Stator casing turning device

A turning device and stator technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity and low work efficiency of workers, and achieve the effect of improving the degree of automation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

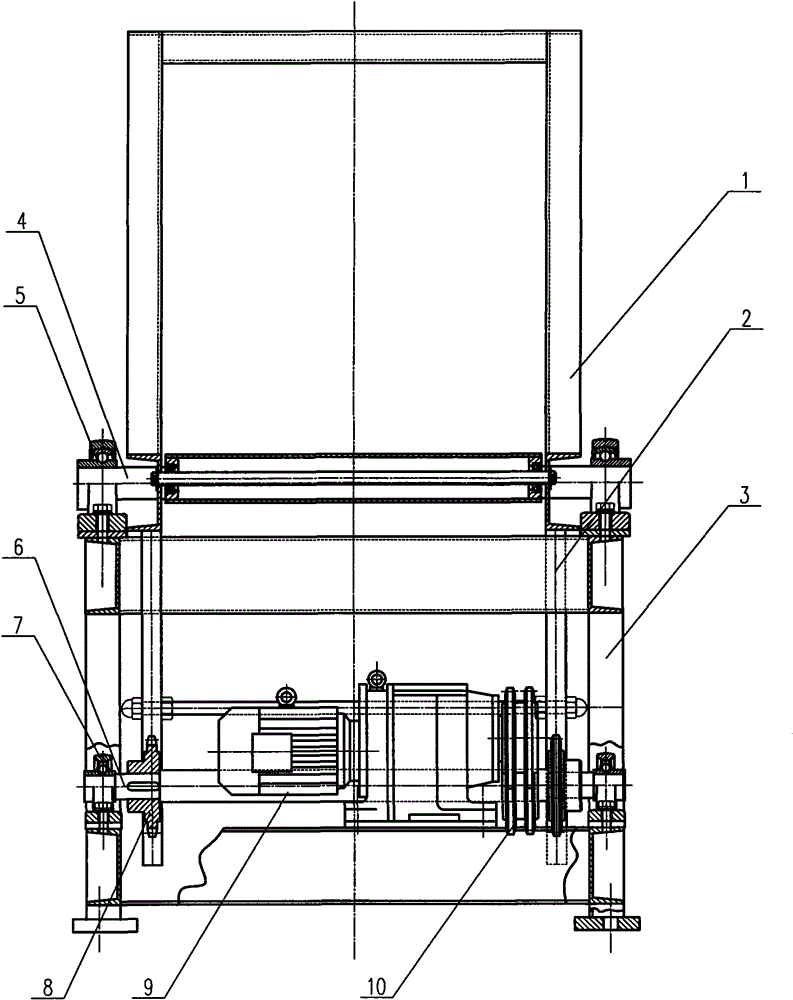

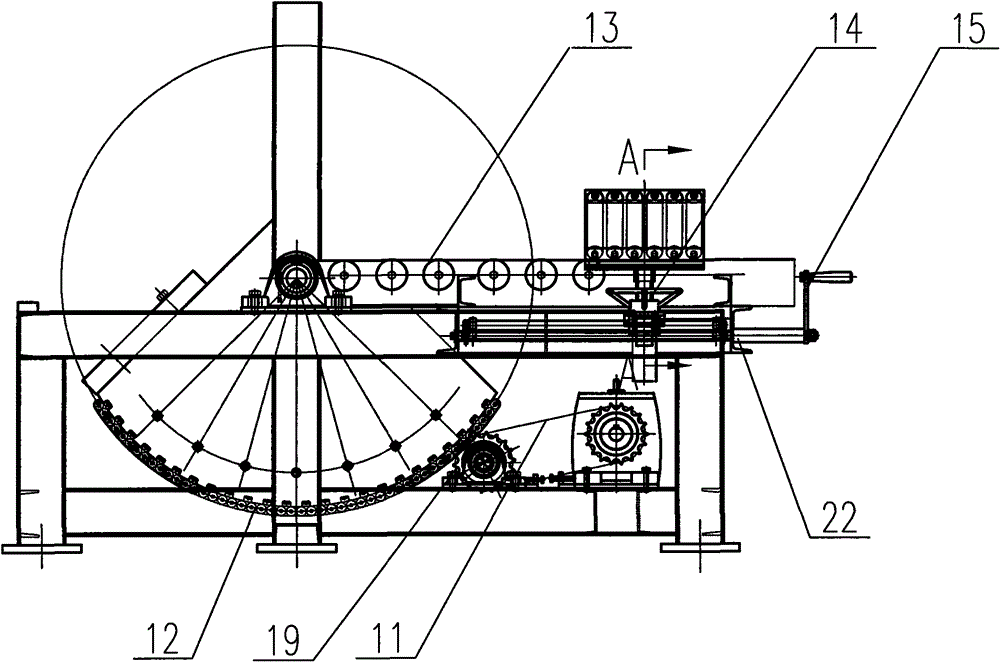

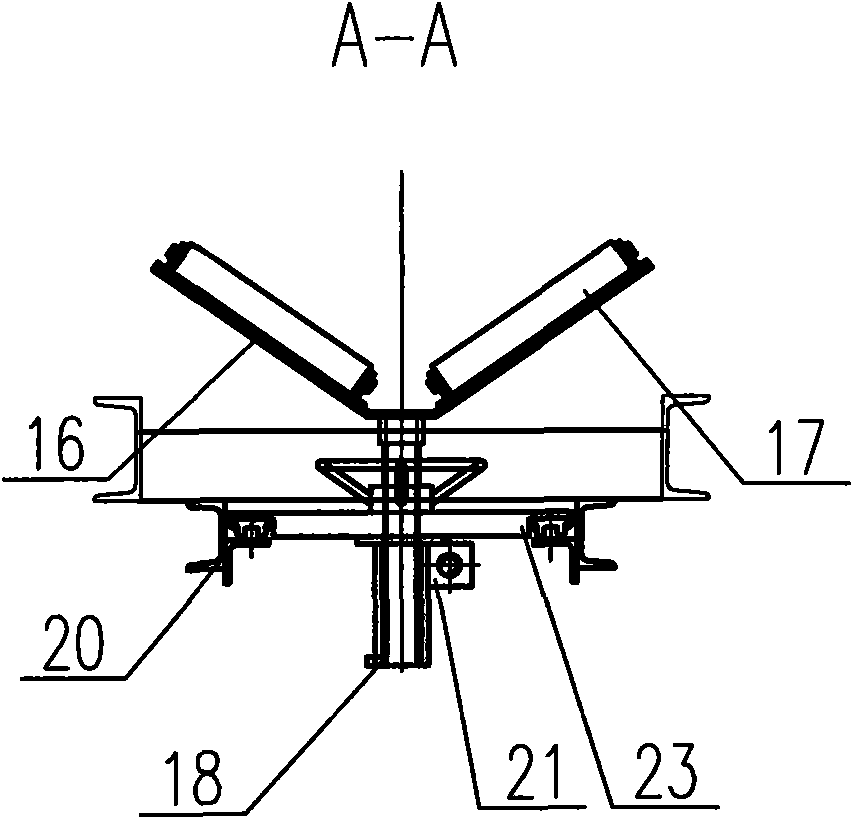

[0018] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as Figures 1 to 4 As shown, the stator casing turning device of the present invention includes a frame 3, a driving motor 9, a transmission shaft 6, a rotating shaft 4, a turning frame 1, a sector plate 2, a bracket 16, a motor stator placement part and a motor casing placement department. The frame 3 is fixed on the ground, and the frame 3 is welded by channel steel. The rotating shaft 4 and the transmission shaft 6 are respectively supported on the frame 3 through bearings. Specifically, they are installed on both sides of the frame 3 Bearing with seat 2 7 for supporting transmission shaft 6, bearing with seat 1 5 for supporting rotating shaft 4 is also installed on both sides of fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com