Device for efficiently and reliably entering lithium battery into shell

A lithium battery, high-efficiency technology, applied in the field of lithium battery efficient and reliable shelling device, can solve problems such as damaged diaphragm and pole piece damage, achieve the effect of precise alignment and improve the quality of shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

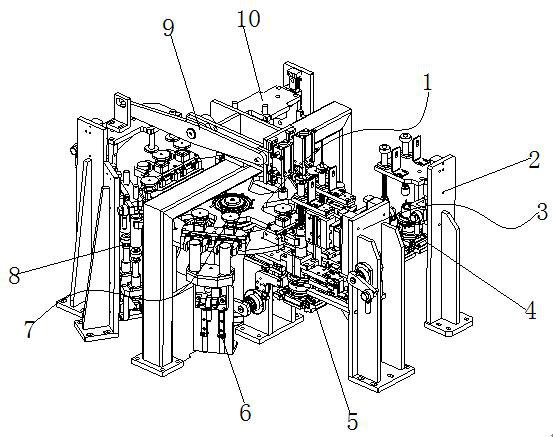

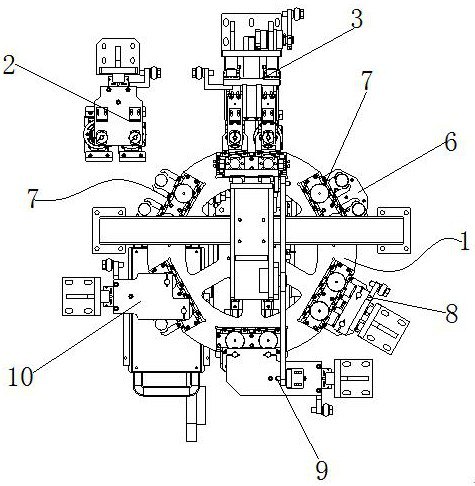

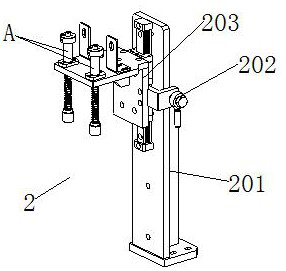

[0035] Such as Figures 1 to 8 As shown, an efficient and reliable lithium battery casing device according to the present invention includes a turntable 1, a battery fixture 4, a plurality of steel casing clamping assemblies 7 fixed on the turntable 1, and is used to pull the steel casing from The steel shell feeding mechanism 10 that is externally transported to the steel shell clamping assembly 7, the dust suction mechanism 6 for removing dust from the steel shell, the steel shell pressing mechanism 3 for inserting the steel shell into the outside of the battery cell, and the steel shell pressing mechanism 3 for pressing the battery core The battery cell press-in mechanism 2 inserted into the battery fixture 4; a jig conveying mechanism 5 for transporting the battery jig 4 is provided between the steel shell press-in mechanism 3 and the cell press-in mechanism 2; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com