Vertical type automatic feeding machine

A feeder, automatic technology, applied in the field of vertical automatic feeders, can solve the problems of high labor intensity of workers, affecting the driving efficiency, and uncontrollable speed, so as to avoid frequent transfer, reduce labor intensity, and improve utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

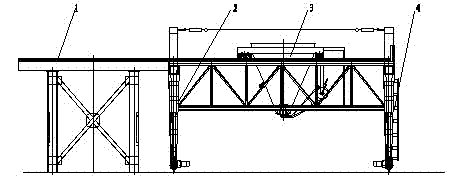

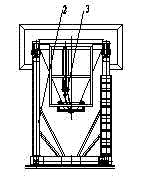

[0013] The present invention includes a cart traveling mechanism and a hopper part, and the cart traveling mechanism includes: a gantry crane 2, a ground rail and a fixed rail 1 on the upper part of the stirring frame docked with the gantry crane 2; the hopper part is set On the double girders of the gantry crane 2, a hopper 3 and a traveling device for moving the hopper on the double girders are included.

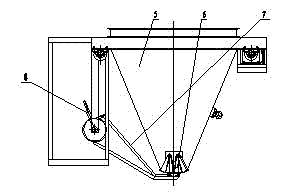

[0014] The hopper 3 of the present invention includes a hopper body 5, a hopper door opening and closing device and an operating mechanism for controlling the hopper door opening and closing are provided at the lower part of the hopper body 5.

[0015] The hopper door opening and closing device includes two hopper doors 6 that cooperate with each other, and the two hopper doors 6 are respectively connected to the operating mechanism through an operating rod 7; The operating rod 7 is arranged on both sides of the handle 8 respectively, and the hopper 3 of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com