Shelling processing system for camellia seeds for preparation of camellia oil

A processing system and technology for camellia oilseeds, which are applied in the field of camellia oil to prepare camellia oilseed shelling processing systems, can solve the problems of reduced oil yield, low efficiency, failure to realize automatic shelling of camellia oilseeds, etc., and achieve complete protection. performance, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

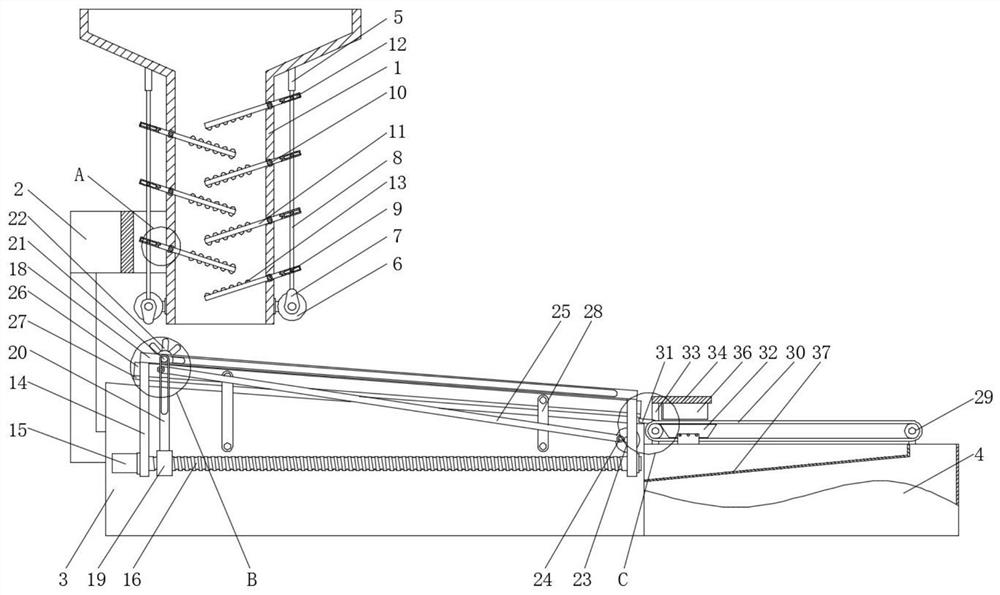

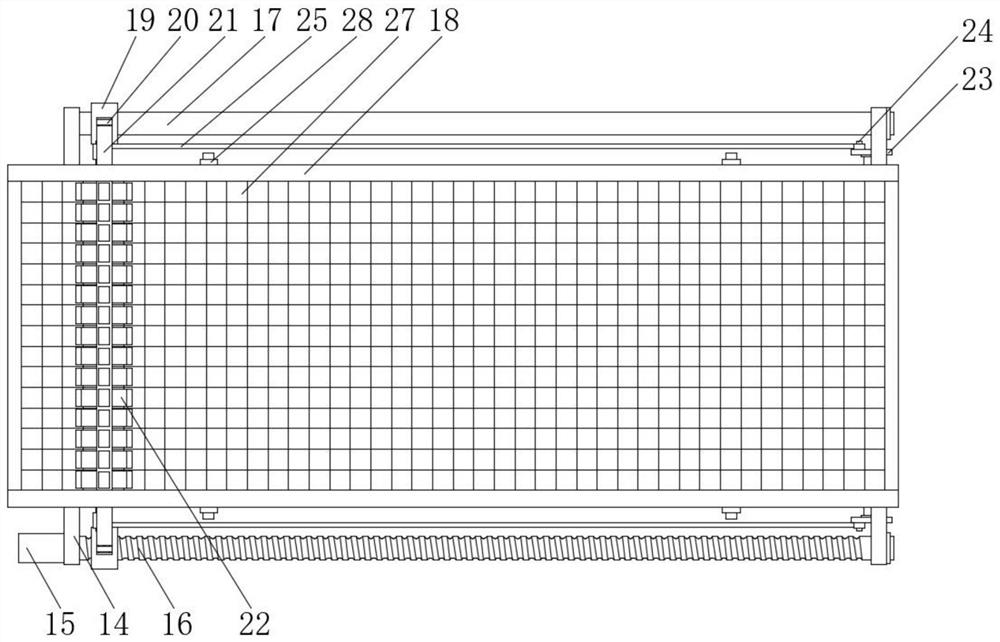

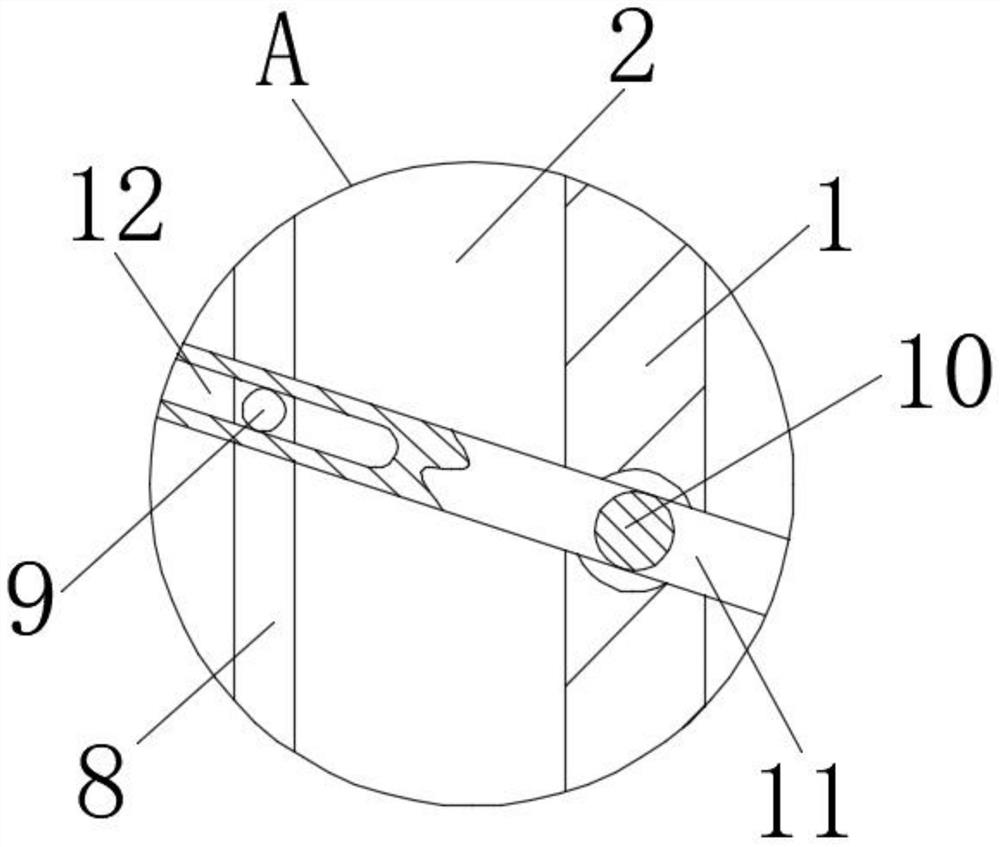

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0035] Such as Figure 1 to Figure 11 Shown, a kind of camellia oil prepares camellia oil seed shelling processing system, comprises feeding shelling device, primary screening device, secondary screening device and connecting arm 2, is characterized in that: feeding shelling device comprises shell 1. The primary screening device includes a tea oil seed collection box 3, and the secondary screening device includes a fruit shell collection box 4. The upper connection end of the connecting arm 2 is in the shape of a claw, and the front and back of the casing 1 are respectively connected to the connecting arm 2. The jaws are fixedly installed, the bottom end of the connecting arm 2 is fixedly installed with the left side of the tea oil seed collection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com