Pyramid-lattice metal sandwich plate and preparation method thereof

A technology of metal sandwich panels and pyramids, which is applied in the direction of metal layered products, chemical instruments and methods, surface pretreatment bonding methods, etc., can solve the problems of complex process, high cost, and low shear strength requirements, etc. To achieve a wide range of application prospects, improve corrosion, high specific stiffness performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

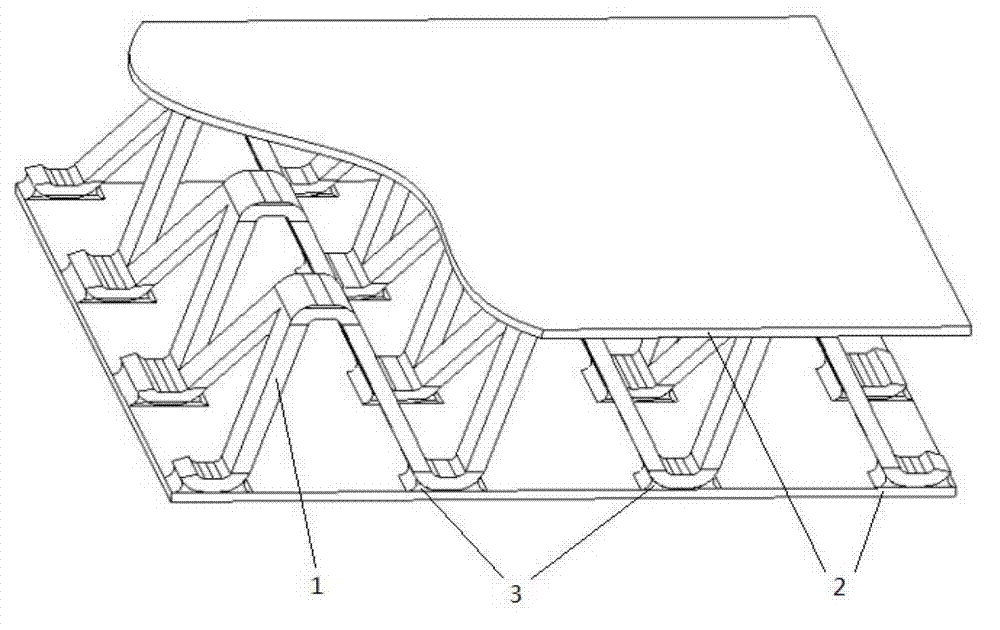

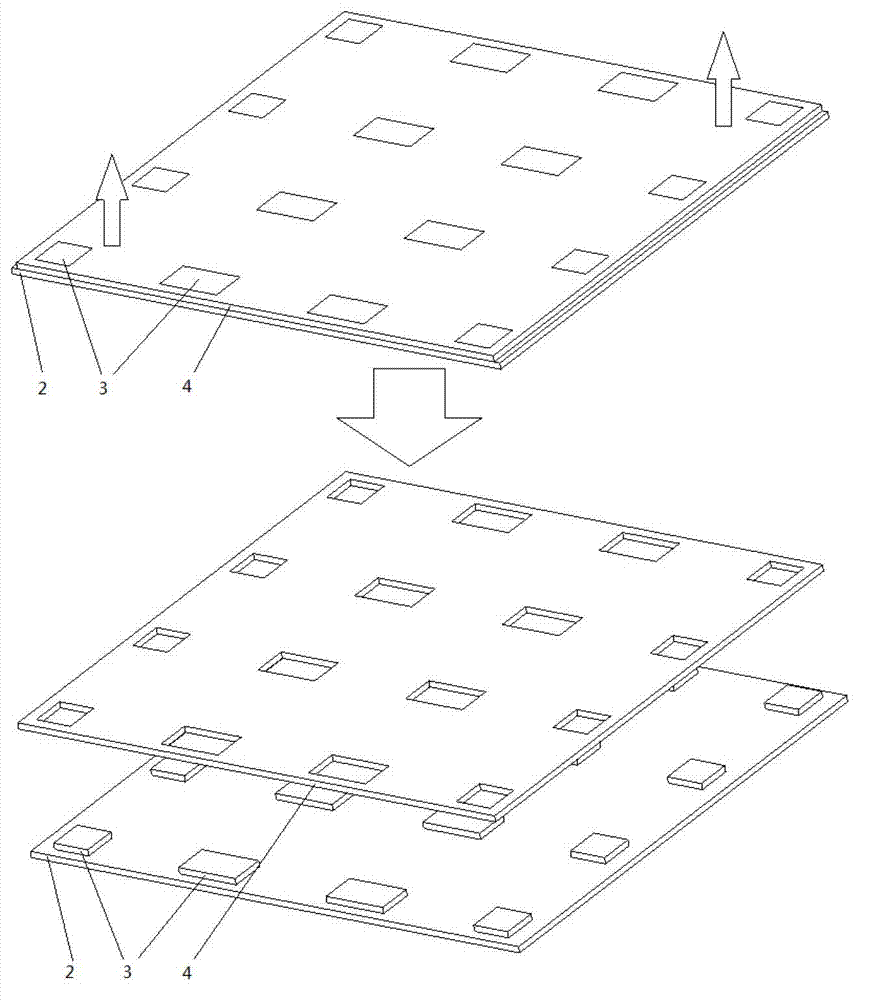

[0022] Example 1: 1) Firstly, the punched diamond-shaped pure aluminum mesh is molded and folded to form a pyramid core 1 with a node platform, and the pyramid core 1 and the metal panel 2 made of aluminum are cleaned to remove oil and rust. And the platform of the pyramid core 1 and the connecting surface of the metal panel 2 corresponding to the platform of the pyramid core 1 are mechanically polished or chemically oxidized by phosphating solution to enhance the bonding strength;

[0023] 2) Then, mix the two components of the two-component epoxy resin glue composed of epoxy resin and curing agent according to the volume ratio of 1:1 and mix thoroughly;

[0024] Then apply epoxy resin glue with a thickness of 0.1mm on each pyramid node platform or the corresponding position of the panel, and then stack the metal panel 2 and the core body 1 in sequence and stick them together;

[0025] 3) Finally, clamp the bonded metal pyramid lattice sandwich panel with a fixture, first pla...

Embodiment 2

[0026] Example 2: 1) First, the punched rhombic aluminum alloy mesh is molded and folded to form a pyramid core 1 with a node platform, and the pyramid core 1 and the metal panel 2 made of aluminum alloy are cleaned to remove oil and rust , and carry out mechanical grinding or chemical oxidation treatment of phosphating solution to the platform of the pyramid core body 1 and the connecting surface of the metal panel 2 corresponding to the platform of the pyramid core body 1, to enhance the bonding strength;

[0027] 2) Then, mix the two components of the two-component epoxy resin glue composed of epoxy resin and curing agent according to the volume ratio of 1:1 and mix thoroughly;

[0028] Then apply epoxy resin glue with a thickness of 0.5mm on each pyramid node platform or the corresponding position of the panel, and then stack the metal panel 2 and the core body 1 in sequence and stick them together;

[0029] 3) Finally, clamp the bonded metal pyramid lattice sandwich panel...

Embodiment 3

[0030] Example 3: 1) Firstly, the punched diamond-shaped titanium mesh is molded and folded to form a pyramid core 1 with a node platform, and the pyramid core 1 and the metal panel 2 made of titanium plates are cleaned to remove oil and rust. And the platform of the pyramid core 1 and the connecting surface of the metal panel 2 corresponding to the platform of the pyramid core 1 are mechanically polished or chemically oxidized by phosphating solution to enhance the bonding strength;

[0031] 2) Then, mix the two components of the two-component epoxy resin glue composed of epoxy resin and curing agent according to the volume ratio of 1:1 and mix thoroughly;

[0032] Then apply epoxy resin glue with a thickness of 1mm on each pyramid node platform or the corresponding position of the panel, and then stack the metal panel 2 and the core body 1 in sequence and stick them together;

[0033] 3) Finally, clamp the bonded metal pyramid lattice sandwich panel with a fixture, first pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com