Ore washing and drying all-in-one machine

An all-in-one machine and ore washing technology, used in dryers, drying, drying of solid materials, etc., can solve the problems of long processing cycle of mineral raw materials, inability to realize mineral transportation, etc., and achieve the effect of shortening processing cycle and being beneficial to production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

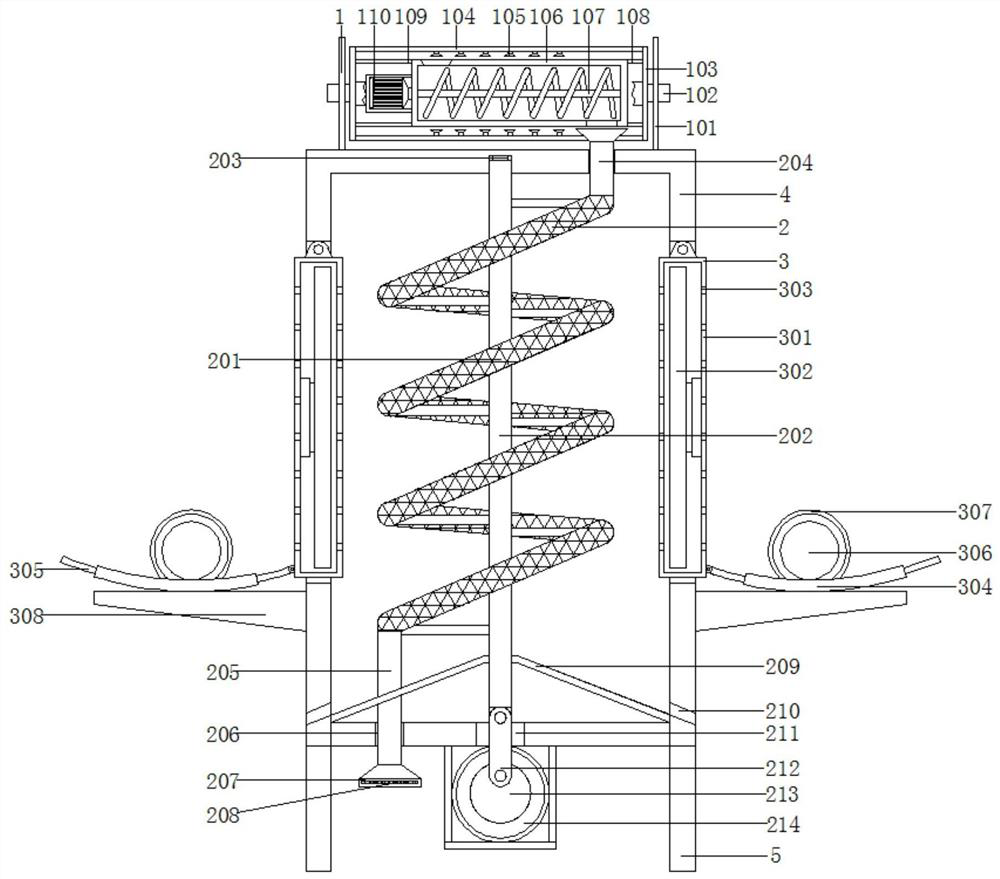

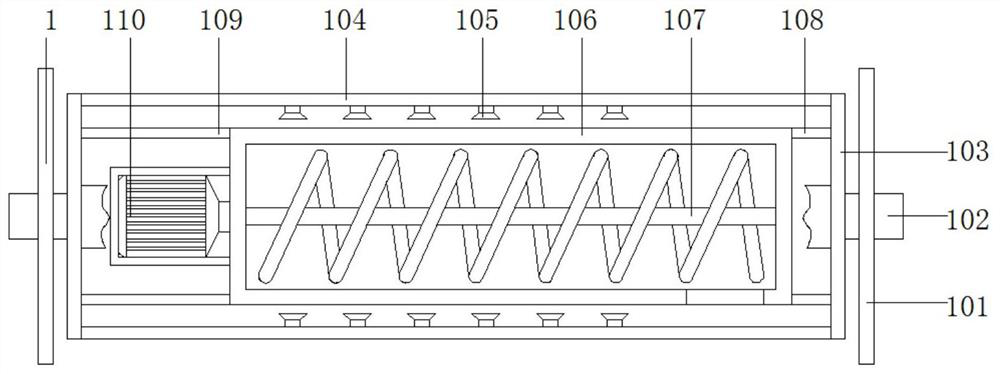

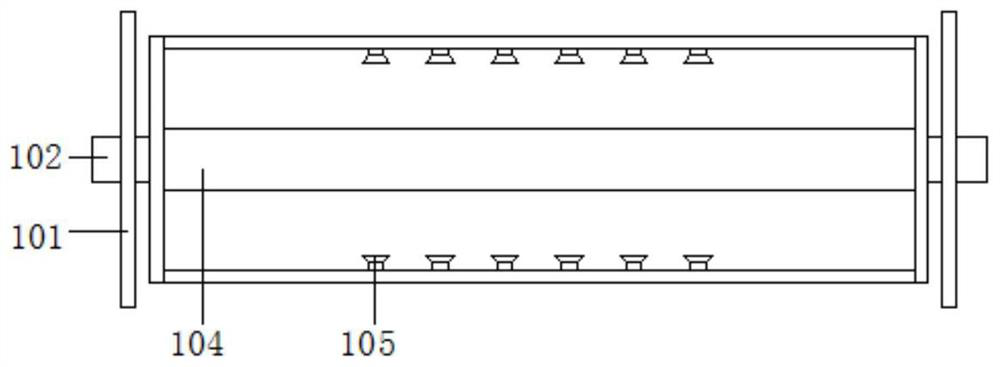

[0028] see Figure 1-3 , an all-in-one machine for washing and drying minerals, including a box body 1, the bottom ends of the box body 1 are fixedly connected with pillars 6; the top of the box body 1 is provided with a cleaning and conveying mechanism 1, and the cleaning and conveying mechanism 1 includes a fixed plate 101, a pipe fitting 102, Hollow disc 103, hollow slat 104, nozzle 105, mesh conveying box 106, screw conveying rod 107, short connecting rod 108, long connecting rod 109 and first motor 110;

[0029] Both sides of the top of the box body 1 are fixedly connected with fixed plates 101, and the middle end of the fixed plate 101 is fixedly connected with a pipe fitting 102, and one end of the pipe fitting 102 is fixedly connected with a hollow disc 103, and the other end of the pipe fitting 102 is connected with a high-pressure water pipe. The water pipe is connected with the high-pressure water pump, and the inner side of the hollow disc 103 is fixedly connected ...

Embodiment 2

[0034] see figure 1 and Figure 4 , both sides of the cabinet 1 are provided with a drying adjustment assembly 3, the drying adjustment assembly 3 includes a casing 301, a vent hole 302, a drying fan 303, an arc-shaped clamping case 304, an arc-shaped slide plate 305, a gear 306, and a third motor 307 , a fixed seat 308 and a toothed strip 309;

[0035] Both sides of the box body 1 are provided with a casing 301, and the top of the casing 301 is flexibly connected with the box body 1. The inside of the casing 301 is fixedly equipped with a drying fan 303, and there are ventilation holes 302 on both sides, through which ventilation holes 302 are used. Ventilation for gas circulation.

[0036] One side of the shell 301 is provided with an arc-shaped clamping shell 304, and the inside of the arc-shaped clamping shell 304 is provided with an arc-shaped slide plate 305, one end of the arc-shaped slide plate 305 is movably connected with the shell 301, and the outer wall of the bo...

Embodiment 3

[0041] see figure 1 , Figure 5 and Figure 6 The box body 1 is provided with a spiral screening mechanism 2. The spiral screening mechanism 2 includes a support rod 201, a screening spiral tube 202, a spring 203, a feeding tube 204, a discharging tube 205, a sliding sleeve 206, a rectangular hollow clamping plate 207, an inserting Plate 208, material guide plate 209, discharge hole 210, movable groove 211, movable rod 212, rotating disk 213 and second motor 214;

[0042] A support rod 201 is arranged inside the box body 1, and the outside of the support rod 201 is fixedly wound with a screening spiral tube 202;

[0043] The top of pole 201 is inserted into the top inside of box body 1, and the top of pole 201 is fixedly connected with spring 203, and spring 203 is fixedly installed inside box body 1, and spring 203 is used for connecting pole 201 from the top, and pole 201 Fixing from the top can also ensure the movement of the pole 201 .

[0044] The bottom end of pole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com