Cone yarn fetching delivery wagon

A technology for conveying vehicles and bobbins, which is applied in transportation and packaging, conveying filamentous materials, thin material processing, etc. It can solve the problems of cumbersome and error-prone processes, heavy labor, and high requirements for workers, so as to save labor and avoid classification The effect of making mistakes and improving the efficiency of production and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

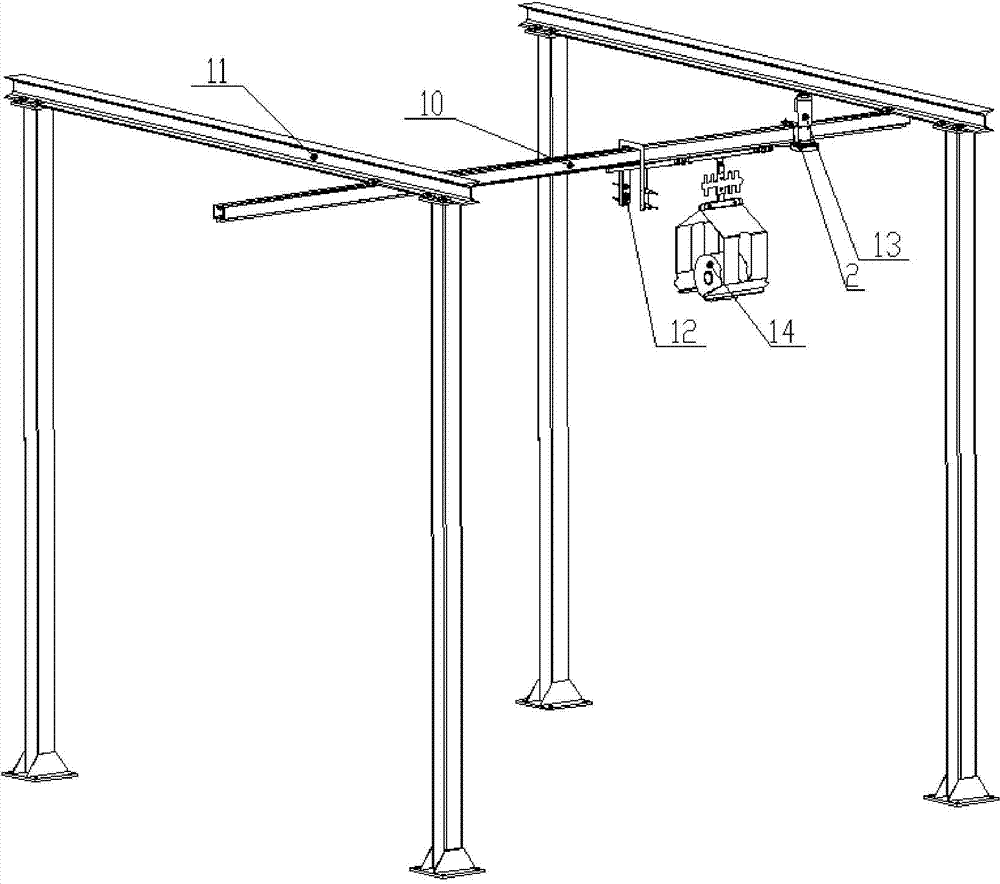

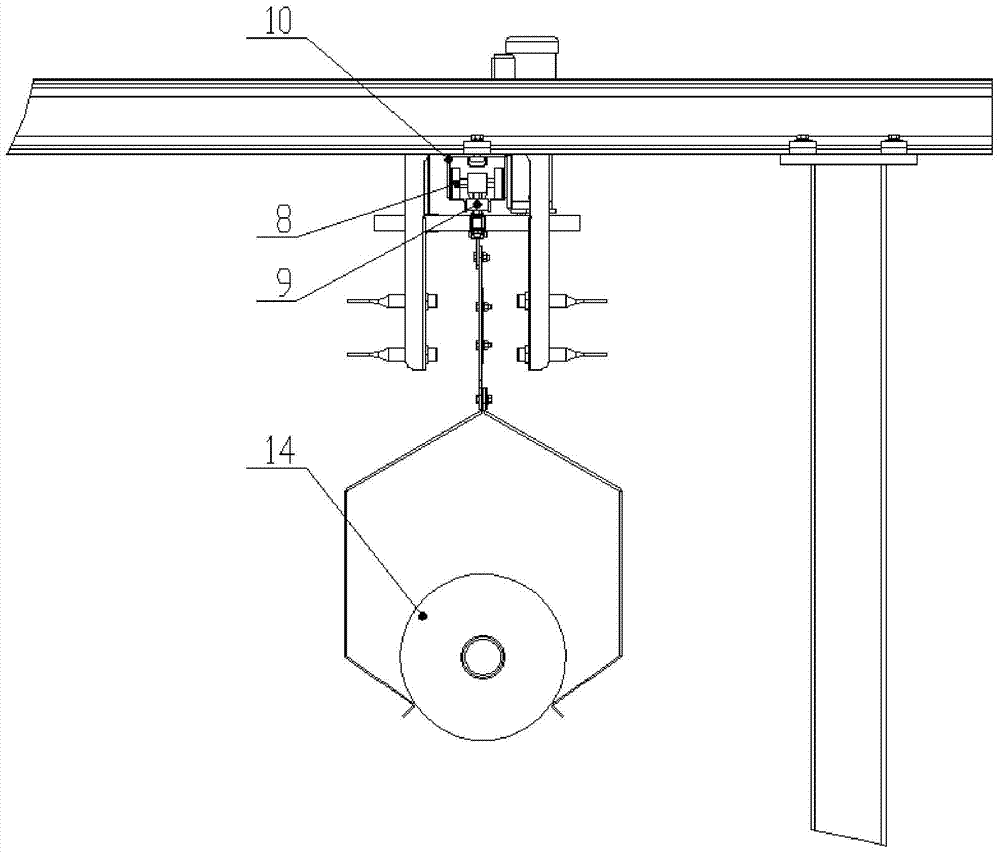

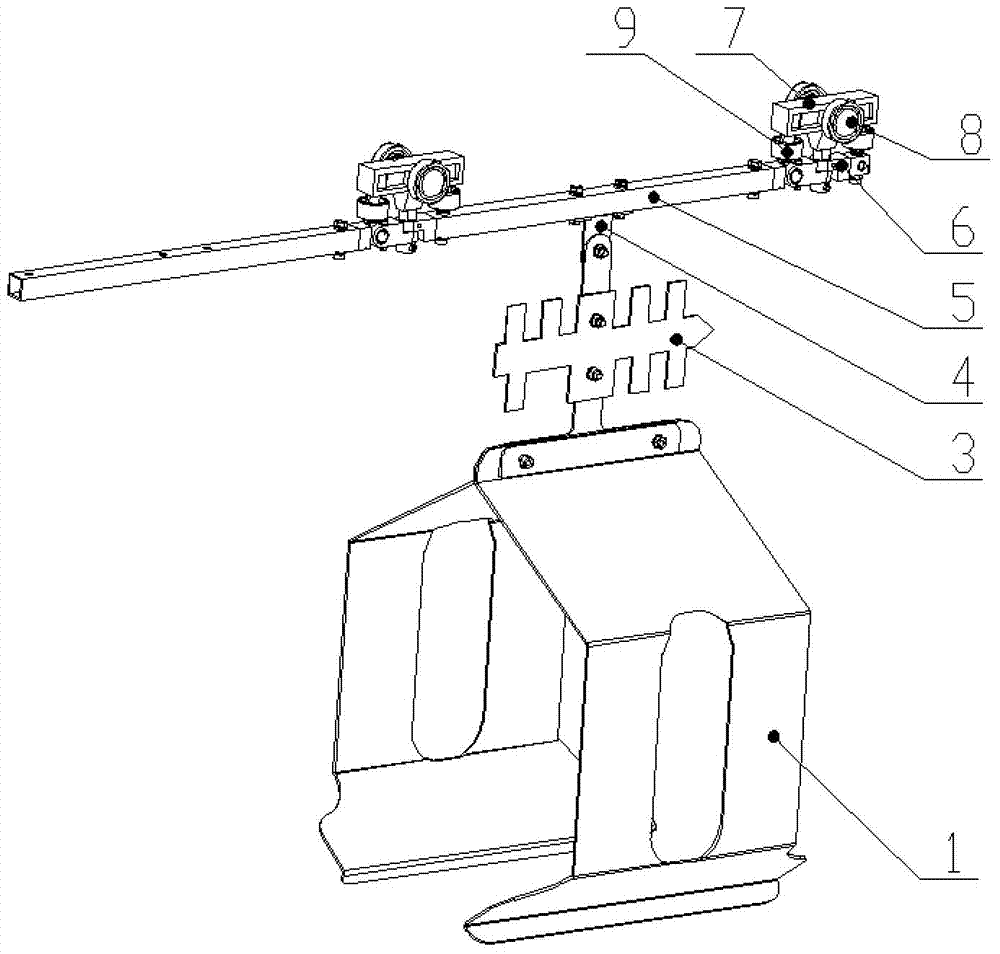

[0019] Embodiment: a bobbin grabbing and conveying vehicle, including a rail 10, a driving device, a conveying mechanism, a bobbin holder 1, a marking card 3, and an inductive identification device 12, wherein: the rail 10 runs through the bobbin production process and The location of the packaging process, the conveying mechanism can move along the extending direction of the track 10 and is positioned on the track 10, the driving device drives the conveying mechanism to move, a number of package yarn holders 1 are installed on the delivery mechanism, and the package yarn holder 1 forms a supply package 14. Stop the holding space for storage. The marking card 3 is installed on the bobbin holder 1. The marking card 3 is provided with a mark corresponding to the bobbin held on the bobbin holder 1. The induction identification device 12 is respectively installed on the At the position corresponding to the bobbin production process and packaging process on the track 10, the inducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com