Welding device for metal structural part

A technology for metal structural parts and welding devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor quality of welding joints and low welding efficiency, and achieve stable welding points, improve efficiency, and improve welding action. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

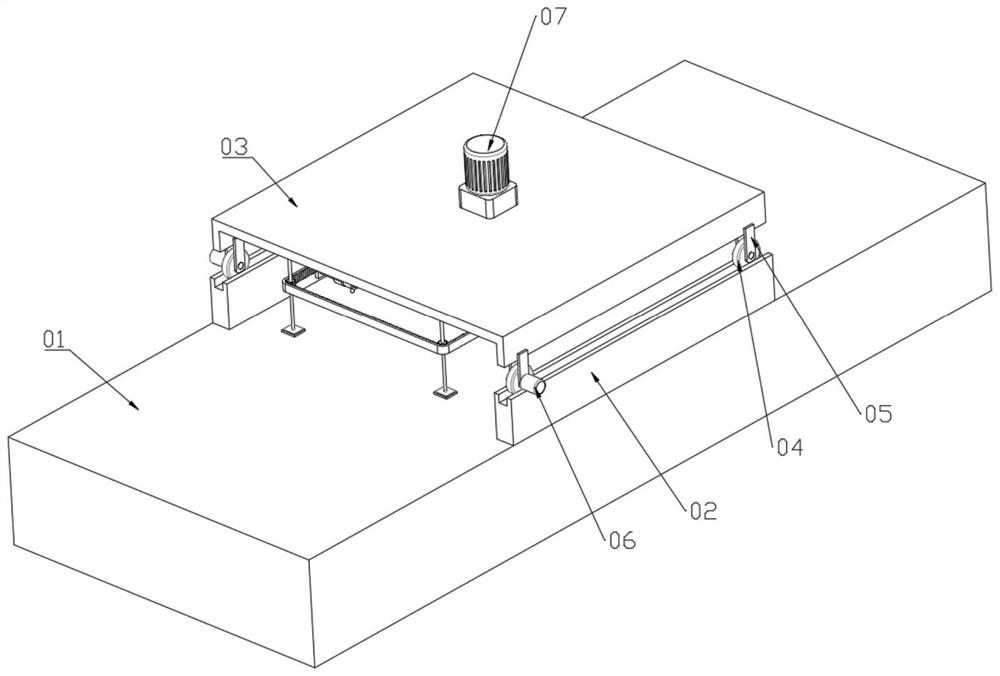

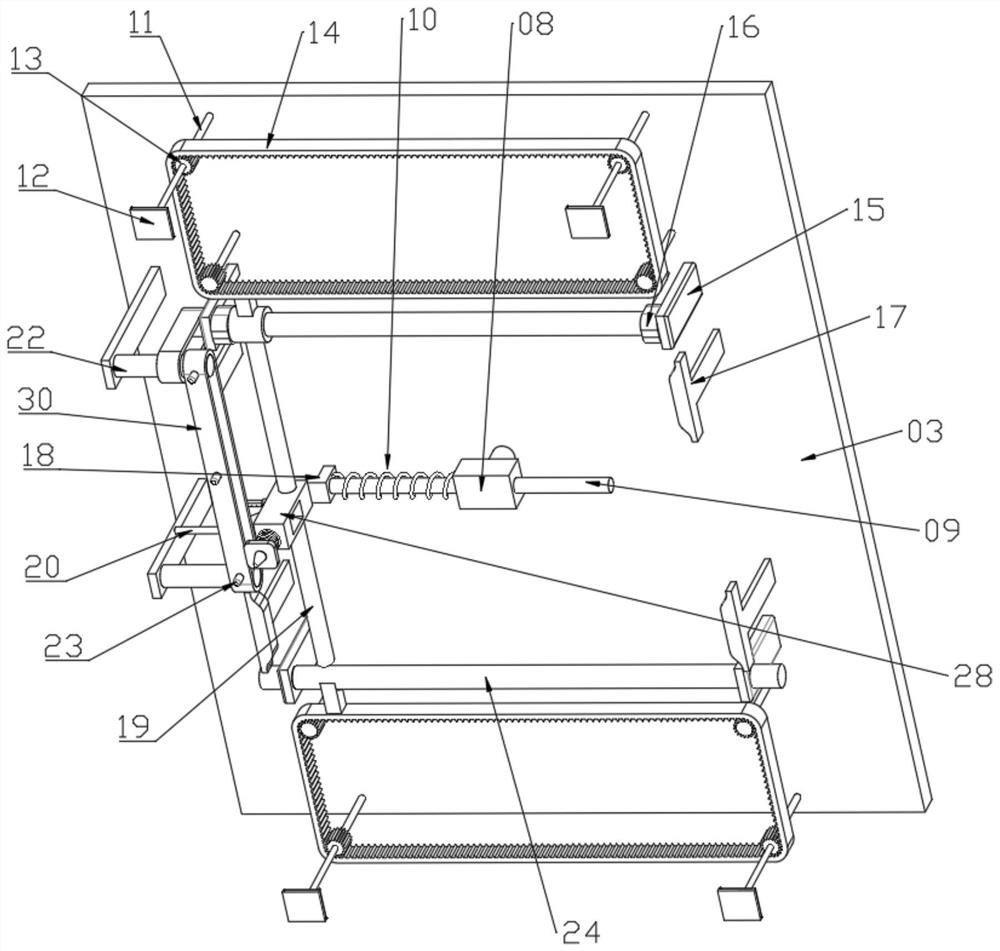

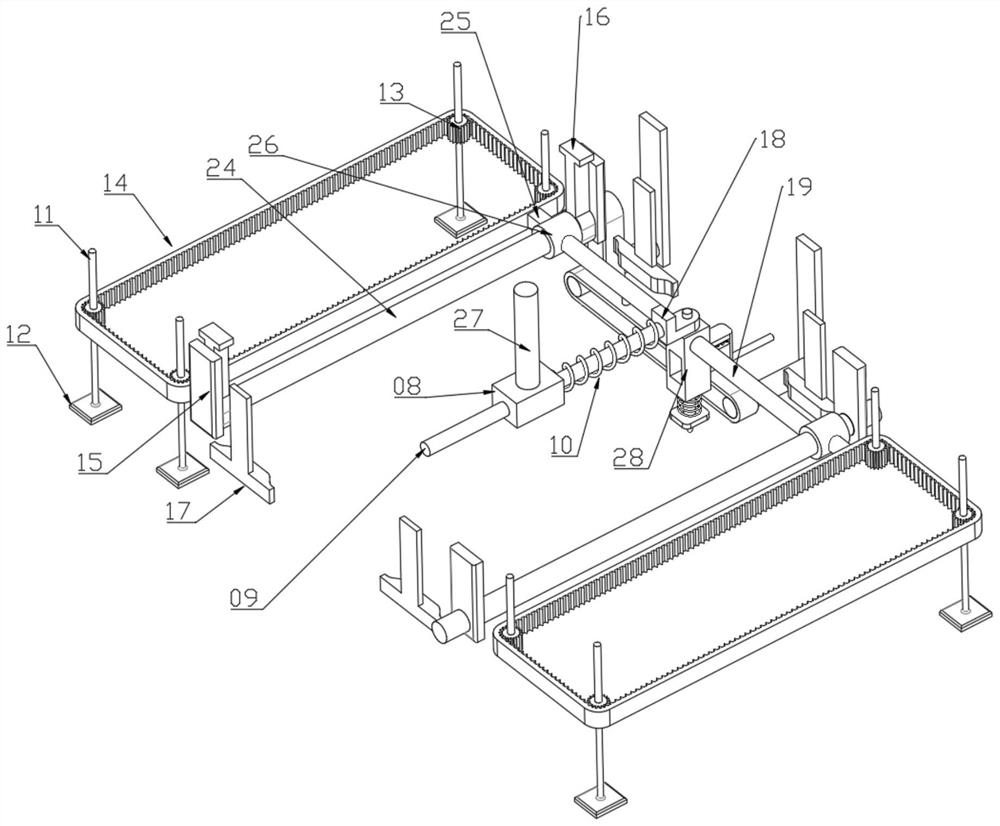

[0026] see Figure 1 to Figure 6 , a welding device for metal structural parts, including a sliding bed 03, the lower surface of the sliding bed 03 is provided with a welding device, the welding device includes a driving shaft 27 that is rotatably connected to the sliding bed 03, and the lower surface of the driving shaft 27 is fixedly connected with Rotating block 08, the upper limit of rotating block 08 is slidably connected with sliding rod 09, and one end of sliding rod 09 close to length limiting rod 19 is fixedly connected with connecting block 18, and the outer wall of sliding rod 09 is located in the outer wall sleeve between rotating block 08 and connecting block 18 A spring 10 is provided, and the connecting block 18 is fixedly rotatably connected with a sliding seat 28. The sliding seat 28 is slidably connected to the length-limiting rod 19. The lower surface of the sliding seat 28 is provided with a welding torch head 32 for welding, and the upper surface of the sli...

Embodiment 2

[0044] see Figure 7 As another embodiment of the post-welding processing device, the post-welding processing device includes a connecting block two 25 fixedly connected to the width-limiting rod 24 on the side away from the derusting device, and a toothed belt 14 is fixedly connected to the connecting block two 25, sliding The lower surface of the bed 03 is rotatably connected with a rotating rod 11, and the rotating rod 11 is fixedly connected with a gear 13. Four rotating rods 11 are arranged in a rectangular distribution, and the lower end of the rotating rod 11 is fixedly connected with a cylindrical cam 41. The lower surface of the sliding bed 03 The second mounting plate 40 is fixedly connected, and the lower end of the second mounting plate 40 is slidingly connected with a hammer rod 39. The lower end of the hammer rod 39 is provided with a part with a diameter larger than the whole body. The protruding rod 42 that moves up and down.

[0045] The driving principle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com