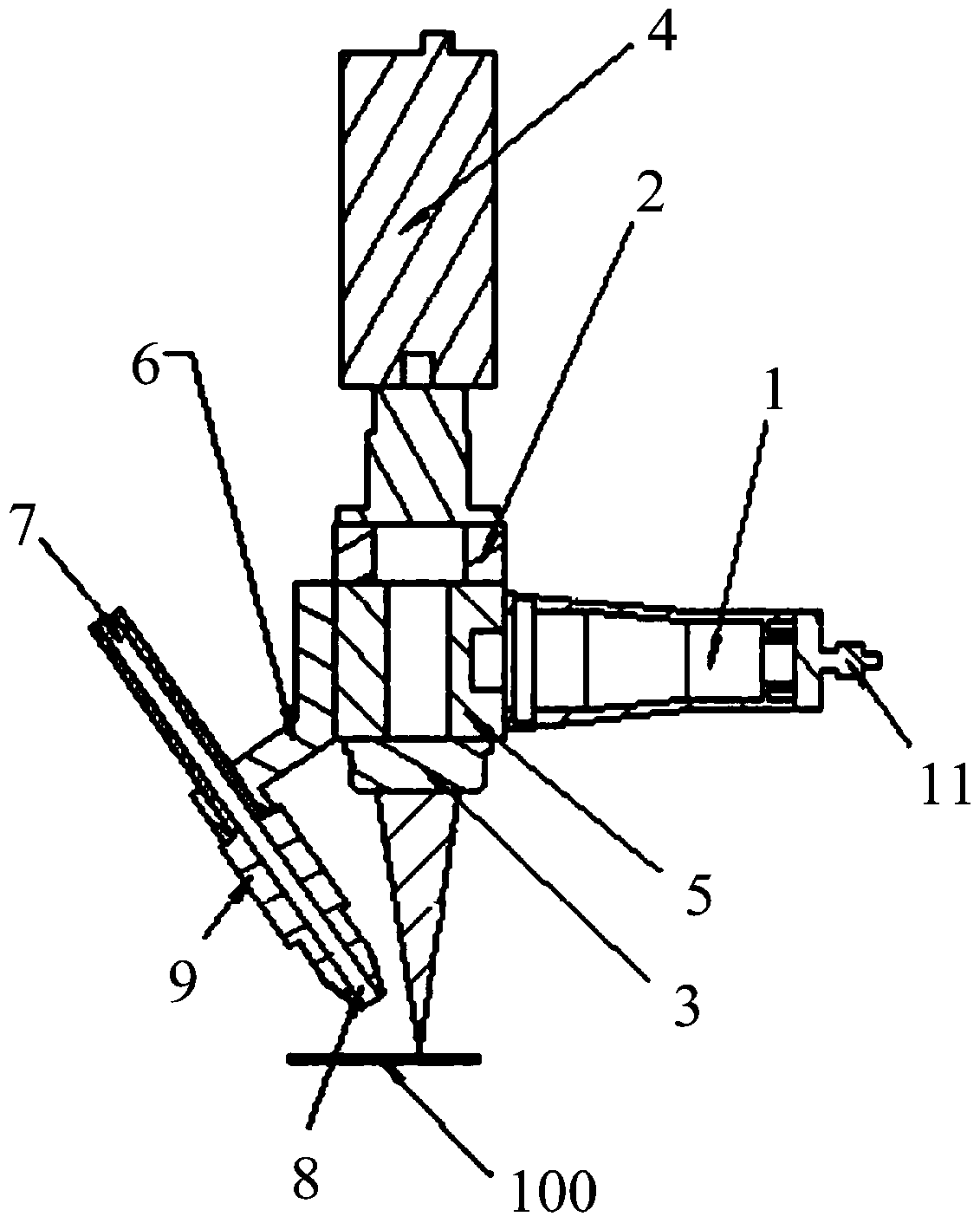

Lead welding device and technique for packaging semiconductor power device

ActiveCN105458435AImprove efficiencySmall heat affected zoneWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding device and technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. The device is a laser wire welding machine and comprises a computer main board, a laser generator, a chip and frame image identification system, a feeding system and an XY workbench. The computer main board is used for controlling all the actions of the laser wire welding machine to achieve the whole automatic and accurate wire welding technique process; the laser generator is used for outputting laser spots of the required power and the required diameter; and the feeding system is used for accurately conveying a frame, a lead and a brazing wire to the work position before welding actions are executed. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers. By the adoption of the device and technique, a wet aluminum pad and a frame are directly melted to achieve the stable and reliable connection of the lead, a chip and the frame, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

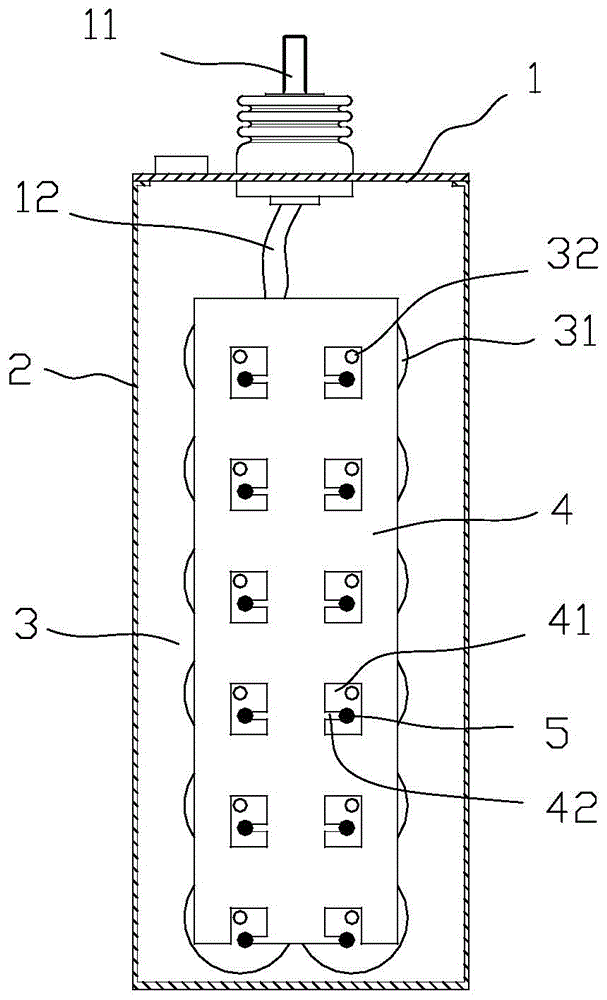

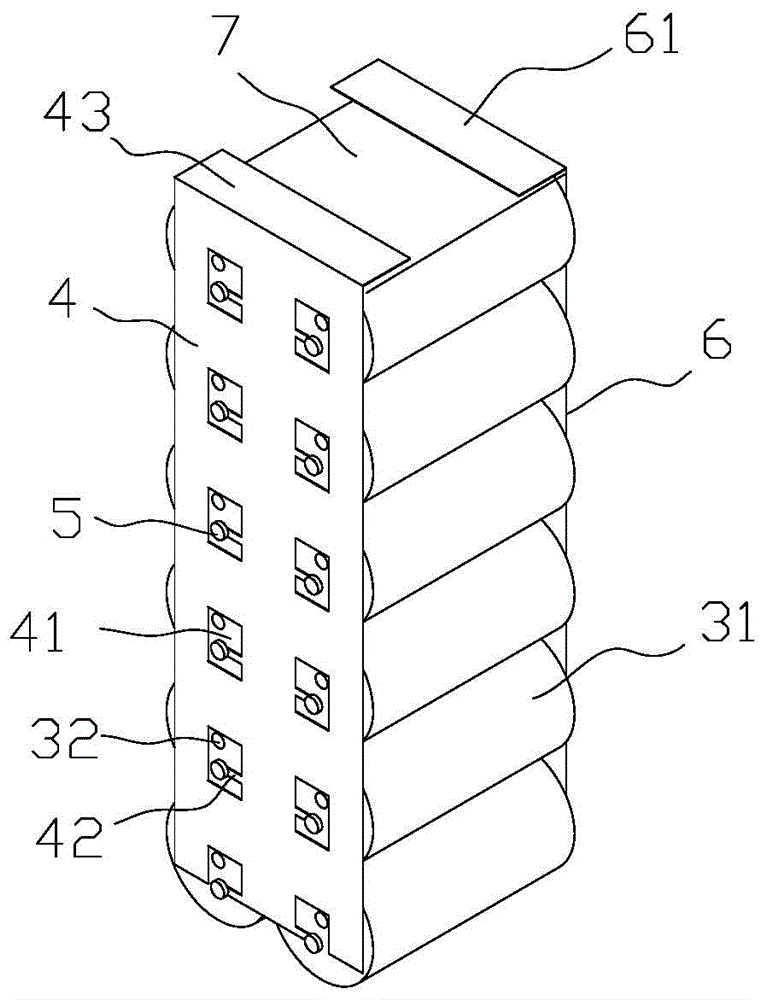

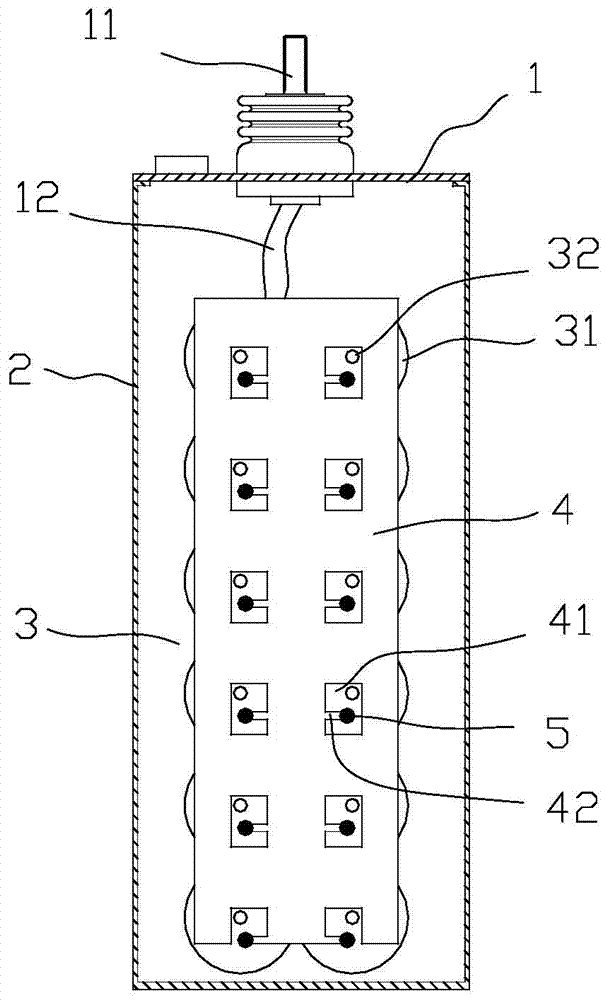

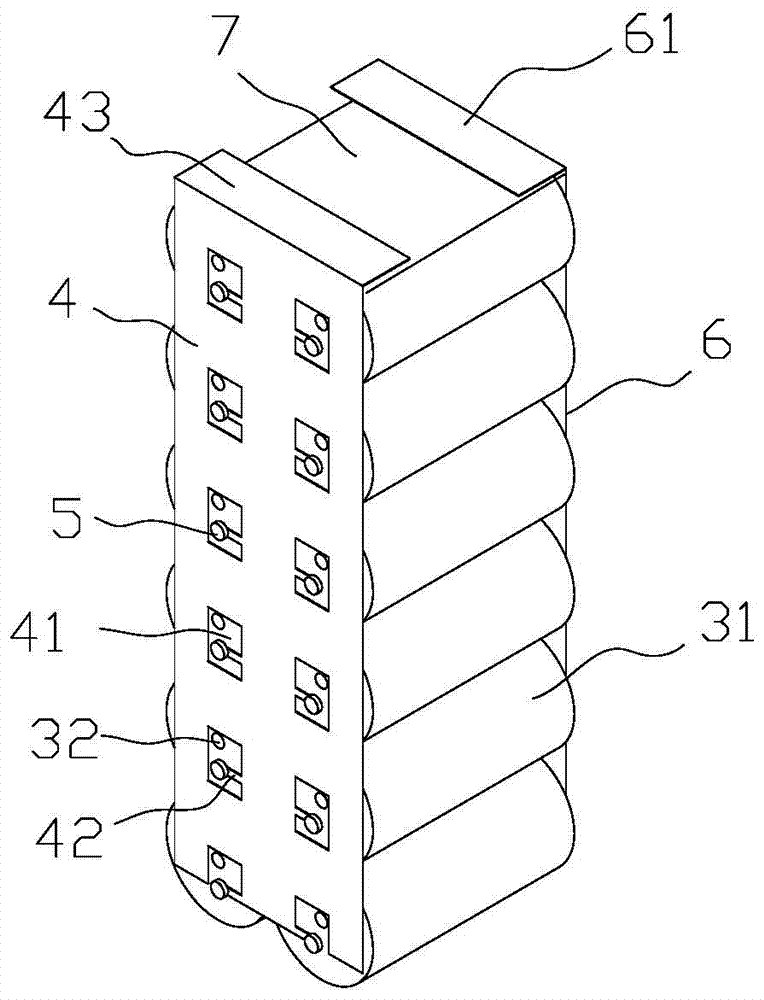

Power capacitor high in heat dissipation performance

ActiveCN104465095AIncrease the flow cross sectionLow calorific valueMultiple fixed capacitorsFixed capacitor housing/encapsulationCapacitanceElectricity

The invention relates to a power capacitor high in heat dissipation performance. The power capacitor high in heat dissipation performance comprises a cover plate assembly, a shell and a capacitor core assembly, wherein the capacitor core assembly is formed by overlaying a plurality of cylindrical capacitor cores, leading-out copper belts are arranged on the metal-sprayed surface of the capacitor core assembly, the two sides of each leading-out copper belt at least extend to the central areas of the metal-sprayed surfaces of the capacitor cores located on the two sides of the capacitor core assembly, a through hole or a groove is formed in the portion, corresponding to the center of the metal-sprayed surface of each capacitor core, of each leading-out copper belt, an opening of each groove is located on one side of the corresponding leading-out copper belt, and elastic fins which extend to the through holes or the grooves and are used for being electrically connected with the metal-sprayed surfaces through welding are arranged on the leading-out copper belts. According to the power capacitor high in heat dissipation performance, by increasing the widths of the leading-out copper belts, current can evenly pass through the power capacitor, and the amount of heat can be reduced; in addition, the areas of the leading-out copper belts are increased in a multiplied mode, and thus the heat dissipation performance is greatly improved.

Owner:ANHUI TONGFENG ELECTRONICS

Transparent circuit board

InactiveCN106211566AStrong solder jointsNot easy to fall offTransparent dielectricsCircuit susbtrate materialsSputteringMetallic materials

The invention relates to a transparent circuit board. The transparent circuit board is characterized by comprising a transparent conductive substrate, at least one layer of circuit is arranged on the transparent conductive substrate, insulating layers and transparent conductive layers are arranged between the circuit layers, conductive connecting potentials in point connection with two adjacent layers of circuits are etched on each insulating layer, and the transparent conductive substrate is plated with at least two metal material layers through magnetron sputtering to form electrodes of the circuit layers. The transparent circuit board and a manufacturing method thereof at least have the advantages that a traditional printed circuit board with a resin material as a substrate is replaced with the transparent conductive substrate, so that the transparent circuit board can be applied to various fields and is convenient to use and attractive in appearance, and welding spots are firm and not prone to disengagement.

Owner:GUANGZHOU QIHONG ELECTRONICS TECH

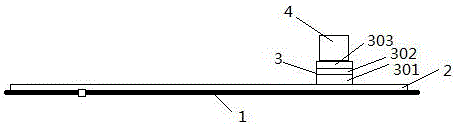

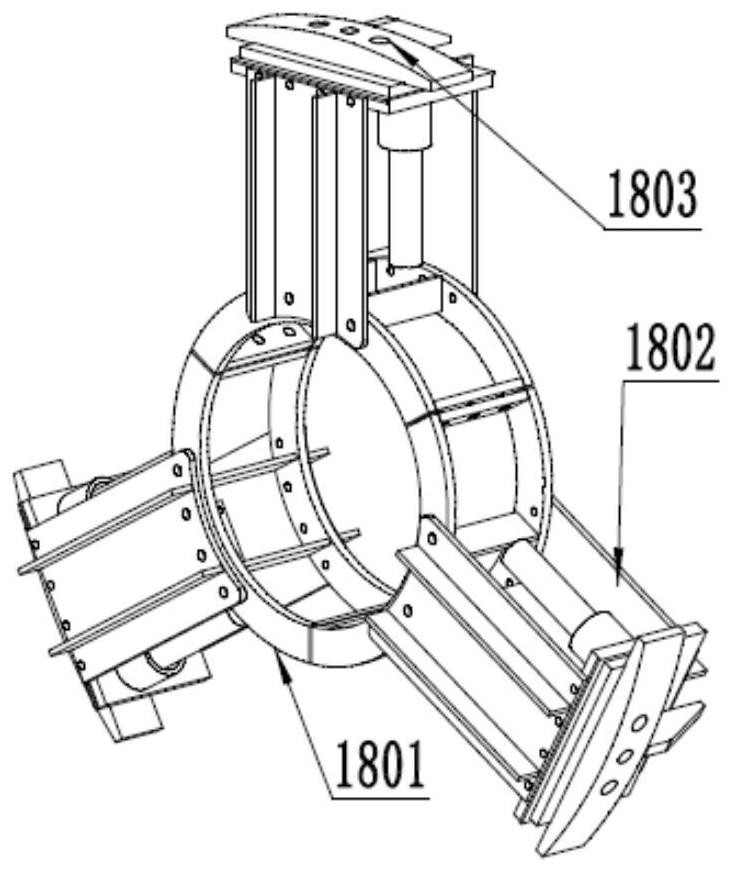

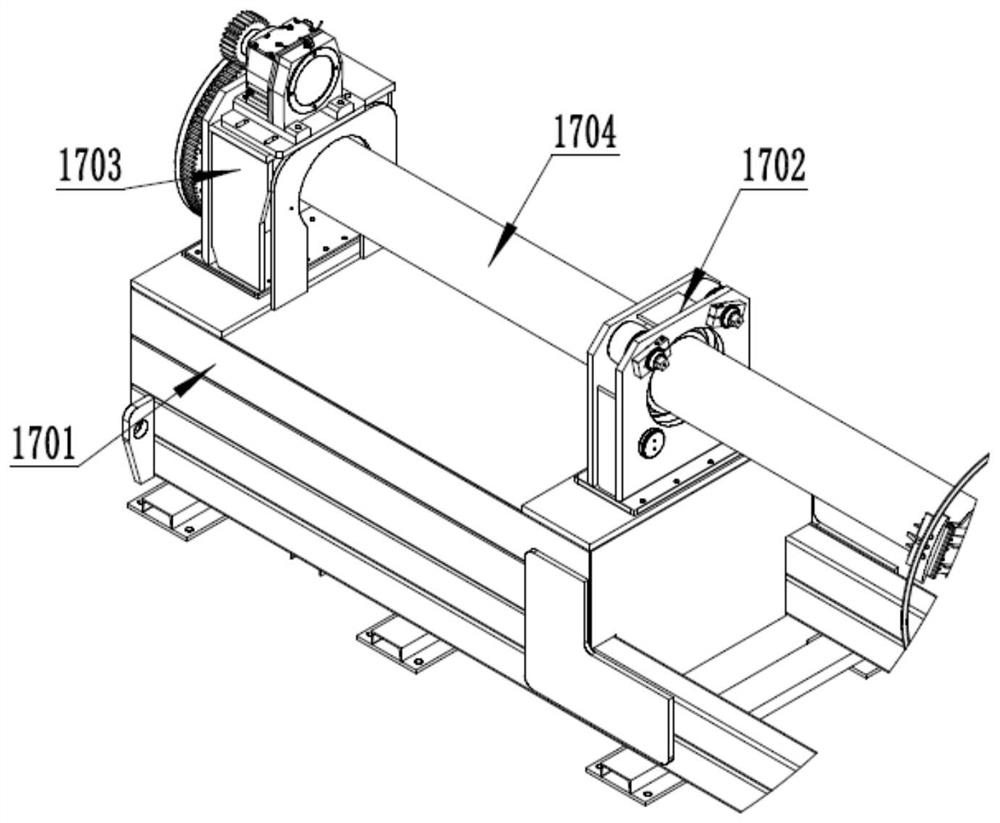

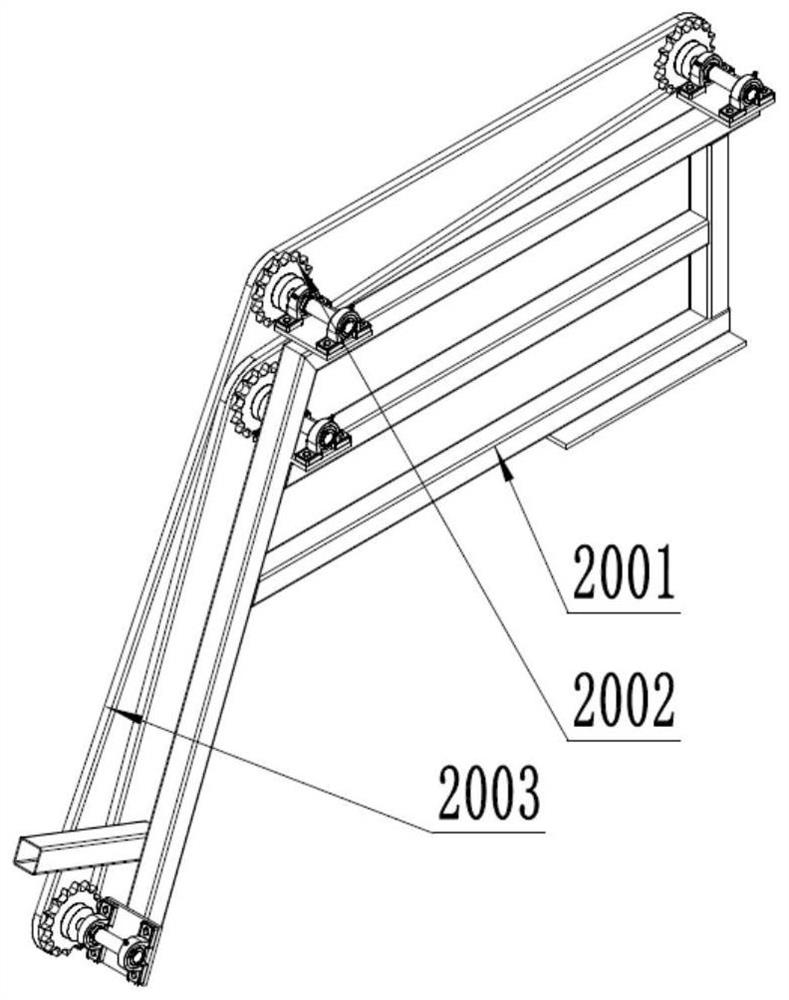

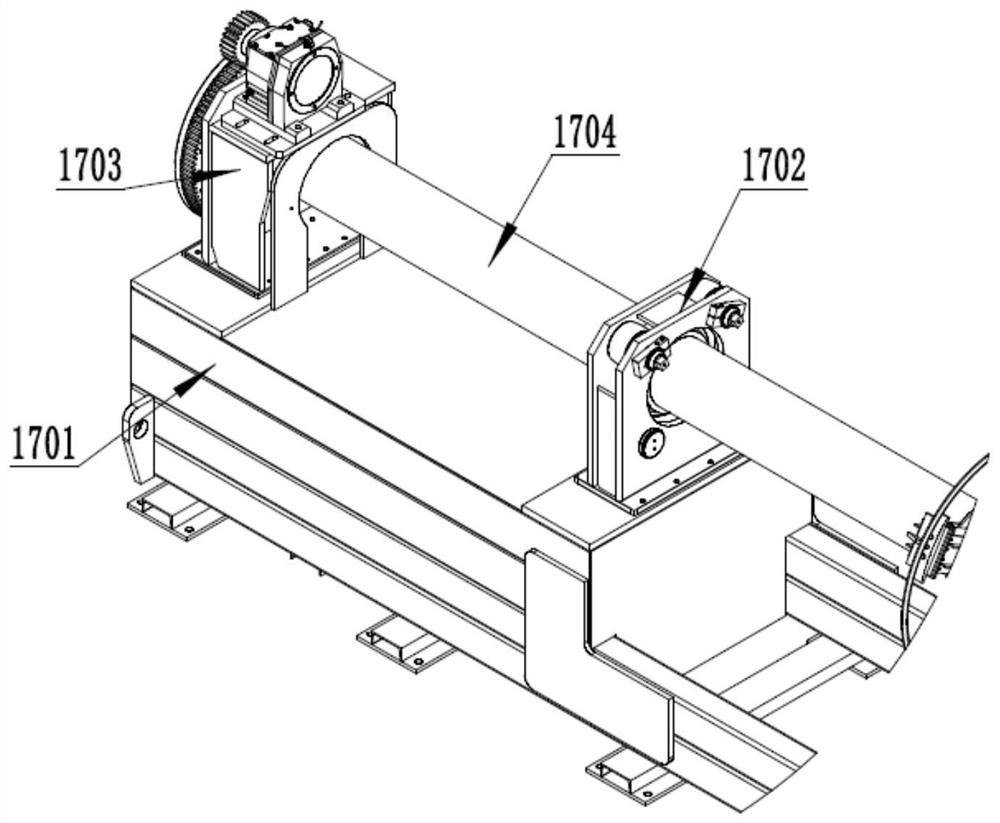

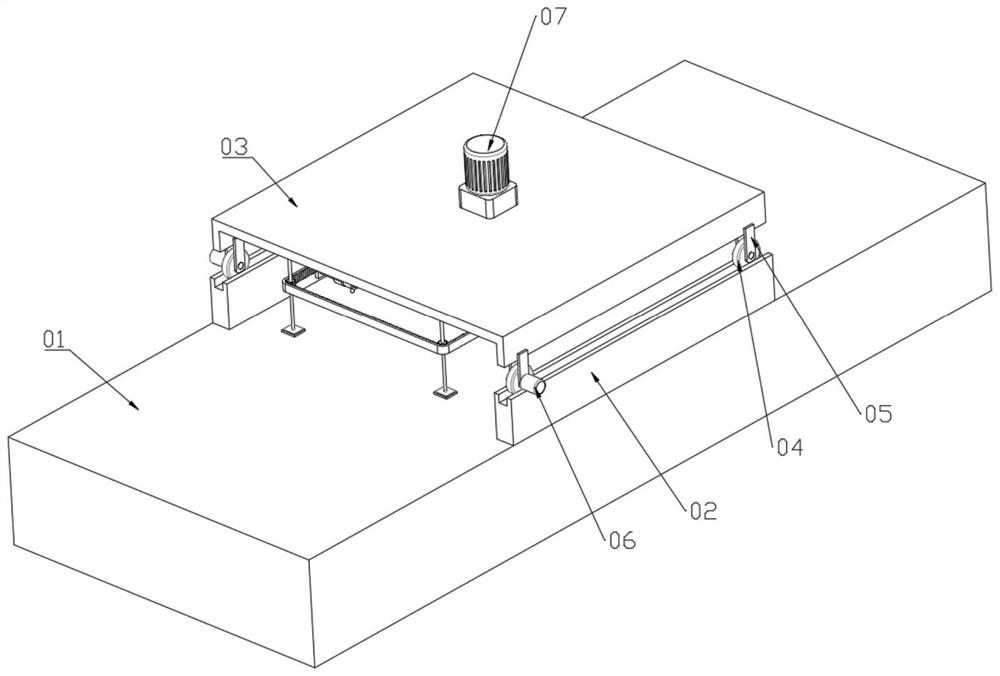

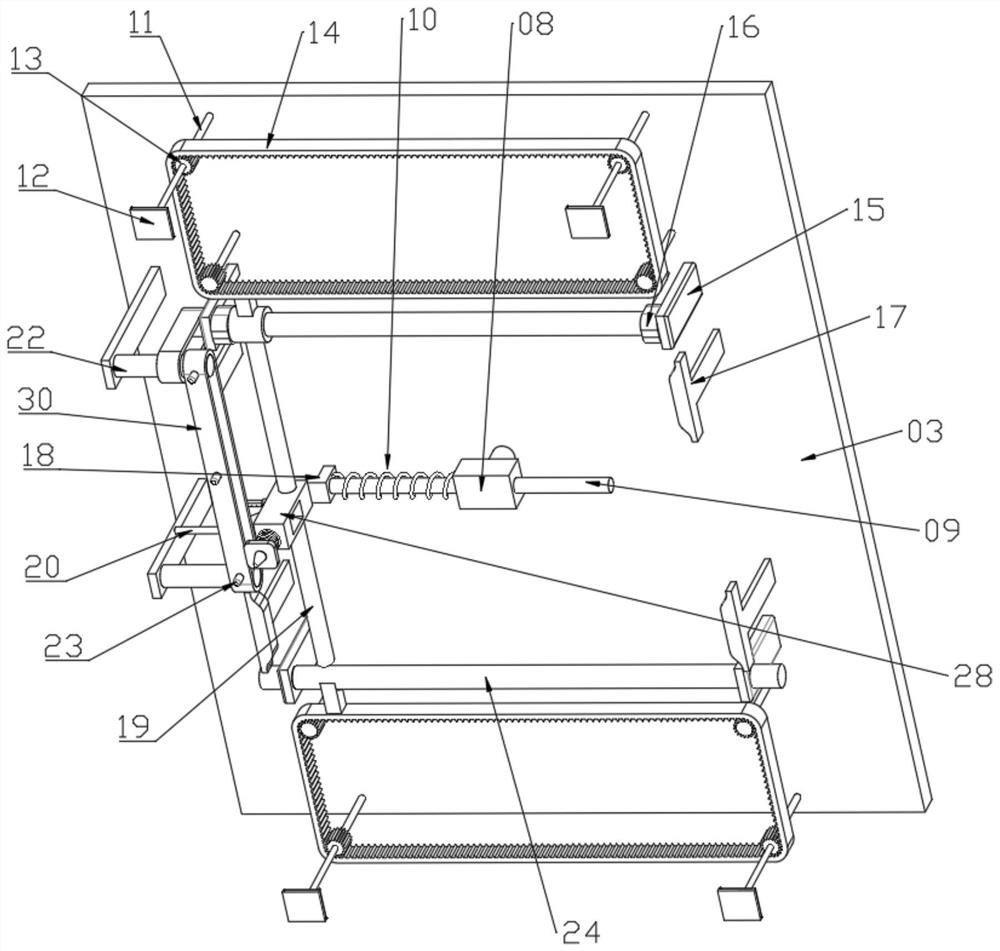

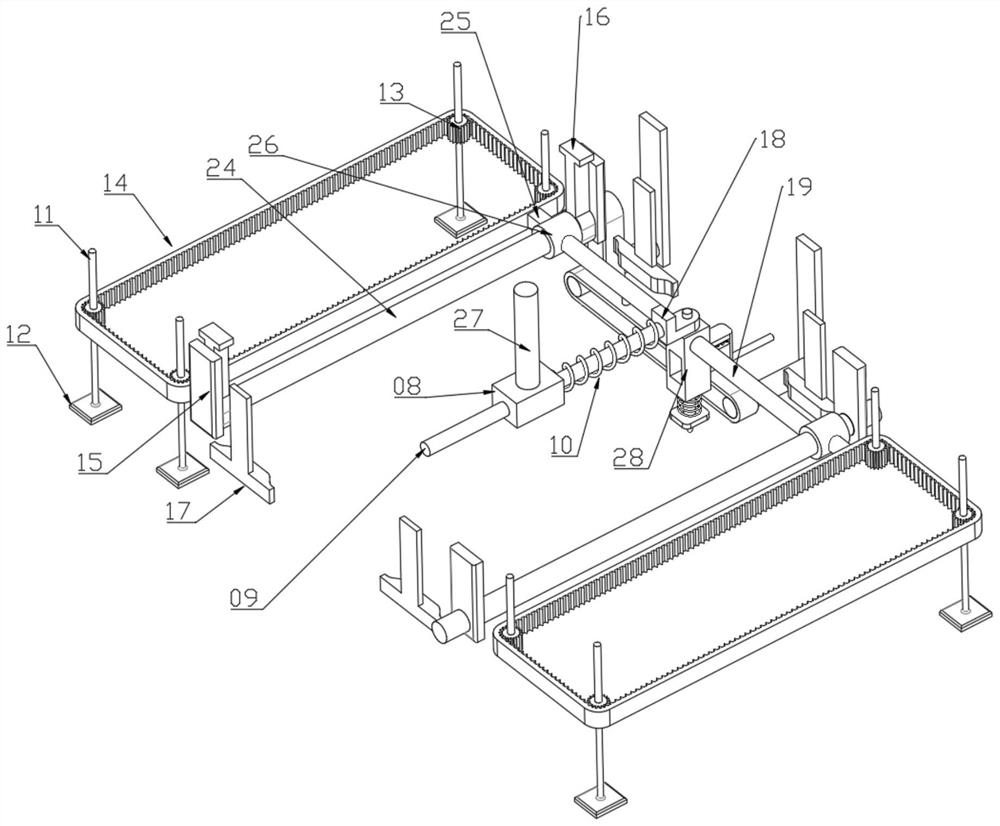

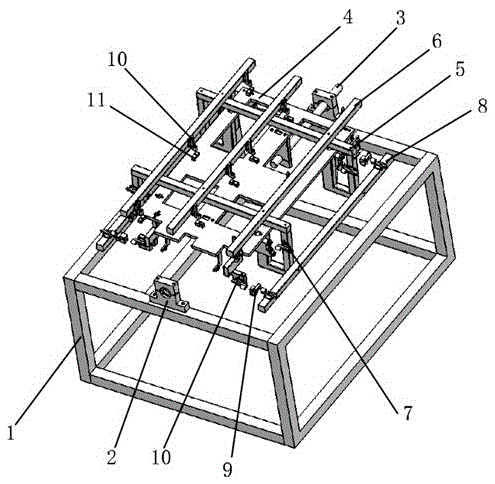

Manufacturing method of reinforcement cage

ActiveCN112355452ARealize automatic weldingIncrease productivityWelding with roller electrodesRebarMachining

The invention discloses a manufacturing method of a reinforcement cage. A winding reinforcement welding mechanism used for winding and welding winding reinforcements, a feeding mechanism used for feeding main reinforcements, a central rotating assembly used for rotating an inner ring, and an inner ring fixing assembly used for fixing the inner ring are included. A detection mechanism used for detecting the length of the main reinforcements and locating the main reinforcements, and a main reinforcement welding mechanism used for welding the main reinforcements are further included. According tothe manufacturing method, automatic machining is realized from feeding to welding and discharging of the reinforcement cage, welding spots of the reinforcement cage are stable, the welding quality ofthe reinforcement cage is stable, manpower input is reduced, the labor intensity of workers is relieved, the production efficiency of the reinforcement cage is greatly improved, and reinforcement cages of different specifications can be produced.

Owner:成都华研机器设备有限公司

A wire bonding process for semiconductor power device packaging

ActiveCN105458434BNo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

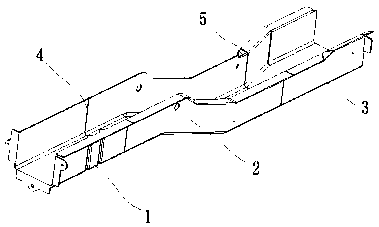

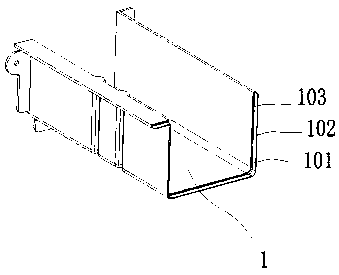

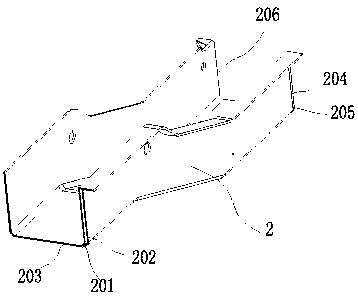

Structure of multi-section rear longitudinal beam

The invention discloses a structure of a multi-section rear longitudinal beam. The structure comprises a first front section of a rear longitudinal beam, a middle sectionof the rear longitudinal beam,a second front section of the rear longitudinal beam, a first welding point and a second welding point, wherein one end of the middle section of the rear longitudinal beam is arranged at one end of the first front section of the rear longitudinal beam; the other end of the middle section of the rear longitudinal beam is arranged at one end of the second front section of the rear longitudinal beam; the first front section of the rear longitudinal beam is connected with one end of the middle section of the rear longitudinal beam through the first welding point; the other end of the middle section of the rear longitudinal beam is connected with one end of the second front section of the rear longitudinal beam through the second welding point; a first front section overlapping end is arrangedoutside one end of the first front section of the rear longitudinal beam; a first front section outer chamfer is arranged outside the first front section overlapping end; and a first front section inner chamfer is arranged inside the first front section of the rear longitudinal beam. The structure is divided into a three-section longitudinal beam, so that the mold opening cost is less; and meanwhile, each section of the beam is small, so that the molding is relatively easy, and the quality of each section of the beam is well controlled.

Owner:HANTENG AUTOMOBILE CO LTD

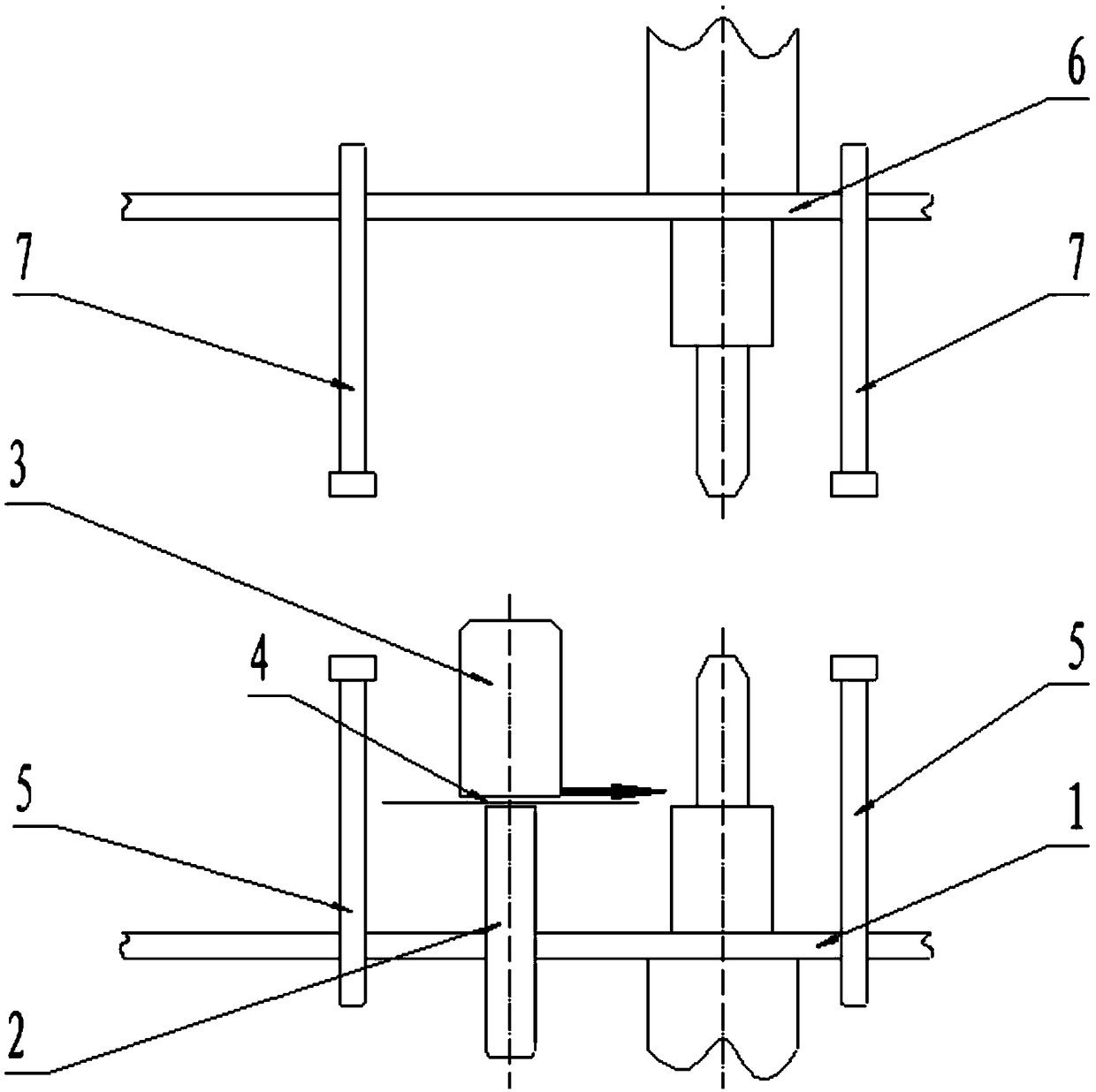

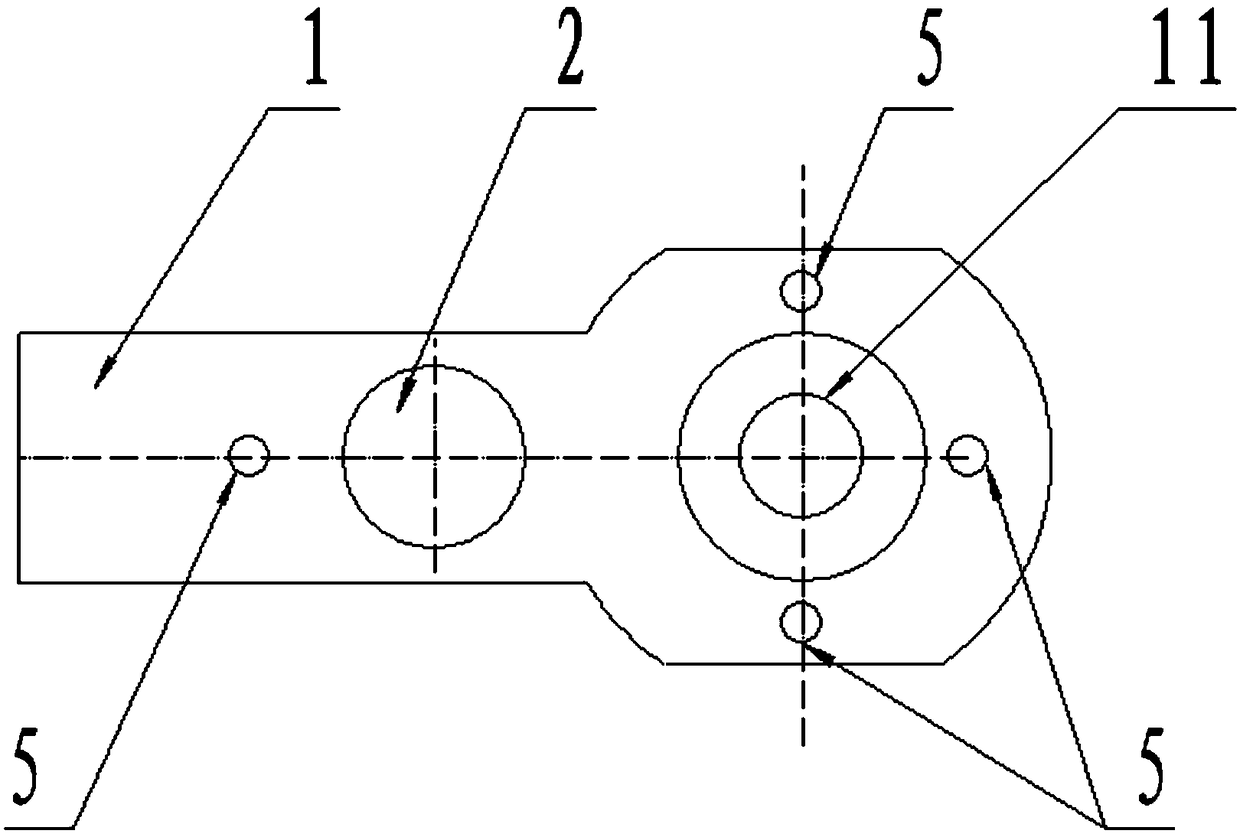

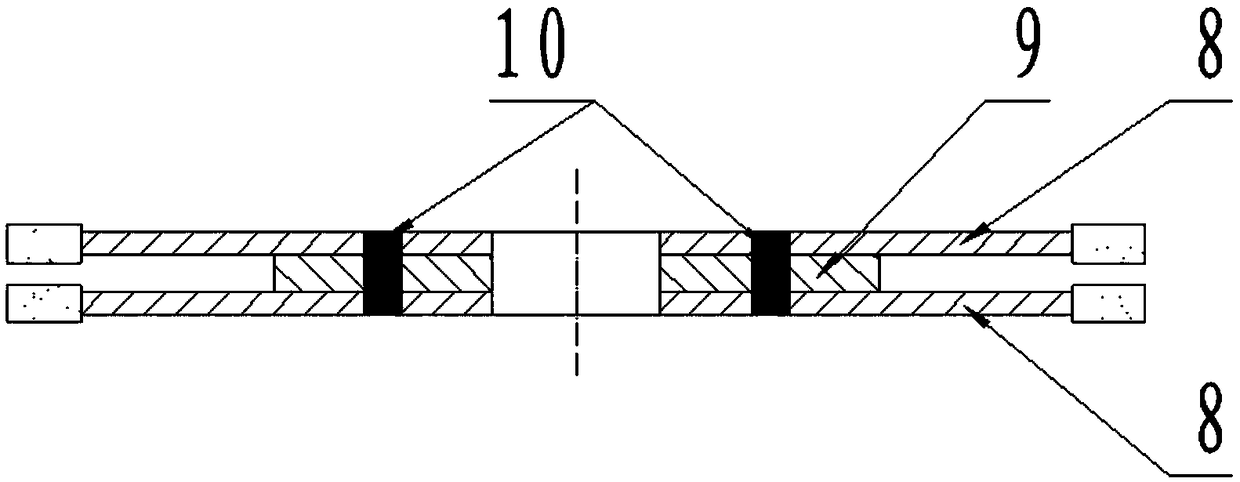

Welding frame of spot welding machine

InactiveCN108746967AEasy to operateStable spot welding processMetal sawing tool makingWelding/cutting auxillary devicesHigh volume manufacturingCircular saw

The invention discloses a welding frame of a spot welding machine, and belongs to the field of manufacturing of diamond tools. The welding frame of the spot welding machine comprises an upper weldingframe body and a lower welding frame body, wherein an upper welding head of the spot welding machine is sleeved with the upper welding frame body and the lower welding frame body. The lower welding frame body is provided with a rotary fixing shaft arranged at the center of a circular saw blade in a sleeved mode and a plurality of lower pressing blocks supporting the periphery of the circular saw blade. The upper welding frame body is provided with upper pressing blocks which are located over the lower pressing blocks and abut against the circular saw blade. The welding frame is an indispensable auxiliary device of the diamond circular saw blade used for spot-welding production. Transition from manual operation to stable mechanical production is achieved. The welding frame is simple in structure and low in investment cost. The welding frame makes the spot welding process more stable and is easy to operate, capable of achieving firm spot welding, attractive and suitable for volume production.

Owner:河北小蜜蜂工具集团有限公司

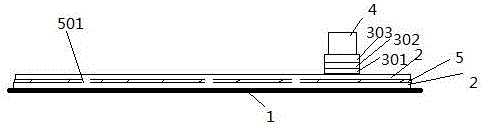

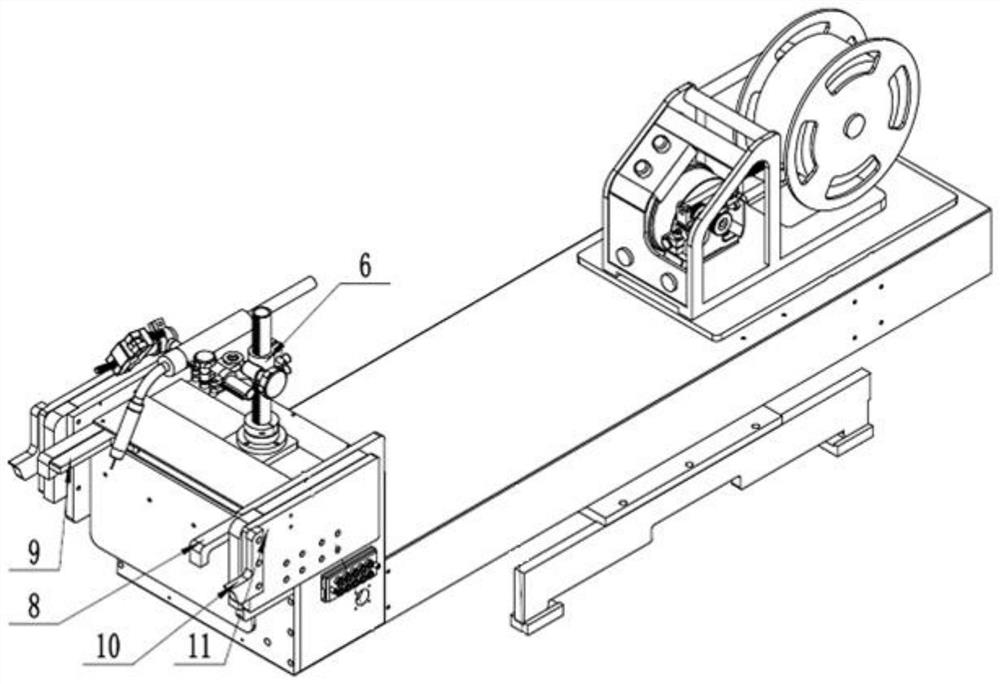

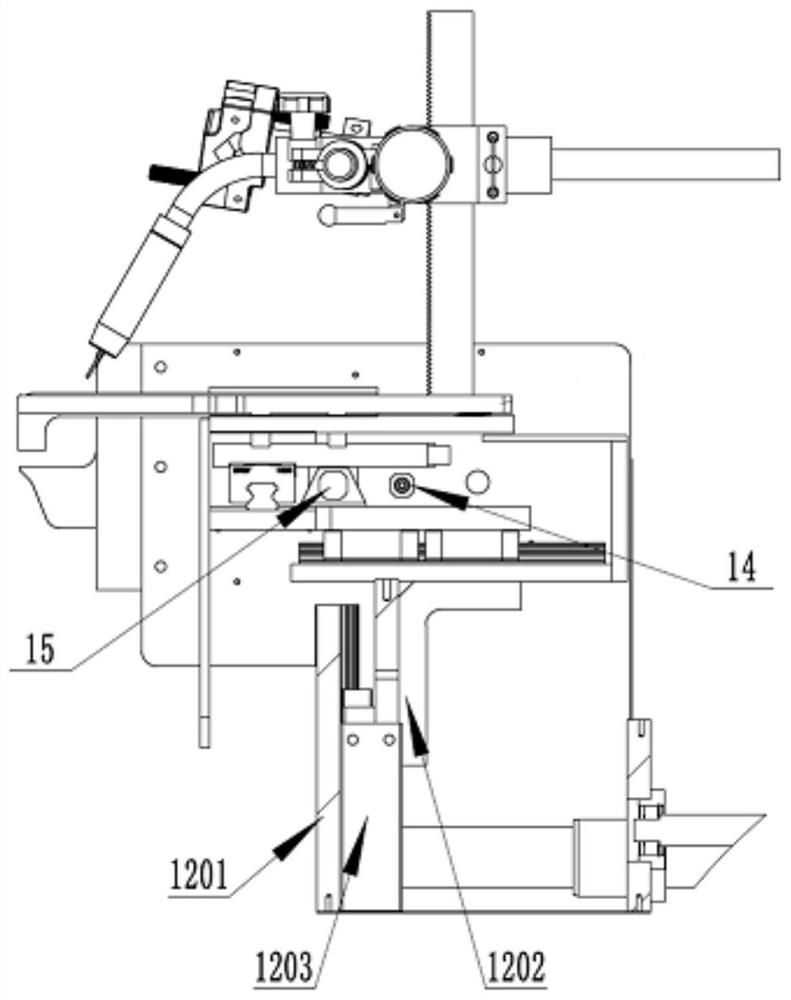

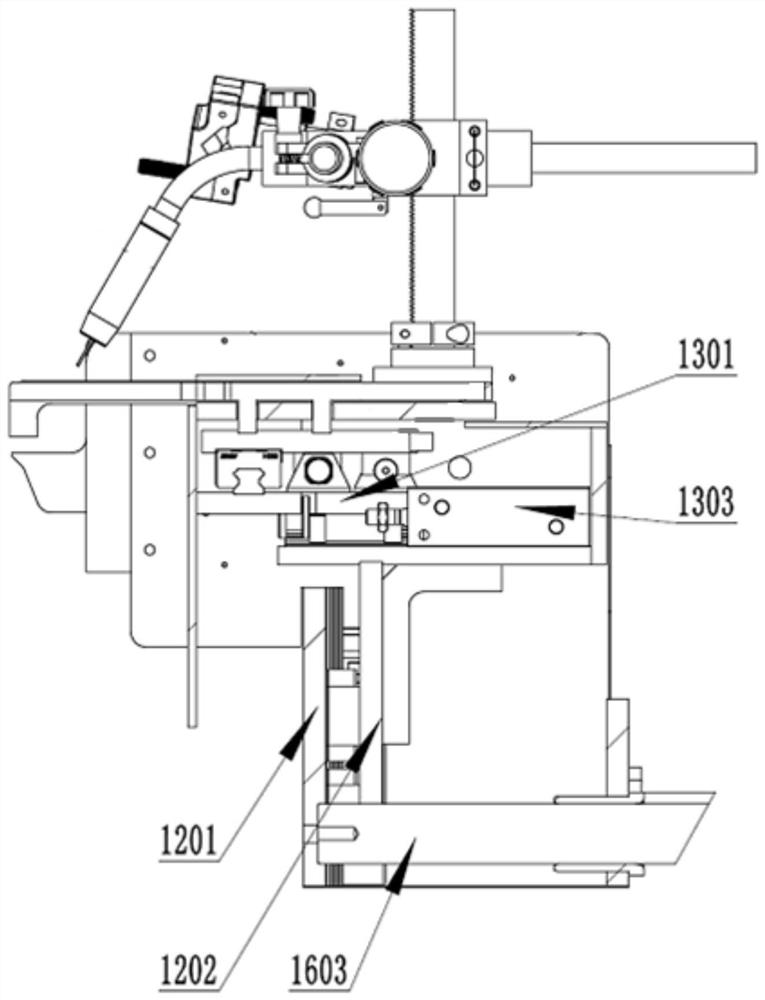

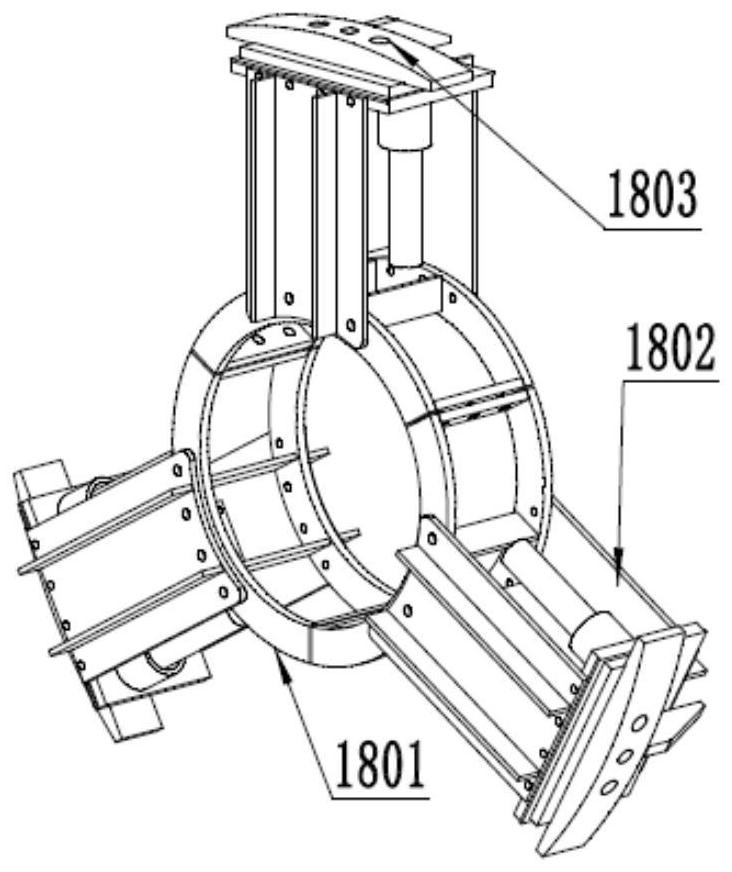

Welding head for welding inner ring and main reinforcement of reinforcement cage

PendingCN112192080APrecise alignmentReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringContact position

The invention discloses a welding head for welding an inner ring and a main reinforcement of a reinforcement cage. The welding head comprises a head body, a main reinforcement fixing device, an innerring position detecting mechanism and a welding gun chuck, wherein the main reinforcement fixing device, the inner ring position detecting mechanism and the welding gun chuck are arranged on the headbody; the main reinforcement fixing device is used for fixing the main reinforcement; the inner ring position detecting mechanism is used for detecting the position of a welding spot for welding the inner ring and the main reinforcement of a reinforcement cage framework; and the welding gun chuck is used for mounting a welding gun. The welding head can automatically take and compress the main reinforcement, realizes automatic welding, and is stable in welding spot, high in welding quality and high in production efficiency; and the inner ring position detecting mechanism can automatically detect the contact position of the inner ring and the main reinforcement, so that the labor intensity of workers is reduced, and the welding is quickly and accurately performed.

Owner:成都华研机器设备有限公司

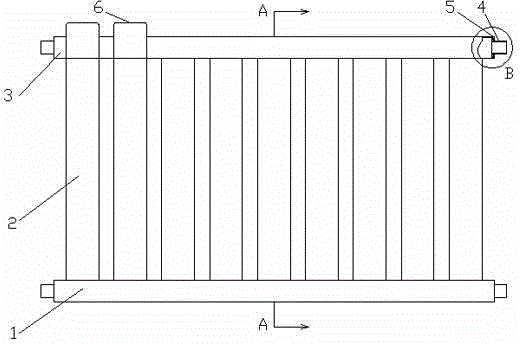

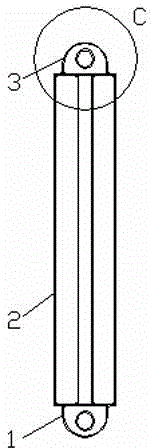

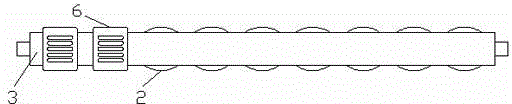

Double-column radiator and manufacturing method thereof

ActiveCN104896570AImprove cooling effectCoordinated and beautiful appearanceLighting and heating apparatusSpace heating and ventilation detailsEngineeringWelding

The invention discloses a double-column radiator and a manufacturing method thereof. The double-column radiator of the invention comprises a lower beam, an upper beam and radiating pipes, wherein the upper beam and the lower beam have the same structure, and each of the upper beam and the lower beam comprises an upper cover and a bottom plate; the upper covers and the bottom plates are welded together through two abreast radiating pipes; connecting water nozzles are arranged on two ends of the upper beam and the lower beam, and are fixedly connected with the upper beam and the lower beam through nozzle sealing plates. The double-column radiator has no weak points in lateral connection and has high strength; when mounting, a colorful cap is mounted on the upper beam, so that the radiating effect of the radiator is improved and the integral appearance is more coordinated and attractive; when manufacturing, the welding position is flat edge welding, so as to omit the polishing process, reduce the welding difficulty, shorten the production process, reduce the labor intensity of workers, ensure the welding quality and improve the yield.

Owner:圣劳伦斯(唐山)金属制品有限公司

Liquid crystal television set housing processing process

The present invention relates to a processing process, particularly to a liquid crystal television set housing processing process. In the existing liquid crystal television set housing processing, a stiffener member affects the whole television set housing appearance. Based on the problem in the prior art, a liquid crystal television set housing processing process is provided. The liquid crystal television set housing comprises a front frame and a rear shell, wherein the rear shell is further provided with a stiffener. The liquid crystal television set housing processing process is characterized by comprising the following steps: (1) respectively carrying out injection molding of a stiffener, a front frame and a rear shell; (2) placing the stiffener on a corresponding position of the rear shell, starting an ultrasonic welding machine, and tightly pressing when a contact position of the rear shell and the stiffener is melted so as to form an integrated body; and (3) assembling the front frame and the rear shell into the television set housing. With the technical scheme, the welding point between the stiffener and the rear shell is firm, no damage on the rear shell is generated, the whole television set housing appearance is beautiful, operation of the process method is simple, and production efficiency is high.

Owner:WUXI DAYAN TECH

Zinc-aluminum-copper-titanium-neodymium spray coating alloy solder and method of manufacturing the same

ActiveCN101318270BLow costExtended service lifeWelding/cutting media/materialsSoldering mediaTin platingSpray coating

The invention relates to a metalizing mylar capacitor metal educing surface alloy solder which is used for working under the environments of a ocean atmosphere zone, a tide range zone and a salt-spray zone, in particular to a zinc aluminum copper titanium neodymium spraying alloy solder and a preparation method thereof. The weight parts of each chemical composition in the solder are as follows: aluminum (Al), 2 to 7; copper (Cu), 0.5 to 1.0; titanium (Ti), 0.05 to 1.5; neodymium (Nd), 0.05 to 0.5; and remaining zinc (Zn). The zinc aluminum copper titanium neodymium spraying alloy solder of the invention has the advantages that the alloy solder has good wetting property with the electrode layer on the end surface of the capacitor metalizing mylar chip and is strong in adhesive force; the metal educing surface formed by the spraying process is good in conductivity, high in mechanical strength and firmly welded with metal pins of the capacitor and when the pins are kovar wire or iron wire nickel plating and tin plating alloys, welding can be carried out by using halogen-free organic soldering flux, and especially when the capacitor works under the severe environment of moist salt-fogcorrosion, the alloy solder still keeps high reliability.

Owner:BEIJING XINLI MACHINERY

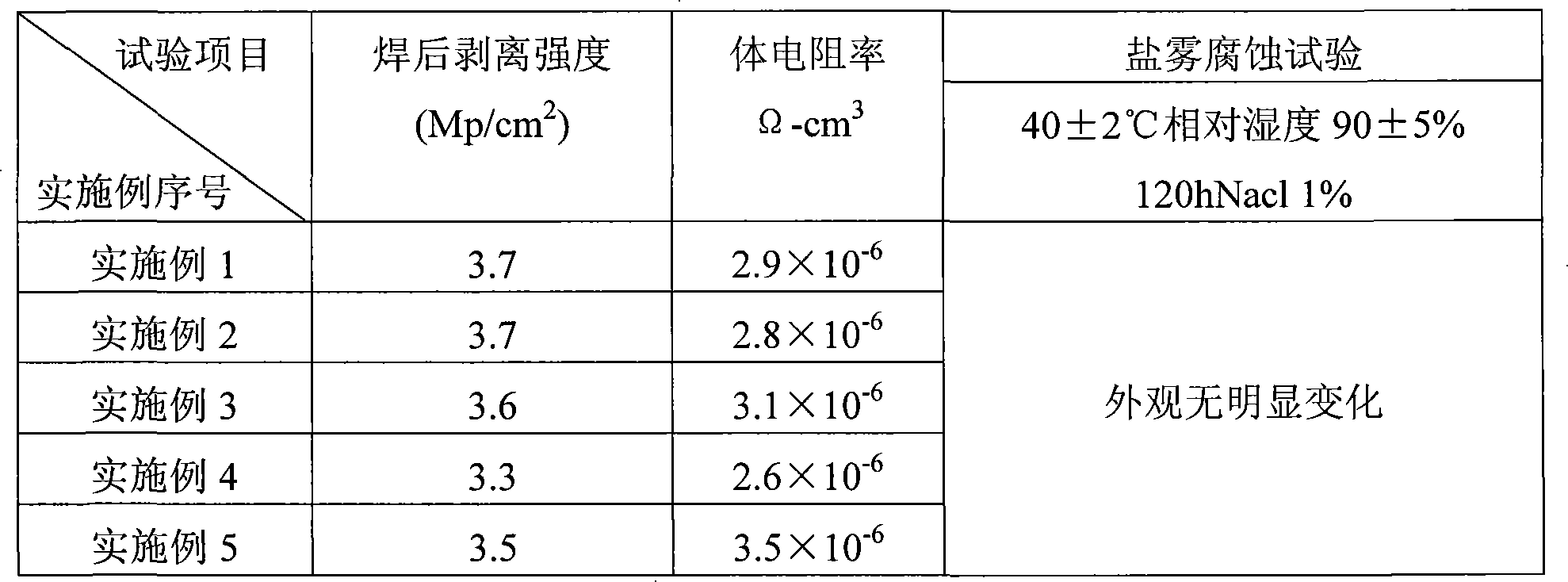

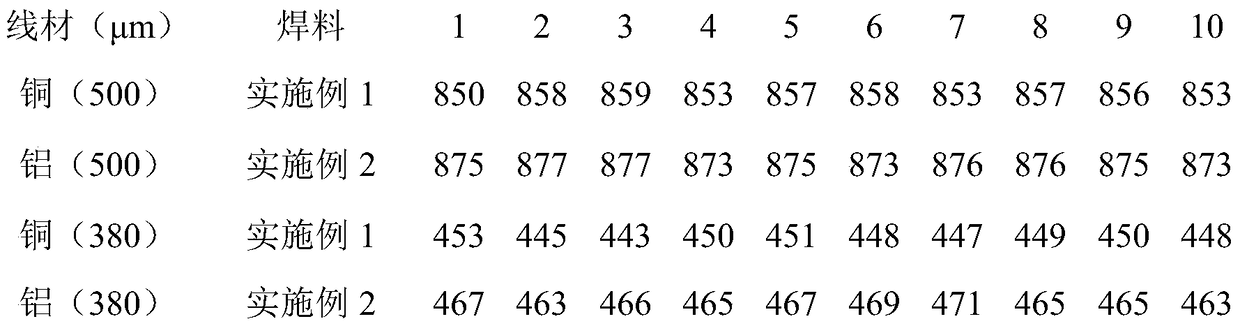

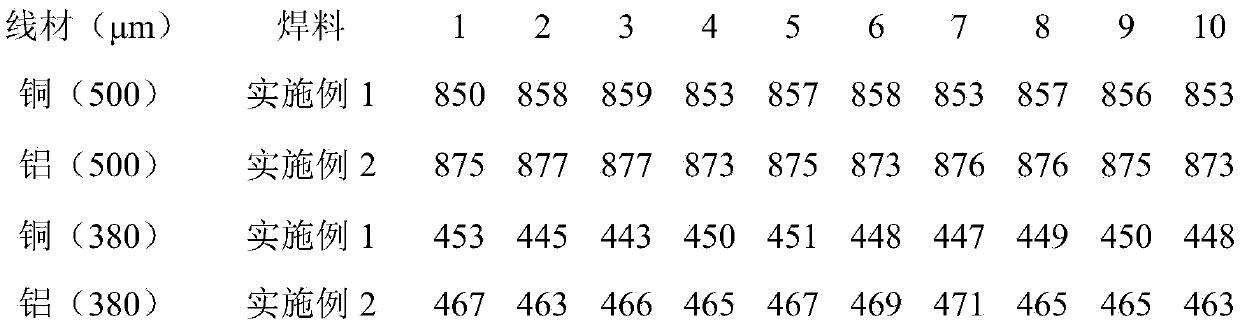

A kind of lead solder solder for semiconductor power device packaging and its preparation method and application

ActiveCN105499829BFirmly connectedAvoid heat damageSolid-state devicesWelding/cutting media/materialsManufacturing technologyCopper

The invention discloses lead welding brazing filler metal for packaging of a semiconductor power device and a preparation method and application thereof, and belongs to the technical field of packaging and manufacturing of semiconductor power devices. The brazing filler metal is brazing filler metal for a copper or aluminum lead; the brazing filler metal for the copper lead (wt.%) comprises 20-29% of Cu, 10.0-20.0% of Al, 2.0-11.0% of Ag, 2.0-5.0% of Bi, 3.0-9.0% of Sb, 3.0-9.0% of In and the balance of Sn; and the brazing filler metal for the aluminum lead (wt.%) comprises 21.0-29.0% of Cu, 18.0-27% of Al, 2.0-9.0% of Ag, 2.0-3.5% of Bi, 6.0-8.0% of Sb, 6.0-8.0% of In and the balance of Sn. In a lead welding process of the brazing filler metal for packaging of the semiconductor power device, the welding temperature is 280-320 DEG C to directly melt and moisten an aluminum pad and a frame to realize stable and reliable connection among the three.

Owner:王伟

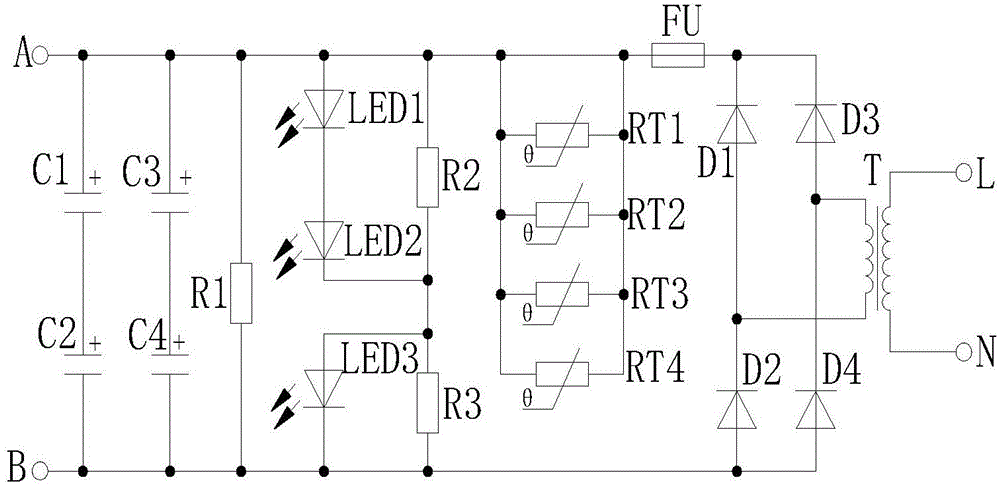

Low voltage point welding machine

InactiveCN104668754AGood value for moneySimple structureStorage discharge weldingCapacitanceElectrolysis

The invention discloses a low voltage point welding machine. The low voltage point welding machine comprises a first electrolysis capacitor, a second electrolysis capacitor, a third electrolysis capacitor, a fourth electrolysis capacitor, a first resistor, a second resistor, a third resistor, a first light-emitting diode, a second light-emitting diode, a third light-emitting diode, a first thermistor, a second thermistor, a third thermistor, a fourth thermistor, a fusible resistor, a first diode, a second diode, a third diode, a fourth diode, and a transformer. When the power supply is connected and the low voltage point welding machine is not used, the electrolysis capacitors are charged, and the light-emitting diodes are lighten up. During welding, the electrolysis capacitors discharge, the light-emitting diodes are turned off, and the charge and discharge durations are very short. The low voltage point welding machine is applicable to welding small and intermediate work pieces; and the low voltage point welding machine has the advantages of secure in welded points as well as high in safety. The whole circuit is simple in structure. Few elements are used. The low voltage point welding machine is low in manufacturing cost, high in cost performance, convenient for mass production, wide in application range, and has a value to be popularized.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

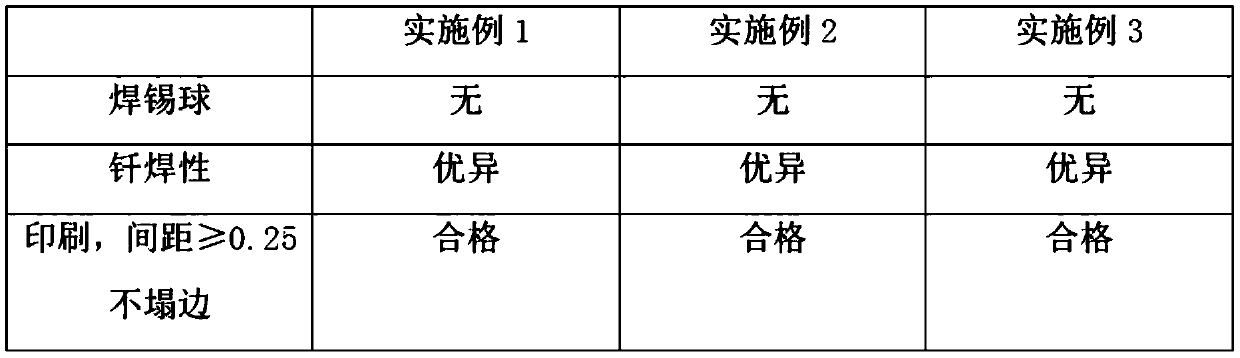

A special solder paste for aluminum welding and its preparation method and use method

ActiveCN108213766BHigh strengthImprove plasticityWelding/cutting media/materialsSoldering mediaActive agentSurface-active agents

Owner:中山翰华锡业有限公司

A method of manufacturing a steel cage

ActiveCN112355452BStrong solder jointsImprove welding qualityWelding with roller electrodesRebarAutomatic processing

The invention discloses a manufacturing method of a reinforcement cage, which includes a welding mechanism for winding and welding the reinforcement around the reinforcement, a feeding mechanism for feeding the main reinforcement, a central rotating assembly for rotating the inner ring, and a center rotating assembly for fixing the inner ring. The fixed inner ring assembly also includes a detection mechanism for detecting and positioning the length of the main reinforcement, and a main reinforcement welding mechanism for welding the main reinforcement. From the loading, welding and unloading of the steel cage, the present invention realizes automatic processing, and the solder joints of the steel cage are stable, so that the welding quality of the steel cage is stable, reducing manpower input and labor intensity of workers, and greatly improving the quality of steel bars. Cage production efficiency, and can produce steel cages of different specifications.

Owner:成都华研机器设备有限公司

Welding device for metal structural part

ActiveCN114101988ANo manualImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftClassical mechanics

The invention discloses a welding device for metal structural parts, which comprises a sliding bed, a welding device is arranged on the lower surface of the sliding bed, the welding device comprises a driving shaft rotationally connected to the sliding bed, a rotating block is fixedly connected to the lower surface of the driving shaft, and a sliding rod is slidably connected to the upper limit of the rotating block. The end, close to the length limiting rod, of the sliding rod is fixedly connected with a first connecting block, the outer wall, located between the rotating block and the first connecting block, of the sliding rod is sleeved with a first spring, the connecting block is rotationally connected with a sliding base through a fixed shaft, the sliding base is slidably connected with the length limiting rod, and a welding gun head used for welding is arranged on the lower surface of the sliding base. The upper surface of the sliding bed is fixedly connected with a servo motor capable of driving the driving shaft to rotate. The welding device further comprises a rectangular limiting device for limiting the welding device. According to the automatic welding device, full-automatic welding can be achieved, the welding efficiency is high, and welding spots after welding are more stable.

Owner:深圳亚士德科技有限公司

Lead-free solder paste

InactiveCN105127612AEvenly dispersedEasy to solderWelding/cutting media/materialsSoldering mediaSolder pasteTin

The invention discloses lead-free solder paste which comprises the following components: 80 parts of tin powder, 6 parts of silver powder, 3 parts of copper powder, 6 parts of tin-silver alloy, 4 parts of tin-copper alloy and 1 part of scaling powder. With the adoption of the lead-free solder paste provided by the invention, the advantages of uniform dispersion, high easiness in welding, high firmness in welding spots, long service life, stable performance, extensive sources and high safety in use and the like are achieved, and a wide market prospect in popularization of lead-free solder paste is further achieved.

Owner:SUZHOU LOTTE CHEM TECH

Electric connector and wire connecting method thereof

ActiveCN101989726BAvoid breakingImprove connection strengthLine/current collector detailsSoldered/welded conductive connectionsEngineeringElectrical connector

The invention discloses an electric connector and a wire connecting method thereof. The connecting method comprises the step of connecting socket wires or plug wires and comprises the following concrete steps: strengthening the end parts of wires; welding and protecting each wire after the end parts of the wires are welded with a socket or a plug; and protecting the integrated wires connected with the socket or the plug. The electric connector comprises a socket, a plug, a first wire cable and a second wire cable, wherein the first wire cable and the second wire cable are respectively connected with the plug or the socket; metal terminals are fixed at the end parts of the wires and are welded together with pins on the plug or the socket; a small thermal shrinkable sleeve is sleeved at the welding part of the wires; a big thermal shrinkable sleeve is sleeved outside the second wire cable; and the sheath of the first wire cable is clamped by a tail clamp of the plug. The connecting method of the invention can enhance the connecting strength, can enhance the tensile resistance and the torsion resistance, and completely can ensure the reliability requirement of a reinforced computer. The electric connector of the invention has high connecting strength, tensile resistance and torsion resistance, and the wires can not be broken easily.

Owner:深圳市研祥智慧科技股份有限公司

Stepping laser welding device for welding resistance wires

PendingCN111250867AImprove welding qualityGuarantee stabilityWelding/cutting auxillary devicesAuxillary welding devicesGalvanometerMaterials science

The invention provides a stepping laser welding device for welding resistance wires. The stepping laser welding device for welding resistance wires comprises a laser welding machine, a galvanometer, afeeding guide device, a stepping feeding cylinder, a clamping device, a welding backing plate and a controller, wherein a welding object is an electrode frame strip; the controller is used for setting welding parameters and stepping feeding speed parameters of the laser welding machine; a to-be-welded section of the electrode frame strip is positioned on the welding backing plate, the clamping end of an electrode frame is positioned at the focus below the galvanometer, and the laser output by a welding laser machine is modulated by the galvanometer and then sequentially irradiates the clamping end of the electrode frame to weld the resistance wire to the electrode frame; and the clamping device moves forward under the driving of the stepping feeding cylinder after clamps the electrode frame strip, and meanwhile, the next section of the electrode frame strip is continuously fed into the range of the welding backing plate under the action of the feeding guide device. The stepping laserwelding device for welding resistance wires solves the key problems of weak welding spots and unstable resistance value, and improves the welding speed and the production efficiency.

Owner:北京凯米迈克科技有限公司

A fixture for welding the movable platform of the climbing car

ActiveCN104400291BWeld firmlyEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesVertical planeClassical mechanics

Owner:ZHEJIANG YANGMINGSI METAL PROD

Lead welding brazing filler metal for packaging of semiconductor power device and preparation method and application thereof

ActiveCN105499829AFirmly connectedAvoid heat damageSolid-state devicesWelding/cutting media/materialsManufacturing technologyCopper

The invention discloses lead welding brazing filler metal for packaging of a semiconductor power device and a preparation method and application thereof, and belongs to the technical field of packaging and manufacturing of semiconductor power devices. The brazing filler metal is brazing filler metal for a copper or aluminum lead; the brazing filler metal for the copper lead (wt.%) comprises 20-29% of Cu, 10.0-20.0% of Al, 2.0-11.0% of Ag, 2.0-5.0% of Bi, 3.0-9.0% of Sb, 3.0-9.0% of In and the balance of Sn; and the brazing filler metal for the aluminum lead (wt.%) comprises 21.0-29.0% of Cu, 18.0-27% of Al, 2.0-9.0% of Ag, 2.0-3.5% of Bi, 6.0-8.0% of Sb, 6.0-8.0% of In and the balance of Sn. In a lead welding process of the brazing filler metal for packaging of the semiconductor power device, the welding temperature is 280-320 DEG C to directly melt and moisten an aluminum pad and a frame to realize stable and reliable connection among the three.

Owner:王伟

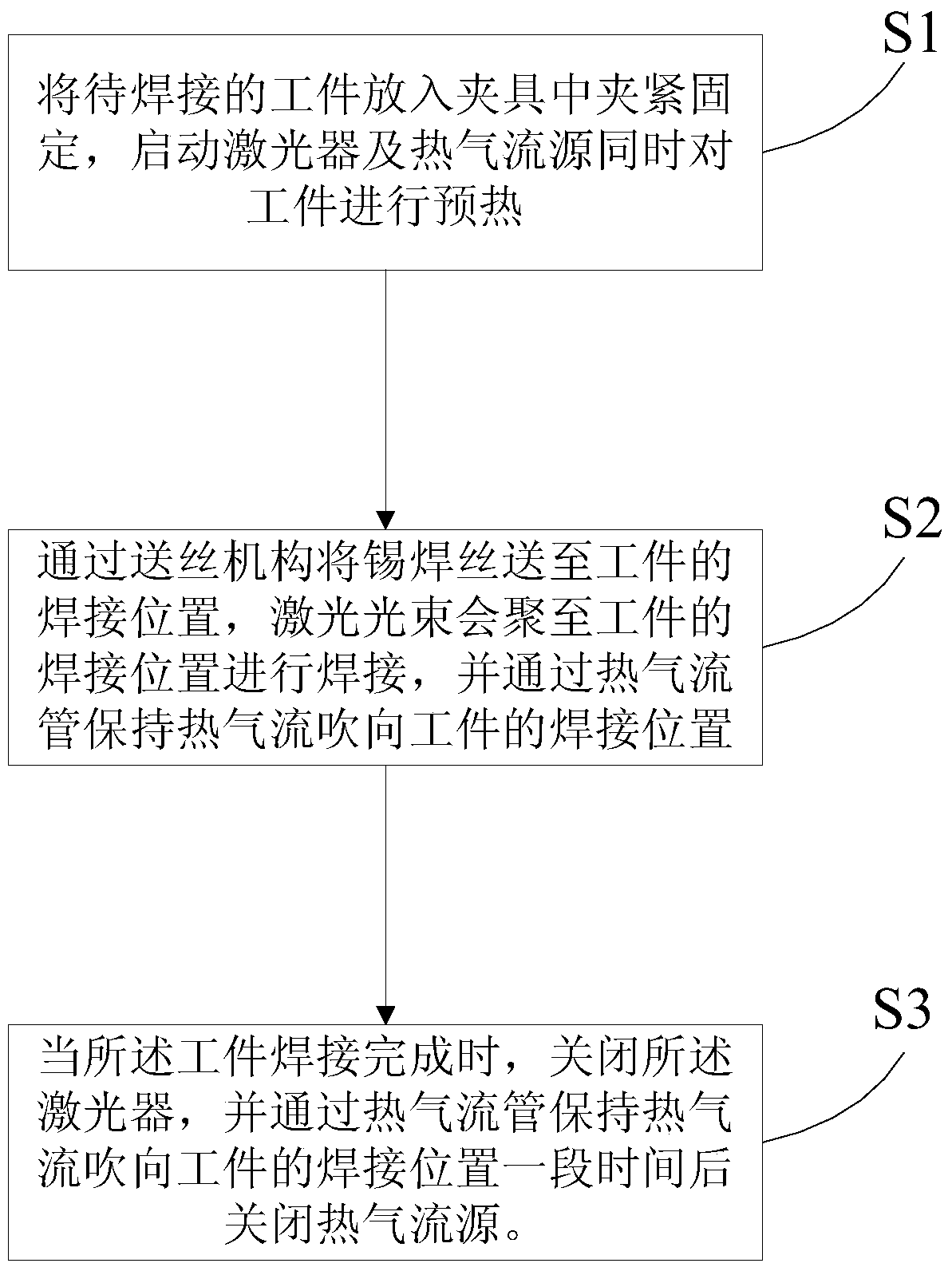

Laser soldering device and welding method

The invention provides a laser tin soldering device and a soldering method. The laser tin soldering device comprises a clamp used for clamping a to-be-soldered workpiece, a laser device, a collimation head connected to the laser device, a charge coupled device (CCD) adjusting microscope base and a focusing head. One end of the collimation head is connected to the laser device through an optical fiber, and the other end of the collimation head is connected to the CCD adjusting microscope base; a CCD lens is disposed at the top end of the CCD adjusting microscope base; the bottom end of the CCD adjusting microscope base is connected to the focusing head; a hot air blowing assembly capable of performing relative rotation is connected to the CCD adjusting microscope base. By means of the laser tin soldering device and the soldering method, large-area heat can be provided, and splashing due to non-uniform heating of tin paste during soldering is effectively avoided; meanwhile, hot air flow can accelerate the flowing of liquid tin, so that the working efficiency and stability of soldering are improved; volatilization of scaling powder can be accelerated, so that solder points are firmer and more attractive.

Owner:HANS LASER TECH IND GRP CO LTD

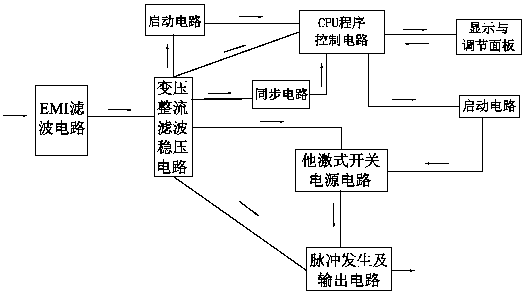

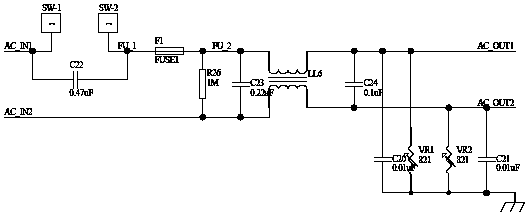

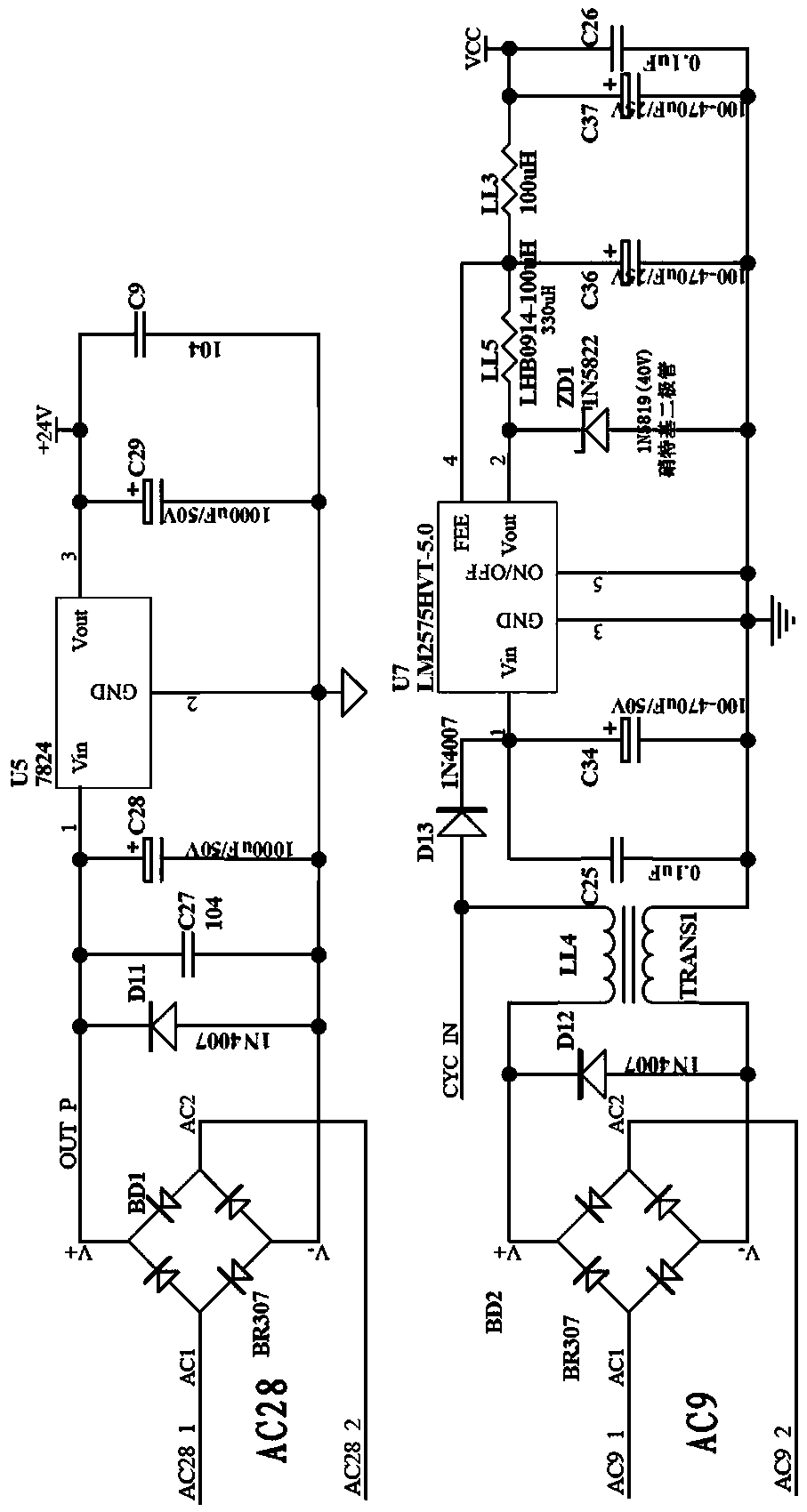

Spot welding machine control system

ActiveCN105414731BImprove anti-interference functionStable jobWelding electric supplyEngineeringSwitching power

The invention discloses a spot welding machine control system, comprising an EMI filtering circuit, a voltage transformation rectifying filtering voltage stabilizing circuit, a synchronous circuit, a CUP program control circuit, a starting circuit, a drive circuit, a separately excited switching power supply circuit, and a pulse generation and output circuit. The IN1 and IN2 of the EMI filtering circuit access AC380V voltage, and through a filter LL6, the voltage is output to a control transformer through an OUT1 and an OUT2. Through the voltage transformation rectifying filtering voltage stabilizing circuit, the voltage is transformed to AC28V and AC9V, and through rectification, filtering, and voltage stabilization, DC5V and DC24V are output to an operating circuit to supply power. The system is advantaged by simple structure, complete functions, and convenient adjustment. Net voltage automatic compensation and high anti-interference functions make the controller can reliably and stably operate in environment of unstable power grid voltage and high-strength electromagnetic interference. A current slowly-rising function effectively restricts welding spark from splattering, and welding spots are firmer.

Owner:佛山市佛镁通用设备有限公司

A method of using a welding protection device for an air-conditioning liquid reservoir

ActiveCN106270915BAvoid oxidation and blackeningAvoid contactGas flame welding apparatusSurface oxidationEngineering

The invention discloses an air conditioner liquid storage device welding protection device and an application method thereof, and belongs to the technical field of welding. The air conditioner liquid storage device welding protection device comprises an outer ventilation block and an inner ventilation block. The outer ventilation block is of a rectangular block-shaped structure and is provided with a transverse air blowing hole and longitudinal air blowing holes and connected with an air source through an outer ventilation connecting hole. An inner air blowing hole is formed in the inner ventilation block and connected with the air source through an inner ventilation connecting hole. According to the method, a cylinder is inflated with protection air through the inner ventilation block in the welding process, the welding position is immediately inflated with the protection air through the outer ventilation block after welding is finished, and air is prevented from making contact with a welding line. By means of the air conditioner liquid storage device welding protection device and the application method thereof, the surface of a welded part can be prevented from being oxidized during liquid storage device welding, the connecting strength of the welding line is improved, the quality of a finished product is improved, and the production cost is reduced.

Owner:ANHUI ZHONGHUI REFRIGERATION

Power capacitors with good heat dissipation performance

ActiveCN104465095BIncrease the flow cross sectionLow calorific valueMultiple fixed capacitorsFixed capacitor housing/encapsulationCapacitanceEngineering

The invention relates to a power capacitor with good heat dissipation performance, which includes a cover plate assembly, a casing and a capacitor core group. The capacitor core group is formed by superimposing several cylindrical capacitor cores, and the lead-out copper strip is arranged on the gold-sprayed surface of the capacitor core group. , the coverage area on both sides of the lead-out copper strip extends at least to the central area of the gold-sprayed surface of the capacitor core located on both sides of the capacitor core group, and the lead-out copper strip has a through hole or an opening in the center of the gold-sprayed surface of each capacitor core A groove on one side of the lead-out copper strip has elastic fins extending into the through hole or groove for electrical connection with the gold-sprayed surface by welding. By enlarging the width of the lead-out copper strip, the current can pass through evenly and the calorific value can be reduced. Moreover, the area of the lead-out copper strip is also doubled, and the heat dissipation performance is significantly enhanced.

Owner:ANHUI TONGFENG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com