A kind of lead solder solder for semiconductor power device packaging and its preparation method and application

A technology of wire welding and power devices, which is applied in the direction of semiconductor devices, welding equipment, electric solid devices, etc., can solve the problems of excessive diffusion depth and warpage, and achieve the effects of reducing welding defects, improving density and excellent welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

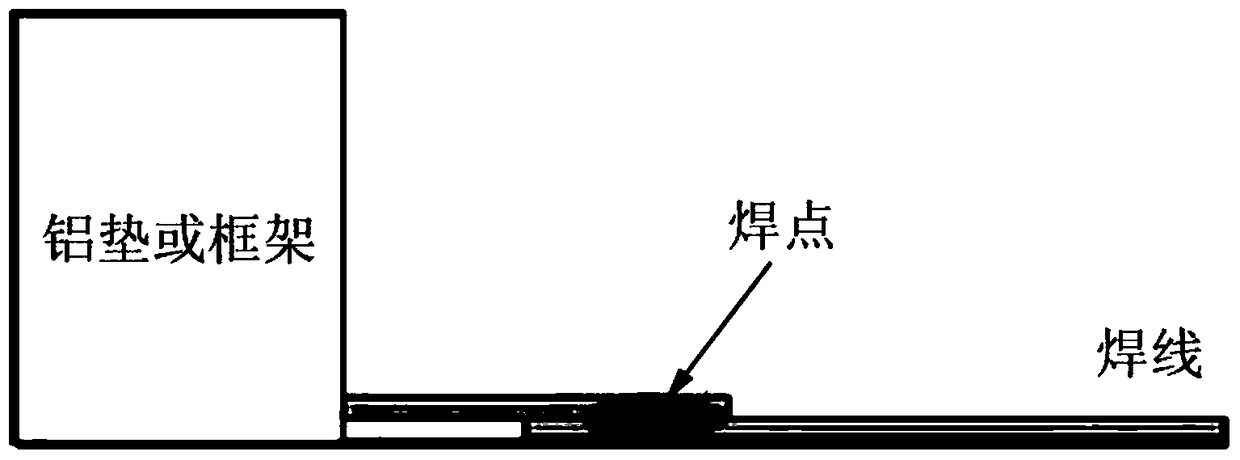

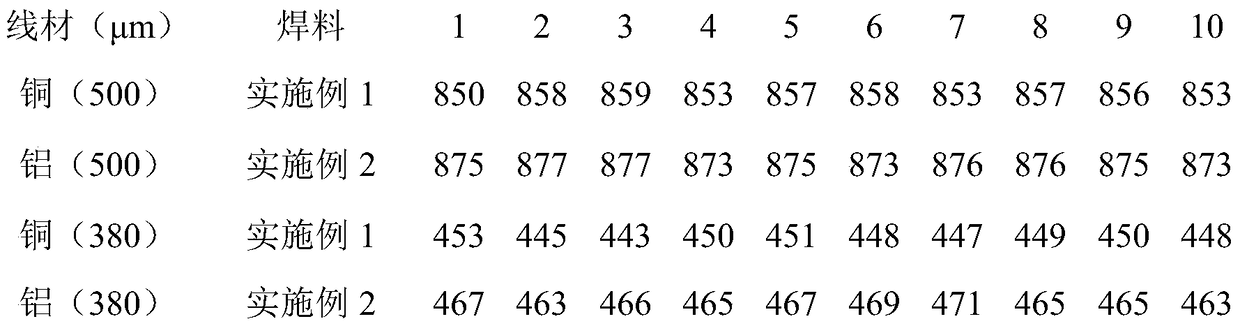

[0056] This embodiment is the soft soldering of copper wire and chip aluminum pad, and copper wire and frame, adopts solder A to carry out welding, and its chemical composition is (wt.%): Sn 34.1%, Cu 22.4%, Al 20 %, Ag 2.0%, Bi 3.5%, Sb 9.0%, In 9.0%.

[0057] The copper wire and the aluminum pad of the chip are welded to form the first solder joint, the preheating temperature is 220°C, the welding temperature is 290°C, the copper wire is welded to the copper frame to form the second solder joint, the preheating temperature is 220°C, and the welding temperature is 300°C.

Embodiment 2

[0061] This embodiment is the soft soldering of copper wire and chip aluminum pad, and copper wire and frame, adopts solder A to carry out welding, and its chemical composition is (wt.%): Cu 23.1%, Al 18.7%, Ag 3.5 %, Bi 3.5%, Sb 8.3%, In 8.0%, Sn balance.

[0062] The copper wire and the aluminum pad of the chip are welded to form the first solder joint, the preheating temperature is 220°C, the welding temperature is 290°C, the copper wire is welded to the copper frame to form the second solder joint, the preheating temperature is 220°C, and the welding temperature is 300°C.

Embodiment 3

[0066] This embodiment is the soldering of aluminum welding wire and chip aluminum pad, and aluminum welding wire and frame, adopts solder B to carry out welding, and its chemical composition is (wt.%): Sn 34.1%, Cu 21.0%, Al 23.4 %, Ag 2.0%, Bi 3.5%, Sb 8.0%, In 8.0%.

[0067] The aluminum wire is welded to the chip aluminum pad to form the first solder joint: the preheating temperature is 220°C, and the welding temperature is 290°C. The aluminum welding wire is welded with the copper frame to form the second solder joint: the preheating temperature is 220°C, and the welding temperature is 300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com