Petroleum drilling mud and solid waste separating and recycling device

A technology for solid waste and oil drilling, applied in filtration separation, separation method, transportation and packaging, etc., can solve the problems of inconvenient lime mixing, increased mixing difficulty, high maintenance cost, etc., to avoid frequent transshipment, reduce dehydration treatment cost, Guaranteed effect of mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

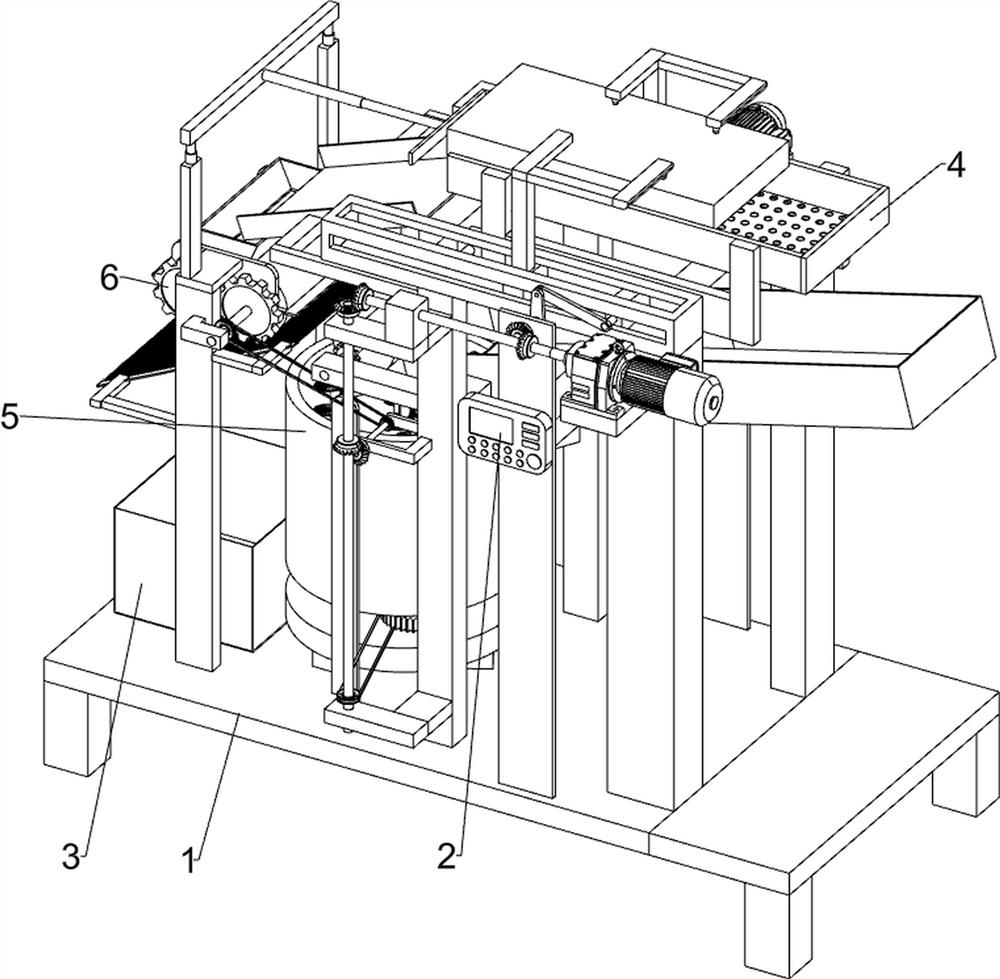

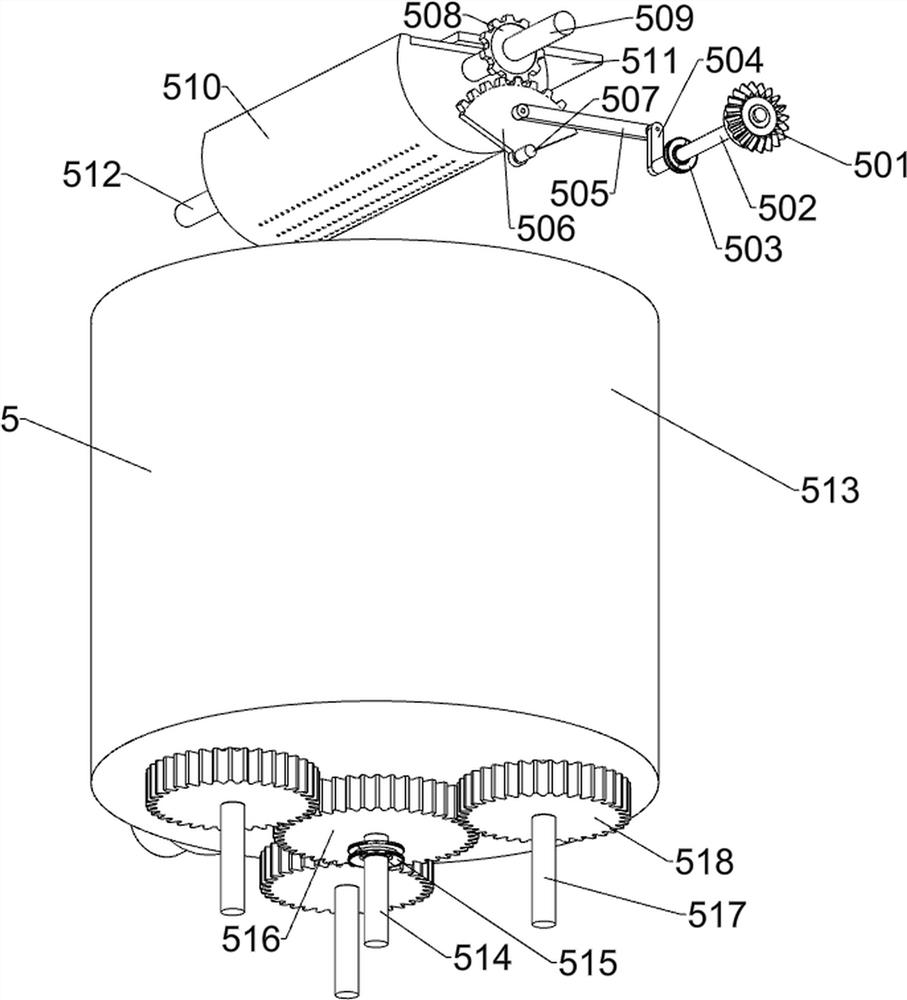

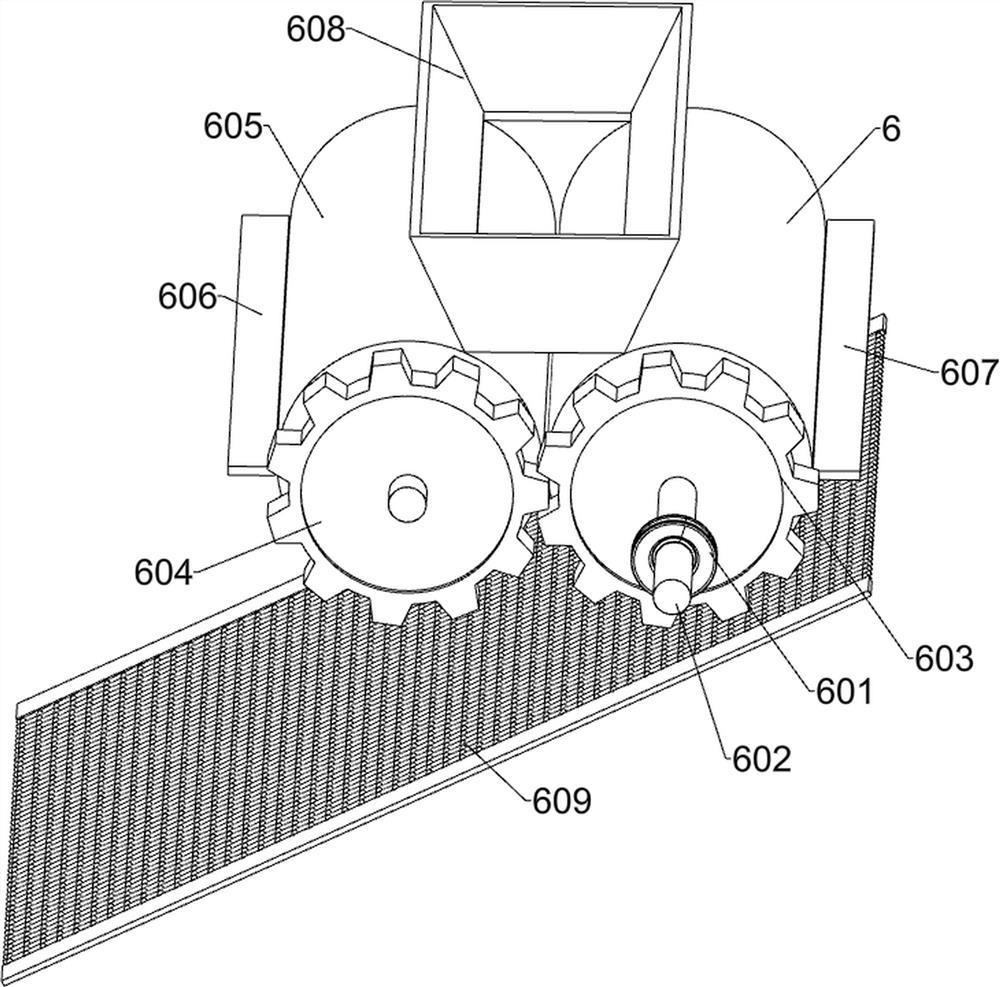

[0027] A device for separating and reusing oil drilling mud and solid waste, such as Figure 1-7 As shown, it includes an underframe 1, a controller 2, a waste water collection tank 3, a mud filter assembly 4, a mixing assembly 5 and a dehydration assembly 6; the underframe 1 is connected to the controller 2; the underframe 1 is connected to the waste water collection box 3 Connection; bottom frame 1 is connected with mud filter assembly 4; bottom frame 1 is connected with mixing assembly 5; bottom frame 1 is connected with dehydration assembly 6; mud filter assembly 4 is connected with mixing assembly 5; mixing assembly 5 is connected with dehydration assembly 6 phase connection.

[0028] When preparing for work, place the device on a horizontal surface, turn on the power supply, and transport the mixture of mud and solid waste to the mud filter assembly 4 on the chassis 1 through the existing technology, and control the mud filter assembly 4 through the controller 2. The mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com