Full-automatic book and periodical shell feeding equipment

A fully automatic, book-making technology, which is applied in the direction of book casing, book binding, and book processing, can solve the problems of increasing manual labor intensity, affecting the efficiency of book casing processing, and taking a long time to process books. Achieve the effect of improving the operating efficiency of the upper shell, improving the stability, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

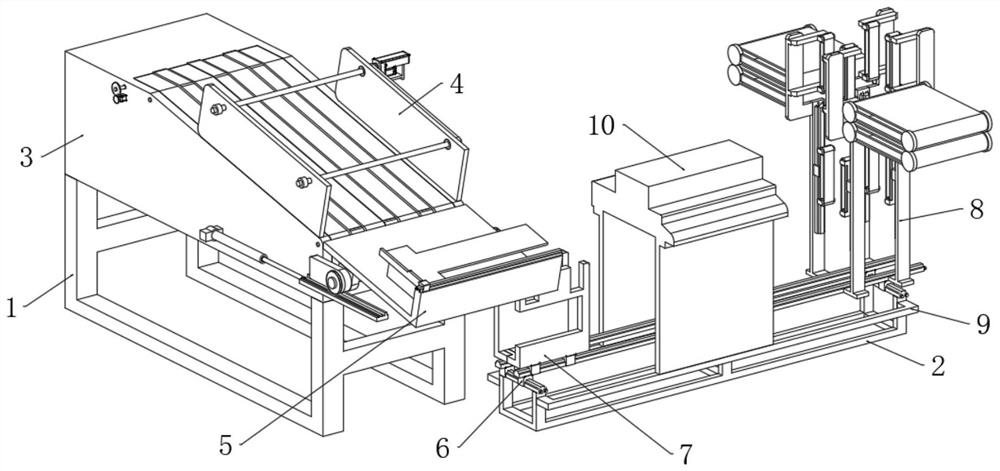

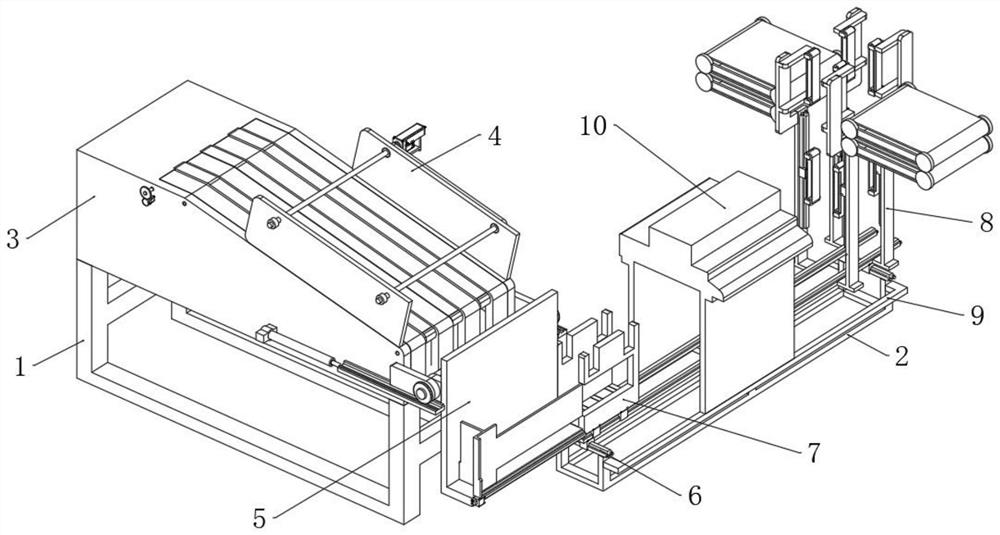

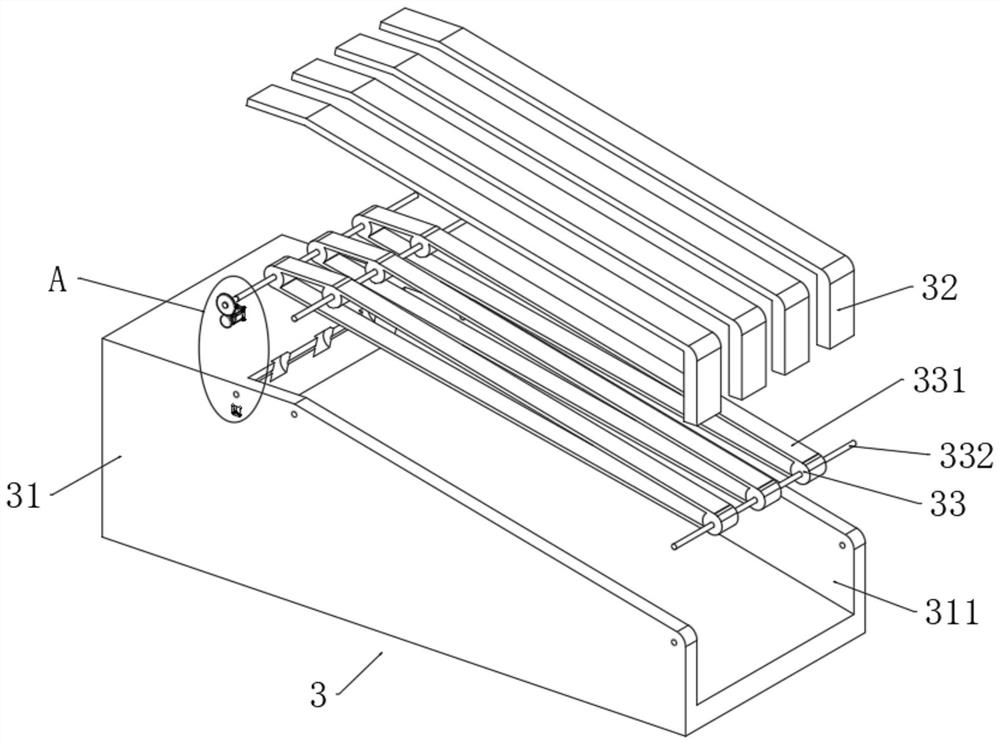

[0033] Example: such as Figure 1-Figure 9As shown, the present invention provides a fully automatic book loading equipment, including a first support 1 and a second support 2, the first support 1 and the second support 2 are vertically distributed, and the top of the first support 1 is fixedly installed with an oblique conveyor Component 3, the top of the oblique transport component 3 is obliquely provided with a sorting component 4, the end of the diagonal transport component 3 close to the sorting component 4 is fixedly installed with a rotating component 5, and the top of the second bracket 2 is fixedly mounted with a plurality of first linear electric cylinders 6. The top of the first linear electric cylinder 6 is provided with a parallel transmission assembly 7 used in conjunction with the rotation assembly 5. The end of the horizontal transmission assembly 7 is provided with an upper shell assembly 8, and the top of the second bracket 2 is fixedly installed with a symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com