Array clamping jaw module and bottle clamping conveying device

A jaw and module technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., to achieve the effect of good adaptability and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

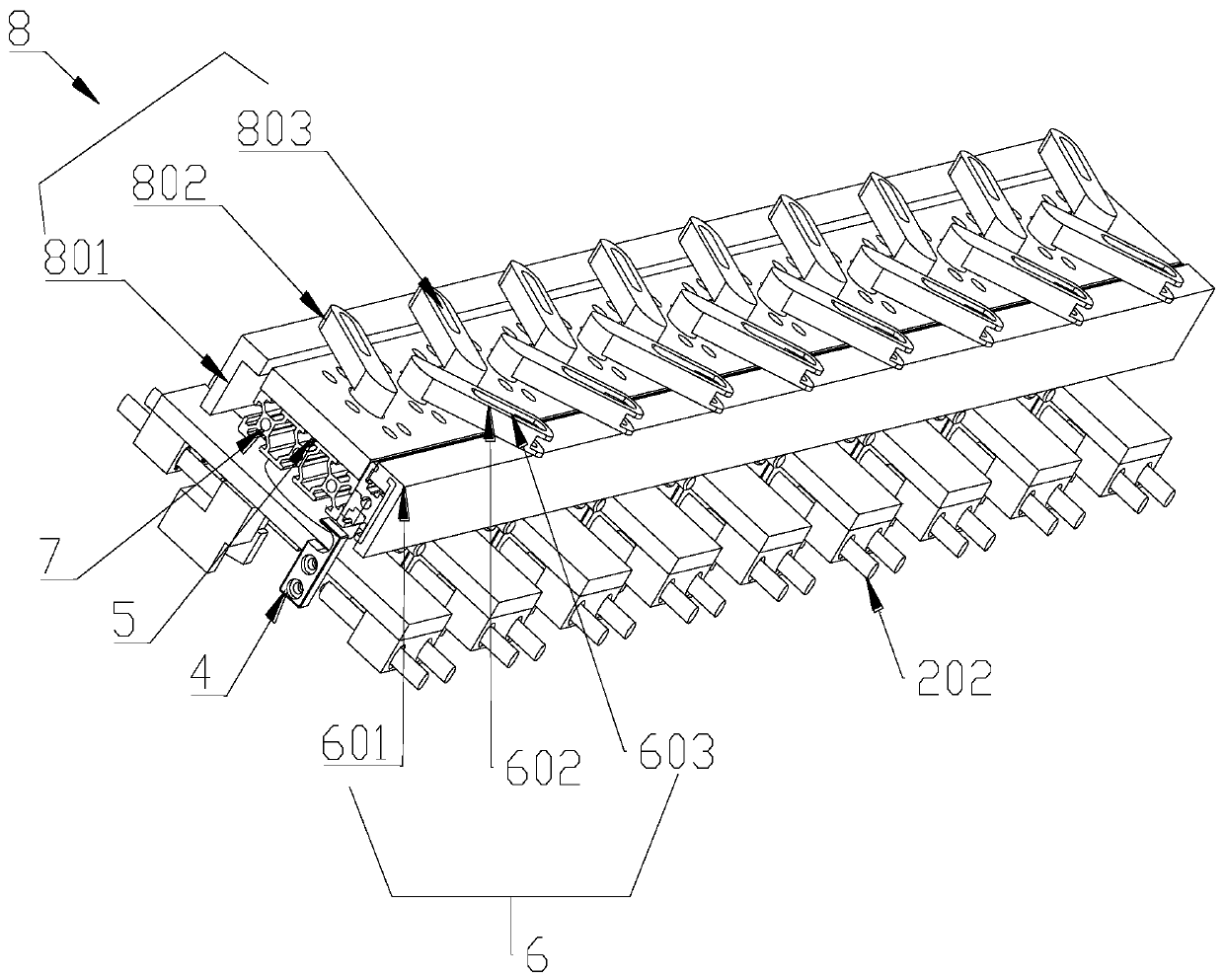

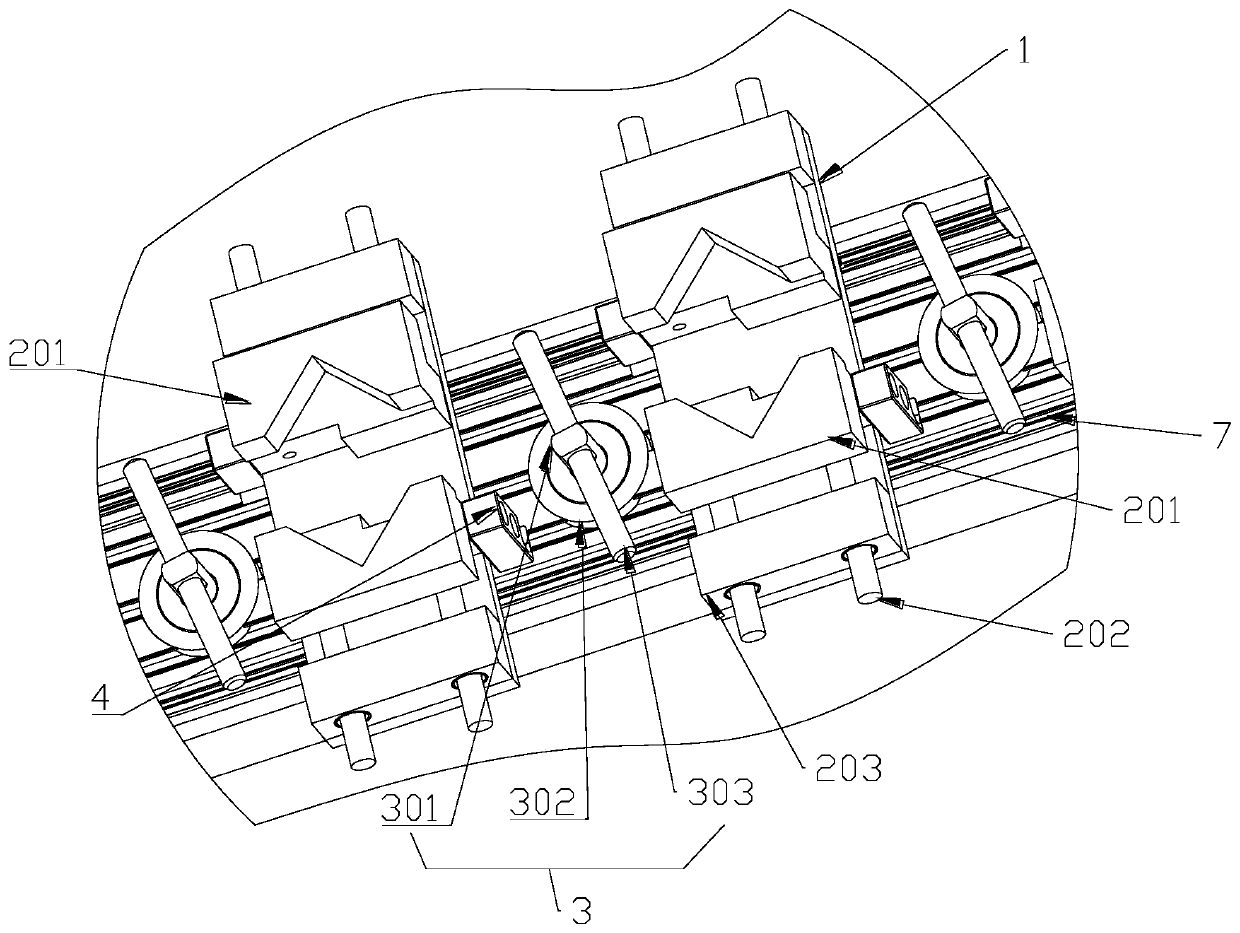

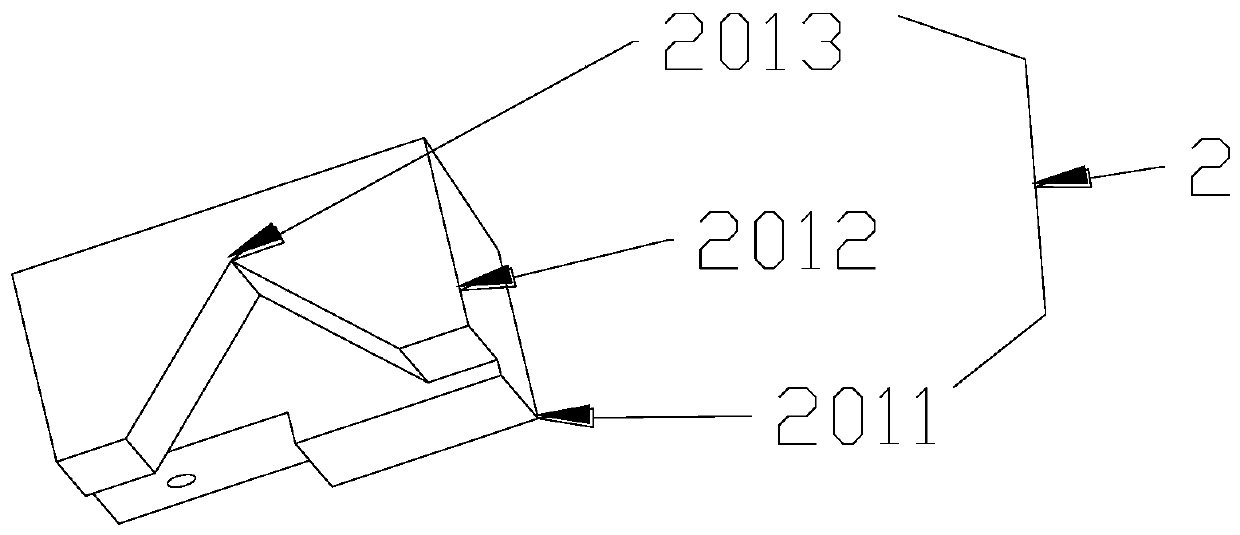

[0041] Such as figure 1 and Figure 7 , figure 1 It is a three-dimensional schematic diagram of the array jaw module provided by Embodiment 1 of the present invention, Figure 7 It is a schematic diagram of the connection part of the profile substrate and the cylinder connection mechanism provided by Embodiment 1 of the present invention, an array jaw module, including a support plate 1, a clamping mechanism 2, a toggle mechanism 3, a toggle block 4, and a fixing plate 5. The first drive mechanism 6, the profile substrate 7, the second drive mechanism 8 and the cylinder connection mechanism 9, one side of the support plate 1 is connected to the profile substrate 7 through one end of the cylinder connection mechanism 9, and the cylinder The connection mechanism 9 runs through the profile substrate 7 while the other end is connected to the fixed plate 5;

[0042] The fixed plate 5 is in the shape of a cuboid, and the top of the fixed plate 5 is respectively provided with a pl...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is that the shape of the gripping groove 2013 is arc-shaped, and the width of the arc-shaped direction toward the opening increases sequentially, so that it can be used to fix bottles of different sizes, while saving a certain amount of water. s material. All the other are with embodiment 1.

Embodiment 3

[0058] A conveying device for clamping bottles, comprising several array jaw modules described in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com