Manufacturing method of reinforcement cage

A manufacturing method and steel cage technology, applied in the direction of manufacturing tools, roller electrode welding, welding equipment, etc., can solve the problems of low efficiency of steel cage welding, unstable welding quality, etc., to improve the scope of use, stable welding quality, The effect of easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A method for making a reinforcement cage, comprising the steps of:

[0076] S3. The length of the main reinforcement is detected by the detection mechanism. If the length of the main reinforcement does not meet the preset length value, the main reinforcement is removed from the detection mechanism: if the length of the main reinforcement meets the preset length value, the detection mechanism moves the main reinforcement to the predetermined position of the main reinforcement;

[0077] S4. The main reinforcement welding mechanism clamps the main reinforcement from the detection mechanism. After the detection mechanism and the main reinforcement are disengaged, the main reinforcement welding mechanism moves the main reinforcement from the detection station to the welding station;

[0078] S5. Determine whether the number of main ribs satisfies the set value, if the number of main ribs does not meet the predetermined value, repeat the step of feeding the main ribs; if the n...

Embodiment 2

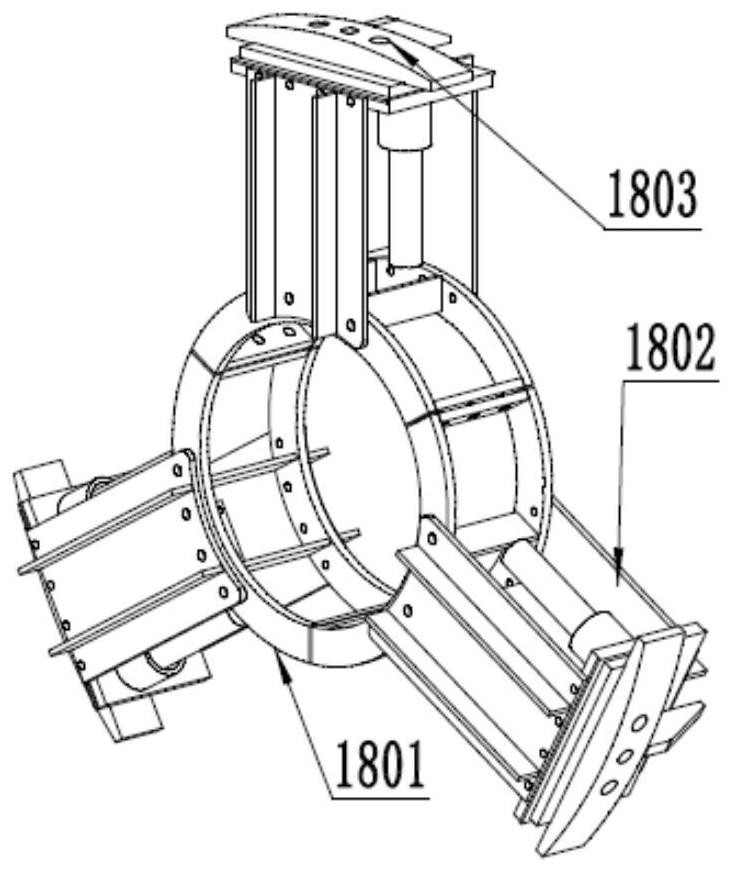

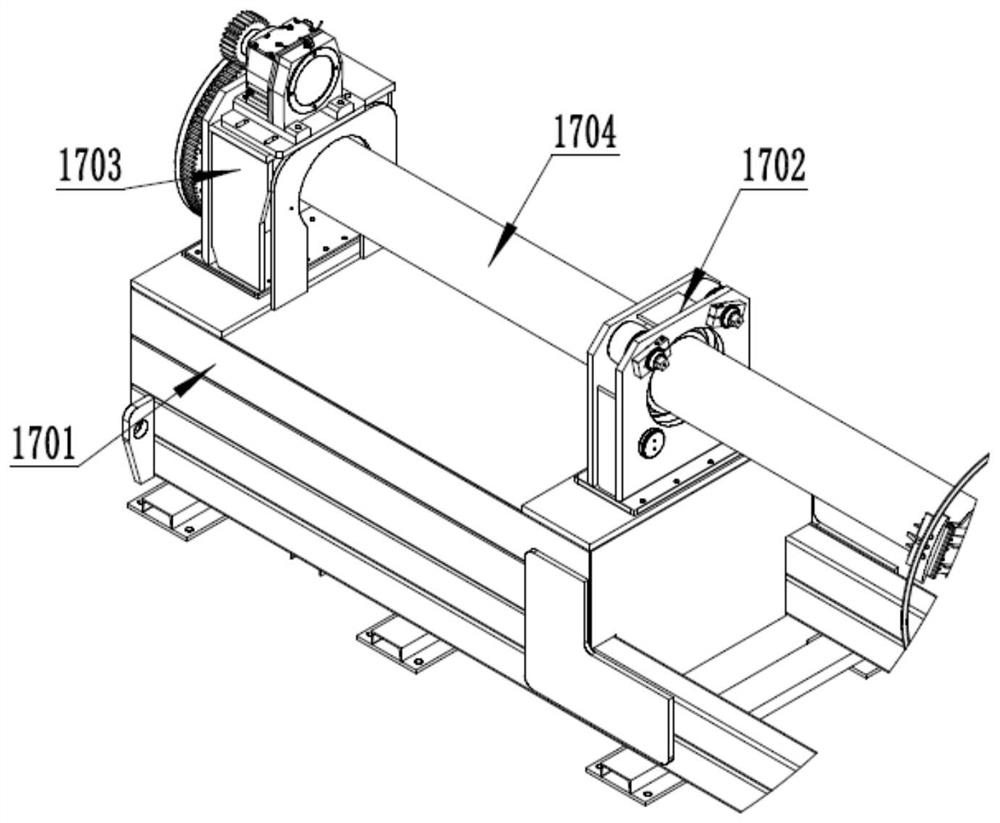

[0091] Such as Figure 1-10 As shown, in step S1, the inner ring fixing assembly includes a clamping hoop 1801 installed on the central shaft 1704, several connecting pieces 1802 fixedly connected with the clamping hoop 1801, and also includes a The connected supporting and fixing block 1803 slides along the connecting piece 1802 through the supporting hydraulic cylinder. In this embodiment, the number of connecting pieces 1802 is three, and each connecting piece 1802 is provided with a supporting and fixing block 1803, and the supporting and fixing block 1803 and the connecting piece 1802 adopt a guide shaft mechanism to realize sliding connection. Further, the connecting piece 1802 adopts It is composed of two flat plates parallel to each other, and the same end of the two plates is vertically fixedly connected with a flat plate to form a U-shaped structure. The supporting and fixing block 1803 is arranged on the U-shaped closed section, and the supporting hydraulic cylinder...

Embodiment 3

[0122] Such as Figure 1-15 As shown, in this embodiment, the base 1 is made of steel structure, the side of the base 1 is in the shape of "L", the roller mold assembly is located on the horizontal end of L, and the clamping assembly and the stopper 2 are respectively located on the roller mold assembly. Both ends; in this embodiment, the clamping assembly and the stopper 2 are installed on the roller mold assembly in a detachable manner, and the detachable method can be threaded connection, which is convenient for adjusting the position of the stopper 2 relative to the clamping assembly , can be applied to main bars of different specifications; the clamping component and the block 2 are equipped with parts for electrical conduction, when the main bar contacts with the stopper 2 and the clamping assembly at the same time, the length of the main bar can be detected by the electrical conduction And whether the main rib is in place.

[0123] The end stopper 201 is used to detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com