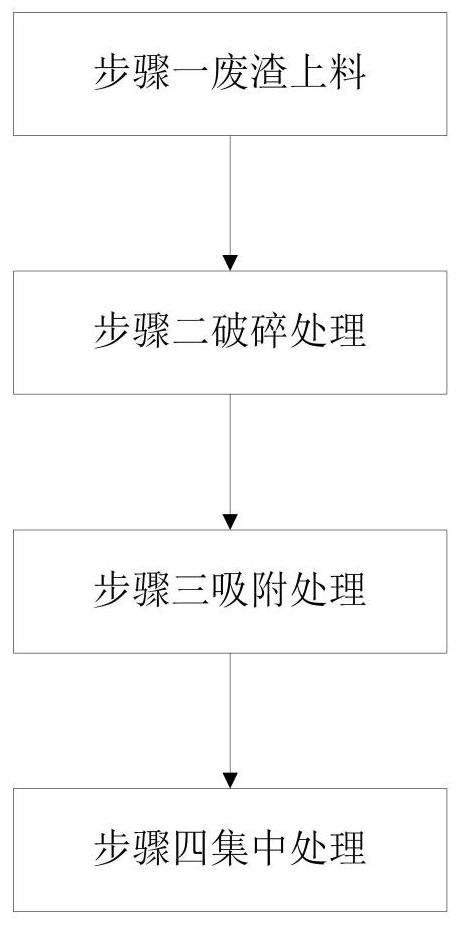

Steel mill waste residue treatment method

A processing method and steelmaking technology, applied in grain processing, chemical instruments and methods, cleaning devices, etc., can solve the problems of high labor intensity and low work efficiency, so as to reduce labor intensity, improve work efficiency, and improve adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

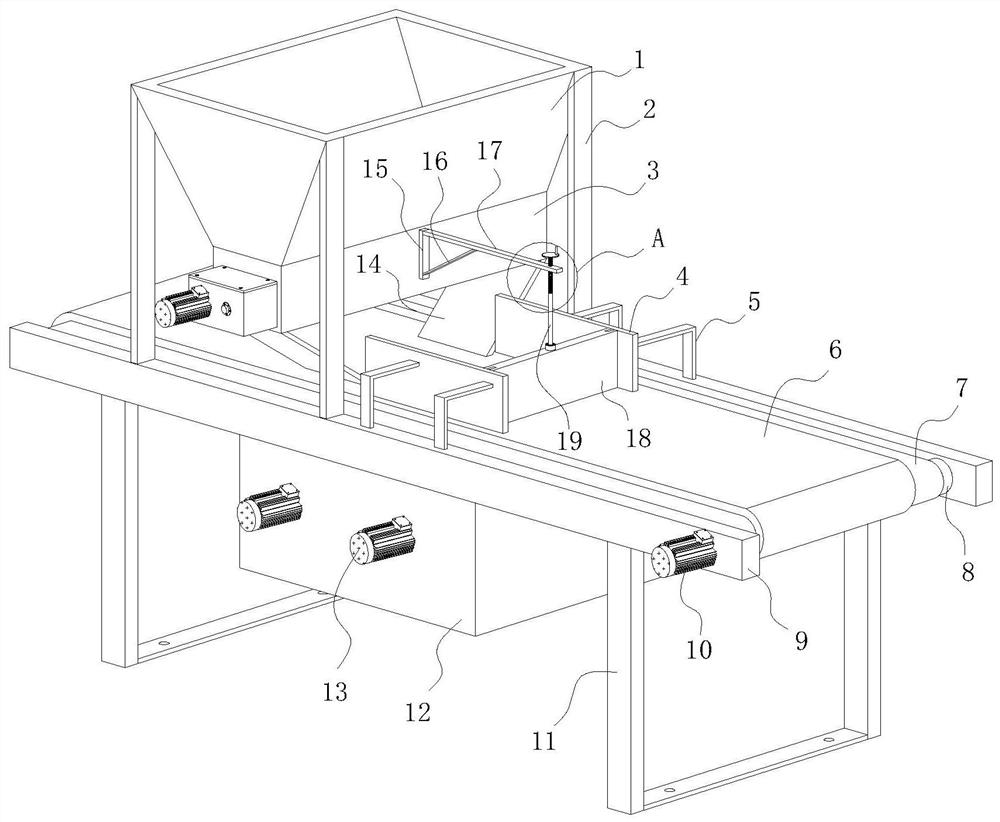

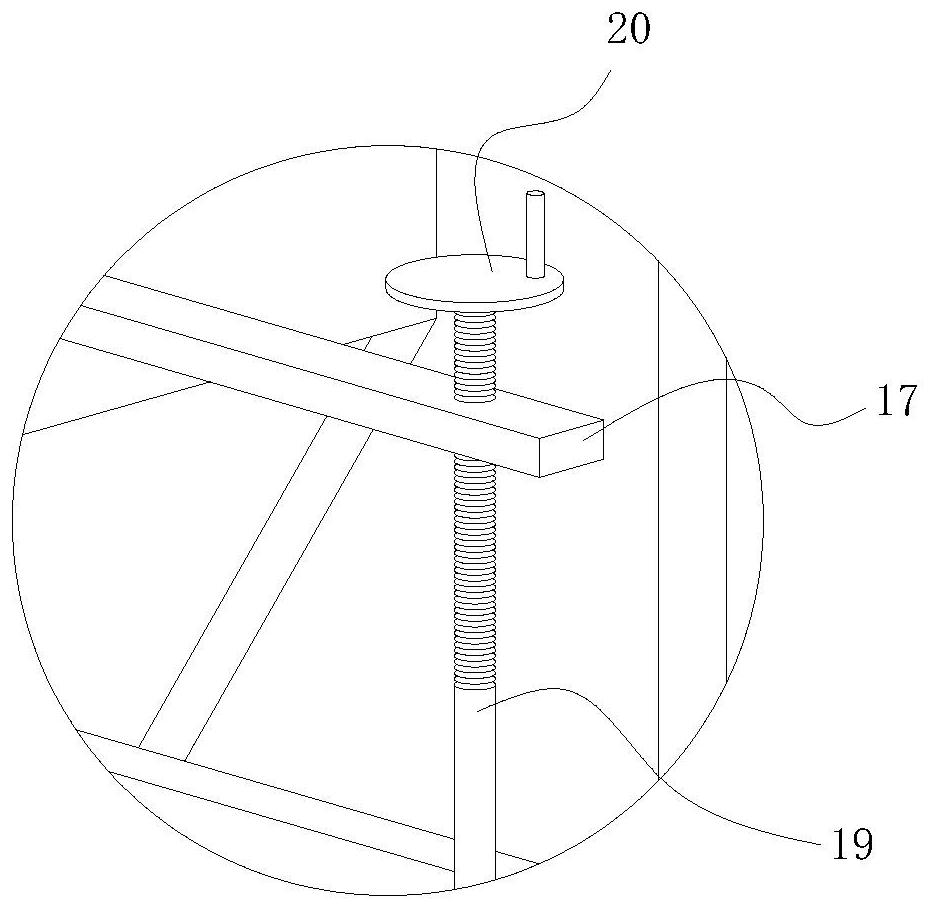

[0049] The specific embodiment: connect the circuit of the second motor 13 after the first motor 10, the first motor 10 drives the first belt roller 8 to rotate, and then the transmission belt 7 rotates between the first belt roller 8 and the second belt roller 22, The second motor 13 drives the brush roller 24 to rotate in the rectangular frame body 12, and the rotation direction of the brush roller 24 is opposite to the moving direction of the transmission belt 7, and the steel slag crushed by the biaxial crusher 3 falls to the bar with a magnet. 21 on the rubber pad 6, and when the first motor 10 drives the transmission belt 7 to rotate, the transmission belt 7 drives the rubber pad 6 to move together, so that the rubber pad 6 drives the crushed steel slag to move, and the iron content in the crushed steel slag is now The waste residue is attached to the surface of the rubber pad 6 under the adsorption of the magnet bar 21, and the rest of the waste residue is discharged fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com