A method for preparing carbon nanotubes from waste tires

A technology of carbon nanotubes and waste tires, which is applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of high cost, high-quality carbon nanotubes that cannot be produced in batches and continuous industrialization, and strict process requirements, and achieve Large economic value and social benefits, high-value utilization, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0036] According to the atomic molar ratio of Ni and Co being 1:10, 1.50 g of Ni (NO3 ) 3 ·6H 2 O and 14.98g of Co(NO 3 ) 2 ·6H 2 O, and dissolved in 200ml ethanol, the concentration of the solution is 82.5g / L, then add 16.48g Al 2 O 3 Mixed uniformly; after continuous stirring at 50°C for 3 hours, drying at 80°C overnight; then placed in a muffle furnace and heated to 600°C at a heating rate of 10°C / min in an air atmosphere, and calcined for 4h, The catalyst is taken out and ground into powder after cooling to room temperature.

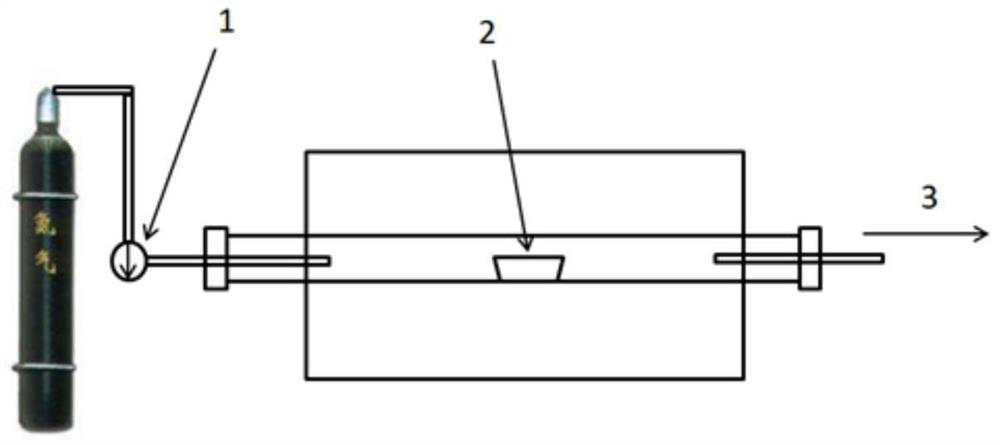

[0037] Weigh 1g of waste tire particles, catalyst Ni-Co / Al 2 O 3 (Ni:Co=3:1) 0.5g, then mix the two evenly and spread them in a quartz boat and put them into a tube furnace, pass nitrogen at a rate of 20ml / min, and under nitrogen protection at a rate of 10°C / min The heating rate is heated to 900 ° C, the temperature is kept at 900 ° C for 0.5 h, and after cooling, it is ground into powder to obtain carbon nanotubes. Add 5 mol / L nitric acid t...

Embodiment example 2

[0039] According to the atomic molar ratio of Ni and Co being 1:5, 1.50 g of Ni (NO 3 ) 3 ·6H 2 O and 7.51 g of Co(NO 3 ) 2 ·6H 2 O, and dissolved in 200ml ethanol, the concentration of the solution is 45g / L, then add 18.02g Al 2 O 3 Mixed uniformly; after continuous stirring at 80°C for 6h, dried at 120°C overnight; then placed in a muffle furnace and heated to 900°C at a heating rate of 30°C / min in an air atmosphere, and calcined for 3h, The catalyst is taken out and ground into powder after cooling to room temperature.

[0040] Weigh 1g of waste tire particles, catalyst Ni-Co / Al 2 O 3 (Ni:Co=3:1) 1g, then mix the two evenly and spread them in a quartz boat and put them in a tube furnace, pass nitrogen at a rate of 80ml / min, and under nitrogen protection at a temperature of 30°C / min The heating rate is heated to 700 °C, and the temperature is kept at 700 °C for 2.5 hours. After cooling, it is ground into powder to obtain carbon nanotubes. Add 8 mol / L nitric acid to...

Embodiment example 3

[0042] According to the atomic molar ratio of Ni and Co being 10:1, 14.98 g of Ni (NO 3 ) 3 ·6H 2 O and 1.50 g of Co(NO 3 ) 2 ·6H 2 O, and dissolved in 400ml ethanol, the concentration of the solution is 41.3g / L, then add 16.48g Al 2 O 3 Mixed uniformly; after continuous stirring at 60°C for 4 hours, drying at 105°C overnight; then placed in a muffle furnace and heated to 600°C at a heating rate of 20°C / min in an air atmosphere, and calcined for 2h, The catalyst is taken out and ground into powder after cooling to room temperature.

[0043] Weigh 0.5g of waste tire particles, catalyst Ni-Co / Al 2 O 3 (wherein Ni:Co=3:1) 1g, then mix the two evenly and spread them in a quartz boat and put them in a tube furnace. Pass nitrogen at a rate of 30ml / min and heat at 20°C / min under nitrogen protection. The speed is heated to 800 ℃, and the temperature is kept at 800 ℃ for 1 hour. After cooling, it is ground into powder to obtain carbon nanotubes. Add 6 mol / L nitric acid to ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com