Fish tofu conveying device

A conveying device, fish tofu technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., to achieve the effect of screening and separation, increasing efficiency, and enriching functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

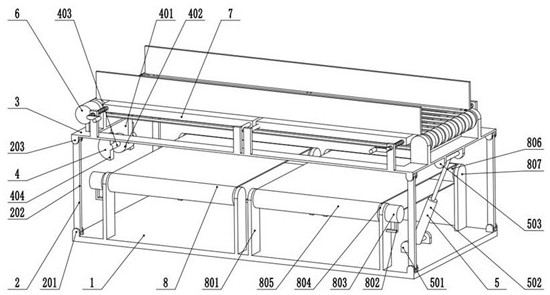

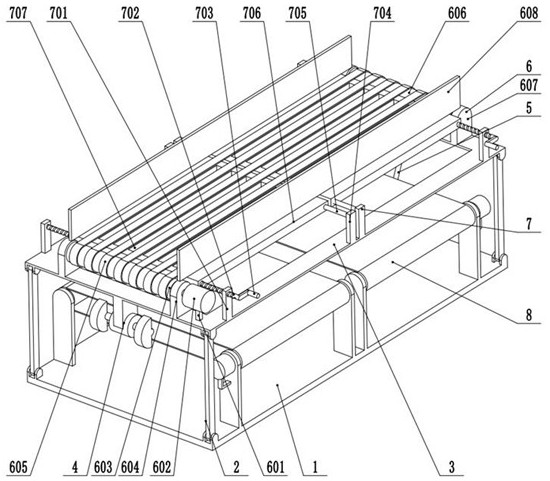

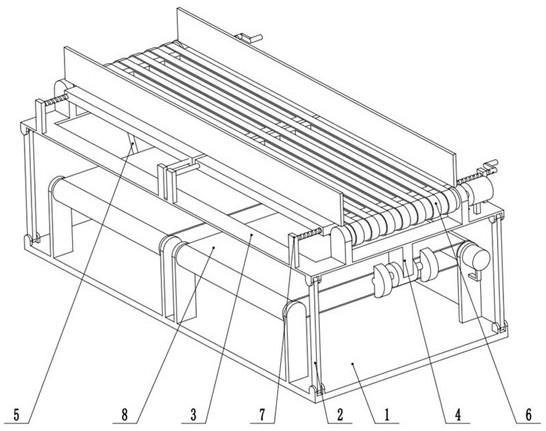

[0026] see Figure 1-7 , a fish tofu conveying device, comprising a base 1, the base 1 is fixedly connected to a connecting rod mechanism 2, the connecting rod mechanism 2 is fixedly connected to a mounting seat 3, the mounting seat 3 is fixedly connected to a vibration mechanism 4, and the base 1 and the mounting seat 3 are fixed between The telescopic mechanism 5 is connected, the mounting base 3 is fixedly connected to the main conveying mechanism 6 and the adjusting plate mechanism 7, and the base 1 is located below the main conveying mechanism 6 and is fixedly connected to the separating conveying mechanism 8;

[0027] The main conveying mechanism 6 includes a second motor bracket 601 fixed on the mounting base 3, the second motor bracket 601 is fixedly connected to the second motor 602, the output shaft of the second motor 602 is fixedly connected to the first main conveying wheel 603, and the first main conveying wheel 603 is rotatably connected to the first main convey...

Embodiment 2

[0036] see Figure 1-7, the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the separation and conveying mechanism 8 includes a first separation and conveying seat 801 fixed on the base 1, and the first separation and conveying seat 801 is fixedly connected to the third motor bracket 802, the third motor bracket 802 is fixedly connected to the third motor 803, the output shaft of the third motor 803 is fixedly connected to the first separation conveying wheel 804, the first separation conveying wheel 804 is rotatably connected to the first separation conveying seat 801, and the first separation conveying wheel 804 is drivingly connected to the separation conveyor belt 805, the separation conveyor belt 805 is drivingly connected to the second separation conveying wheel 806, the second separation conveying wheel 806 is rotatably connected to the second separation conveying seat 807, and the second separation conveying seat 807 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com