Polyester type polyurethane damping material and preparation method

A technology of polyester polyurethane and damping materials, which is applied in the field of polyester polyurethane damping materials and its preparation, can solve the problems of low loss factor of damping alloys, unsatisfactory damping performance, low elastic modulus, etc., and achieve good mechanical properties and high Effect of loss factor and damping temperature range wide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Room temperature vulcanized polyester polyurethane damping material

[0040] (1) Add 100g of polyneopentyl adipate (PNA-2000) into a three-necked flask equipped with a stirrer and a thermometer, dehydrate at 120-140°C for 2 hours under vacuum -0.095MPa, and then cool down to 50 ℃, add 17.7g of TDI-100, slowly raise the temperature to 80±5℃ and react for 2h, then degas at 85~90℃ under vacuum-0.095MPa to prepare the prepolymer and seal it for later use;

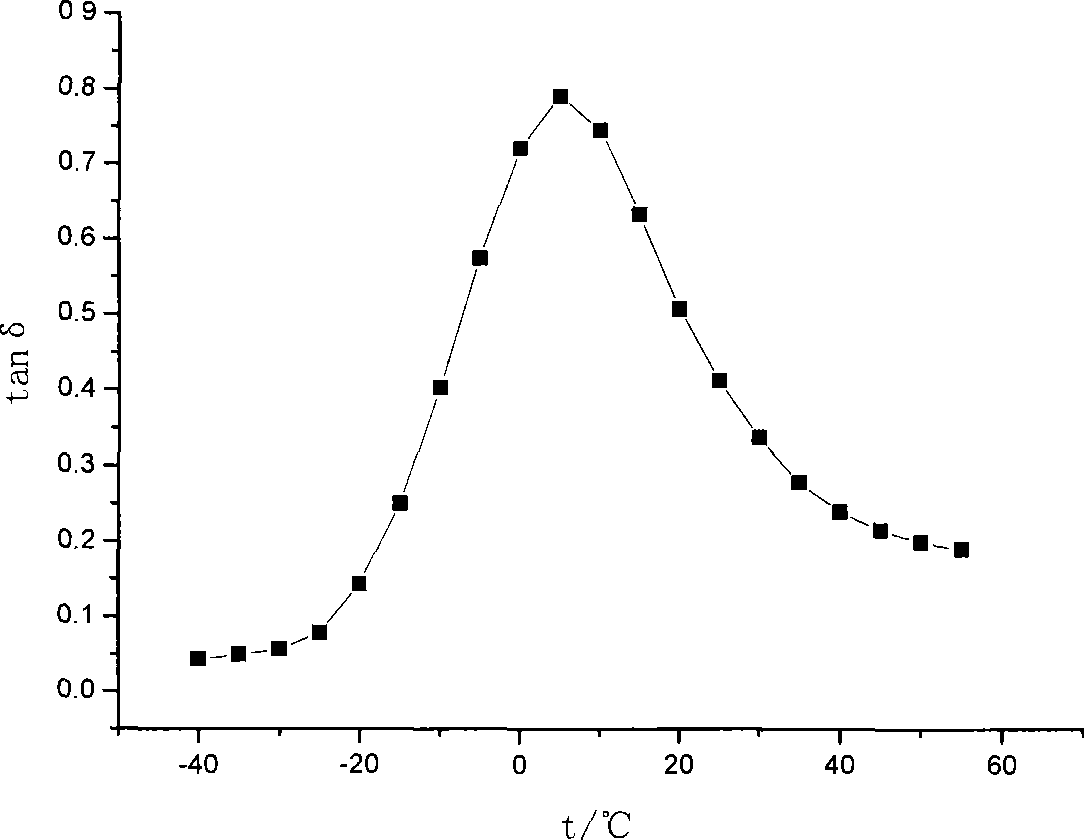

[0041] (2) Take 100g of prepolymer at 85°C, add 11.2g of MOCA melted at 100-120°C, stir evenly and pour it into a hot glass mold coated with a release agent. Place the sample at room temperature for 7 days to vulcanize, and test its various properties, see figure 1 and Table 1.

[0042]Table 1 Mechanical properties of room temperature vulcanized PU damping materials

[0043]

Embodiment 2

[0045] (1) same as embodiment 1;

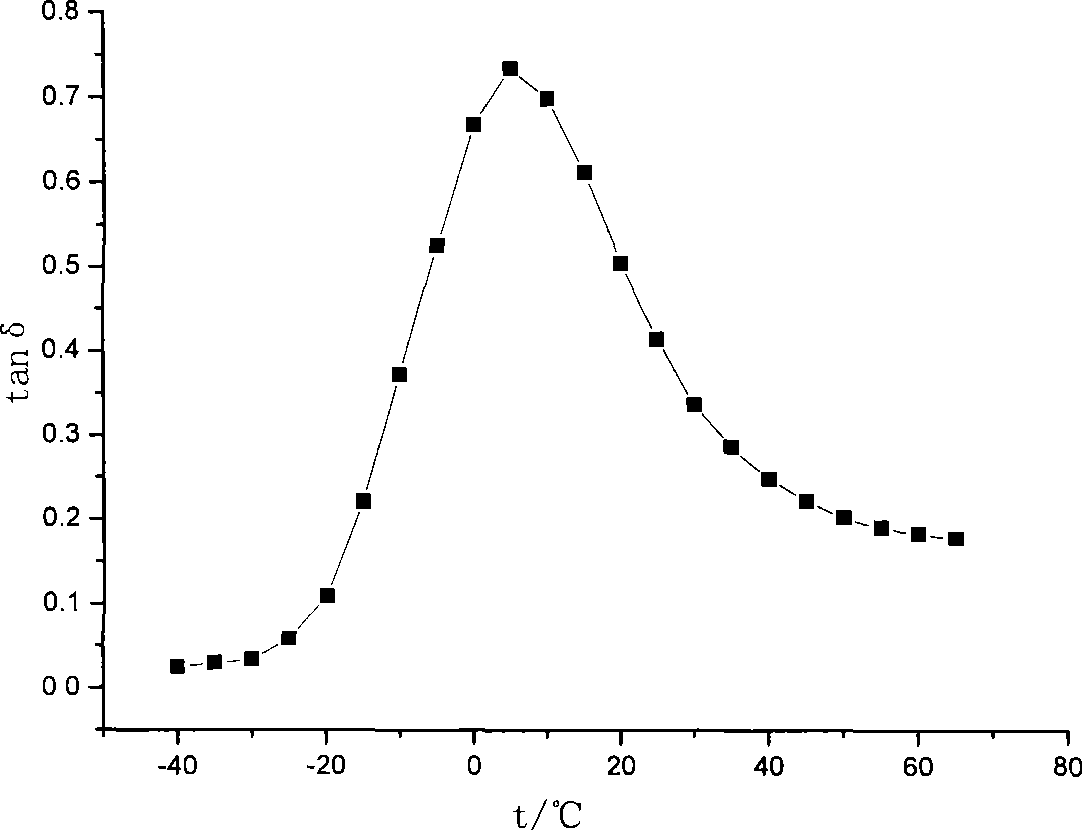

[0046] (2) The vulcanization condition was changed to 100°C×4h, and then placed at room temperature for seven days to test various properties, and the others were the same as in Example 1. See figure 2 ,Table 2.

[0047] Table 2 Mechanical properties of high temperature vulcanized PU damping material

[0048]

Embodiment 3

[0050] (1) Add 100g of polyneopentyl adipate (PNA-1000) into a three-necked flask equipped with a stirrer and a thermometer, dehydrate at 120-140°C for 2 hours under vacuum-0.095MPa, then cool down to 50°C, Add 36.0g of TDI-100, slowly raise the temperature to 80±5°C for 2 hours, degas at 85-90°C under vacuum-0.095MPa, and seal the prepolymer for use;

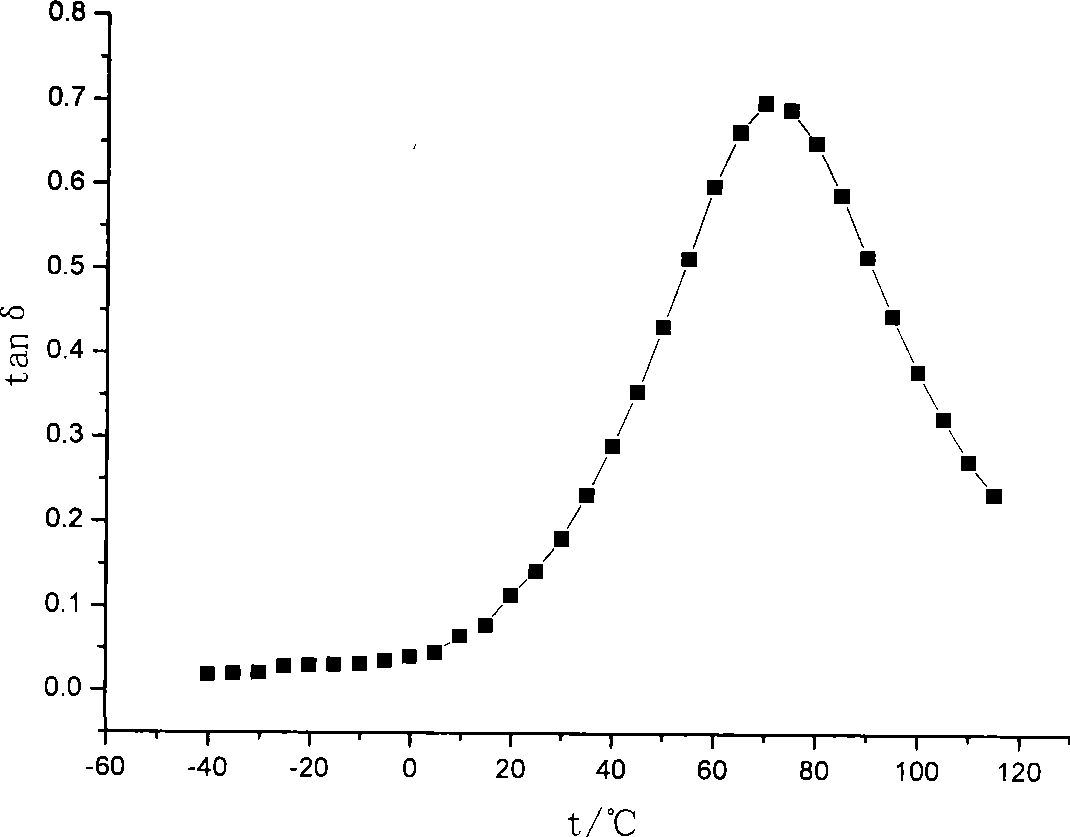

[0051] (2) Take 100g of prepolymer at 85°C, add 19.9g of MOCA melted at 100-120°C, stir evenly and pour it into a hot glass mold coated with a release agent. Place the sample at room temperature for 7 days to vulcanize, and test its various properties, see image 3 ,table 3.

[0052] Table 3 Mechanical properties of PU damping materials

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com