Patents

Literature

30results about How to "Avoid frequent transfers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

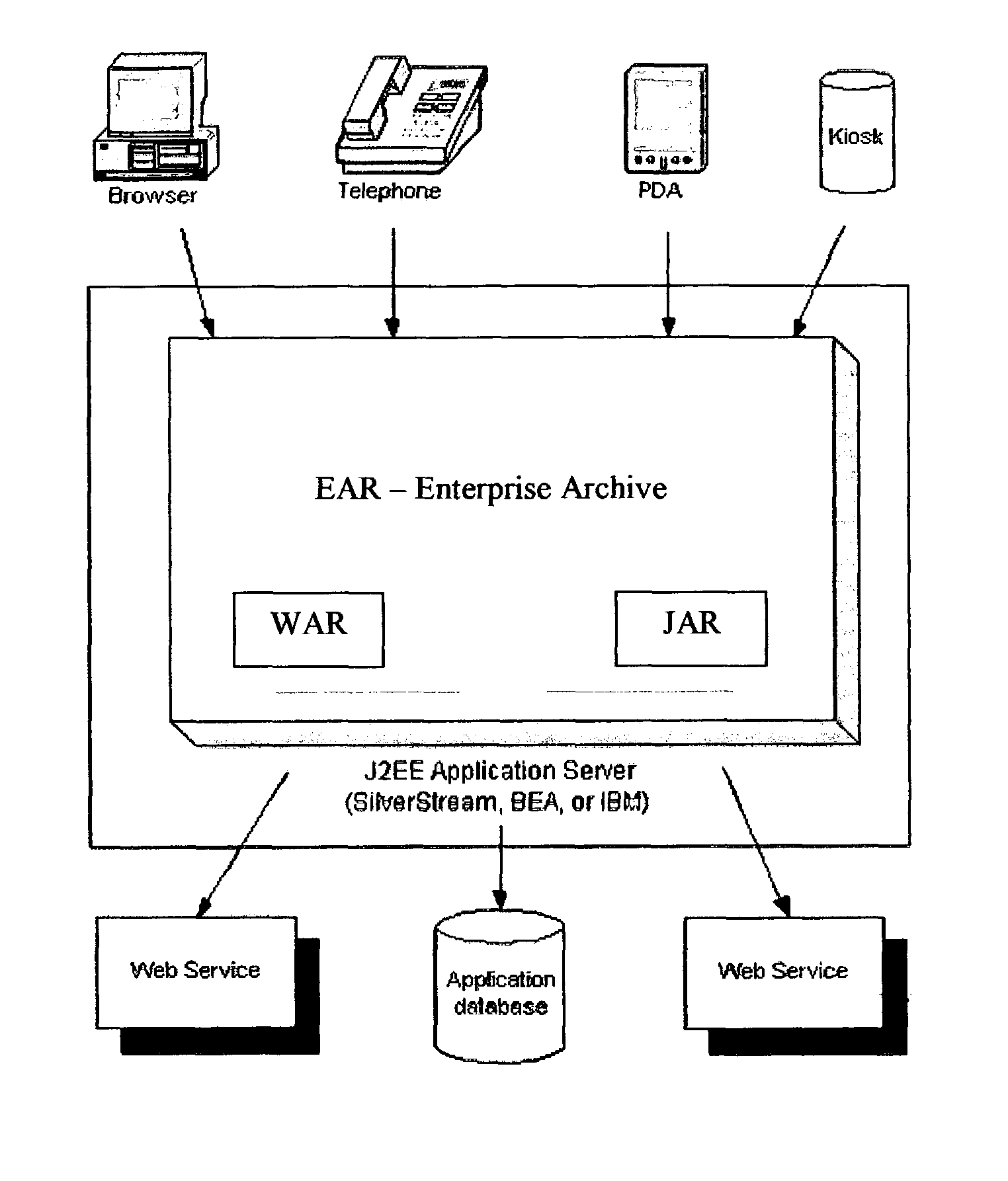

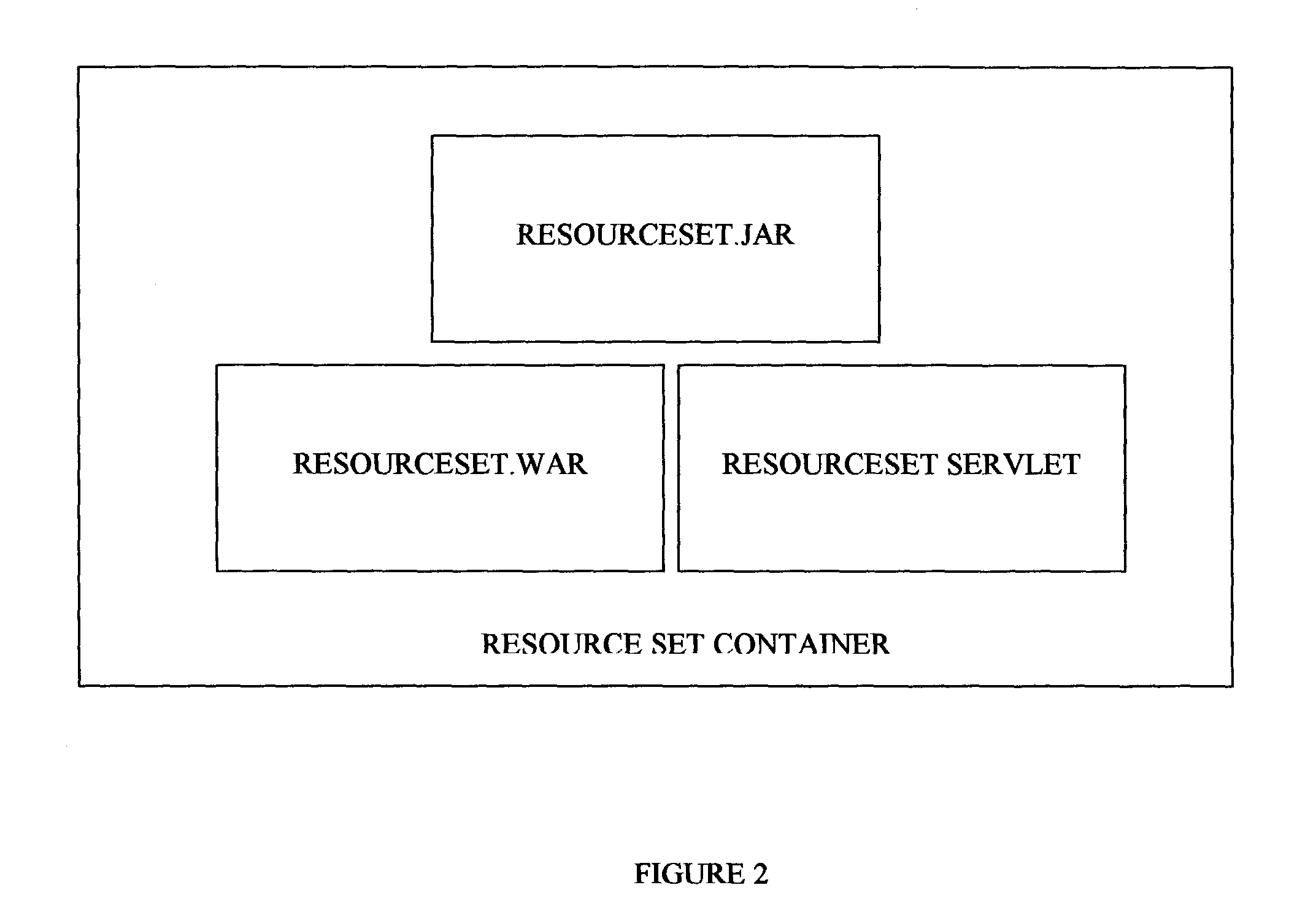

Resource repository and technique for populating same

InactiveUS20040158602A1Productive dynamic resource loadingAvoid frequent transfersDigital data processing detailsMultiprogramming arrangementsOperating systemWeb system

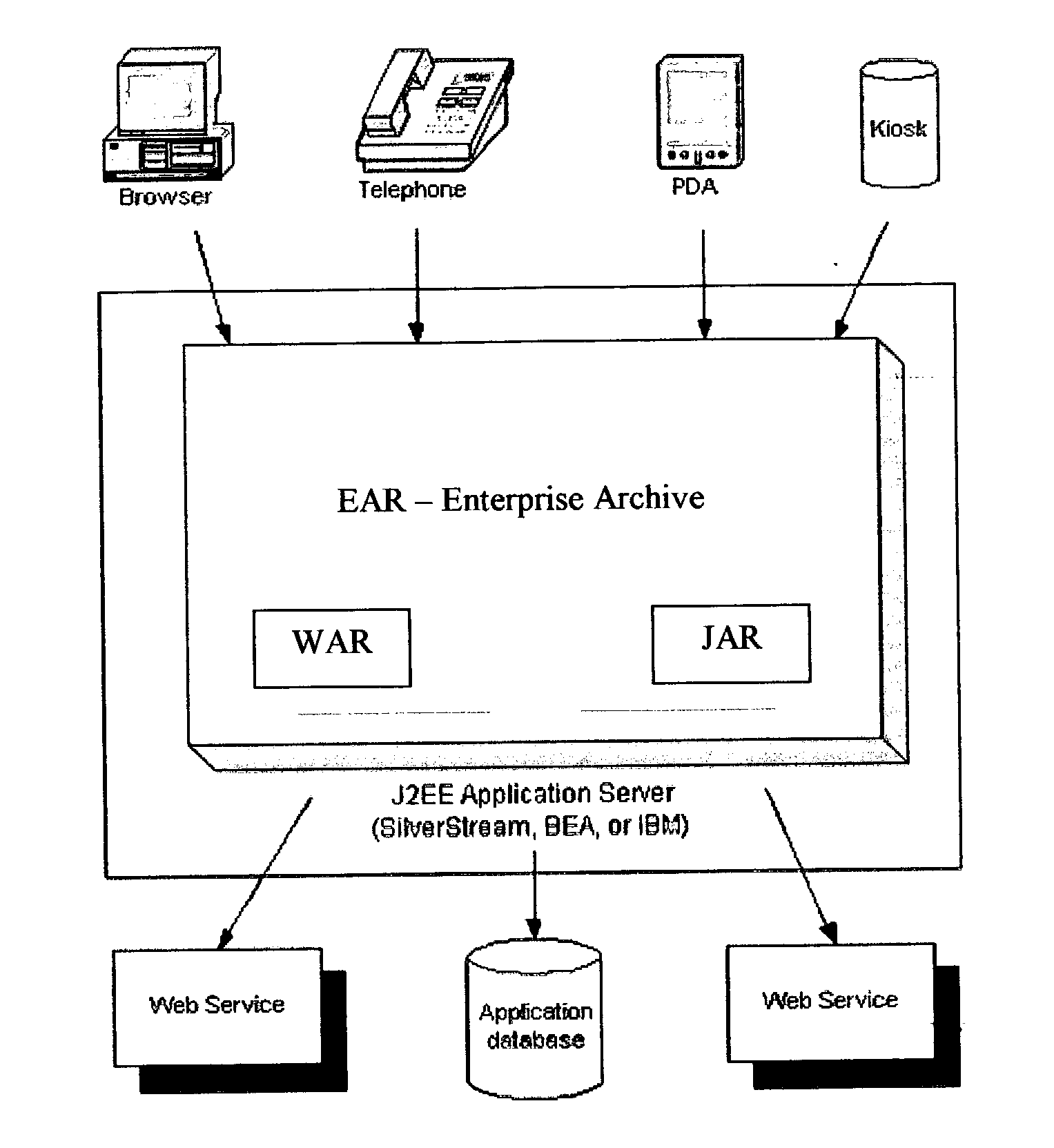

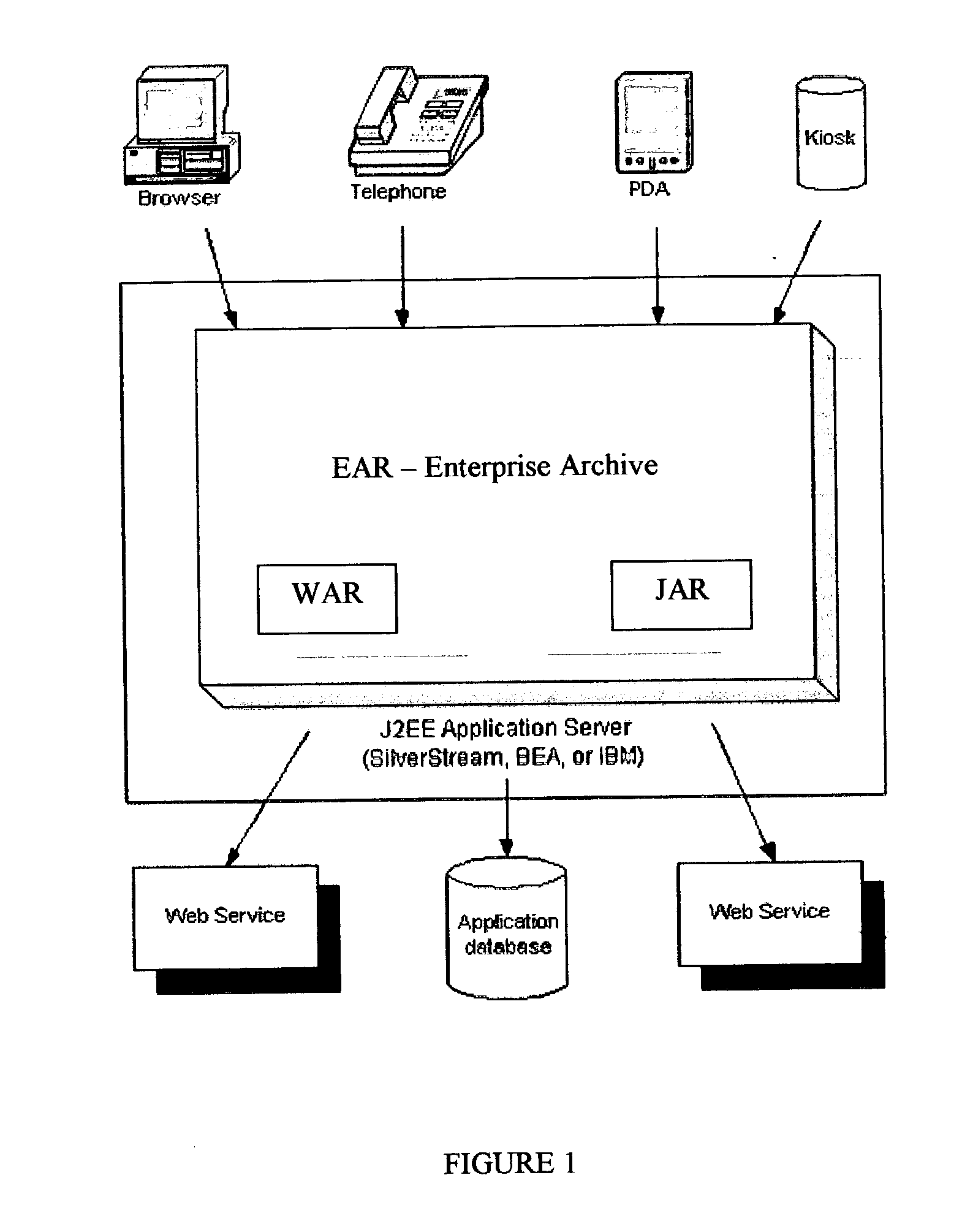

Among other embodiments set forth herein, there is provided, in a network system including a first server running a first application and a second server running a second application, the second server being remote from the first server, each of the first and second server further including a set of application resources associated therewith, a method for dynamically loading application resources from the first server to the second server, the method comprising the steps of: generating and dispatching a monitoring mechanism from the first server to the second server; in accordance with a predefined criteria (such as the expiration of a certain time interval), i) comparing the application resources of the first server and the second server to determine whether the application resources associated with the first server has been modified; and ii) based on the determination, dynamically loading the modified application resources from the first server to the second server.

Owner:APPLE INC

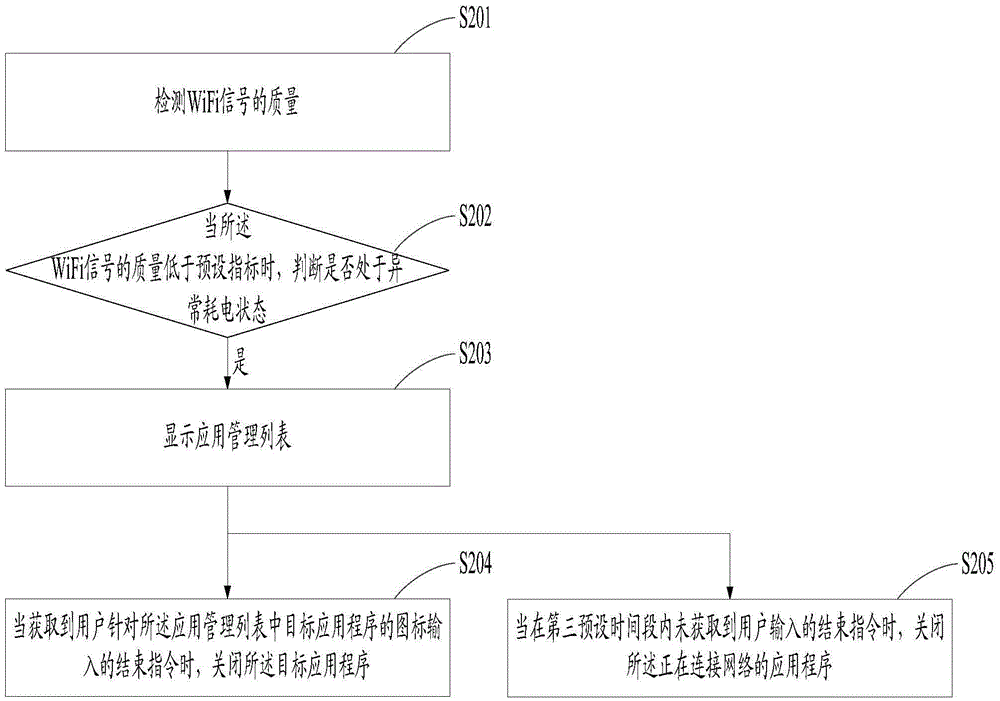

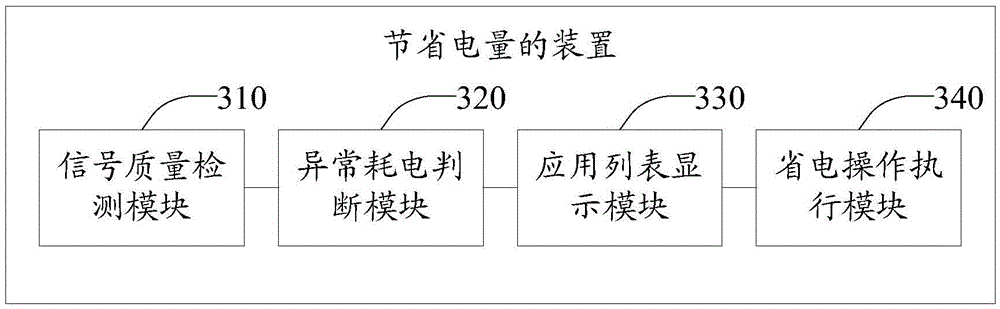

Power conservation method and apparatus, and electronic device

InactiveCN105653006AAvoid frequent transfersExtend battery lifePower supply for data processingElectric equipmentReal-time computing

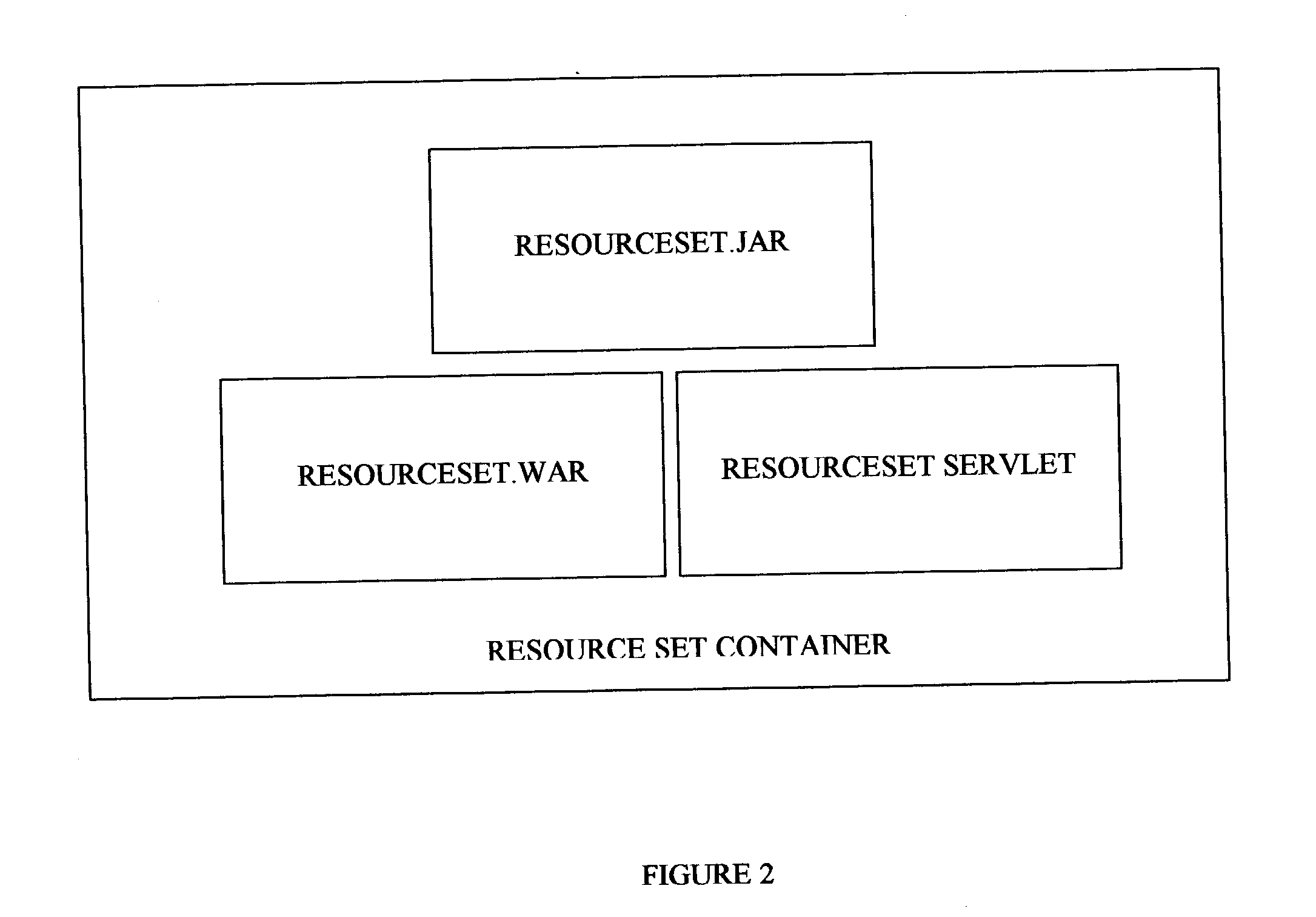

Embodiments of the present invention disclose a power conservation method. The method comprises: detecting the quality of a wireless local area network WiFi signal; when the quality of the WiFi signal is lower than a preset indicator, determining whether an application is in an abnormal power consumption state; if the application is in the abnormal power consumption state, displaying an application management list, wherein the application management list comprises an icon of an application that is connected to a network; and when acquiring an ending instruction input by a user for an icon of a target application in the application management list, closing the target application. Correspondingly, the embodiments of the present invention further disclose a power conservation apparatus and an electronic device. By adopting the method and apparatus, and the electronic device disclosed by the present invention, power consumption when the quality of the WiFi signal is relatively poor can be reduced, and power endurance time can be prolonged.

Owner:KINGSOFT

System and method for dynamically loading application resources from a source device to a target device based on modifications to the application resources at the source device

InactiveUS7765551B2Productive dynamic resource loadingAvoid frequent transfersDigital data processing detailsMultiprogramming arrangementsApplication softwareOperating system

Among other embodiments set forth herein, there is provided, in a network system including a first server running a first application and a second server running a second application, the second server being remote from the first server, each of the first and second server further including a set of application resources associated therewith, a method for dynamically loading application resources from the first server to the second server, the method comprising the steps of: generating and dispatching a monitoring mechanism from the first server to the second server; in accordance with a predefined criteria (such as the expiration of a certain time interval), i) comparing the application resources of the first server and the second server to determine whether the application resources associated with the first server has been modified; and ii) based on the determination, dynamically loading the modified application resources from the first server to the second server.

Owner:APPLE INC

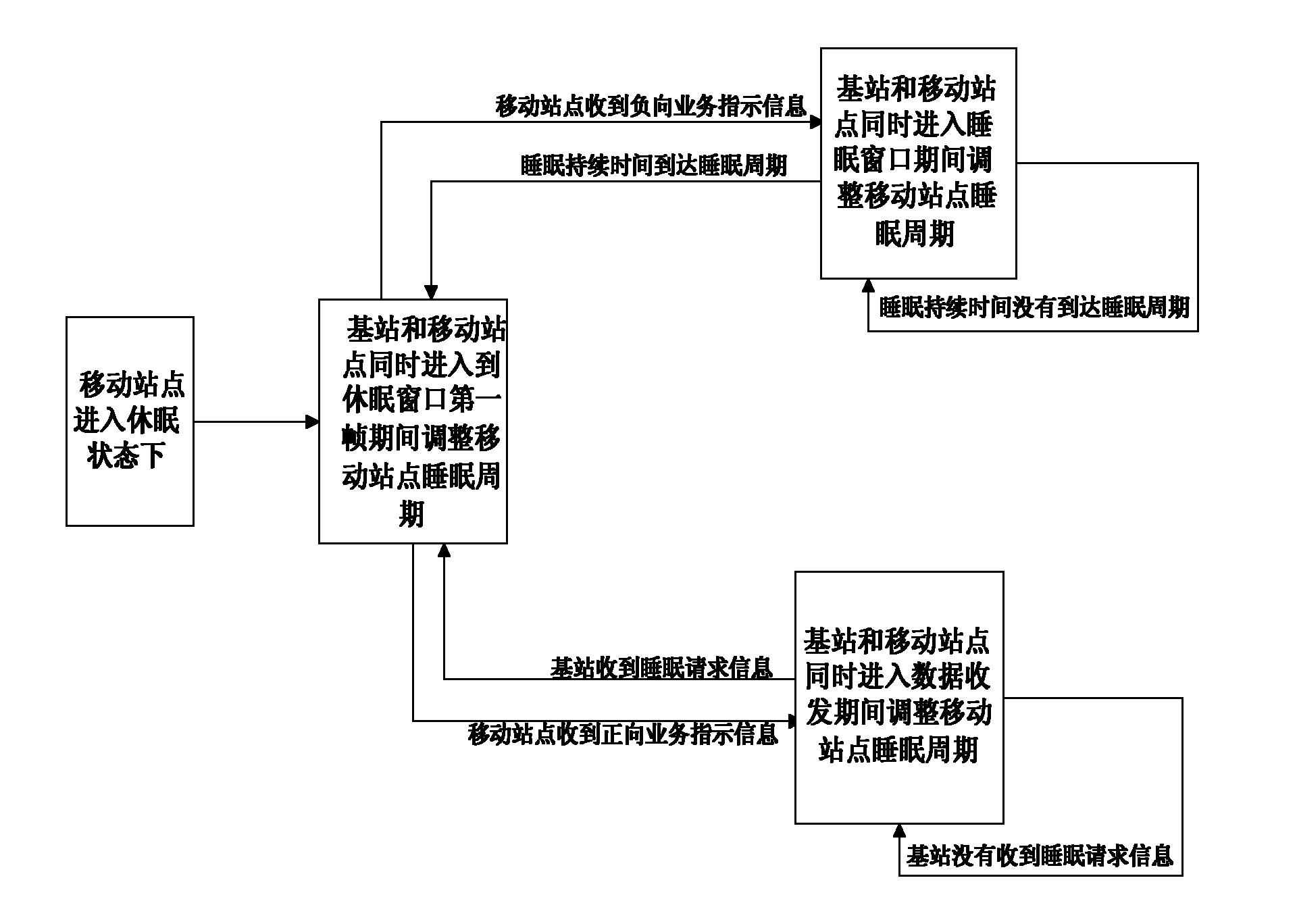

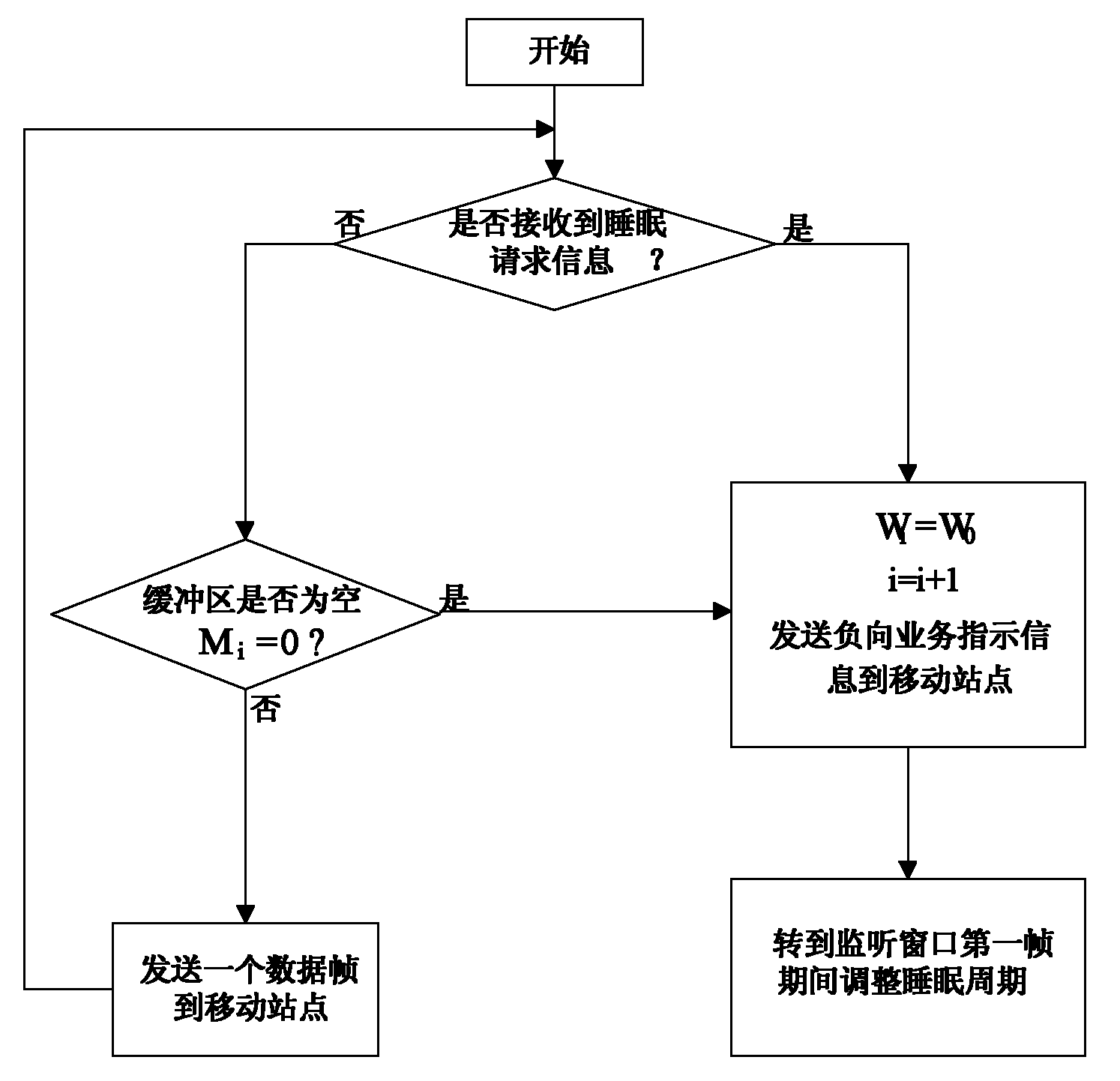

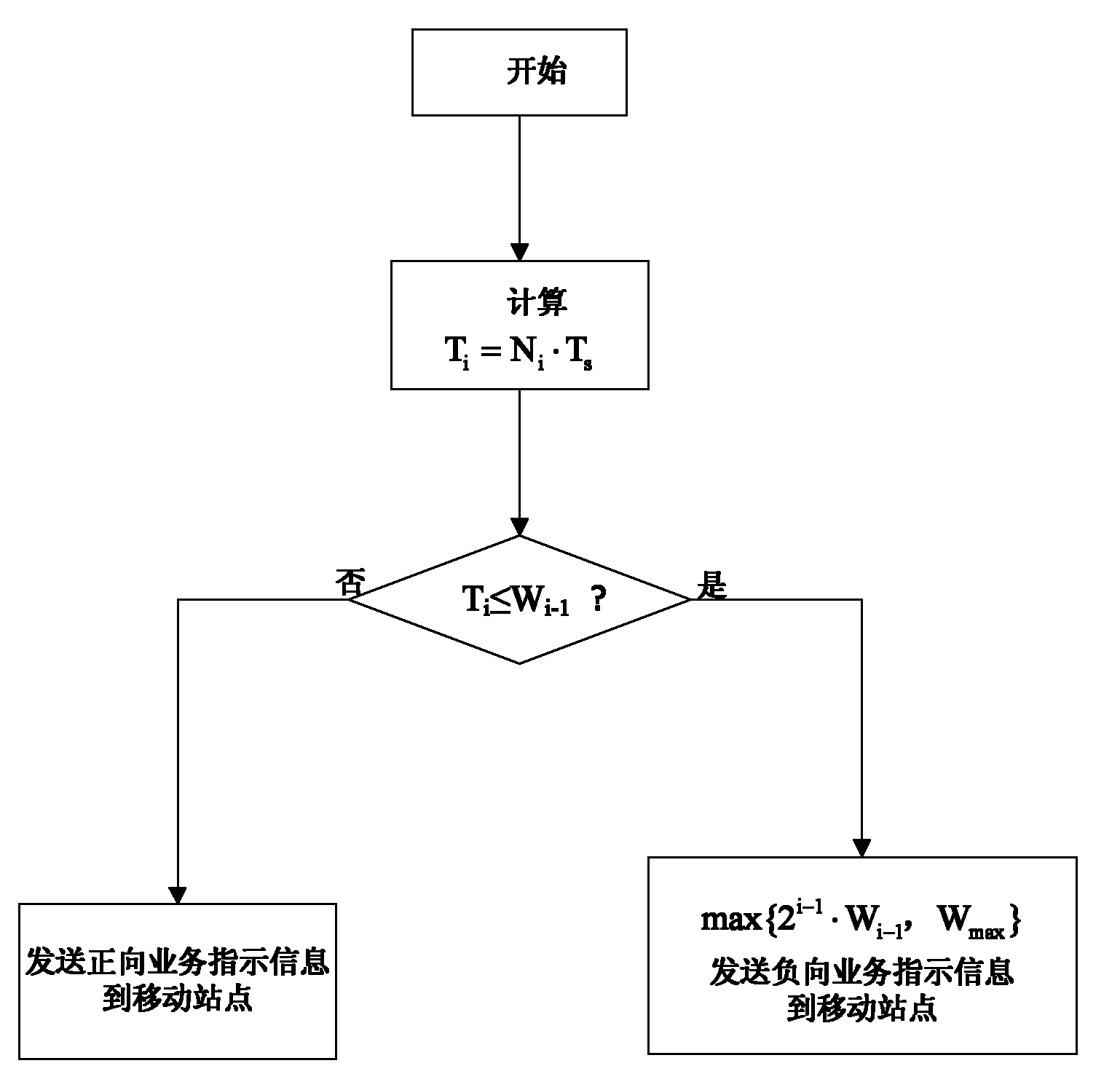

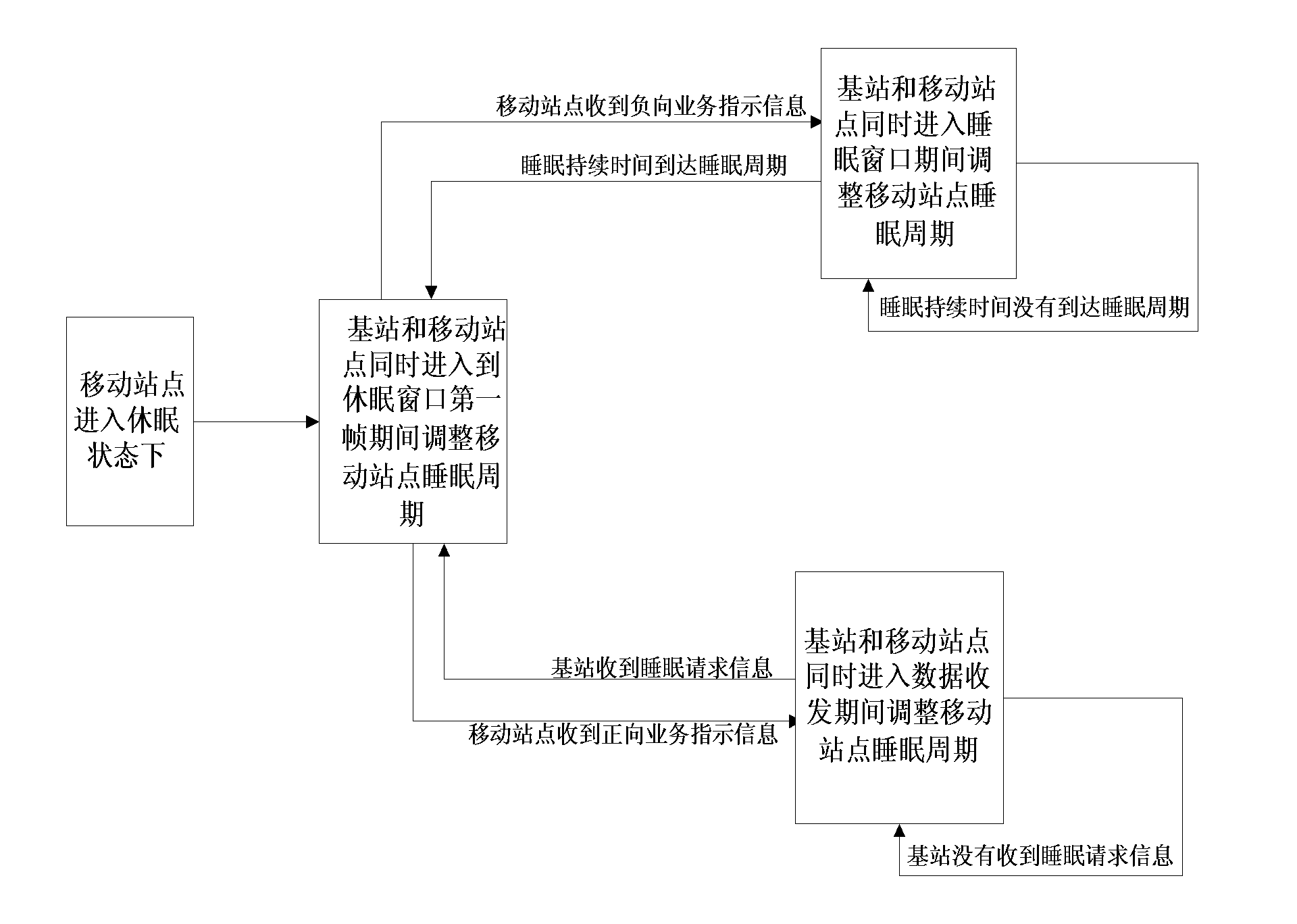

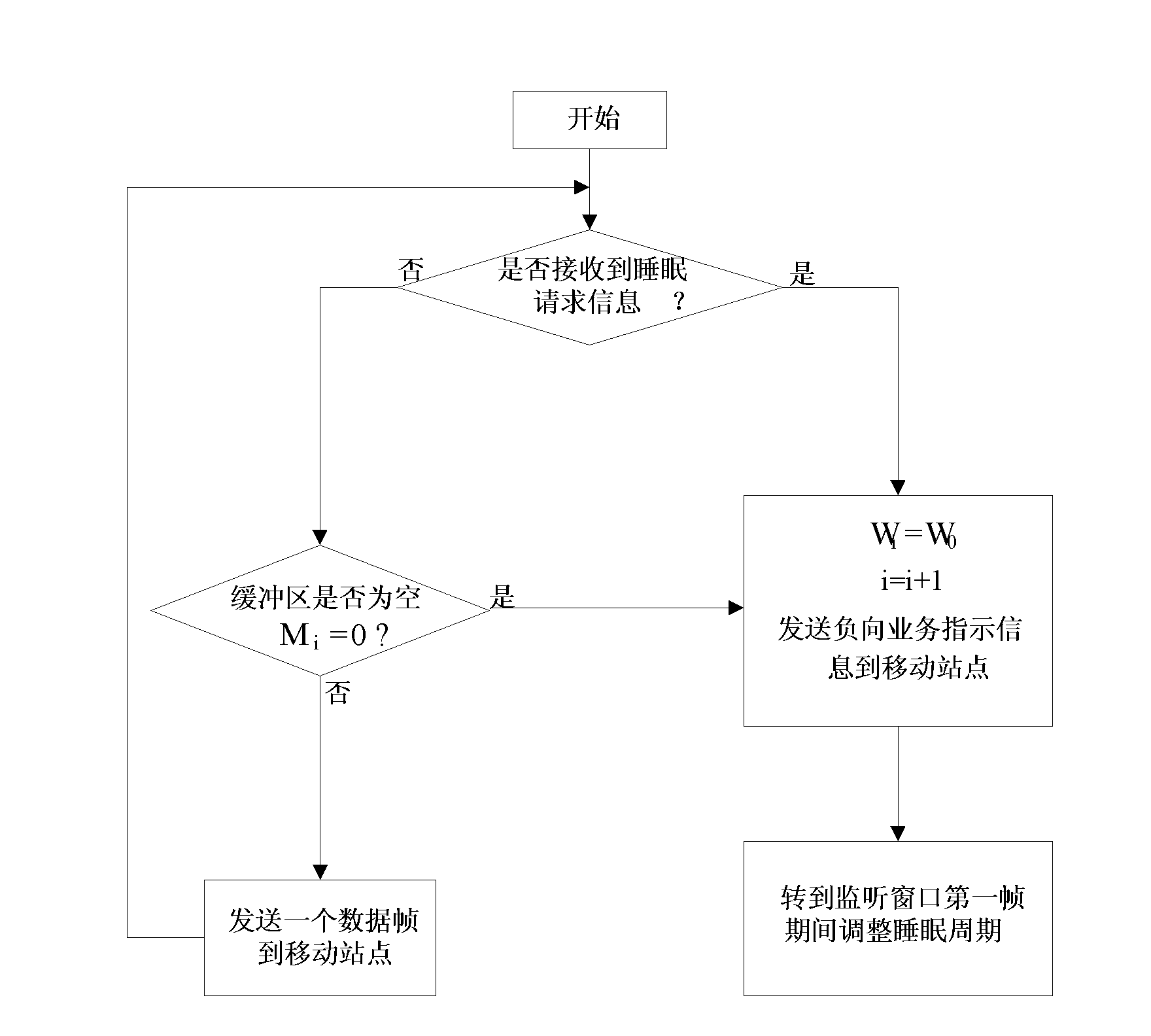

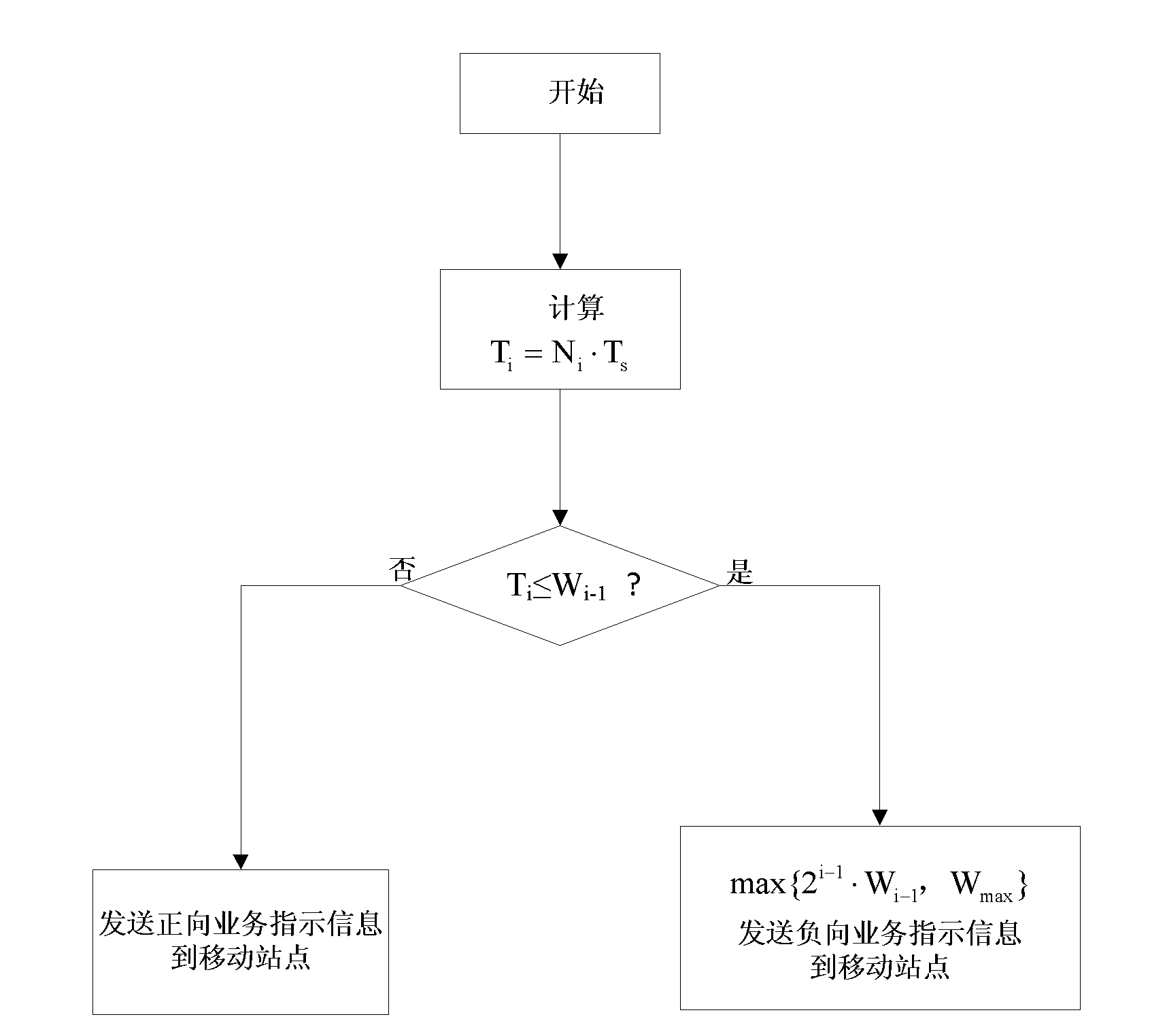

Method for regulating sleep cycle of mobile station on basis of service reshaping and channel prediction

InactiveCN102104941AAvoid frequent transfersReduce switching timesPower managementEnergy efficient ICTTime conditionTransceiver

The invention discloses a method for regulating a sleep cycle of a mobile station on the basis of service reshaping and channel prediction and mainly solves the problem that the mobile station is frequently switched between a monitoring window and a sleeping window in the conventional method. In the method, the regulation is carried out in three states of a monitoring window first frame period, adata sending and receiving period and a sleeping window period, wherein in the monitoring window first frame period, a base station compares time for transmitting data packets in a buffer zone with the length of a last sleep cycle so as to reshape small burst services into large burst services; in the data sending and receiving period, the mobile station carries out channel prediction, so that the base station regulates the sleep cycle of the mobile station according to a real-time condition of a channel; and in the sleeping window period, a transceiver is turned off through the mobile station so as to reduce energy consumption. In the invention, the sleep cycle of the mobile station can be regulated according the real-time condition of the channel and the sizes of the burst services, so that the energy consumption of the mobile station is minimized under the condition of guaranteeing the service quality of service (QoS).

Owner:XIDIAN UNIV

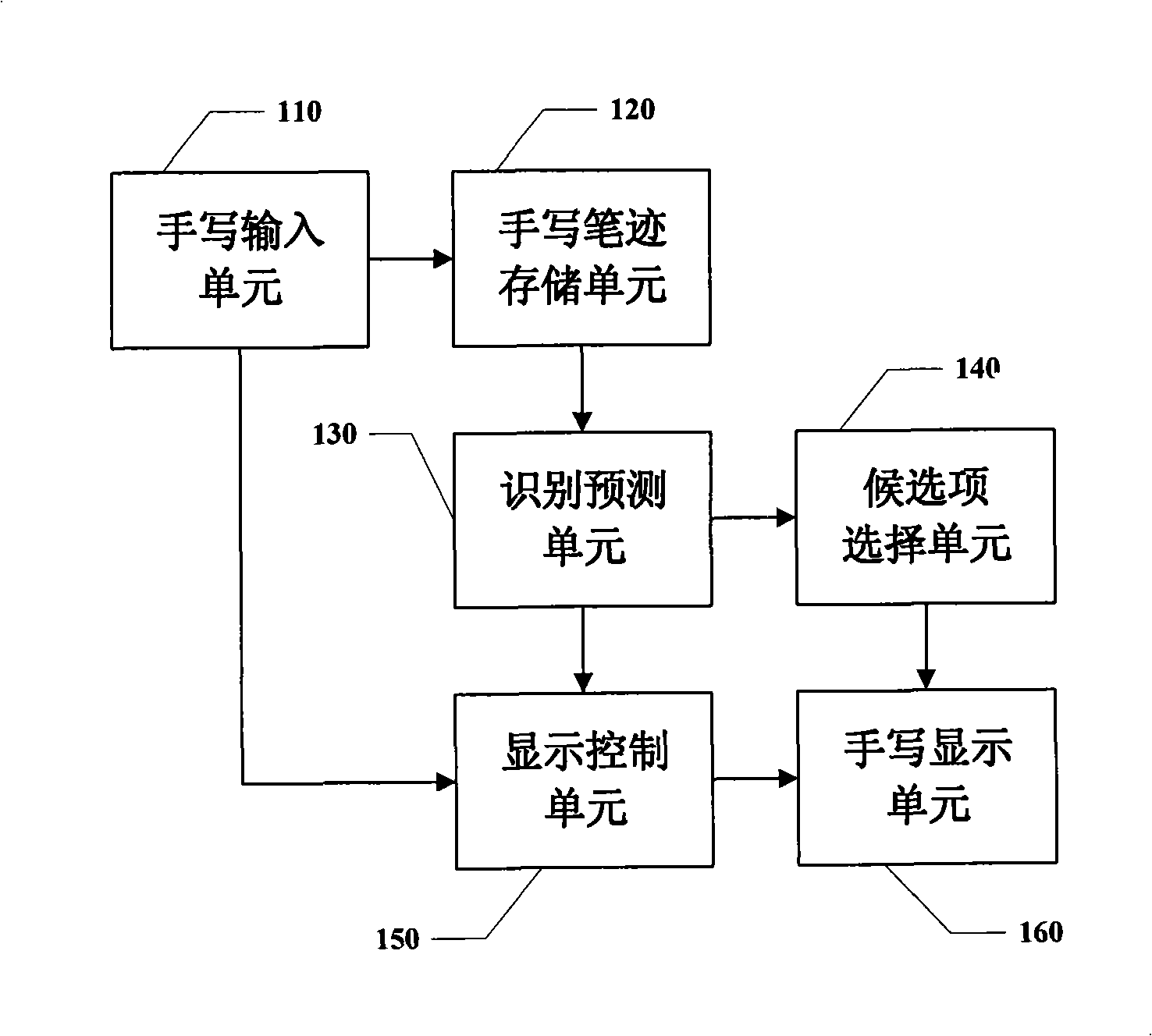

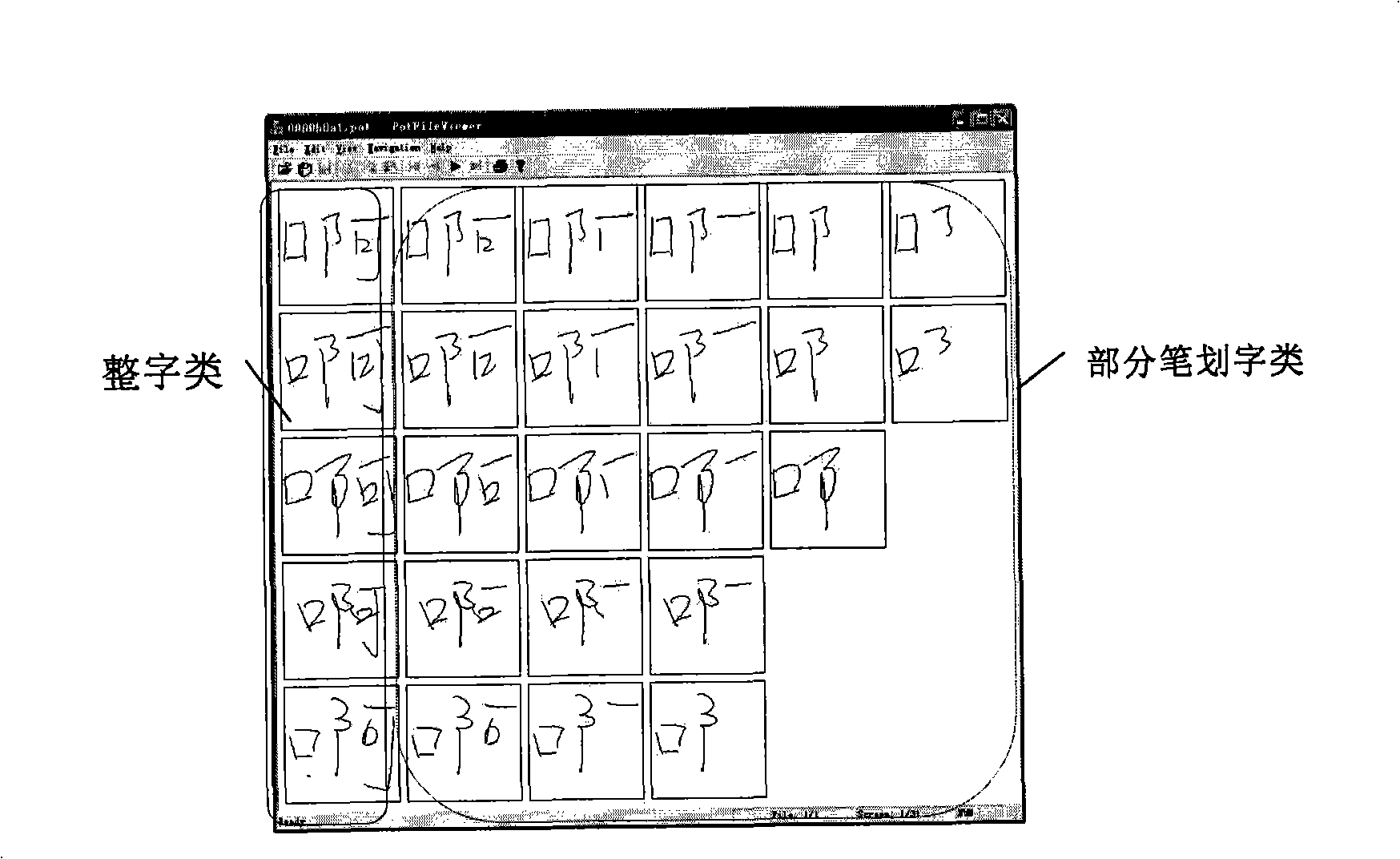

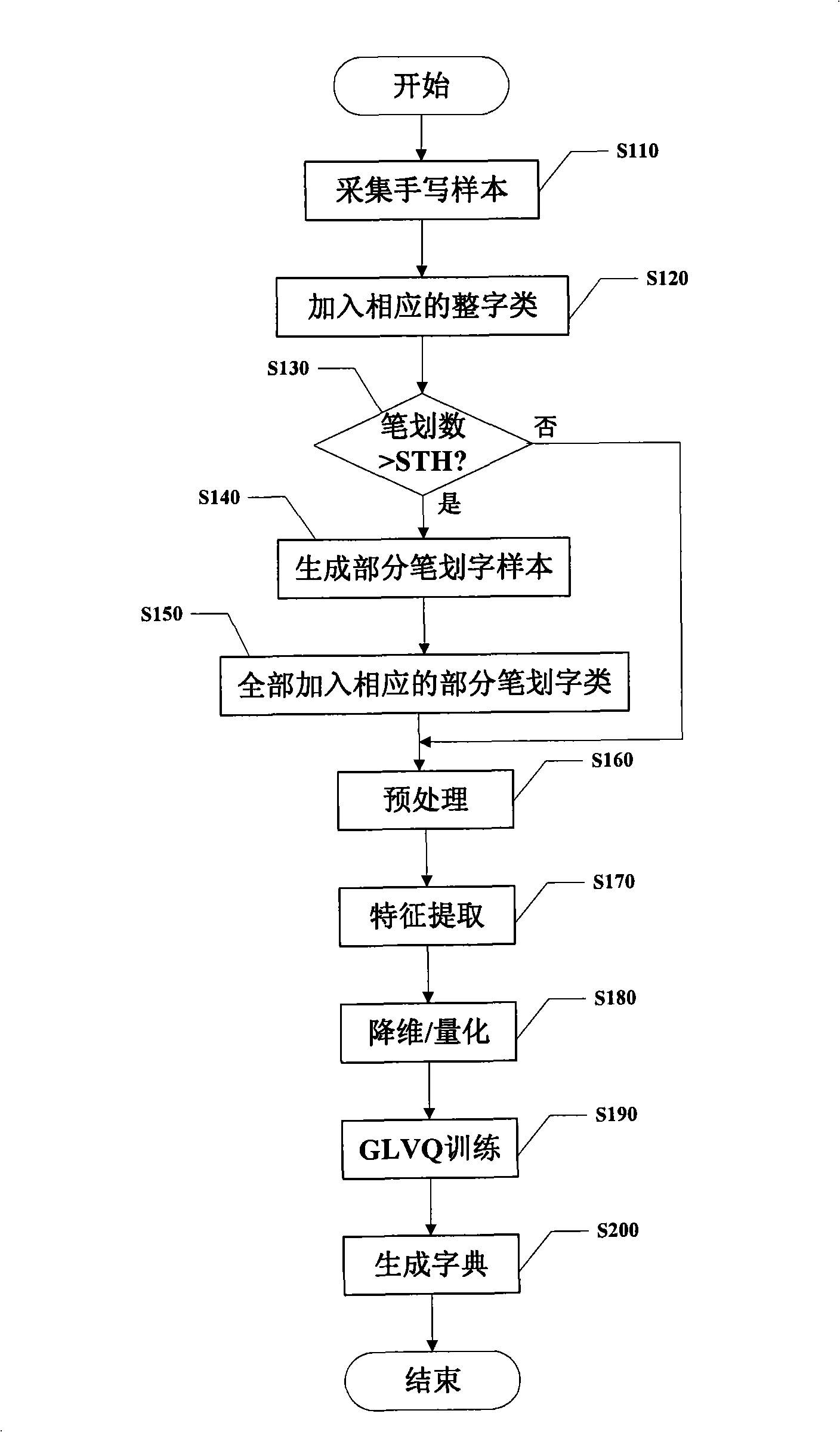

Method for making dictionary, hand-written input method and apparatus

InactiveCN101354749AReduce the burden onSimple structureCharacter and pattern recognitionHandwritingRapid identification

The invention discloses a method for manufacturing a dictionary, a handwriting input method and equipment. The method for manufacturing the dictionary can predict a character input by strokes so as to relieve the burden of a user. The method comprises the following steps: the feature of the integral character of an integral character sample of characters and the feature of partial strokes of a partial stroke sample of the characters with the number of the strokes larger than a preset value are extracted; and a learning algorithm by a machine is used to carry out learning to the feature of the integral character and the feature of the partial strokes to generate an integral character template and / or a partial stroke template of the characters, which are used as items of the dictionary. The system has the advantages of simple structure, low hardware requirement, rapid identification speed, high identification rate, and so on, and can be realized in an embedded type system and so on.

Owner:SHARP KK

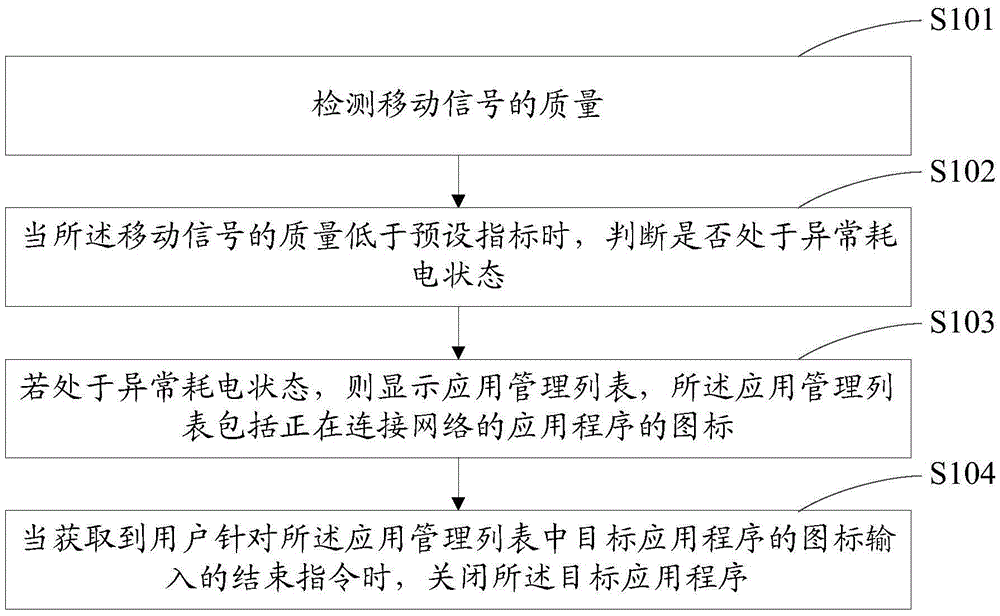

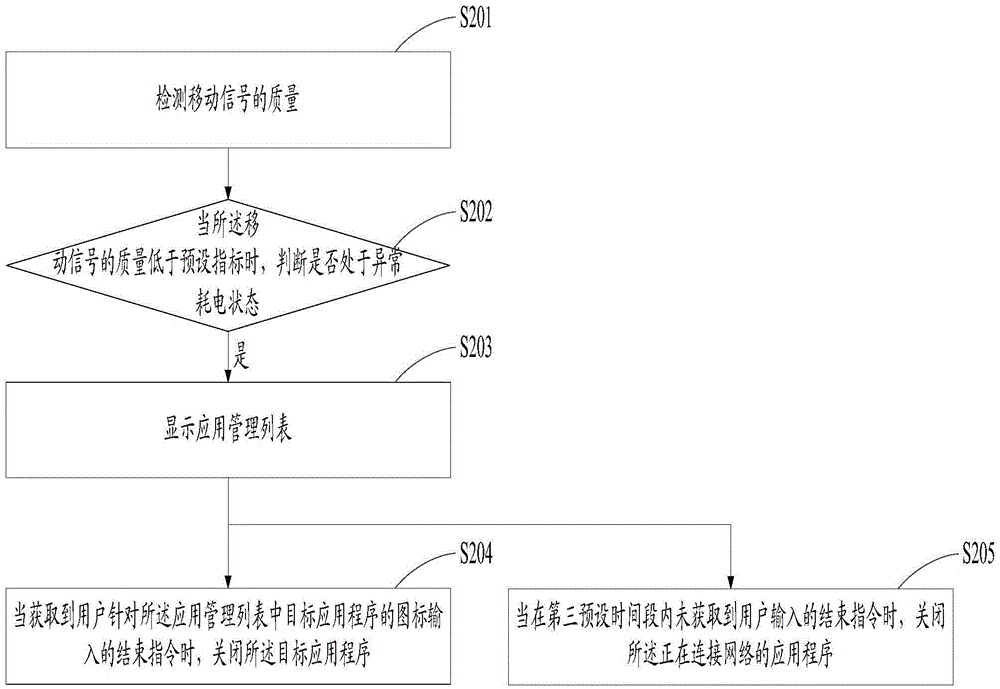

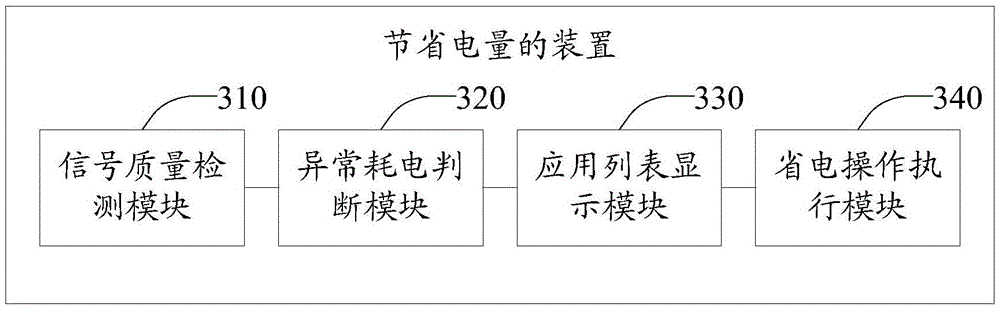

Method and device for saving electric quantity, and electronic equipment

InactiveCN105653007AAvoid frequent transfersExtend battery lifePower supply for data processingElectricityApplication software

The embodiment of the invention discloses a method for saving an electric quantity. The method comprises the following steps: detecting the quality of a mobile signal; when the quality of the mobile signal is lower than a preset index, judging whether an application is under an exceptional electricity consumption state or not; if the application is under the exceptional electricity consumption state, displaying an application management list, wherein the application management list comprises the icon of an application program which is connected with a network at present; and when an end instruction input by a user by aiming at the icon of a target application program in the application management list, closing the target application program. Correspondingly, the embodiment of the invention also discloses a device for saving the electric quality and electronic equipment. When the method, the device and the electronic equipment are adopted, the electricity consumption amount generated when the quality of the mobile signal is poor in quality can be reduced, and the duration of flight of the electric quantity is prolonged.

Owner:KINGSOFT

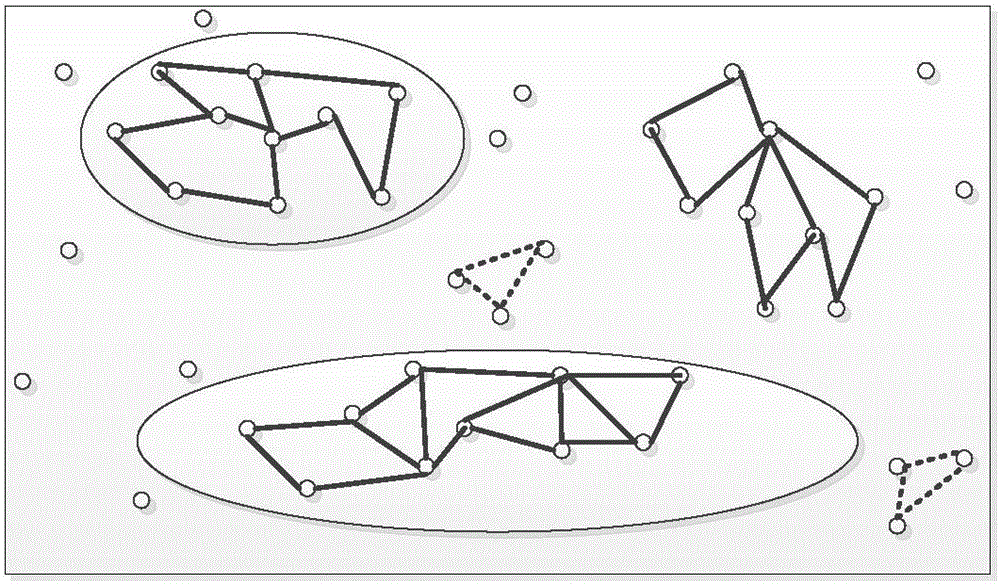

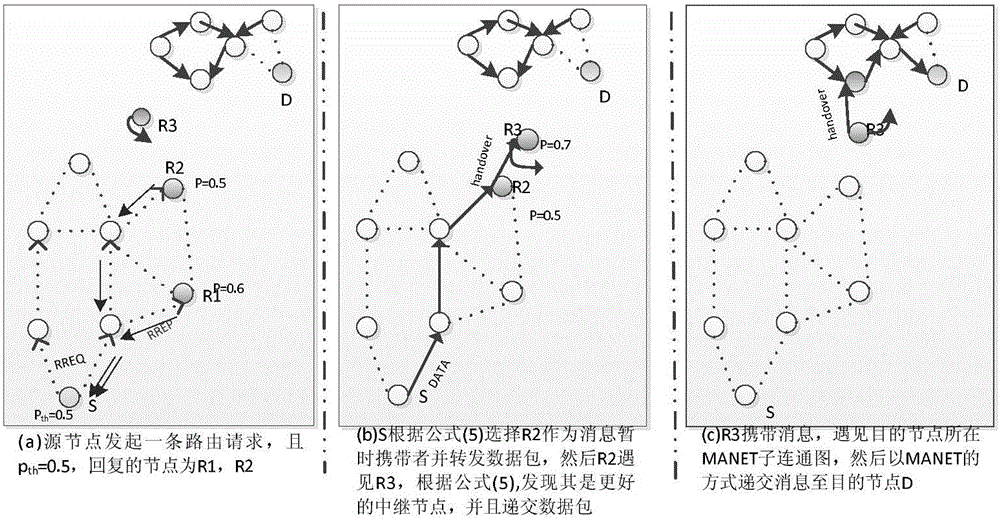

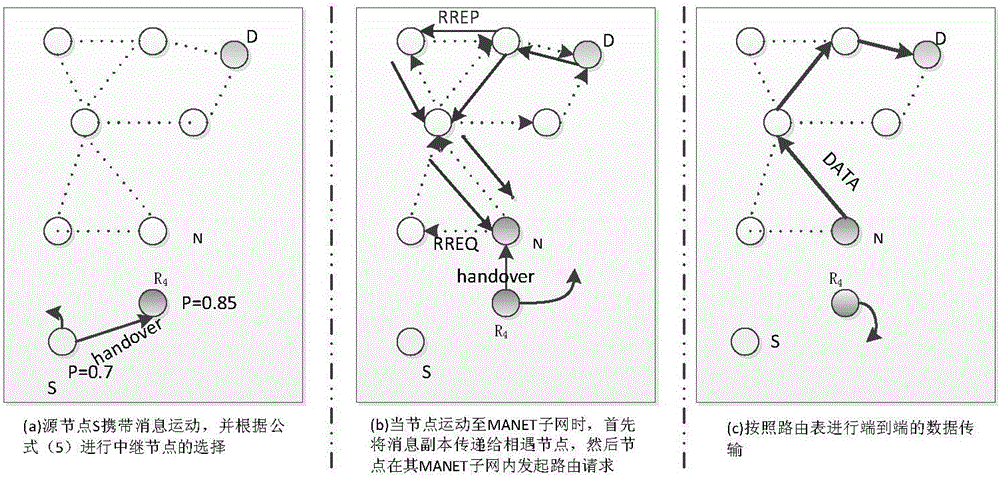

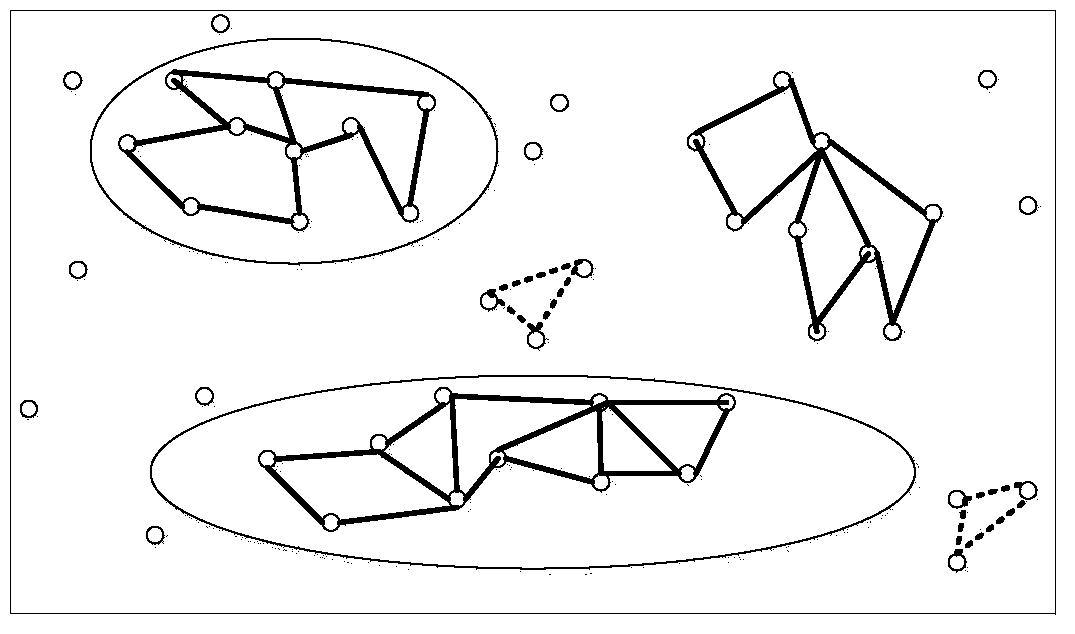

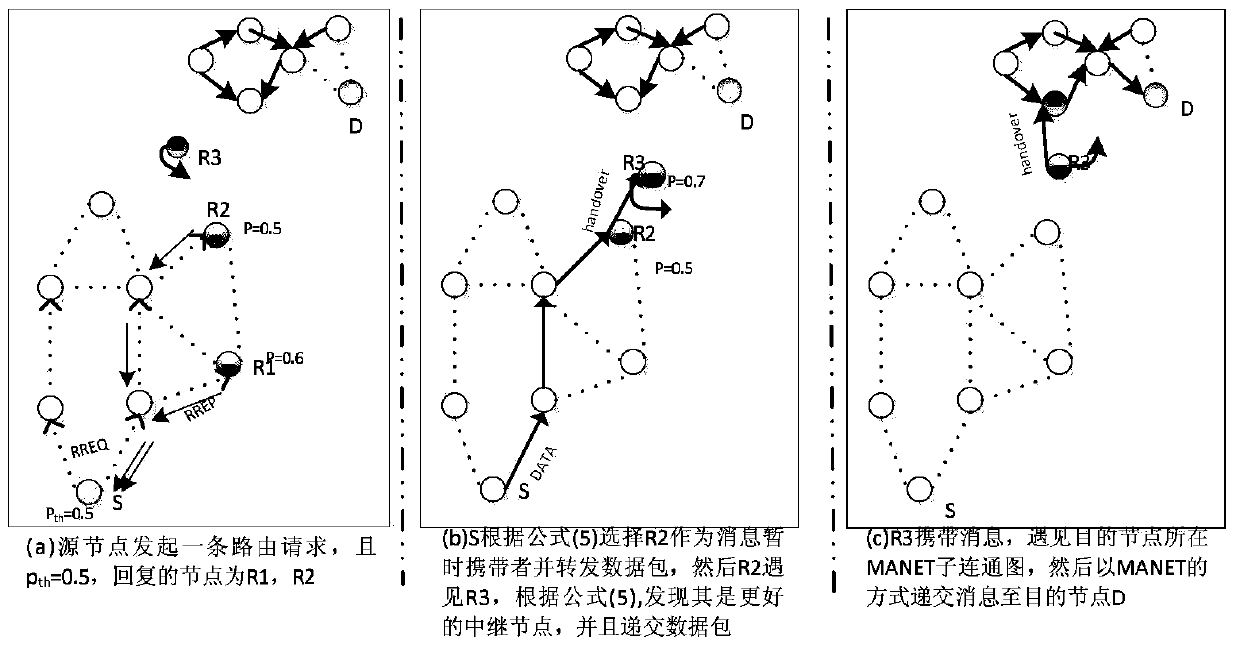

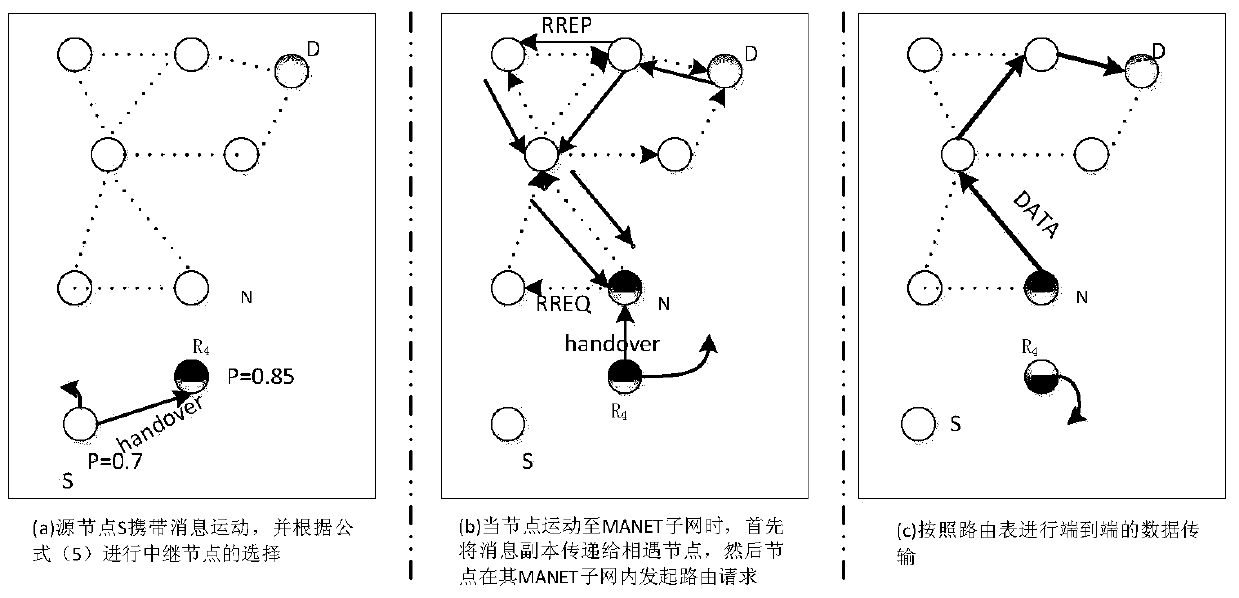

Situation awareness-based adaptive data transmission method applied to opportunistic crowd sensing network

The invention relates to a situation awareness-based adaptive data transmission method applied to an opportunistic crowd sensing network and belongs to the wireless sensor network and mobile ad hoc network technical field. According to the method, nodes in the network estimate the node residual energy of the nodes themselves, the encounter probability of the nodes and a destination node and the hops of message transmission according to the conditions of the nodes themselves and the historical information of the network, judge a network environment where the nodes are located currently by using local topological information of positions where the nodes are located, and selects suitable data transmission mechanisms. With the method adopted, communicated MANET subnets in the network can be accurately identified, and are fully utilized in a data transmission process, and the communicated MANET subnets have little possibility of being affected by the mobility of the nodes and the time variance of network topology, and the success rate of data transmission can be improved, network overhead can be reduced, and the robustness of a data transmission strategy can be improved.

Owner:鲲腾技术有限公司

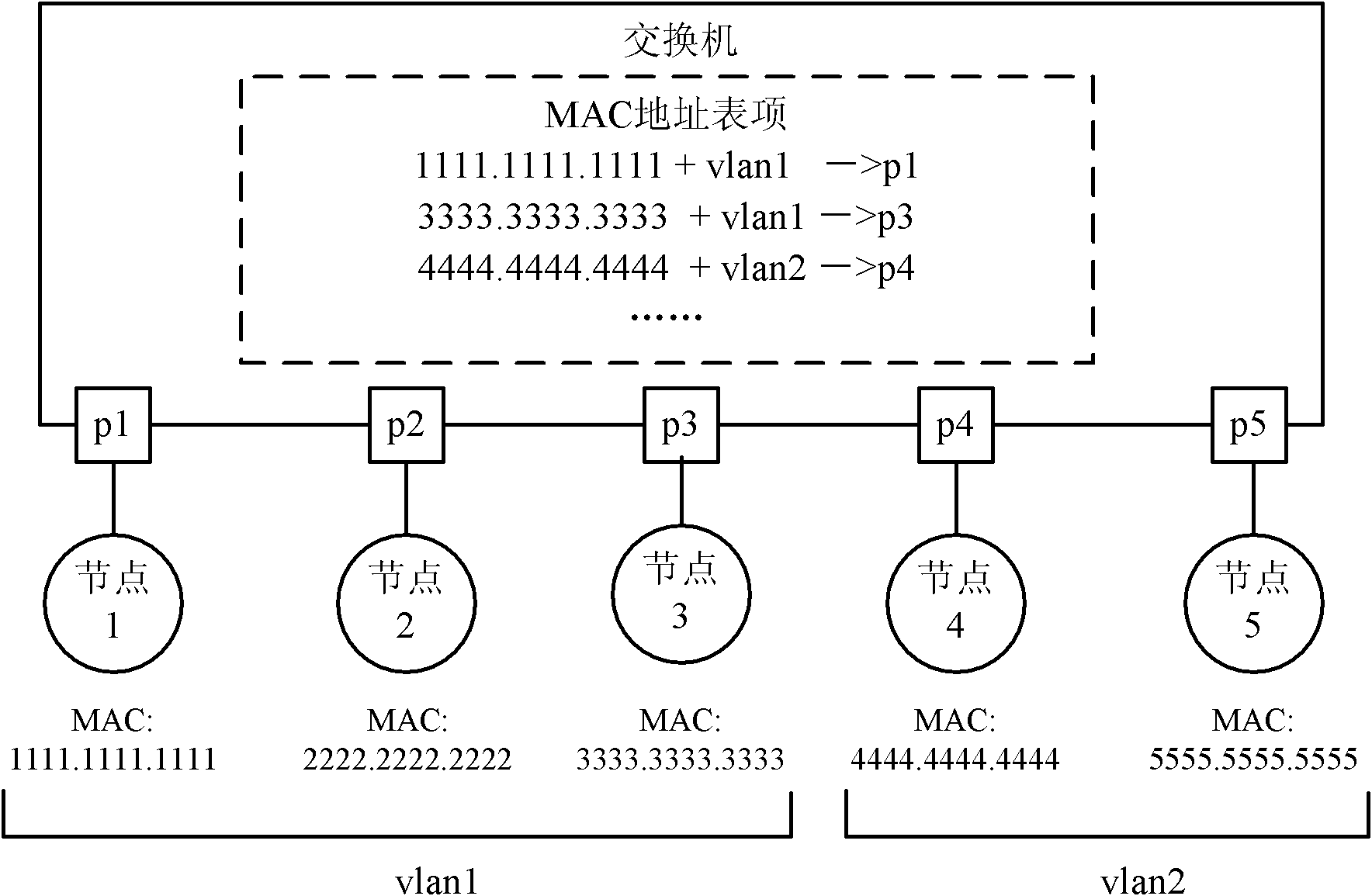

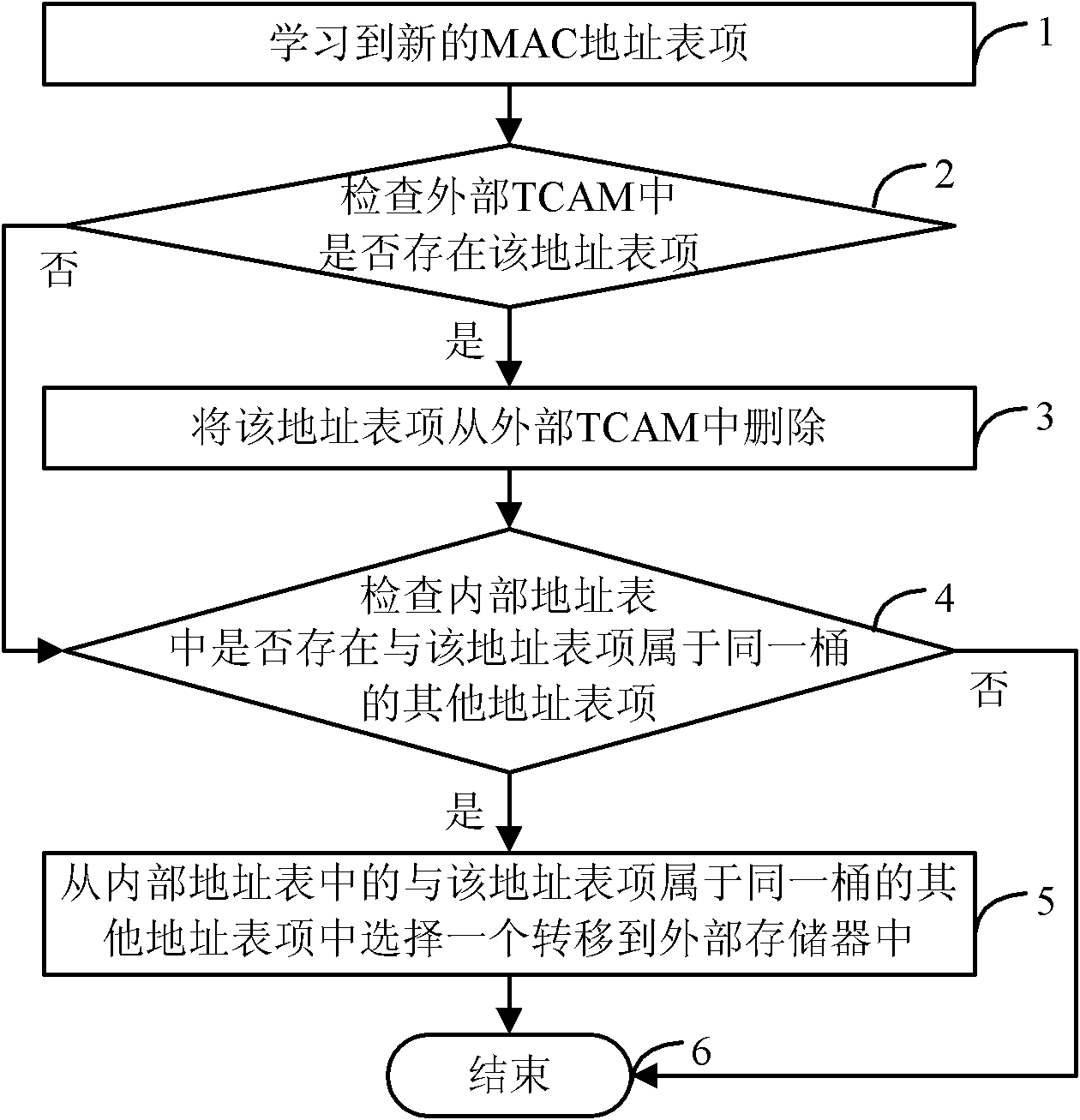

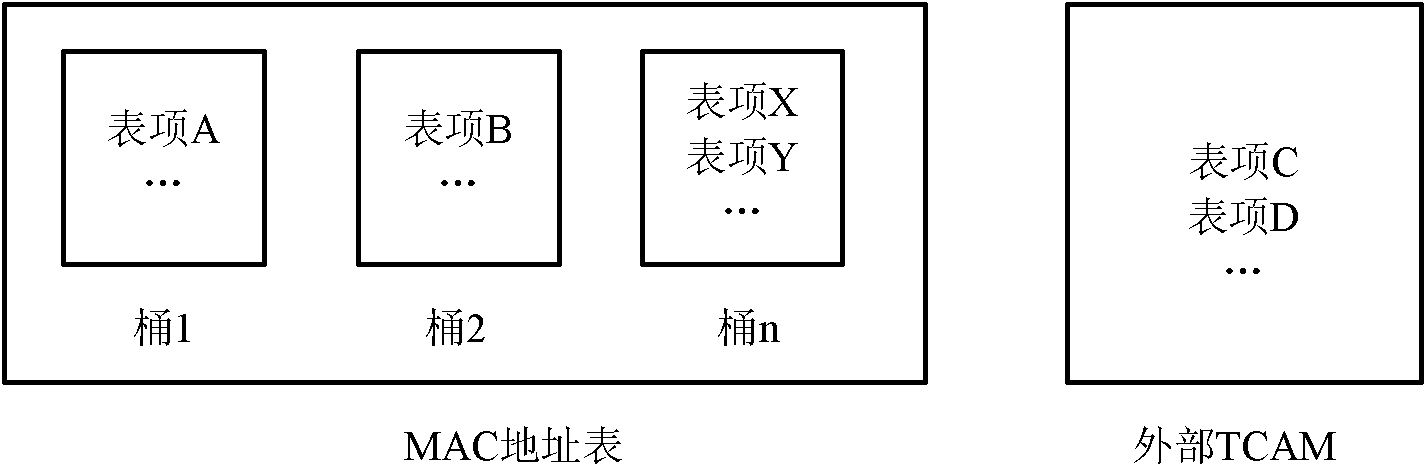

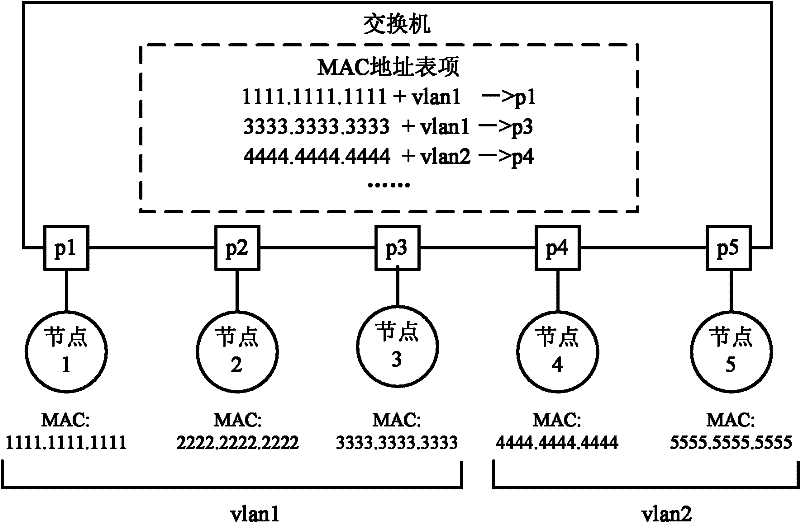

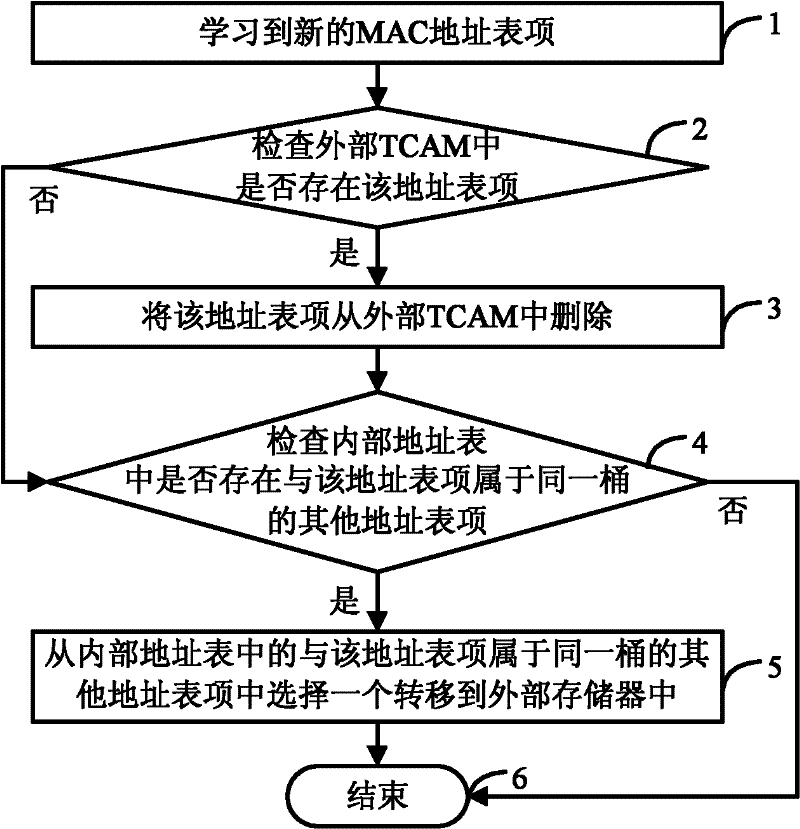

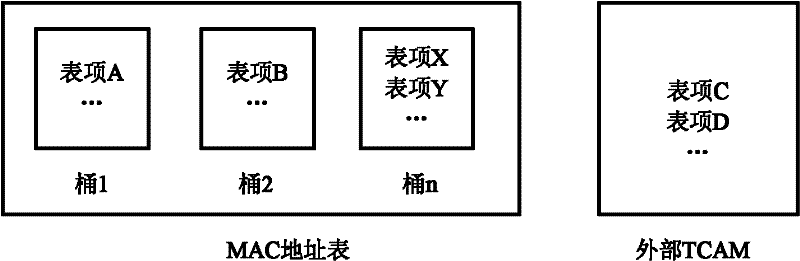

Updating method, device and network equipment of media access control address table

ActiveCN102045262AAvoid frequent transfersReduce occupancyData switching by path configurationOccupancy rateExternal storage

The invention discloses an updating method, device and network equipment of a media access control address table. The updating method comprises the following steps: when learning new address table entries, judging whether the number of the address table entries in an internal address table is more than the set upper waterline; when the number of the address table entries in the internal address table is larger than the set upper waterline, transferring at least one address table entry except the new address table entries from the internal address table to an external storage until the number of the address table entries in the internal address table is less than the set lower waterline; and when the number of the address table entries in the internal address table is not more than the set upper waterline, avoiding the address table entries in the internal address table from being transferred to the external storage. By utilizing the method, the frequent transferring of the address table entries between the internal address table and the external storage is avoided, the memory occupancy rate is reduced, and the system performance of the network equipment is improved.

Owner:BEIJING ZHIGU TECH SERVICE

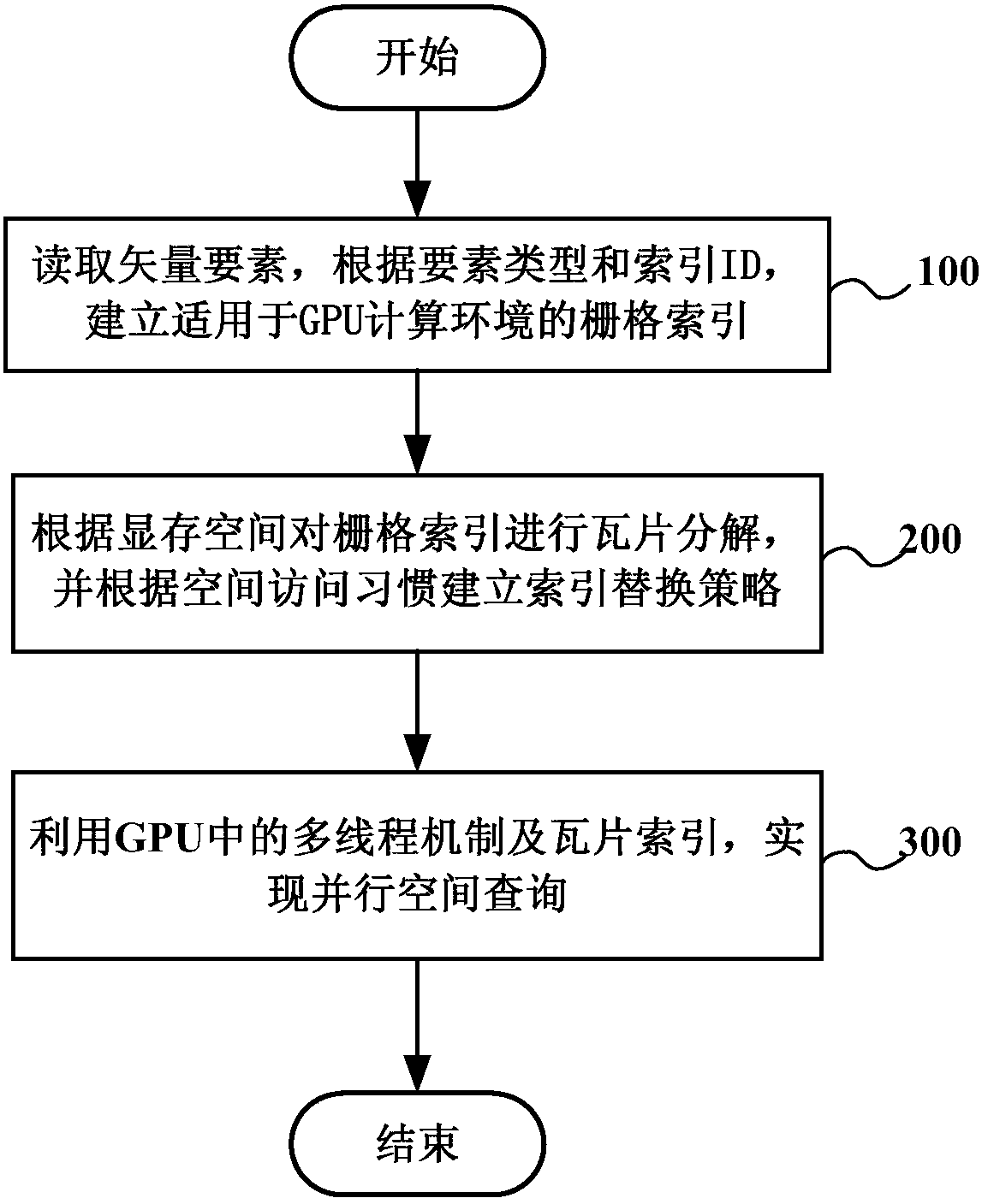

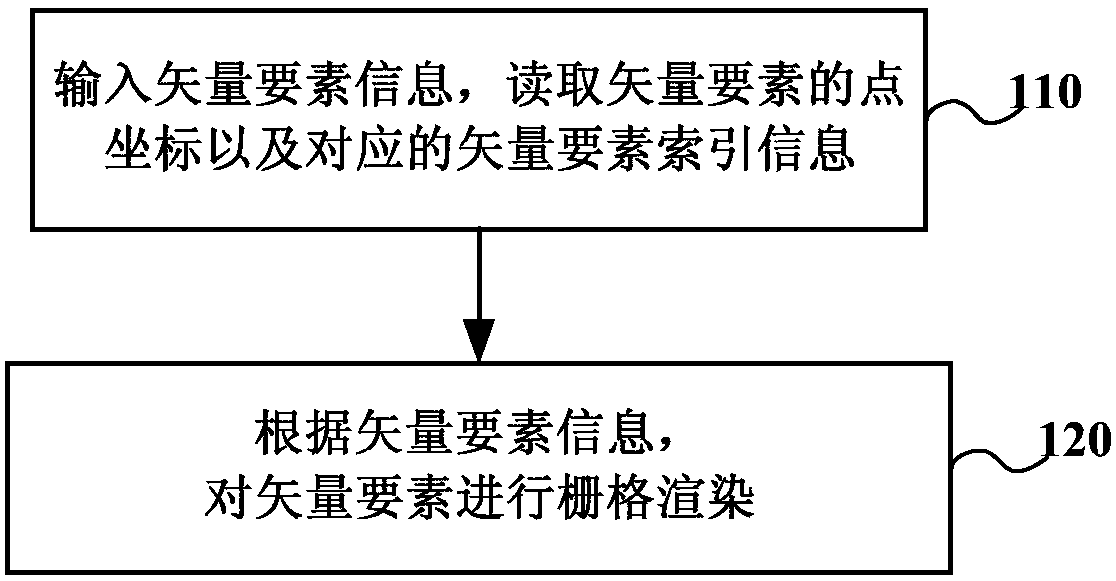

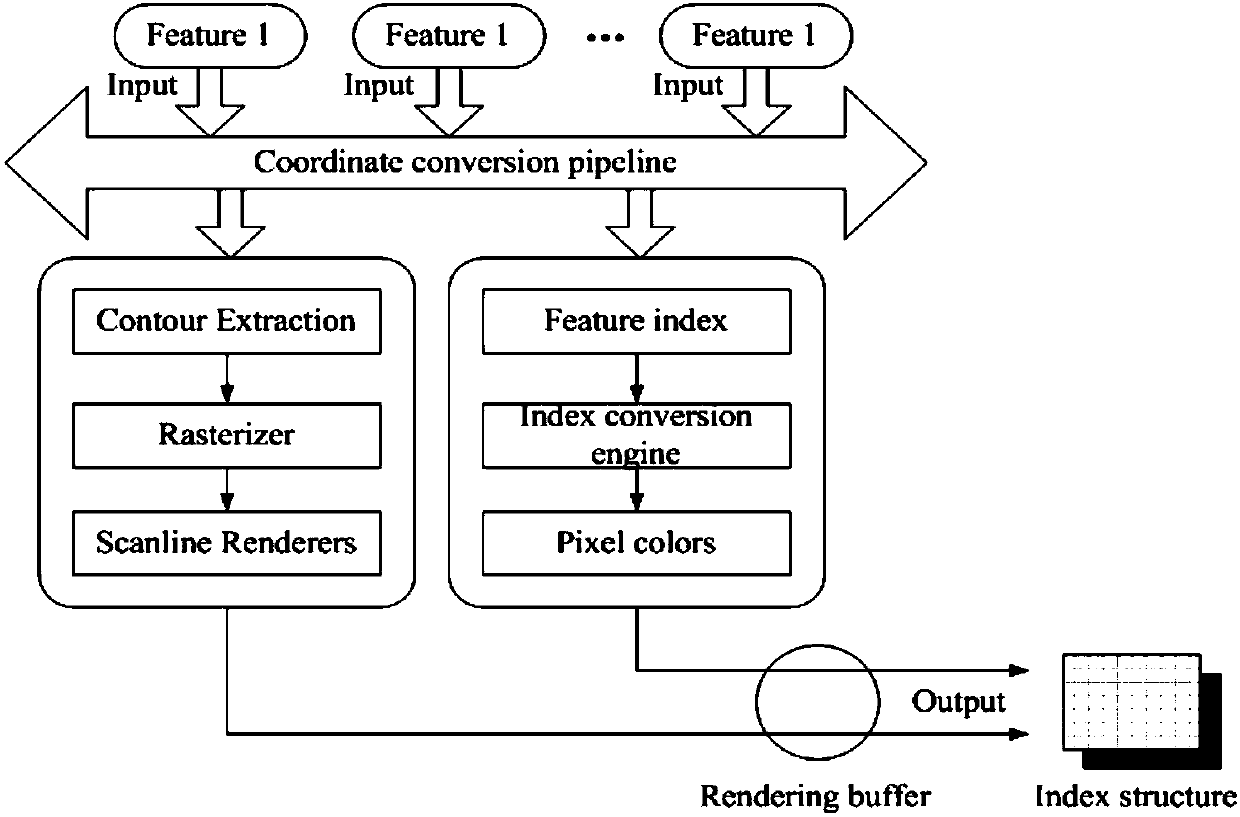

Parallel spatial query method based on CUDA

InactiveCN107784001AAvoid frequent transfersAvoid calculationGeographical information databasesSpecial data processing applicationsComputation processResult set

The invention relates to a parallel spatial query method based on a CUDA, and belongs to the technical field of computers. Compared with a common spatial query method using a tree index, the designedparallel spatial query method has obvious advantages. A query result set can be determined as long as parallel extraction is conducted on corresponding positions of grid indexes according to query conditions. The filtering step and the refining step of an original method are combined, frequent transmission of candidate sets in a display memory and a main memory is avoided, a large number of calculation processes are avoided during accurate matching, and the query efficiency is greatly improved.

Owner:BEIJING INST OF COMP TECH & APPL

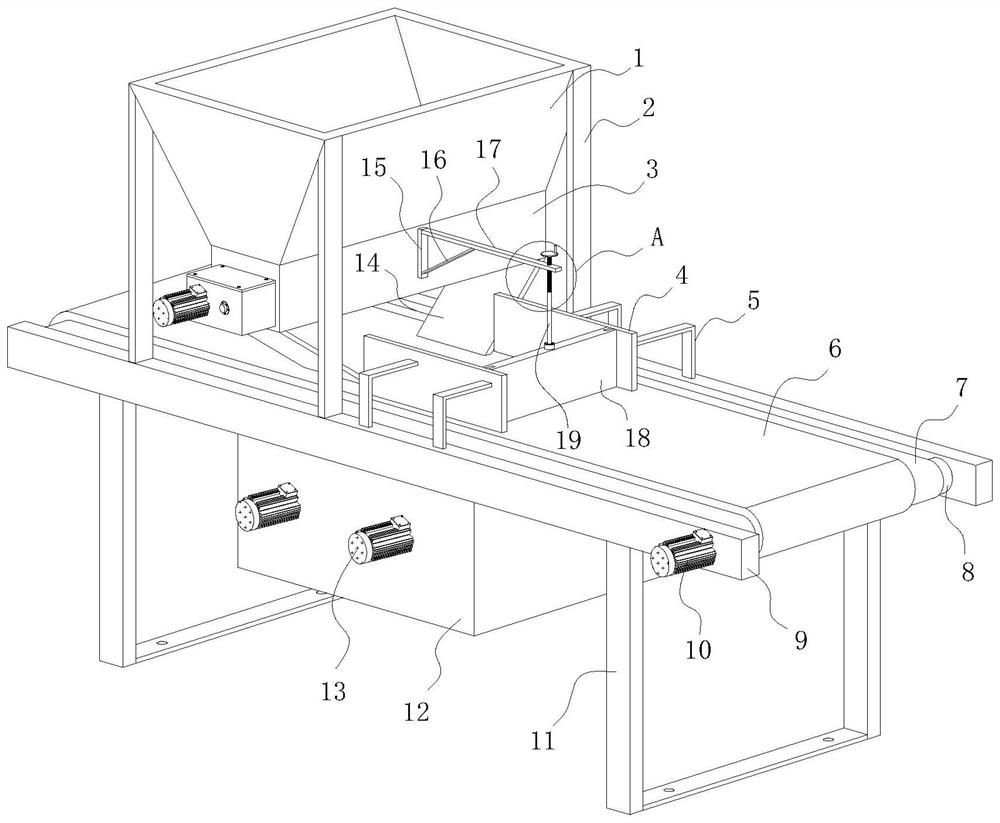

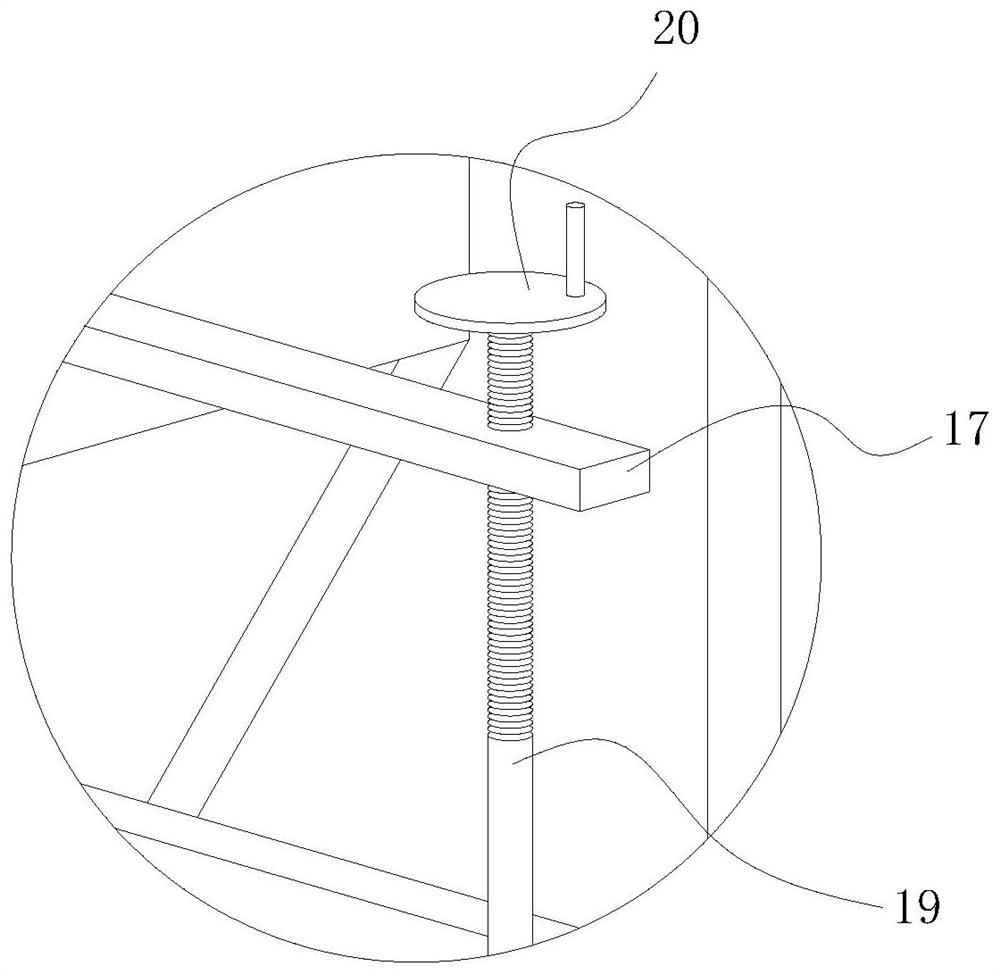

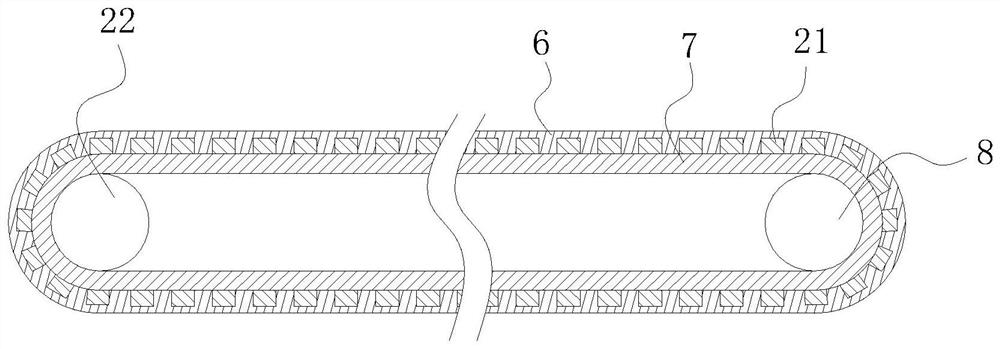

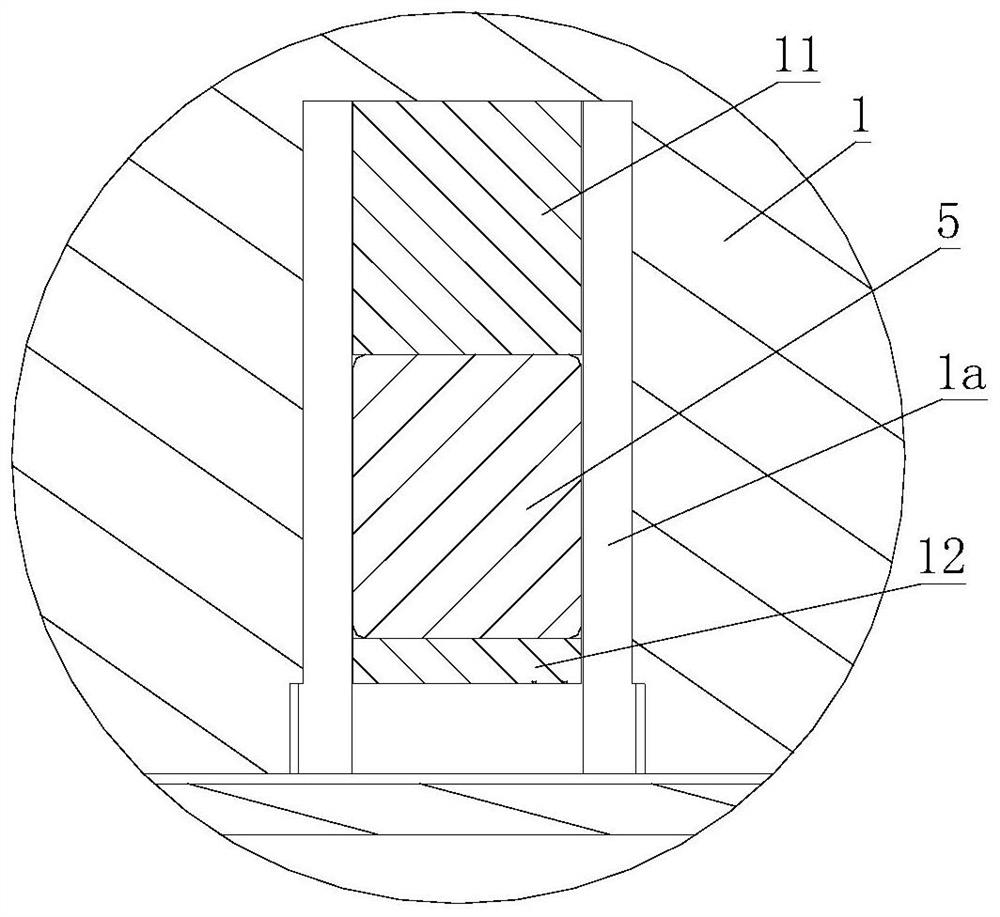

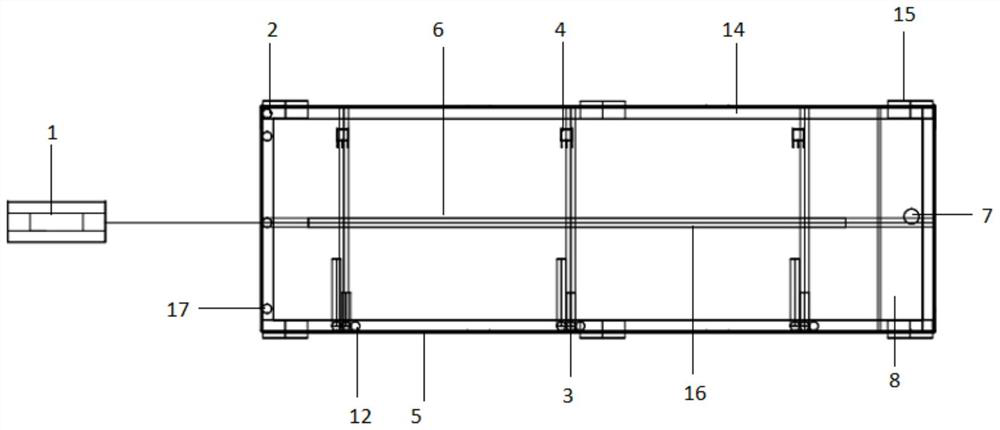

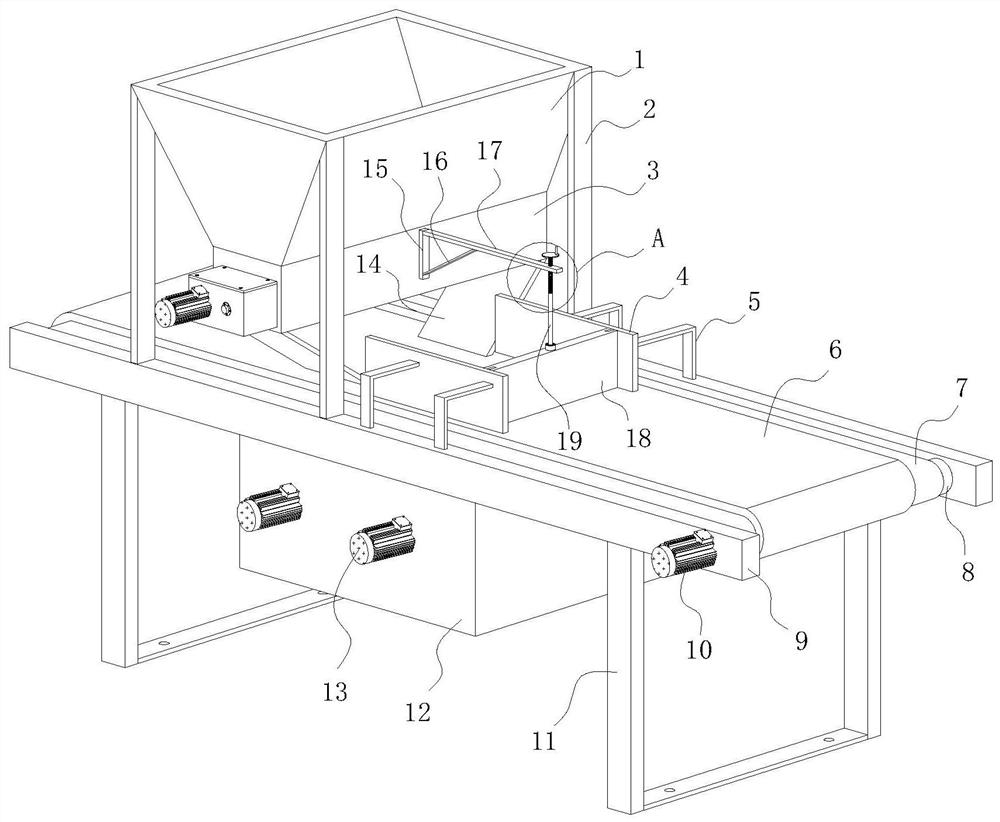

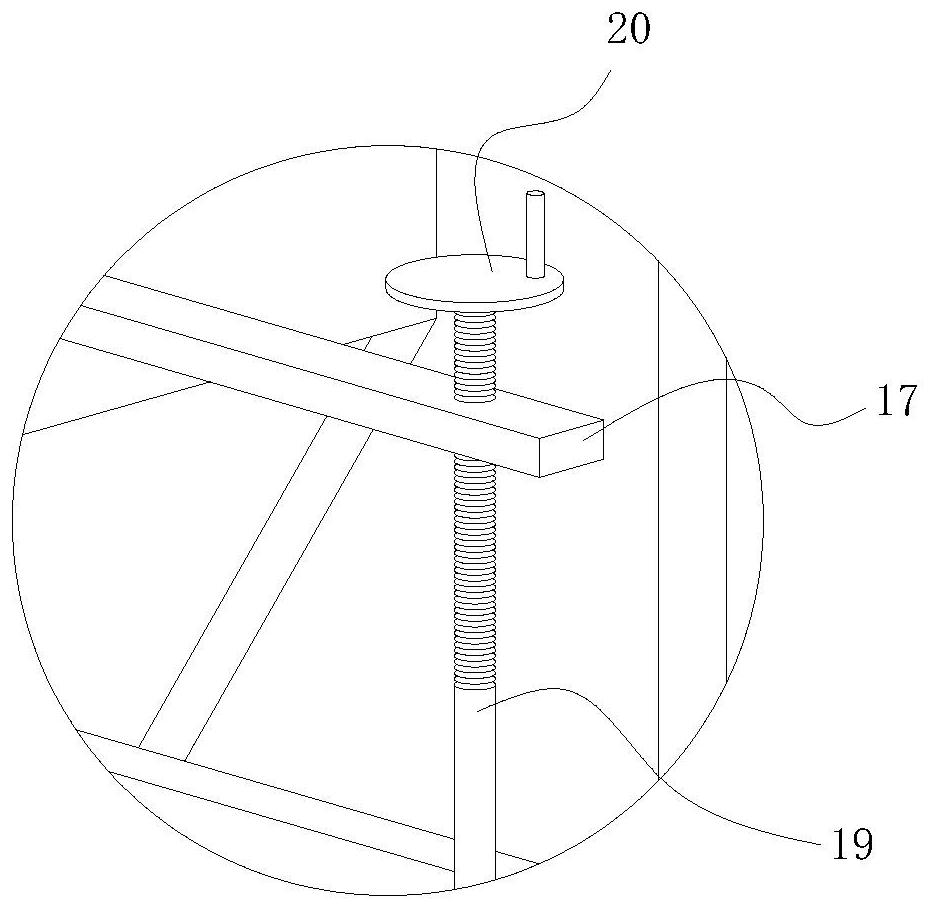

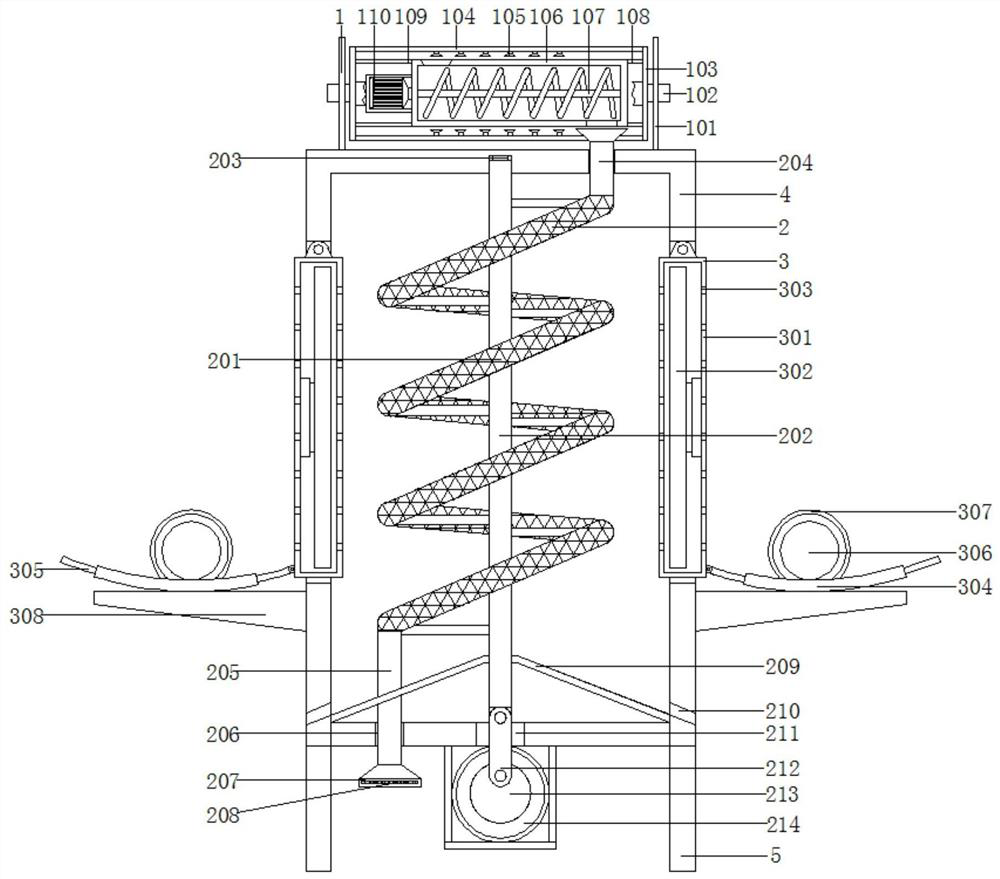

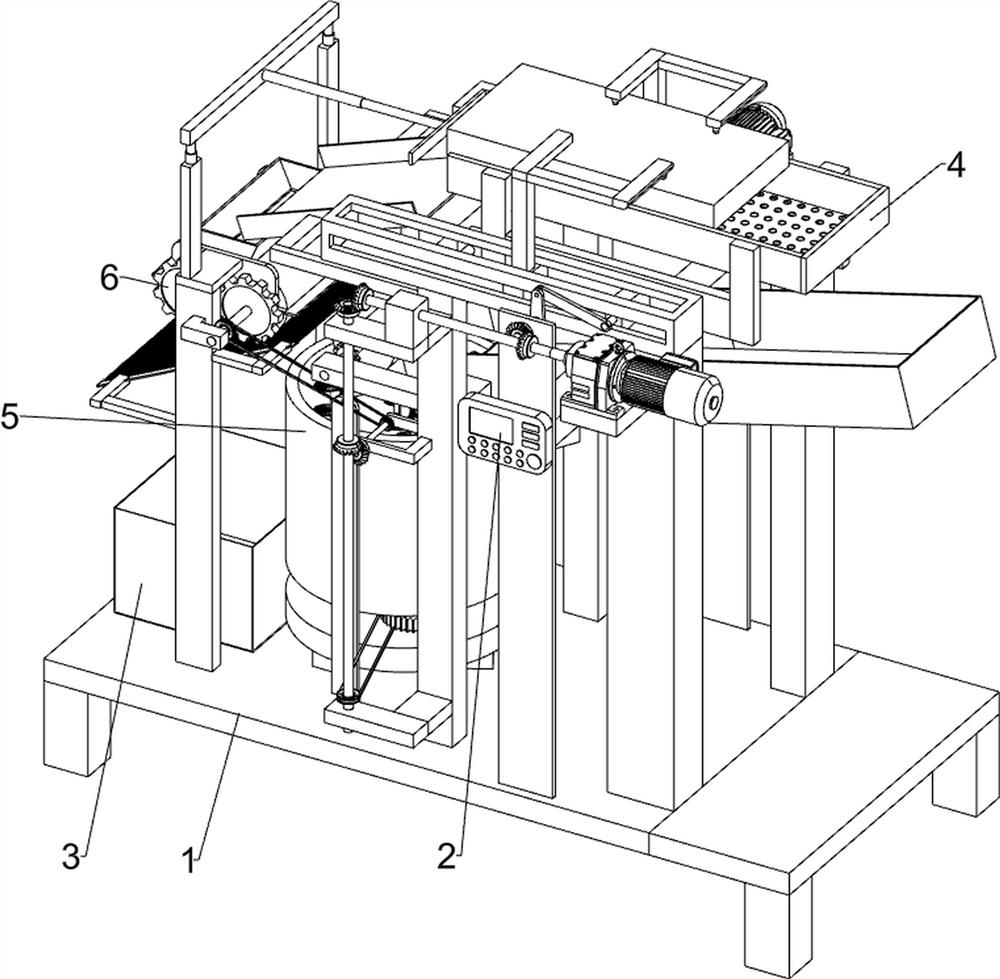

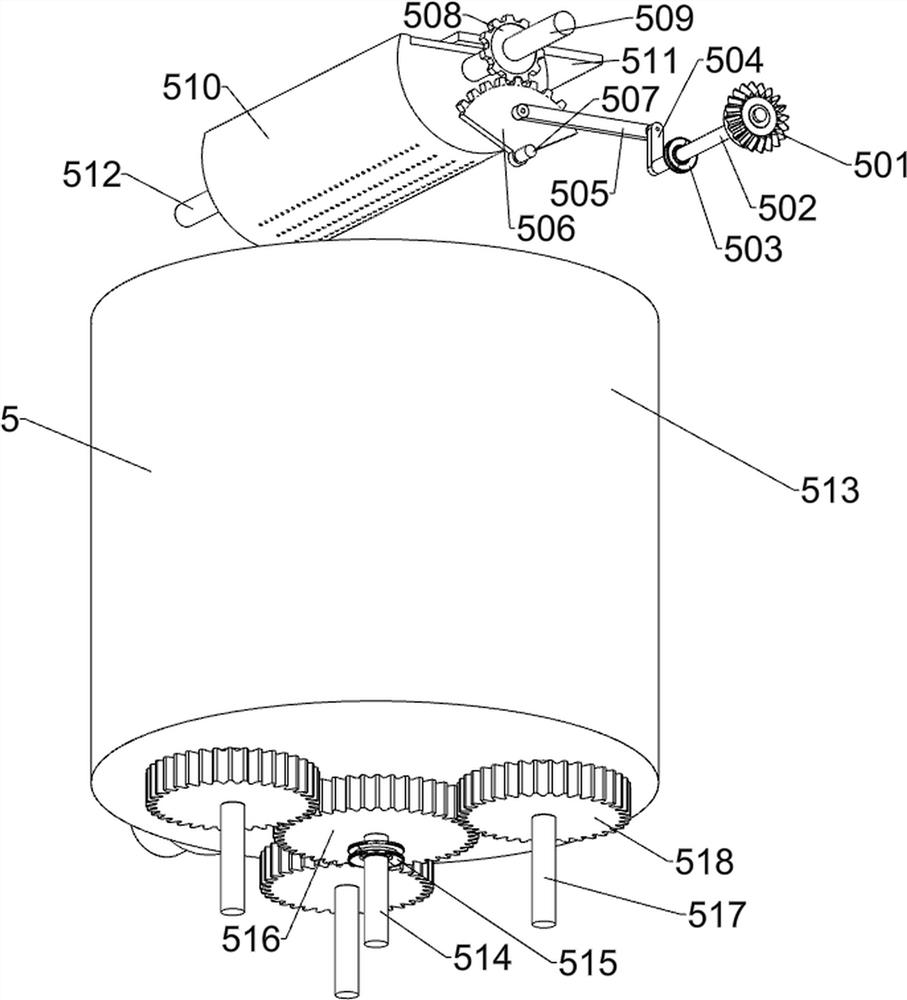

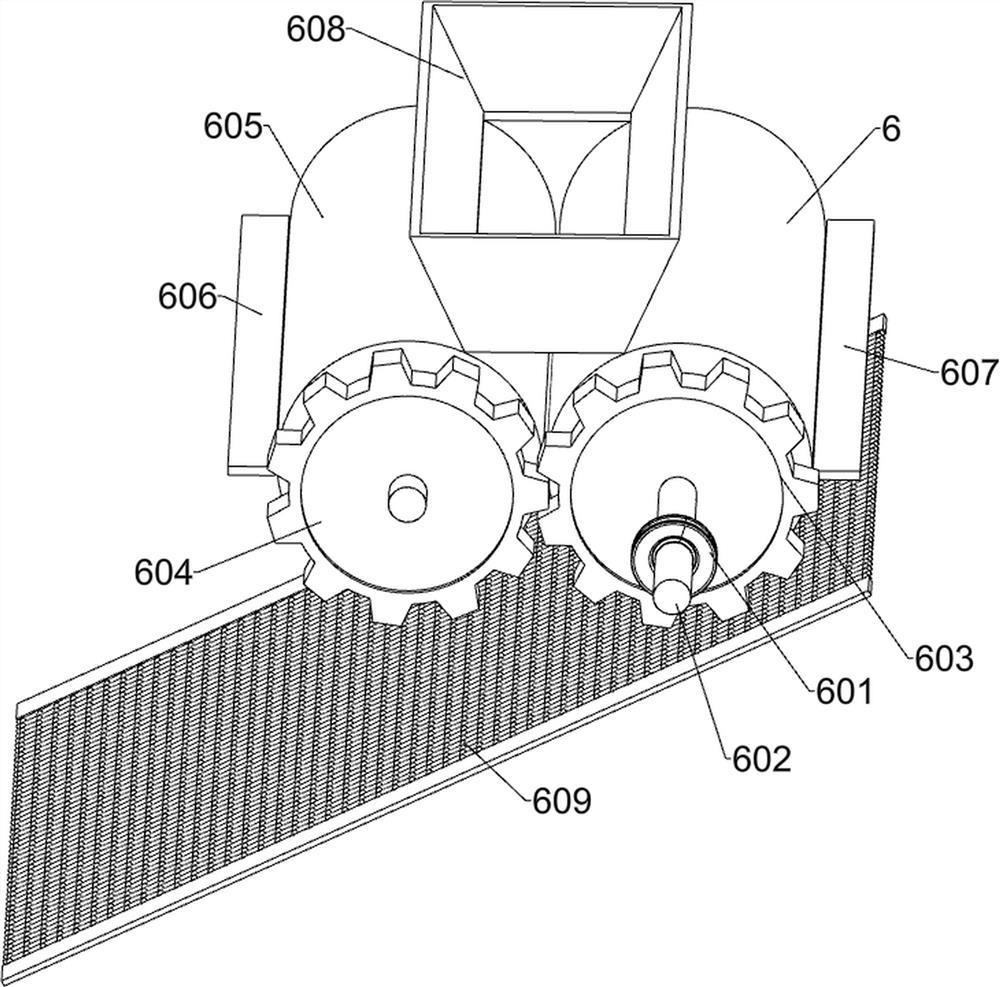

Steel mill waste residue crushing magnetic-separation processing device

The invention relates to the technical field of waste residue treatment, and particularly relates to a steel mill waste residue crushing magnetic-separation processing device. The device comprises a stock bin, a double-shaft crusher, a cross beam, a supporting plate, a first belt roller, a second belt roller, a transmission belt, a rubber pad, a magnet strip, a rectangular frame body and a brush roller, wherein the steel slag crushed by the double-shaft crusher falls onto the rubber pad with the magnet strip; the rotating transmission belt drives the rubber pad to move together, so that the rubber pad drives the crushed steel slag to move, iron waste residues in the crushed steel slag are attached to the surface of the rubber pad under the adsorption of the magnet strip at the moment, other waste residues are discharged to the ground from the rubber pad, and the purpose of separating the iron waste residues is achieved; and when the rubber pad moves into the rectangular frame body, therotating brush roller sweeps off the iron waste residues attached to the rubber pad to the ground on the lower side of the rectangular frame body, so that the integration of steel slag crushing and separation is realized, frequent transfer of the steel slag is avoided, the labor intensity is reduced, and the working efficiency is improved.

Owner:祁小蒙

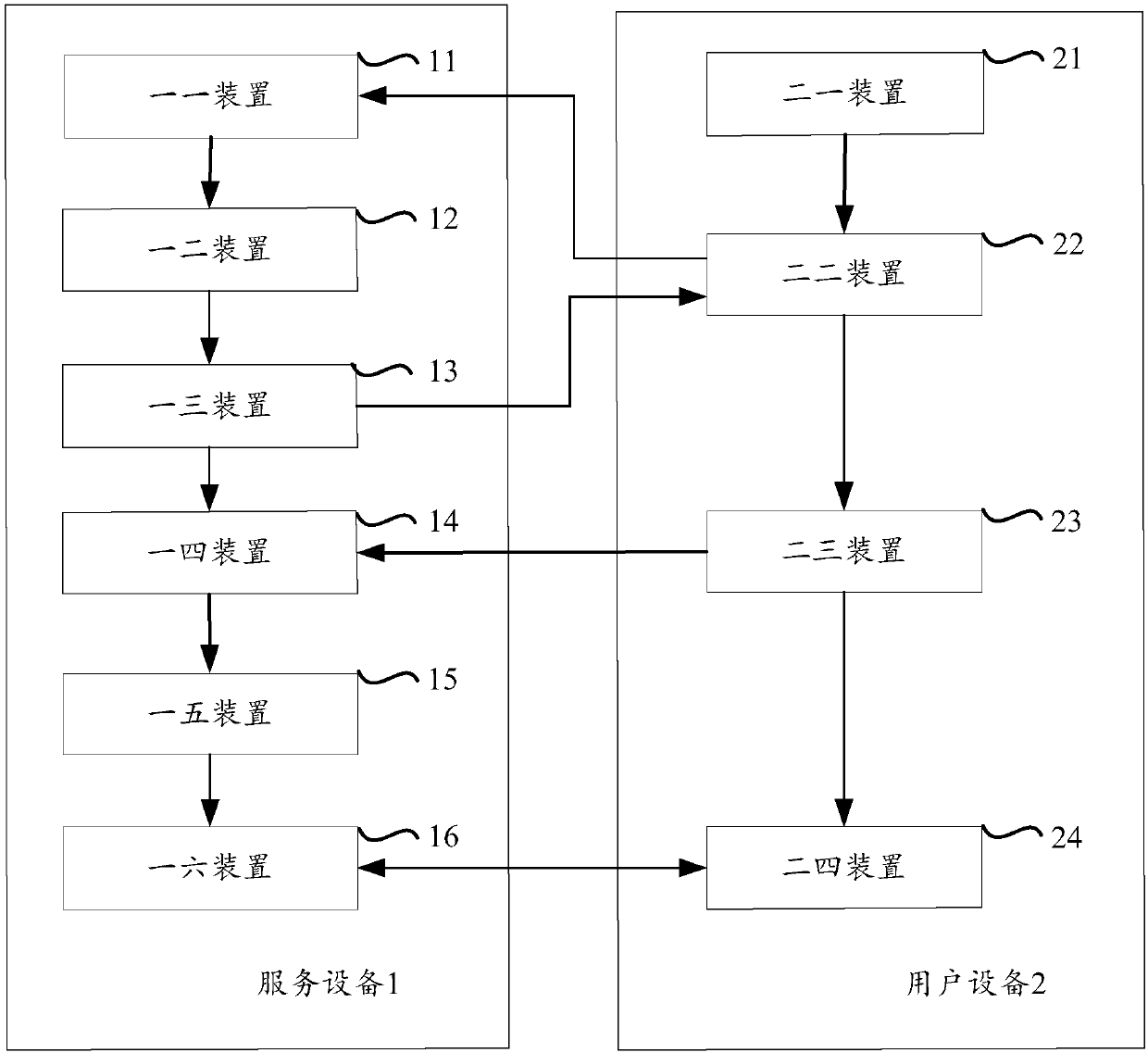

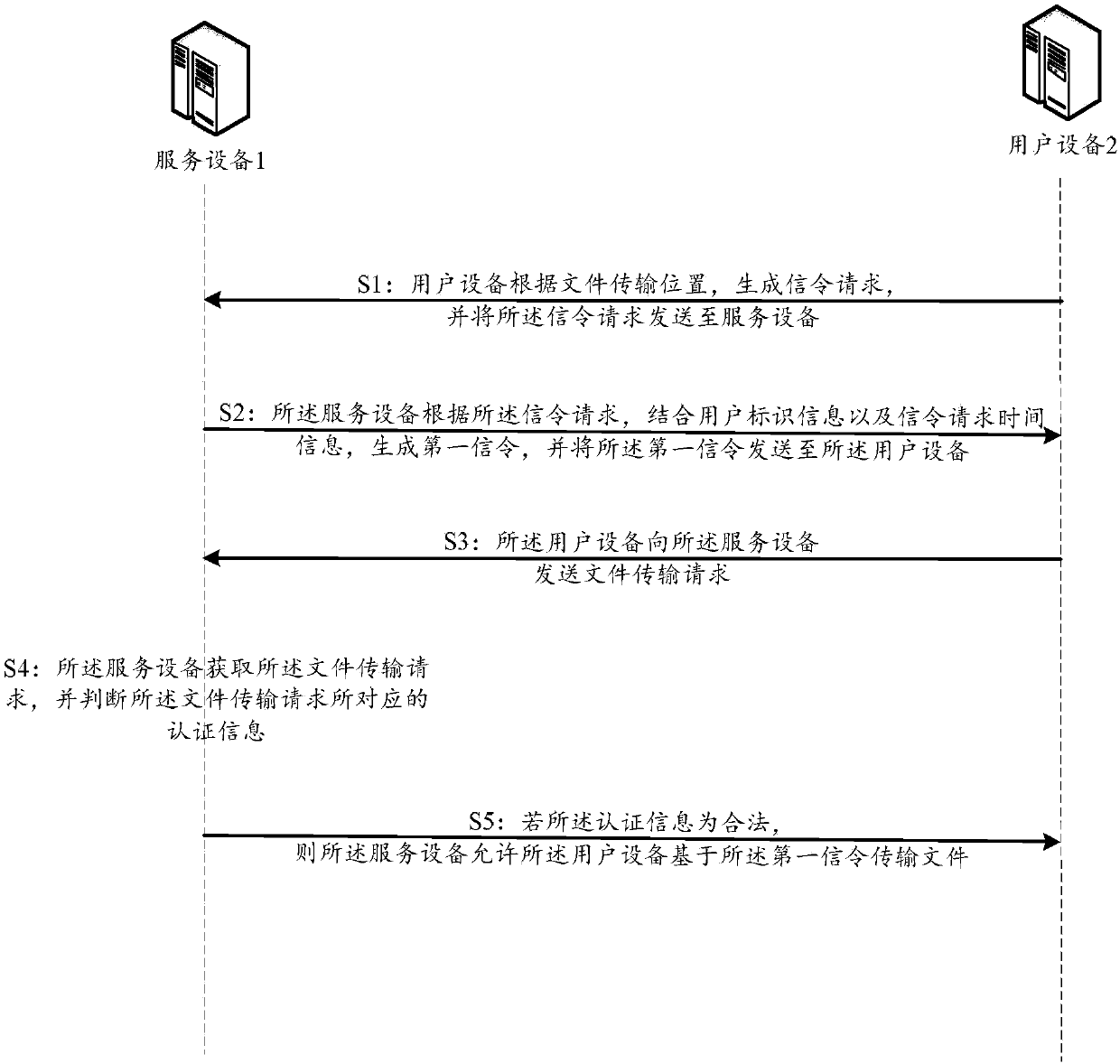

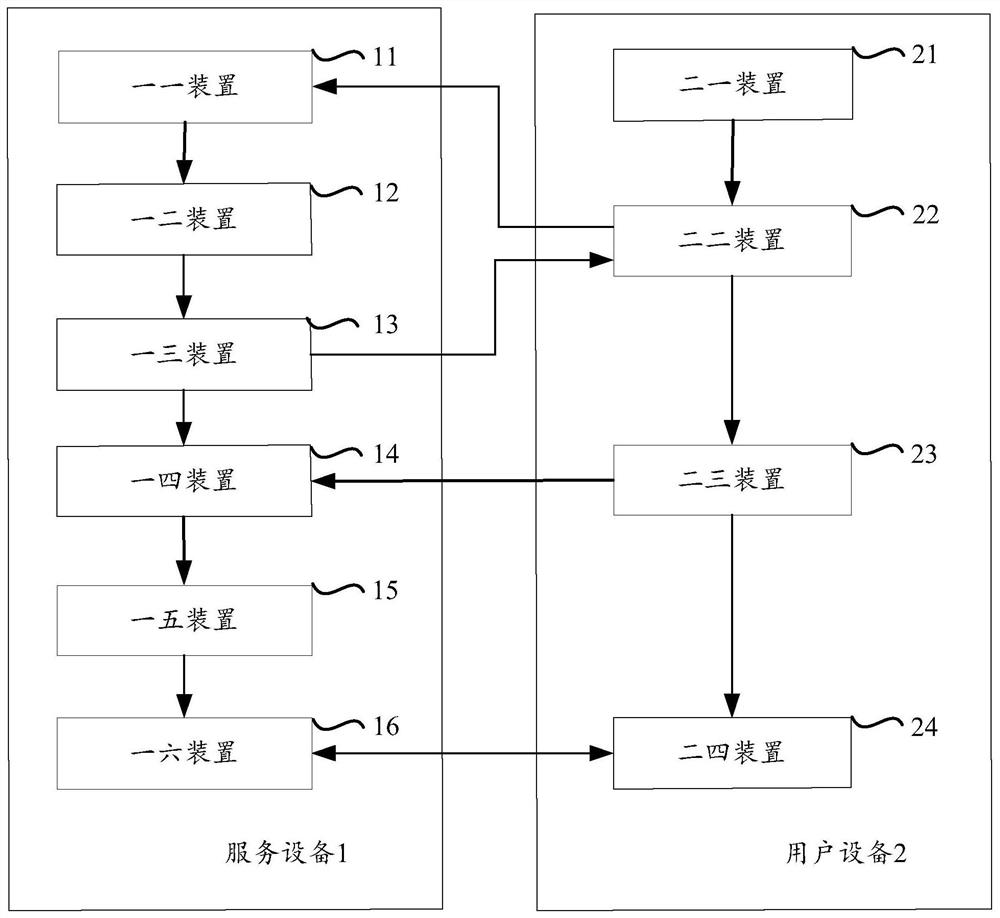

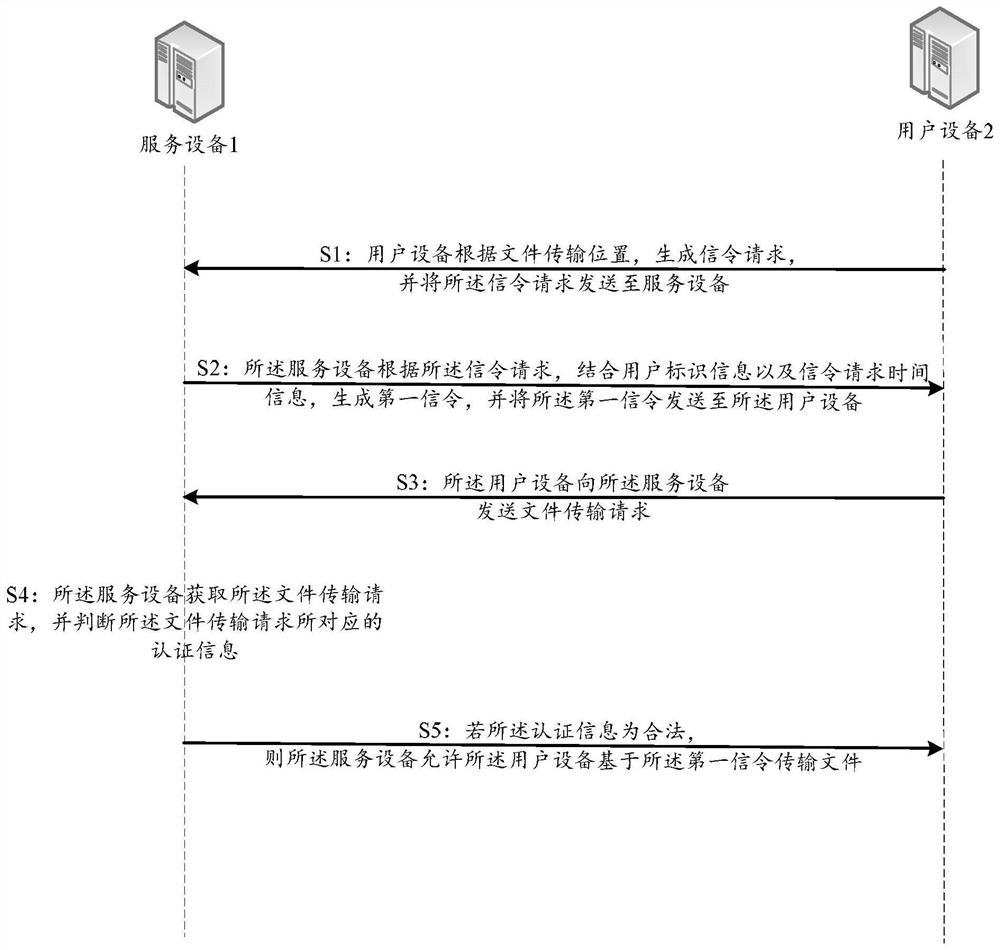

Method and device for file transmission

ActiveCN107707630AImprove user experienceEnsure safetyTransmissionComputer hardwareFile transmission

The invention aims at providing a method and device for file transmission and a system. Compared with the prior art, the method has the advantages that a first signal is generated through adoption ofa service device; when a user device sends a file transmission request, the file transmission request is verified based on the first signal; if the first signal corresponds to a transmitted file, thefile transmission request is rejected, on the contrary, if the first signal does not correspond to the transmitted file, the user device is allowed to carry out the data transmission; the file transmission times is limited through adoption of the first signal; one signal is guaranteed to only correspond to single-time file transmission; a conflict possibly occurring when repeated file uploading iscarried out can be effectively avoided; and moreover, under the condition that a user is allowed to check the uploaded file, the uploaded file is prevented from being checked repeatedly. According tothe method, the device and the system, the file transmission security, reliability and validity can be effectively ensured, and moreover, the use experience of the user is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

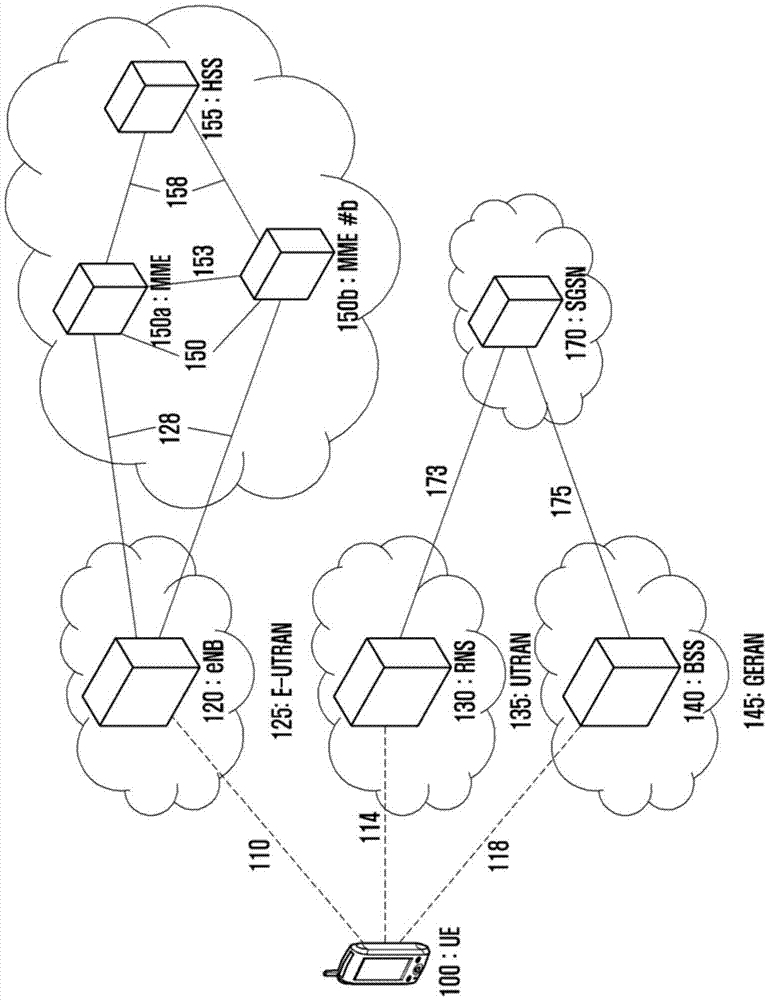

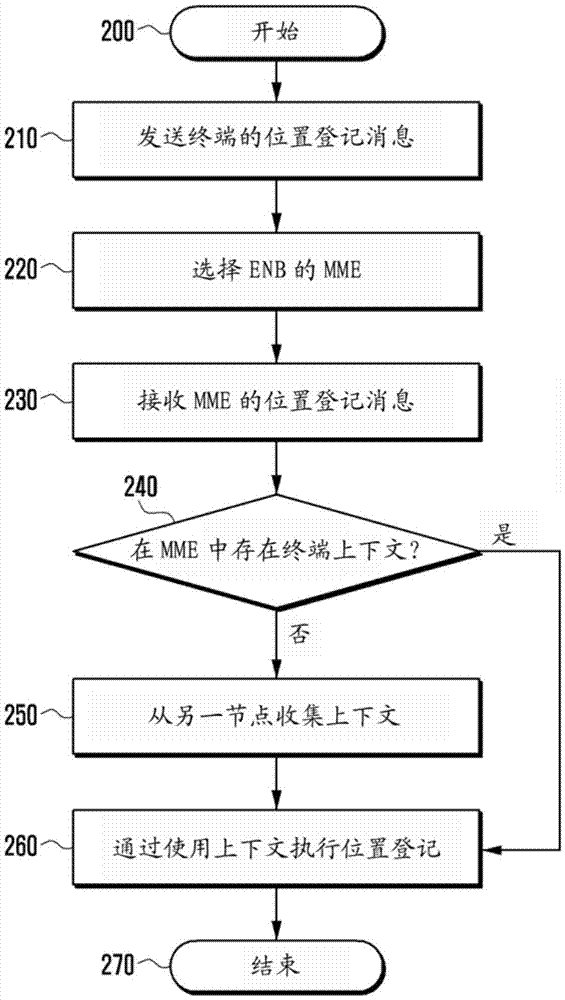

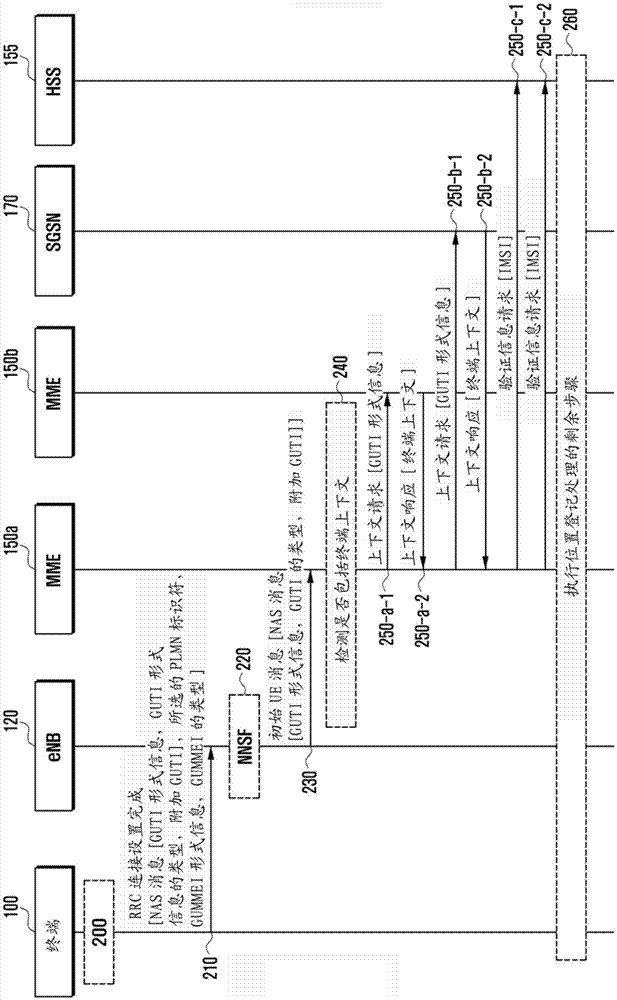

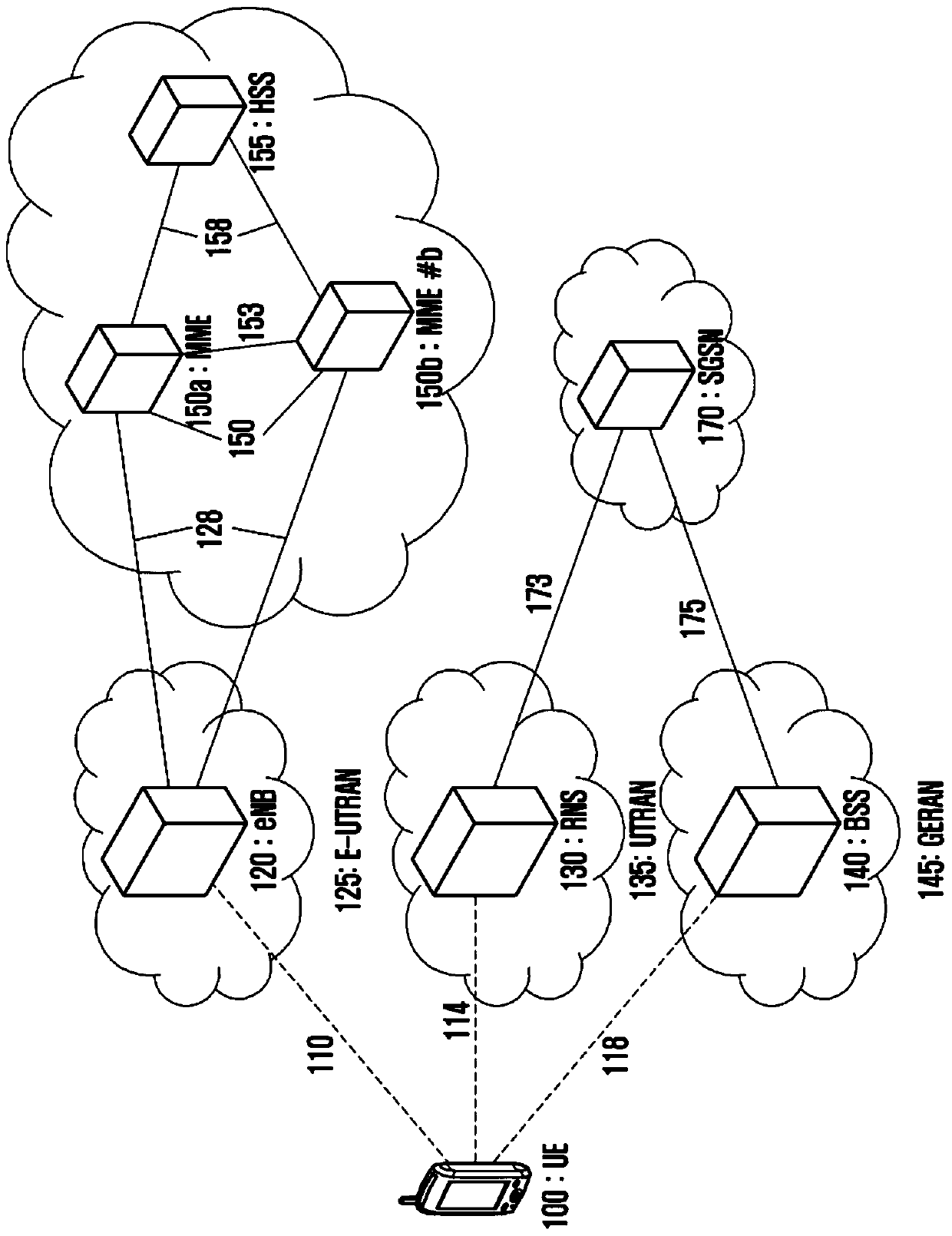

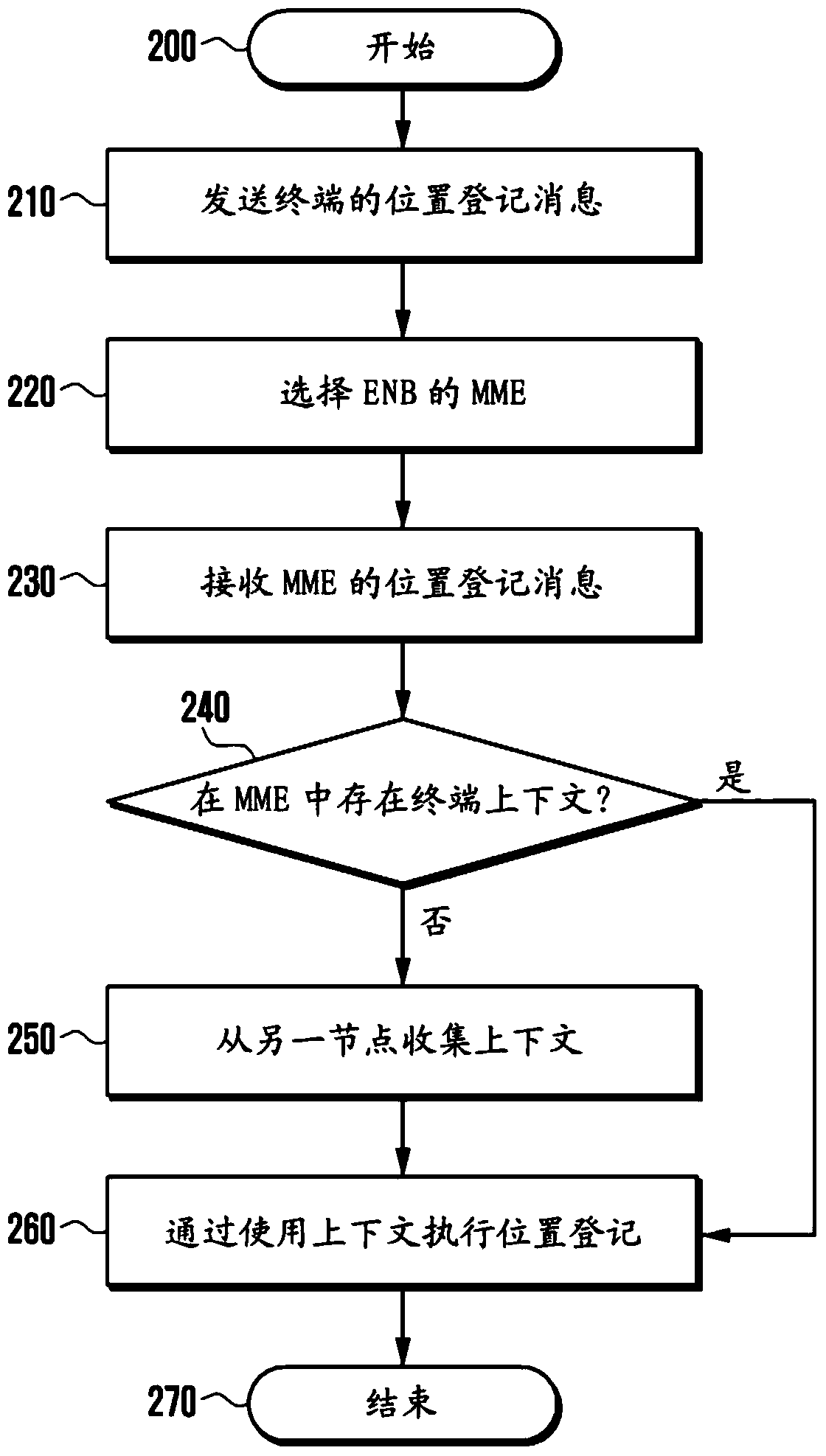

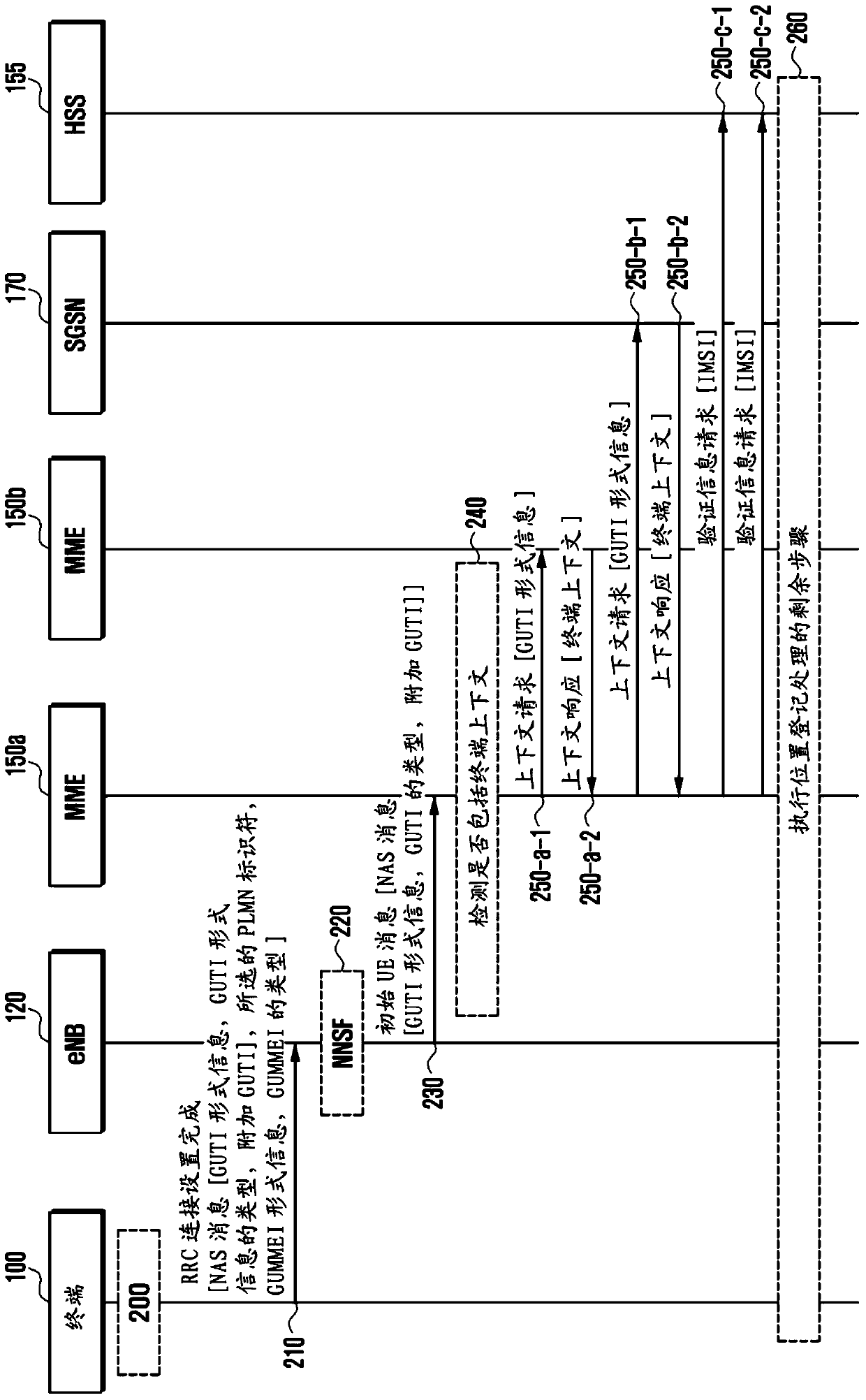

Method and apparatus for obtaining authentication information

ActiveCN105453617AAvoid frequent transfersPrevent overloadNetwork traffic/resource managementSecurity arrangementComputer terminalMobility management

An embodiment of the present invention relates to a method and an apparatus for collecting authentication information of a terminal while reducing the load of a home subscriber server (HSS). The present invention provides a method and an apparatus for transmitting a location registration message of a terminal for convenience of the mobility management node selection by a base station, a method and an apparatus for the mobility management node selection by a base station, and a method and an apparatus for collecting authentication information by the mobility management node. According to the embodiment of the present invention, it is possible to obtain authentication information of the terminal while reducing the load of the HSS.

Owner:SAMSUNG ELECTRONICS CO LTD

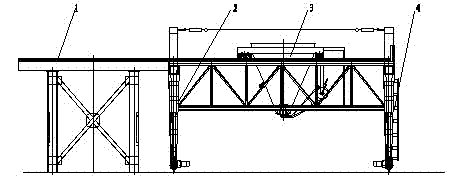

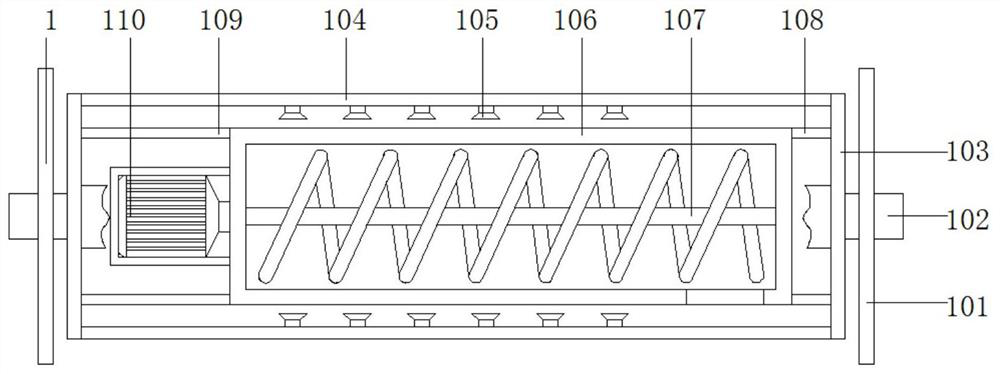

Vertical type automatic feeding machine

InactiveCN102848463AAvoid frequent transfersIncrease usageCeramic shaping apparatusGround trackEngineering

The invention relates to a vertical type automatic feeding machine. The feeding machine comprises a cart travelling mechanism and a hopper component, wherein the cart travelling mechanism comprises a portal crane, a ground track, and a fixed track which is butted with the portal crane and located at the upper part of a stirring frame; and the hopper component is arranged on two beams of the portal crane, and comprises a hopper and a travelling device for enabling the hopper to move on the two beams. According to the vertical type automatic feeding machine disclosed by the invention, four points of the hopper are fixed on the two beams, so that the stability is high; an independent track is adopted, so that the operation of the crane is not interfered, and the utilization ratio of unit space is improved; and a fixed track frame is arranged under a stirring station, and when a cart travels to a designated position, the body of the hopper leaves the cart and automatically travels to the fixed track frame, thus achieving the purpose of freely receiving materials under the stirring station, preventing the hopper from frequently transferring, and lowering the labor intensity of workers.

Owner:江苏邦威机械制造有限公司

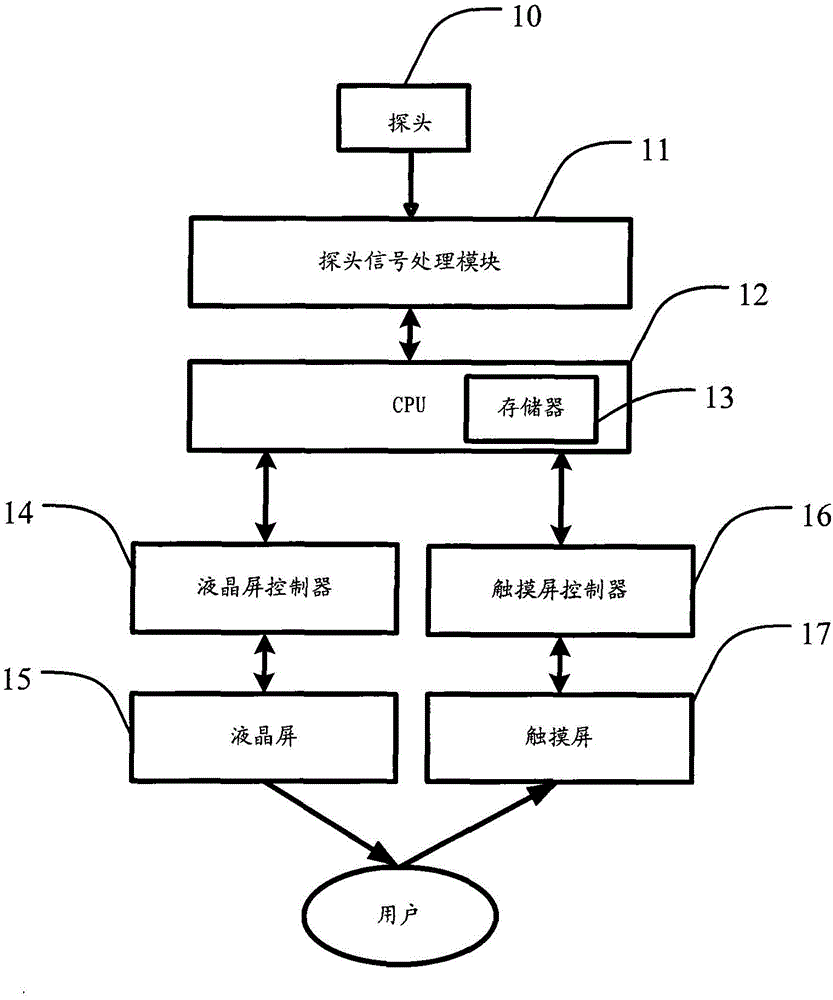

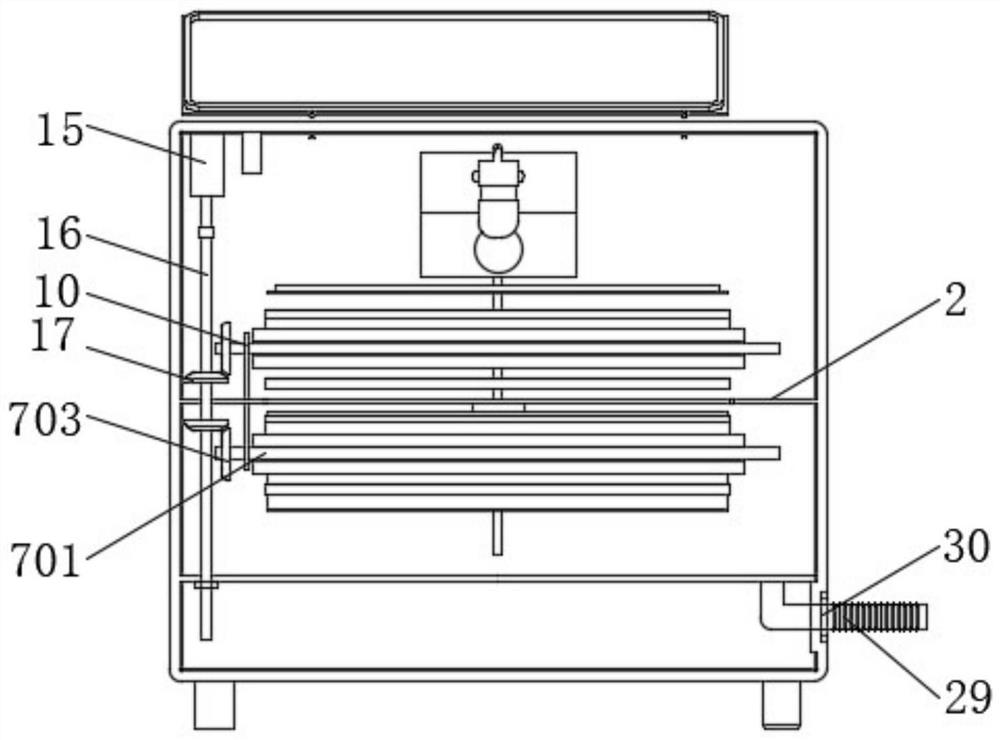

Digital oscillographic signal display device

InactiveCN104569529AReduce volumeAvoid frequent transfersDigital variable displayLiquid-crystal displayDisplay device

The embodiment of the invention relates to the field of measuring electronic signals, and provides a digital oscillographic signal display device. The digital oscillographic signal display device comprises a probe signal processing module, a CPU, a touch screen, a touch screen controller, a liquid crystal display screen, and a liquid crystal screen controller, so that the device can be displayed, operated and controlled in a unified manner, frequent attention diversion during operation of users is avoided, and observation and operation are convenient. The man-machine interaction degree is increased, a complex man-machine interaction interface is easy to implement, and complex functions are easy to realize. The size of the device is decreased, and the cost is reduced.

Owner:XIAN QUNFENG ELECTRONICS INFORMATION TECH

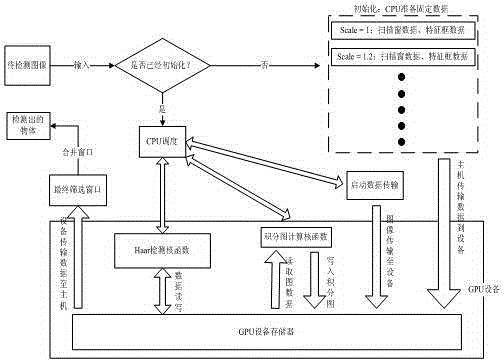

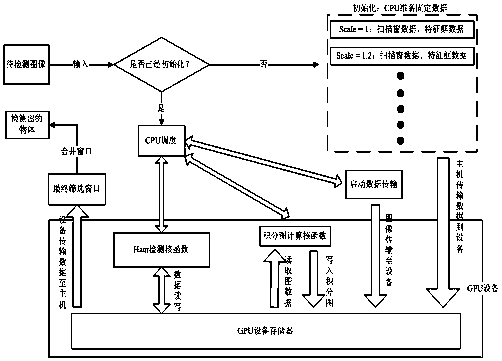

Haar detection method based on GPU acceleration

ActiveCN105160350AAvoid frequent transfersFast implementationCharacter and pattern recognitionAlgorithmData preparation

The invention discloses a Haar detection method based on GPU acceleration. The method is characterized by comprising the following steps that: (1) system initialization is carried out, and a CPU transmits all scanning windows under an amplification coefficient, characteristic frame information and classifier parameter data and stores all the scanning windows under the amplification coefficient, the characteristic frame information and the classifier parameter data to GPU equipment; (2) thread numbers are set in sequence according to the column number of a image matrix, a kernel function is called twice, matrix transposition is carried out twice, and integration graphs and square integration graphs of images are are obtained; (3) the scanning windows and characteristic rectangle frames are arranged in a global memory of a GPU, and haar algorithm detection is carried out; and (4) rectangle frame merging is carried out on all the scanning windows passing strong classifiers, and a detection result is obtained. According to the invention, an existing haar algorithm is improved in three aspects of data preparation modes, rapid calculation of the integration graph, and staged and pointed Haar detection, so that the realization speed of the haar algorithm is substantially increased, the practical value is fully reflected, and the practical value and the popularization value are very high.

Owner:深圳市哈工交通电子有限公司

Method for regulating sleep cycle of mobile station on basis of service reshaping and channel prediction

InactiveCN102104941BAvoid frequent transfersReduce switching timesEnergy efficient ICTPower managementTime conditionTransceiver

Owner:XIDIAN UNIV

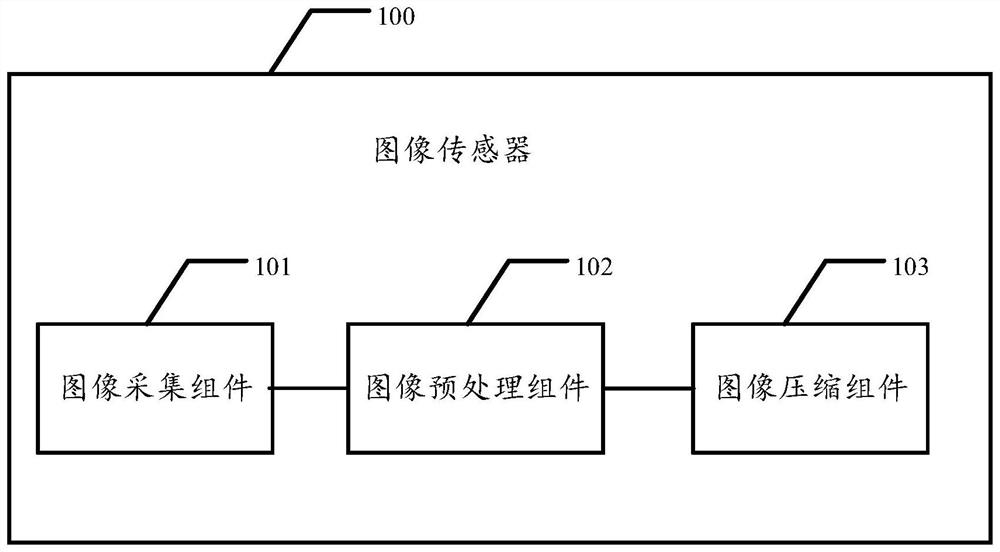

Image sensor, image processing device, image processing method and storage medium

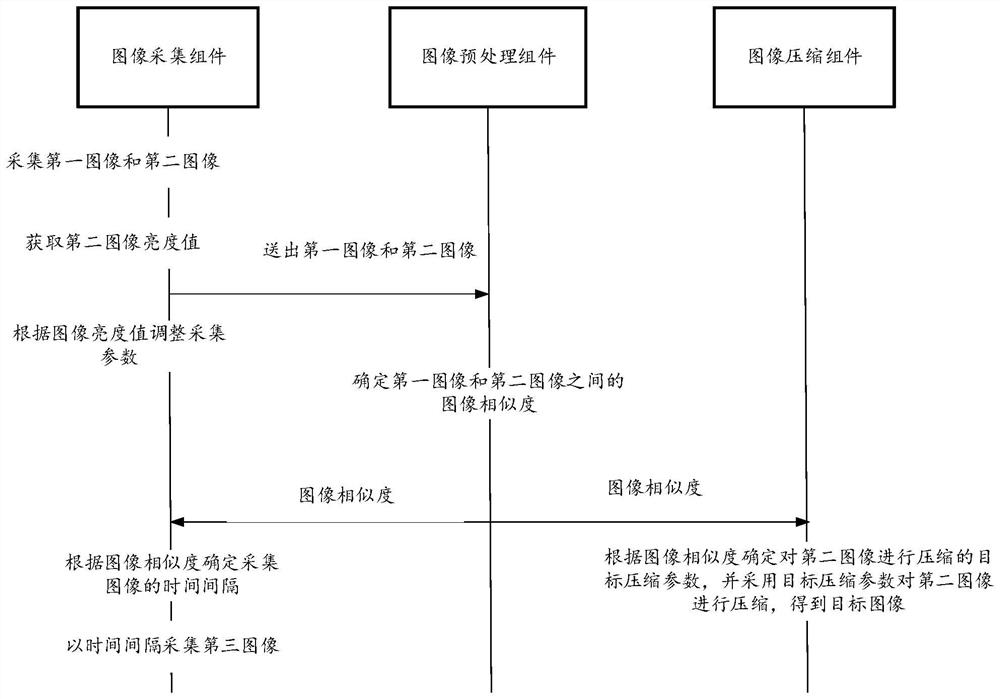

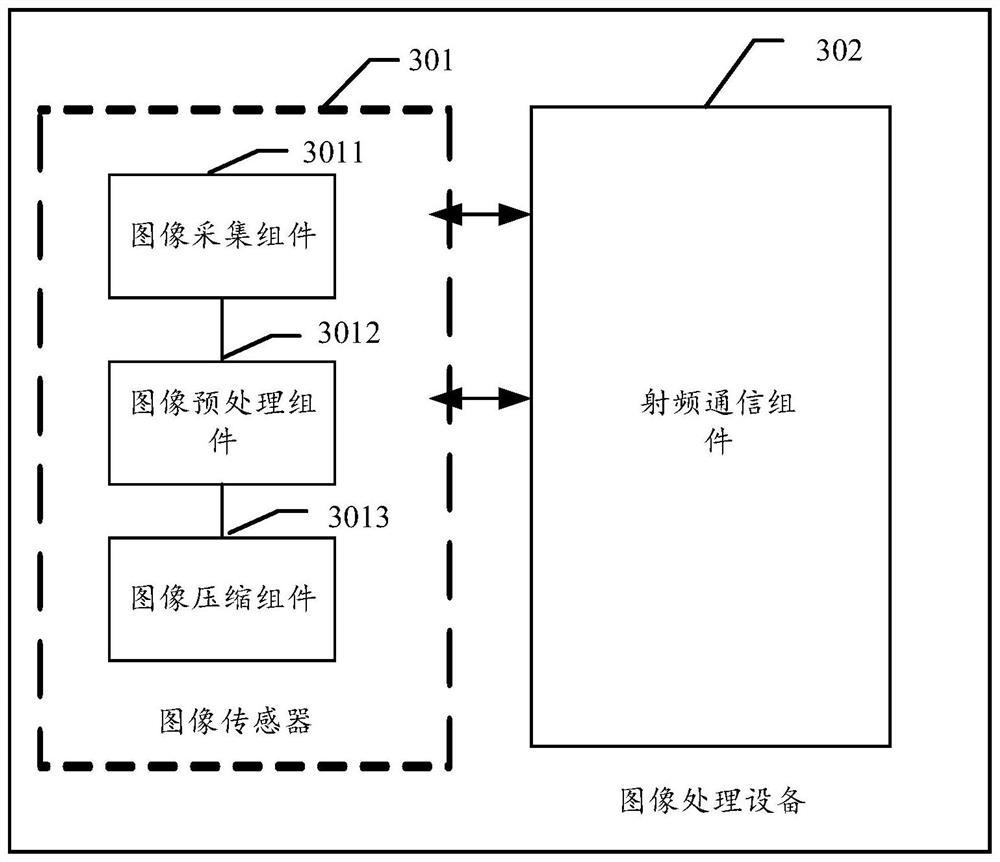

ActiveCN111314613BReduce processing timeImprove processing efficiencyTelevision system detailsColor television detailsImaging processingRadiology

The embodiment of the present invention discloses an image sensor, an image processing device, an image processing method, and a storage medium, wherein the image sensor includes: an image acquisition component, an image preprocessing component, and an image compression component, and the image acquisition component is connected to the image preprocessing component. The image preprocessing component is connected with the image compression component, and the image acquisition component is used to collect images, and the collected images include a first image and a second image, and the first image and the second image are continuous; the image preprocessing component is used for Determine the image similarity between the first image and the second image; the image compression component is used to determine the target compression parameters required for the second image compression process according to the image similarity, and compress the second image with the target compression parameters Process to get the target image. By adopting the embodiment of the present invention, image processing can be performed more effectively.

Owner:重庆金山医疗技术研究院有限公司

Method and device for obtaining verification information

ActiveCN105453617BAvoid frequent transfersPrevent overloadNetwork traffic/resource managementSecurity arrangementMobility managementServer

Owner:SAMSUNG ELECTRONICS CO LTD

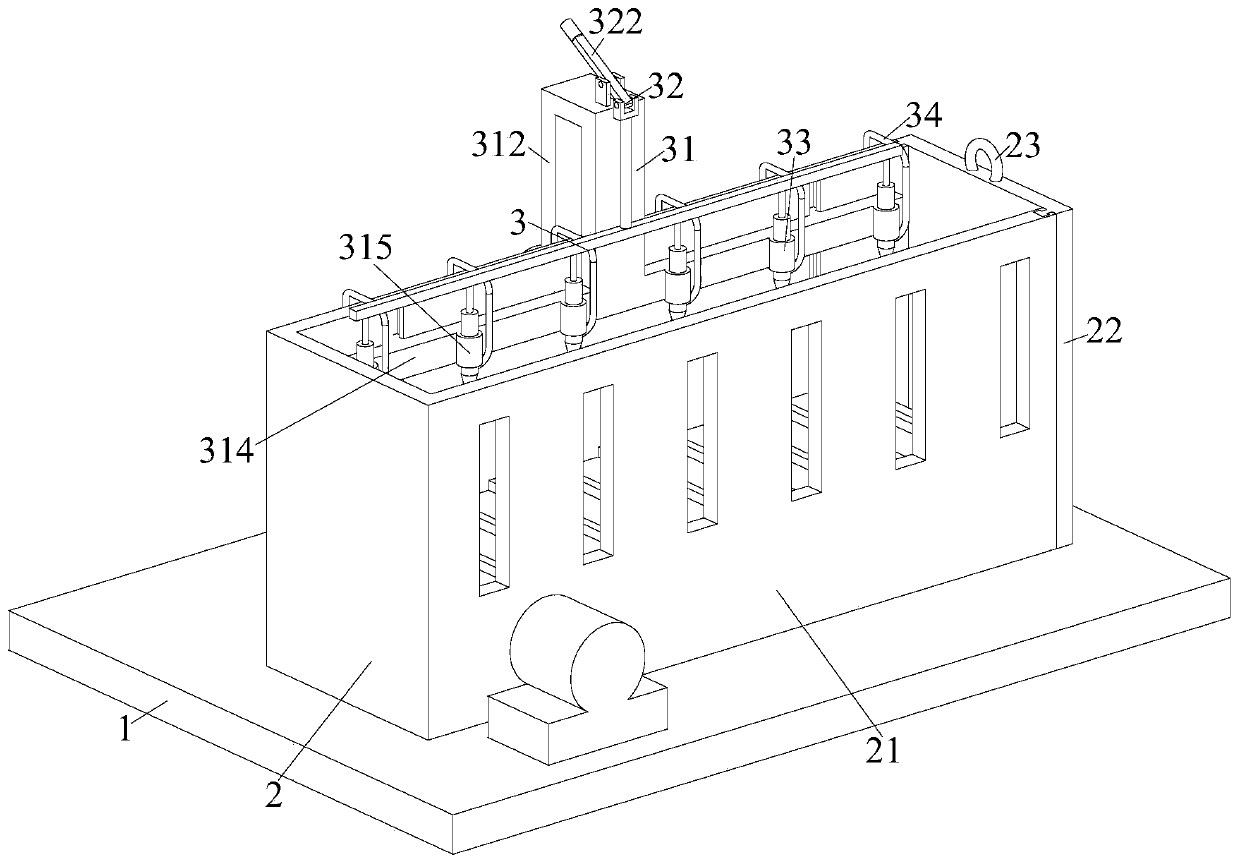

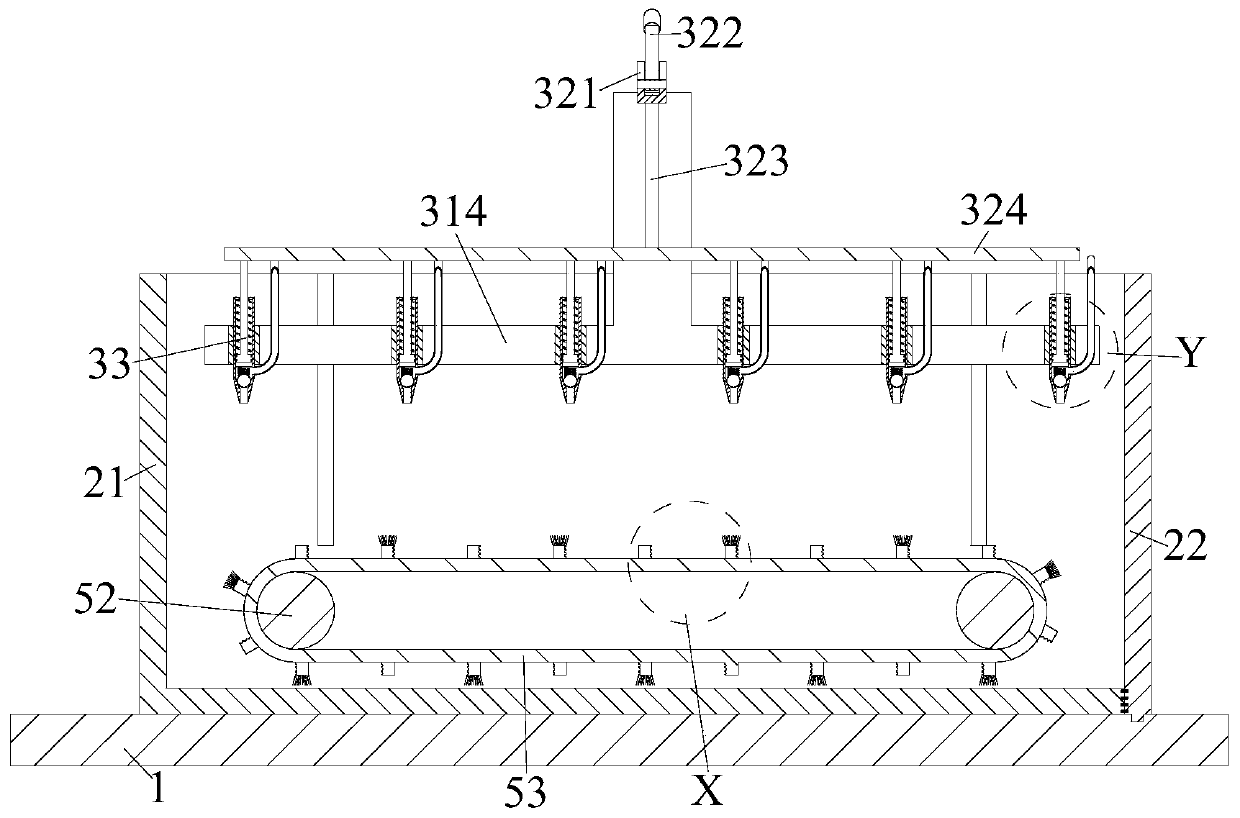

Waste engine oil recovery and treatment method

InactiveCN110835579AImprove recycling ratesAvoid frequent transfersLubricant compositionProcess engineeringPetroleum engineering

The invention relates to a waste engine oil recovery and treatment method. An apparatus for realizing the method comprises a mounting table, a sedimentation tank, a layered oil suction device, a filtering device and a rotary deslagging device, the sedimentation tank, is welded to the middle part of the upper end of the mounting table, the layered oil suction device is mounted at the rear side of the sedimentation tank, the filtering device is arranged at the rear end of the layered oil suction device and welded to the middle part of the upper end of the mounting table, and the rotary deslagging device is mounted at the lower end in the sedimentation tank,. The waste engine oil recovery and treatment method can solve the problem of tedious waste engine oil recovery process of existing wasteengine oil recovery apparatuses due to filtration carried out after settlement and the problem of reduction of the waste engine oil recycling rate due to manual regular cleaning of a tank bottom andclassification treatment of the waste machine oil.

Owner:郭寒生

Updating method, device and network equipment of media access control address table

ActiveCN102045262BAvoid frequent transfersReduce occupancyData switching by path configurationOccupancy rateExternal storage

The invention discloses an updating method, device and network equipment of a media access control address table. The updating method comprises the following steps: when learning new address table entries, judging whether the number of the address table entries in an internal address table is more than the set upper waterline; when the number of the address table entries in the internal address table is larger than the set upper waterline, transferring at least one address table entry except the new address table entries from the internal address table to an external storage until the number of the address table entries in the internal address table is less than the set lower waterline; and when the number of the address table entries in the internal address table is not more than the setupper waterline, avoiding the address table entries in the internal address table from being transferred to the external storage. By utilizing the method, the frequent transferring of the address table entries between the internal address table and the external storage is avoided, the memory occupancy rate is reduced, and the system performance of the network equipment is improved.

Owner:BEIJING ZHIGU TECH SERVICE

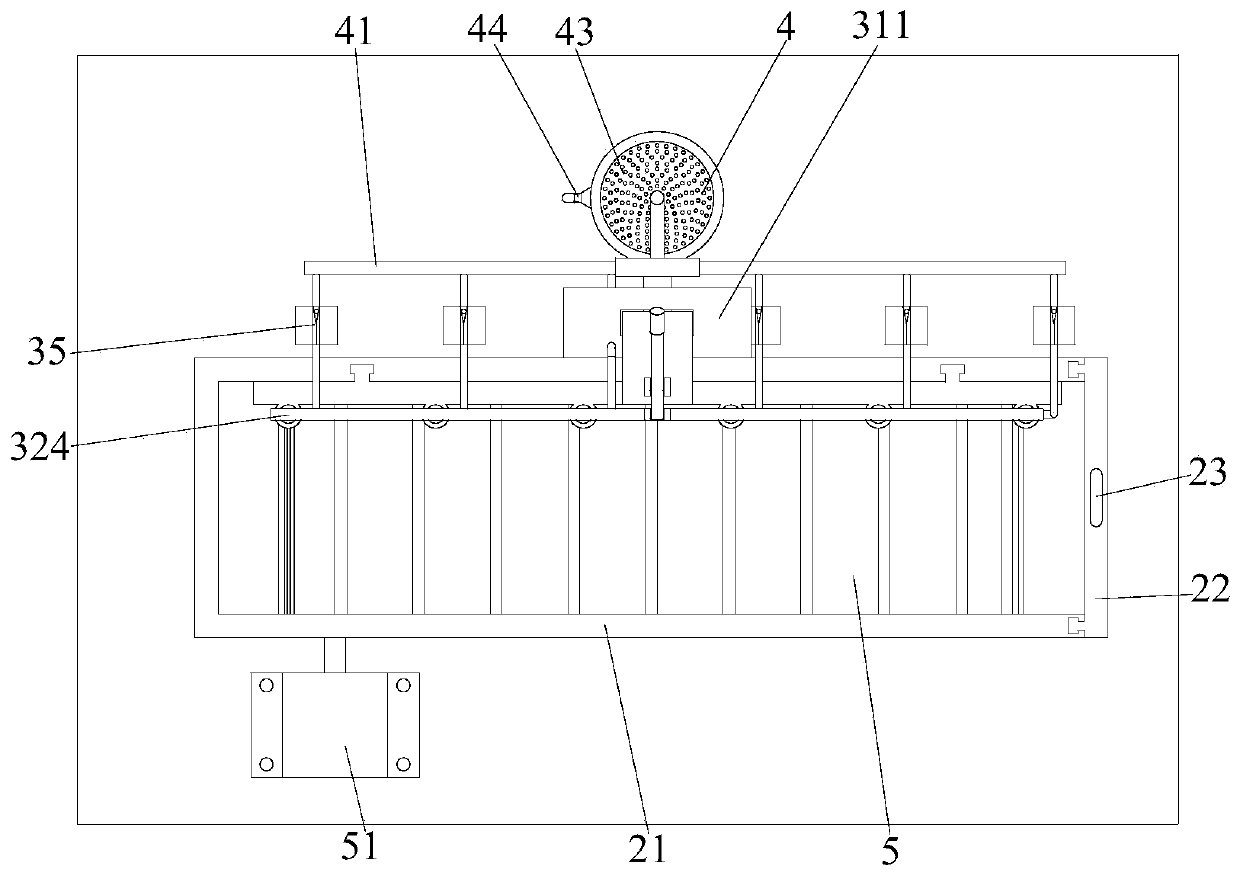

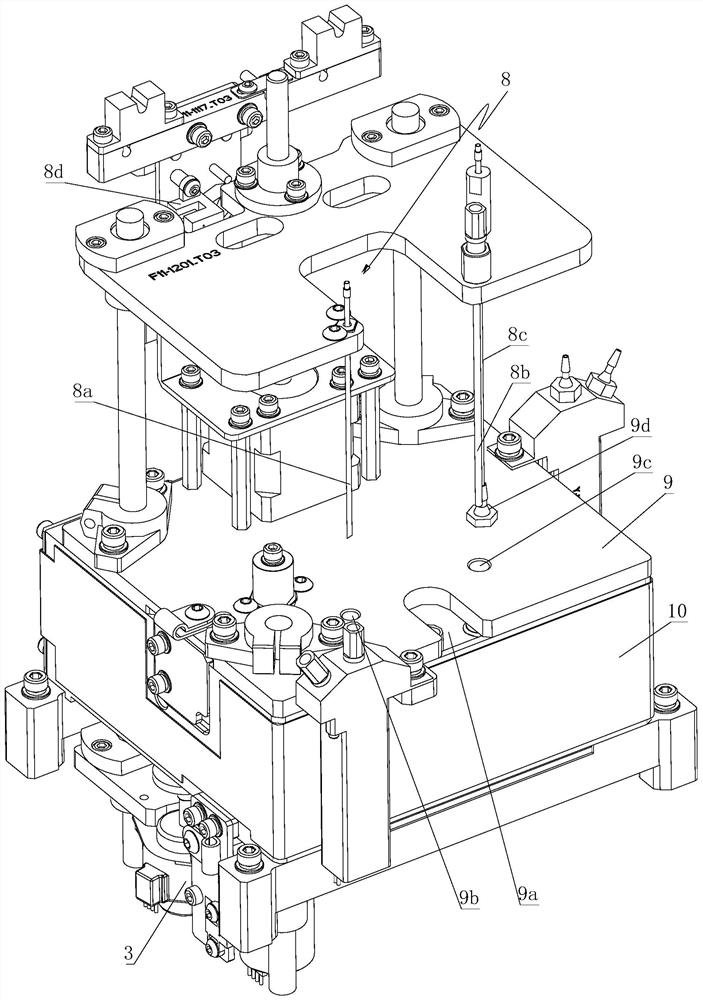

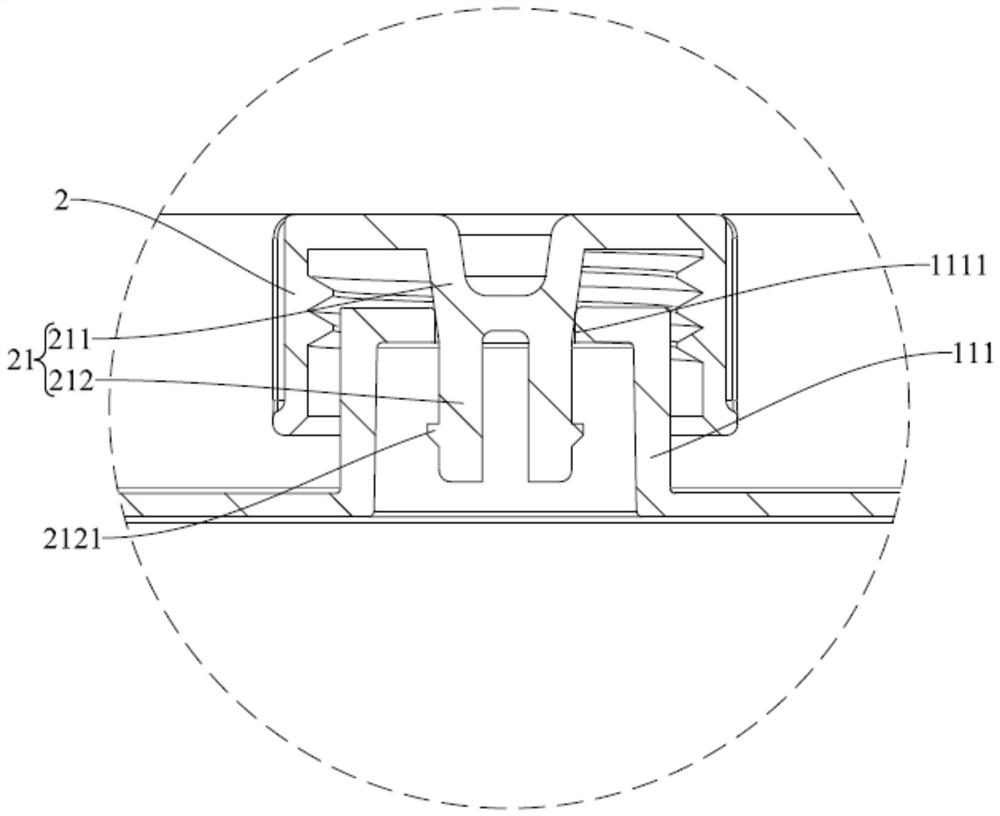

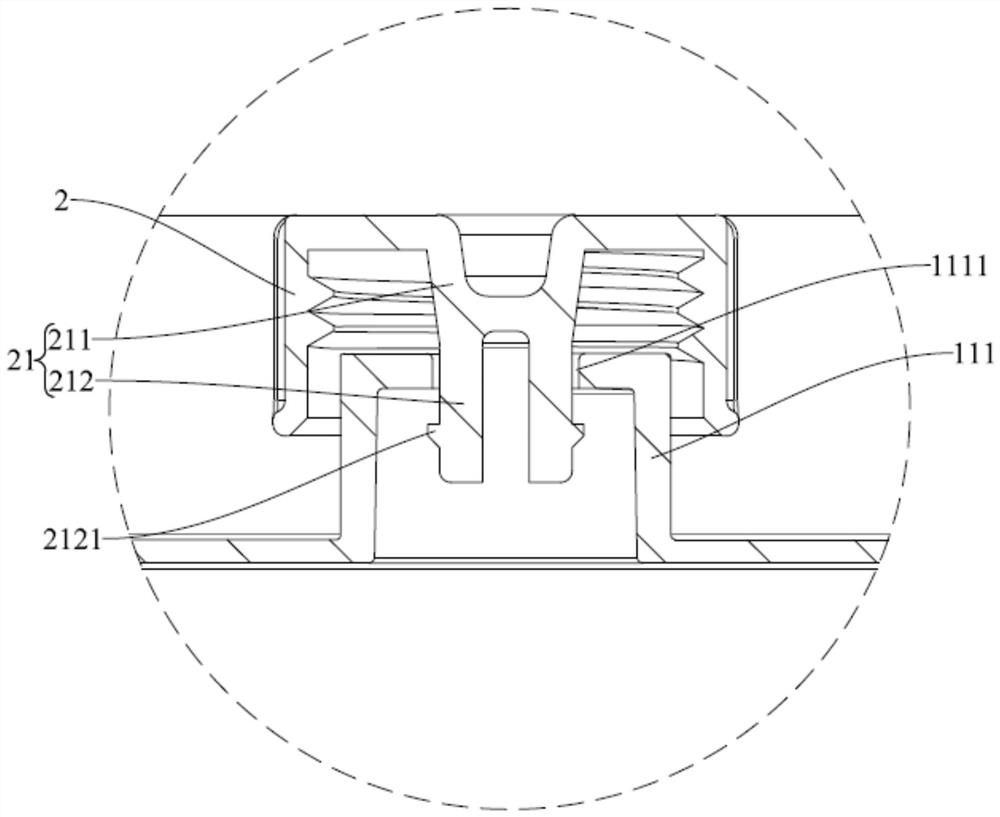

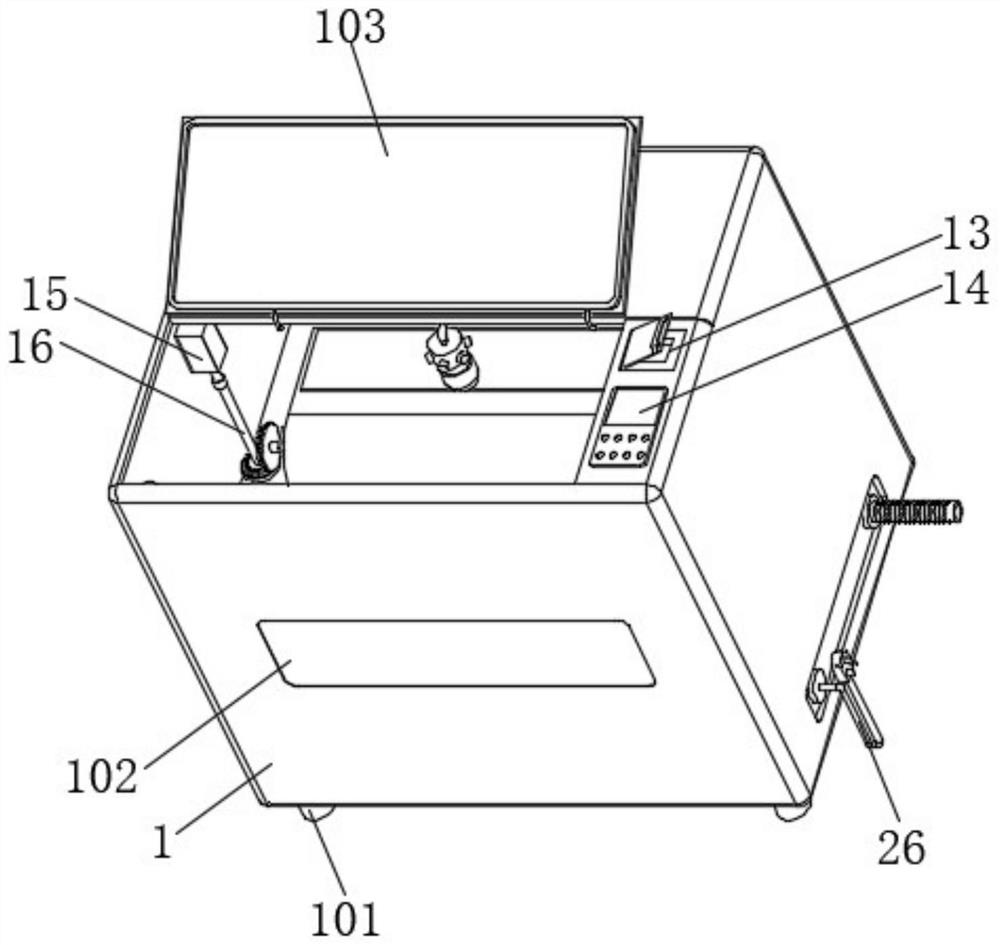

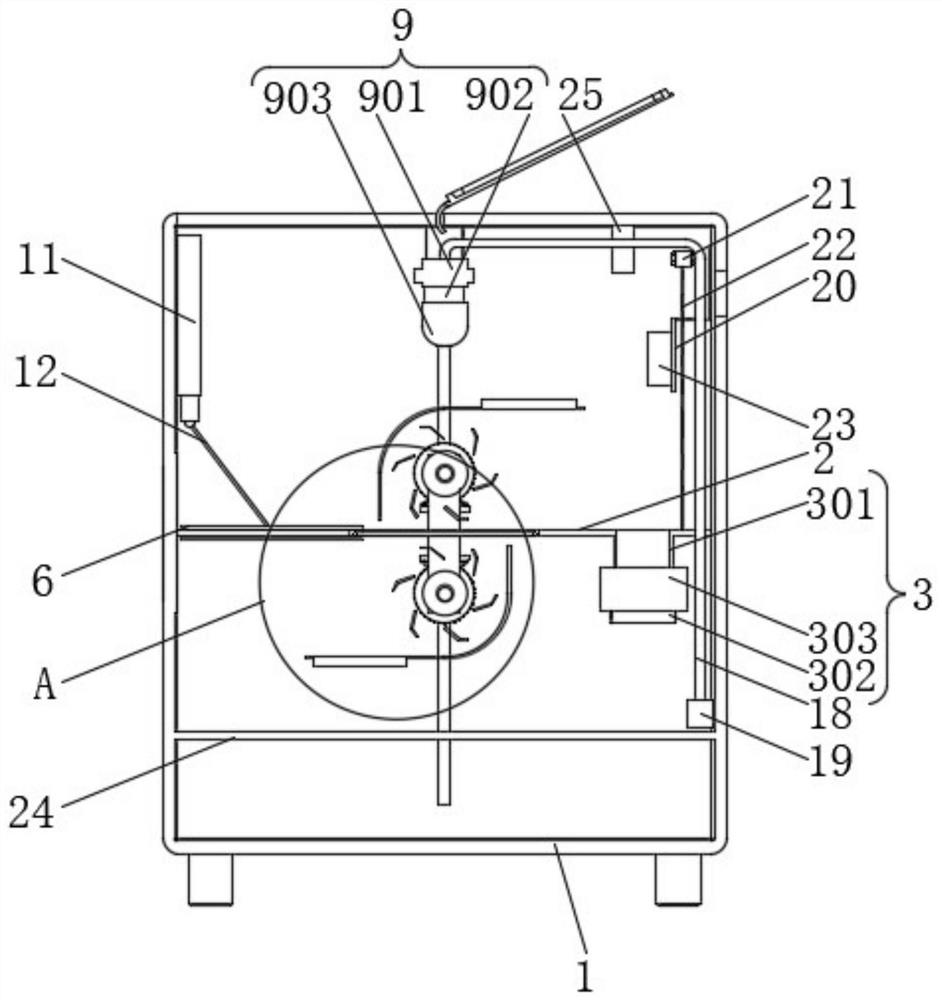

Washing module of full-automatic chemiluminescence immunoassay analyzer

PendingCN114833141AImprove detection accuracyThe overall structure is simpleCleaning using gasesPhysicsMechanical engineering

The invention discloses a washing module of a full-automatic chemiluminescence immunoassay analyzer. The washing module comprises a base, wherein a cavity is formed in the upper end of the base; the supporting disc is rotationally mounted in the cavity, and supporting holes are distributed in the supporting disc in a circumferential array manner and are used for vertically mounting reaction cups; the shaking-up mechanism is arranged below one of the supporting holes in a manner of moving up and down through a lifting assembly; the magnetic blocks are fixedly embedded in the base, the magnetic blocks are uniformly distributed in an array mode in the circumferential direction where the supporting disc is located, and the heights of the magnetic blocks are gradually reduced in the circumferential direction of the supporting disc; the driving mechanism is mounted at the bottom of the base and used for driving the supporting disc to rotate; and the liquid supplying and taking system is positioned above the base and is used for injecting liquid into the reaction cup or extracting waste liquid. The reaction cup washing device has the beneficial effects that operations such as shaking up, cleaning liquid filling, waste liquid extraction and substrate filling on different reaction cups can be synchronously realized, the washing efficiency is higher, and the product structure is more compact.

Owner:科来思(深圳)科技有限公司

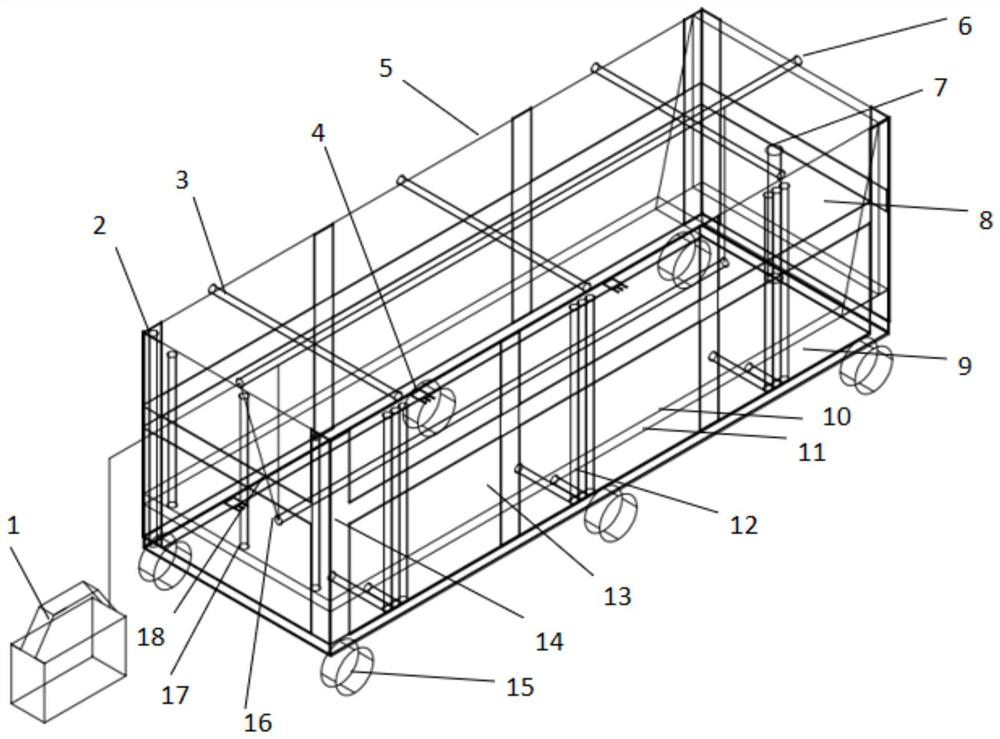

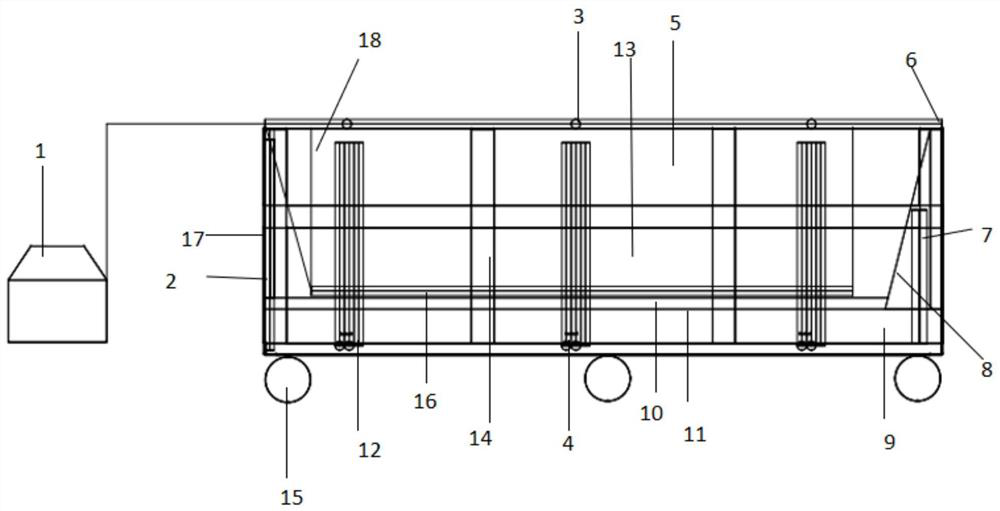

Simulation platform, experimental system and method for reservoir seepage detection experiment

ActiveCN111366303BHigh simulationAvoid frequent transfersDetection of fluid at leakage pointEarth material testingWater storageLeaking water

The disclosure relates to a simulation platform, an experimental system and a method for a reservoir leakage detection experiment, including a sand box, the upper part of the sand box has an opening to expose the inner cavity of the sand box; the upper surface of the bottom wall of the sand box is covered with a soil layer One end of the sand box is provided with a simulated dam body, the simulated dam body is supported by the overburden layer, and the side of the simulated dam body close to the sand box inner cavity is enclosed with the sand box inner wall to form a water storage tank, and the simulated dam body and the sand box The relative position can be adjusted to change the size of the water storage tank; the water storage tank can be filled with experimental water to simulate the water resources stored in the reservoir; the bottom wall of the sand box is provided with a drainage device to drain the seepage from the covering soil layer. Drain the leaked water.

Owner:SHANDONG UNIV

Adaptive Data Transmission Method for Situation Awareness in Opportunistic Crowd Intelligence Sensing Network

ActiveCN106068027BReduce overheadExtend your lifeNetwork topologiesHigh level techniquesWireless mesh networkCrowds

The invention relates to a situation awareness-based adaptive data transmission method applied to an opportunistic crowd sensing network and belongs to the wireless sensor network and mobile ad hoc network technical field. According to the method, nodes in the network estimate the node residual energy of the nodes themselves, the encounter probability of the nodes and a destination node and the hops of message transmission according to the conditions of the nodes themselves and the historical information of the network, judge a network environment where the nodes are located currently by using local topological information of positions where the nodes are located, and selects suitable data transmission mechanisms. With the method adopted, communicated MANET subnets in the network can be accurately identified, and are fully utilized in a data transmission process, and the communicated MANET subnets have little possibility of being affected by the mobility of the nodes and the time variance of network topology, and the success rate of data transmission can be improved, network overhead can be reduced, and the robustness of a data transmission strategy can be improved.

Owner:鲲腾技术有限公司

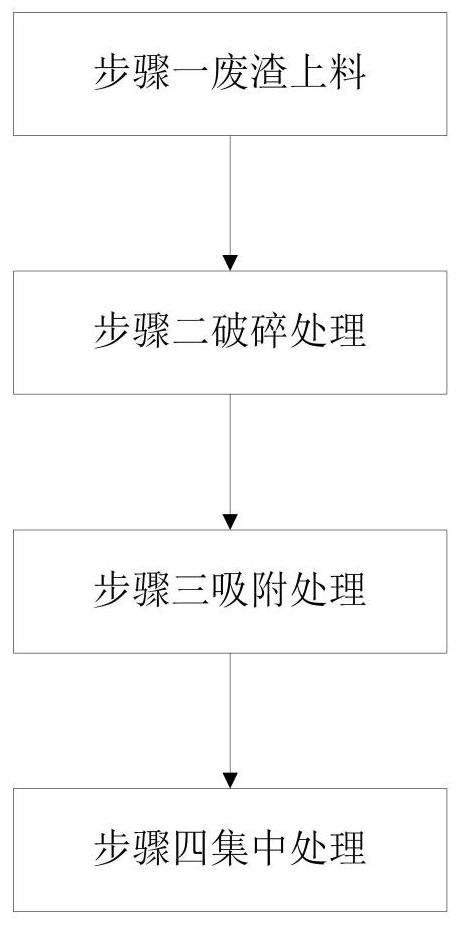

Steel mill waste residue treatment method

ActiveCN111921706AAchieve smashAchieve separationCleaningMagnetic separationSlagEnvironmental engineering

The invention relates to the technical field of waste residue treatment, and particularly relates to a steel mill waste residue treatment method which uses waste residue treatment equipment. The steelmill waste residue treatment equipment is used for treating steel mill waste residues and comprises multiple steps such as waste residue feeding, crushing treatment, adsorption treatment and centralized treatment. In the working process of the waste residue treatment equipment, steel slag crushed by a double-shaft crusher falls onto a rubber pad with a magnet strip, and a rotating transmission belt drives the rubber pad to move together, so that the rubber pad drives the crushed steel slag to move, iron waste residues in the crushed steel slag are attached to the surface of the rubber pad under the adsorption of the magnet strip at the moment, and the purpose of separating the iron waste residues is achieved; and when the rubber pad moves into a rectangular frame body, a rotating brush roller sweeps off the iron waste residues attached to the rubber pad to the ground on the lower side of the rectangular frame body, so that the integration of steel slag crushing and separation is realized, and the frequent transfer of the steel slag is avoided.

Owner:SHANXI TONGCAI IND & TRADE

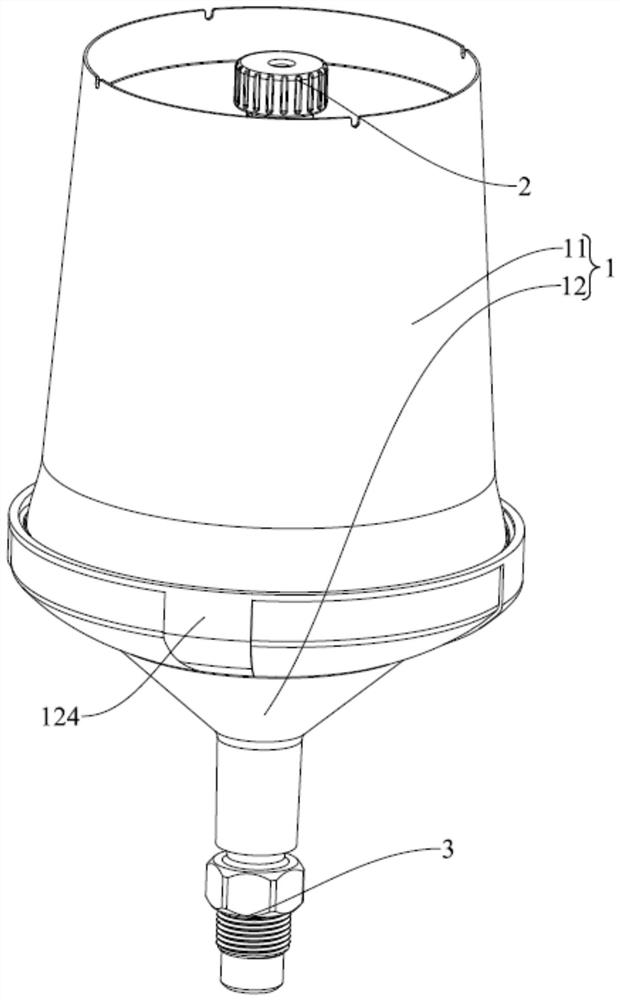

a fluid storage tank

The invention discloses a fluid storage tank. The fluid storage tank includes a tank body and a ventilation piston. The tank body is used for storing paint. One end of the tank body can be connected to a spray gun, the other end is provided with an air inlet, and the ventilation piston is provided with a plug. The plug-in part is inserted into the air inlet, and the plug-in part is provided with a limit protrusion, and the limit protrusion is used to prevent the ventilation piston from coming out of the air inlet. The fluid storage tank can be used not only as a watering can, but also as a paint storage can in cooperation with the spray gun, avoiding the traditional operation of frequently transferring paint back and forth between the special watering can and the special storage can, and improving the spraying efficiency. Efficiency in storing paint.

Owner:SHENZHEN WISDOM SCI & TECH

A method and device for file transfer

The object of the present invention is to provide a method, device and system for file transmission. Compared with the prior art, the present invention uses the service device to generate the first signaling, and when the user equipment sends the file transfer request, verifies the file transfer request based on the first signaling, if the first If the signaling already corresponds to the transferred file, reject the file transfer request; otherwise, if the first signaling has not yet corresponded to the transferred file, then allow the user equipment to perform file transfer; thereby using the first signaling to Limit the number of file transfers to ensure that one signaling corresponds to only one file transfer, which effectively avoids possible conflicts when multiple file uploads occur, and also allows users to check the uploaded files, avoiding Multiple views of uploaded files. Therefore, the present invention can ensure the security, reliability and effectiveness of file transmission, and at the same time improve user experience.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

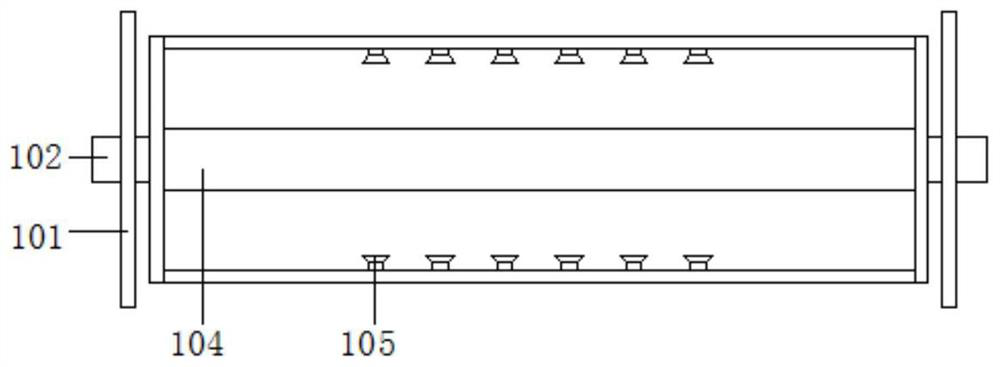

Ore washing and drying all-in-one machine

PendingCN114459207AConducive to productionShorten the processing cycleDrying gas arrangementsCleaning using liquidsElectric machineryProcess engineering

The invention discloses an ore washing and drying all-in-one machine, and relates to the field of mining industry equipment, the ore washing and drying all-in-one machine comprises a box body, the top of the box body is provided with a cleaning and conveying mechanism, and the cleaning and conveying mechanism comprises a fixed plate block, a pipe fitting, a hollow disc, a hollow batten, a spray head, a net-shaped conveying box, a spiral conveying rod, a short connecting rod, a long connecting rod and a first motor. According to the ore washing and drying all-in-one machine, through the arrangement of the cleaning and conveying mechanism, large and small blocks of mineral raw materials can be conveyed in a net-shaped conveying box through a spiral conveying rod, water penetrates through the net-shaped conveying box through a spray head to clean the mineral raw materials, and the mineral raw materials are conveyed and discharged to other stations while being cleaned; the production of the mineral raw materials is more facilitated, and the processing period of the mineral raw materials is effectively shortened.

Owner:ANHUI JINRISHENG MINING

Special protective washing device for bras

InactiveCN112342725AReduce wearImprove efficiencyOther washing machinesWashing machine with receptaclesEngineeringStructural engineering

The invention discloses a special protective washing device for bras. The special protective washing device comprises a shell, a partition plate, a washing assembly, a shaft seat, an electric telescopic rod, a stepping motor, a washing pipe and a lifting table, wherein the shell is a cuboid shell with an open upper end, footstands are fixed to four corners of the lower surface of the shell, a transparent window is arranged in the middle of the front side face of the shell, and a cover plate is hinged to the opening in the front end of the upper side face of the shell; and the partition plate is horizontally fixed to the middle of the inner side face of the shell, a circulating assembly is arranged on a connector at the rear side end of the partition plate, a rectangular through hole is formed in the middle of the partition plate, horizontal sliding grooves are oppositely formed in the left side wall and the right side wall of the rectangular through hole, a sliding seat in sliding fitwith the sliding grooves is arranged in the rectangular through hole, and a carrier is fixed to the front side end of the sliding seat. The special protective washing device for the bras is used for washing the bras made of real silk and other materials, so that the efficiency is improved, meanwhile, abrasion to the bras is reduced, and the service life is prolonged.

Owner:温州含孜纺织品有限公司

A haar detection method based on gpu acceleration

ActiveCN105160350BAvoid frequent transfersFast implementationCharacter and pattern recognitionAlgorithmData preparation

The invention discloses a Haar detection method based on GPU acceleration, which is characterized in that it includes the following steps: (1) System initialization, CPU transmits and saves the scan window, feature frame information and classifier parameter data under all magnification factors to the GPU device; (2) Set the number of threads in sequence according to the number of columns of the image matrix and call the kernel function twice to perform matrix transposition twice to obtain the integral map and square integral map of the image; (3) scan the window and feature The rectangular frames are arranged in the global memory of the GPU, and the haar algorithm is used for detection; (4) the rectangular frames are merged through the scanning windows of all strong classifiers to obtain the results to be detected. The present invention improves the existing haar algorithm in three aspects: the data preparation method, the fast calculation of the integral graph, and the targeted implementation of Haar detection in stages, so that the implementation speed of the haar algorithm is greatly improved, and the practical value is improved. It is more fully reflected and has high practical value and promotion value.

Owner:深圳市哈工交通电子有限公司

Petroleum drilling mud and solid waste separating and recycling device

ActiveCN113181794AAchieve separationAvoid frequent transfersSludge treatmentTransportation and packagingWell drillingWastewater

The invention relates to the technical field of petroleum drilling platforms, in particular to a petroleum drilling mud and solid waste separating and recycling device. The technical problem to be solved by the invention is to provide the petroleum drilling mud and solid waste separating and recycling device. According to the technical scheme, the petroleum drilling mud and solid waste separating and recycling device comprises a bottom frame, a controller, a waste water collecting box, a mud filtering assembly, a mixing assembly and a dewatering assembly, and the mixing assembly is connected with a dewatering assembly. When the device is used, slurry and solid waste are separated, after separation, the slurry is collected and mixed with lime at the same time, the mixing time is indirectly shortened while the mixing effect is guaranteed, meanwhile, the separated solid waste is dewatered through simple operation, the condition that the waste needs to be frequently transferred during treatment is avoided, and meanwhile, the dehydration treatment cost is reduced.

Owner:榆林昌荣华城再生能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com