Variable-rigidity double-mass vibration motor type super-huge vibration mill

A vibrating motor and dual-mass technology, applied in the field of vibrating mills, general vibrating mills or extra-large vibrating mills, and variable-stiffness dual-mass vibrating motor type super-large vibrating mills, can solve the problem of reduced efficiency, the influence of the surrounding environment of the operator, Repair the problem of high frequency to achieve the effect of reducing the probability of failure, improving energy utilization, and high structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

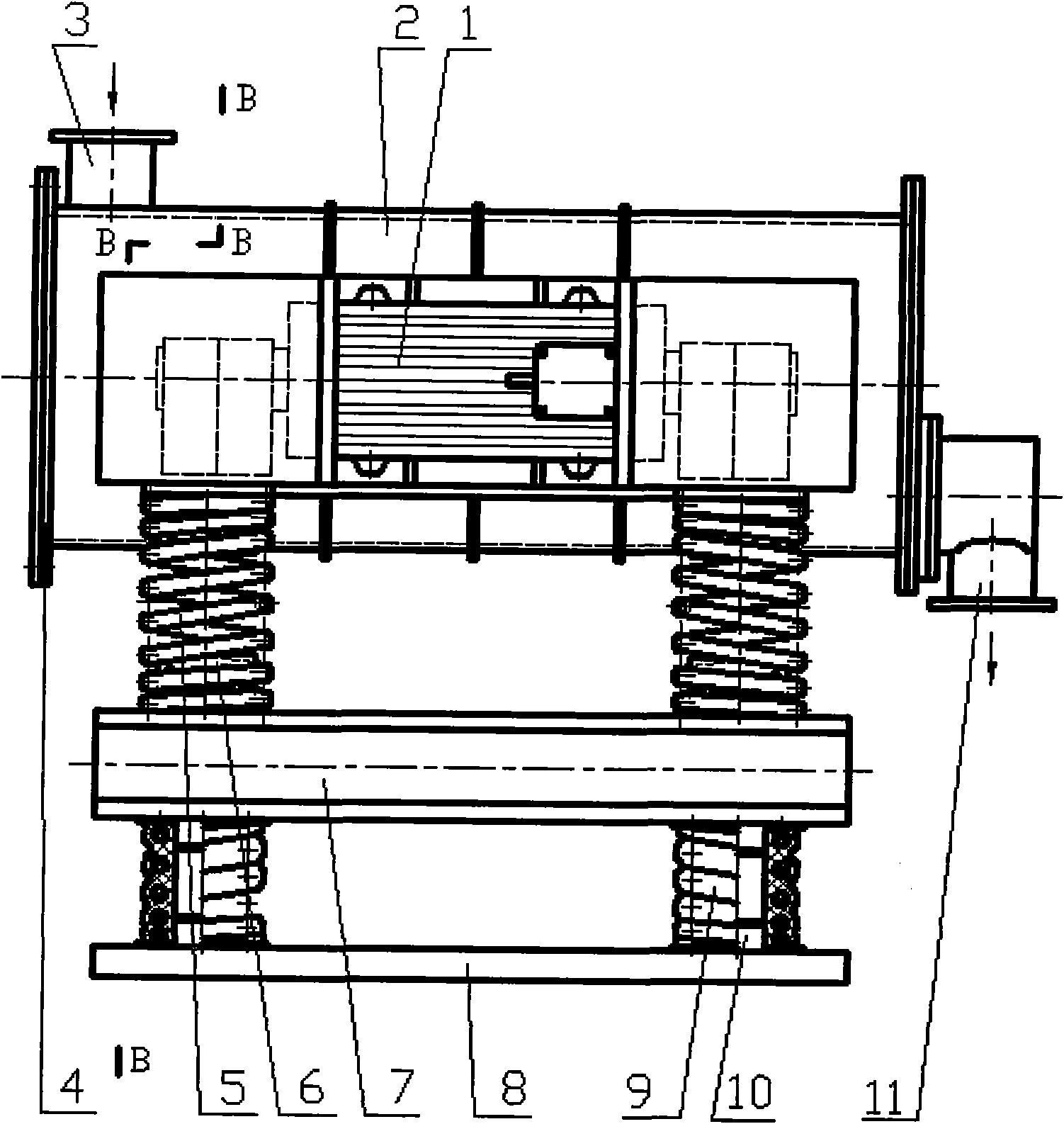

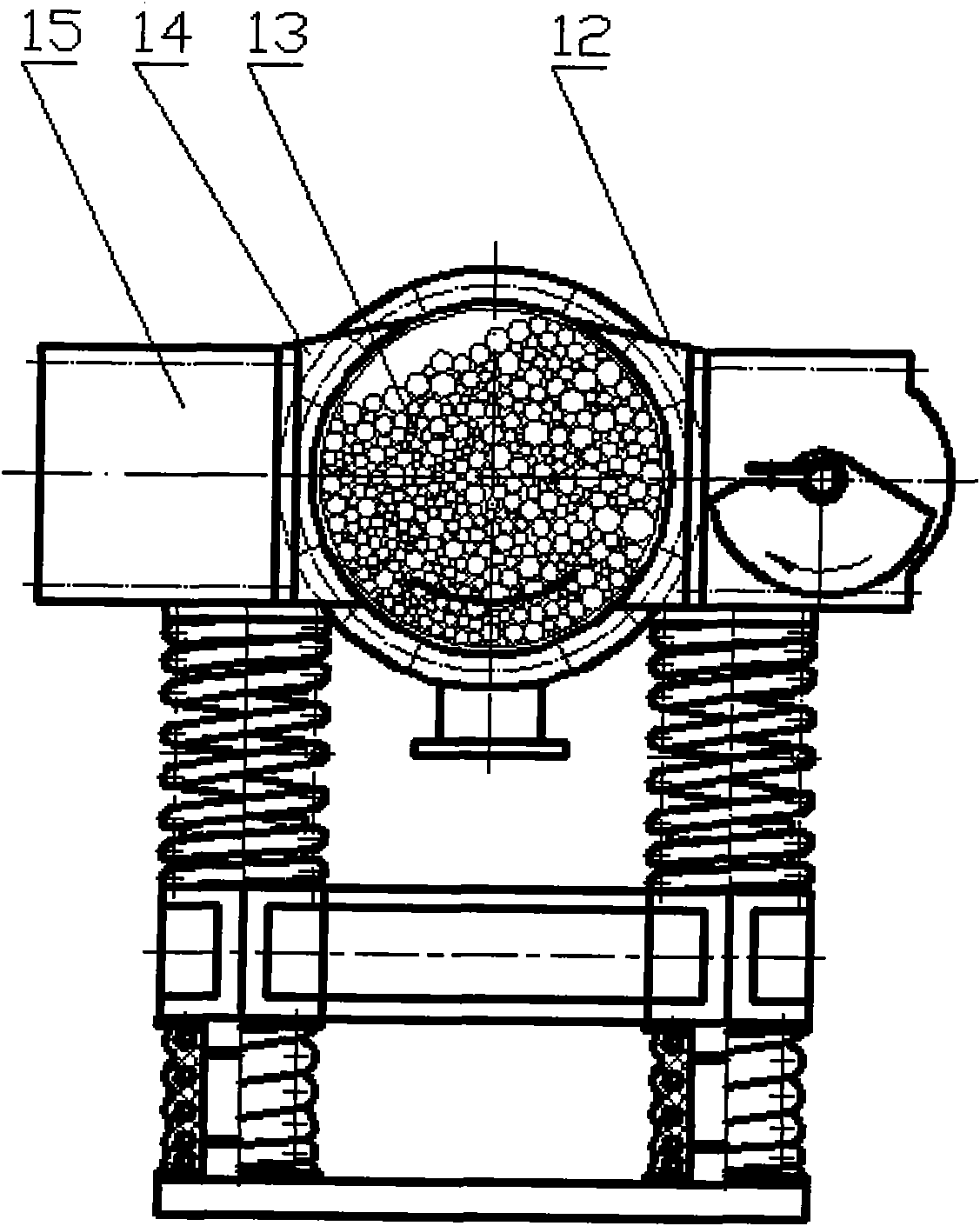

[0038] Refer to attached Figure 1-2 , variable stiffness two-mass vibrating motor type extra-large vibrating mill includes upper mass body, main vibration spring 5, main vibration spring guide post 6, lower mass body 7, base 8, vibration isolation spring 9 and vibration isolation spring guide post 10, Wherein the upper body comprises a vibrating motor 1, a cylinder body 2, a feed inlet 3, an end cover 4, a discharge outlet 11, a right connecting frame 12, a grinding medium 13, a left connecting frame 14, and a counterweight 15.

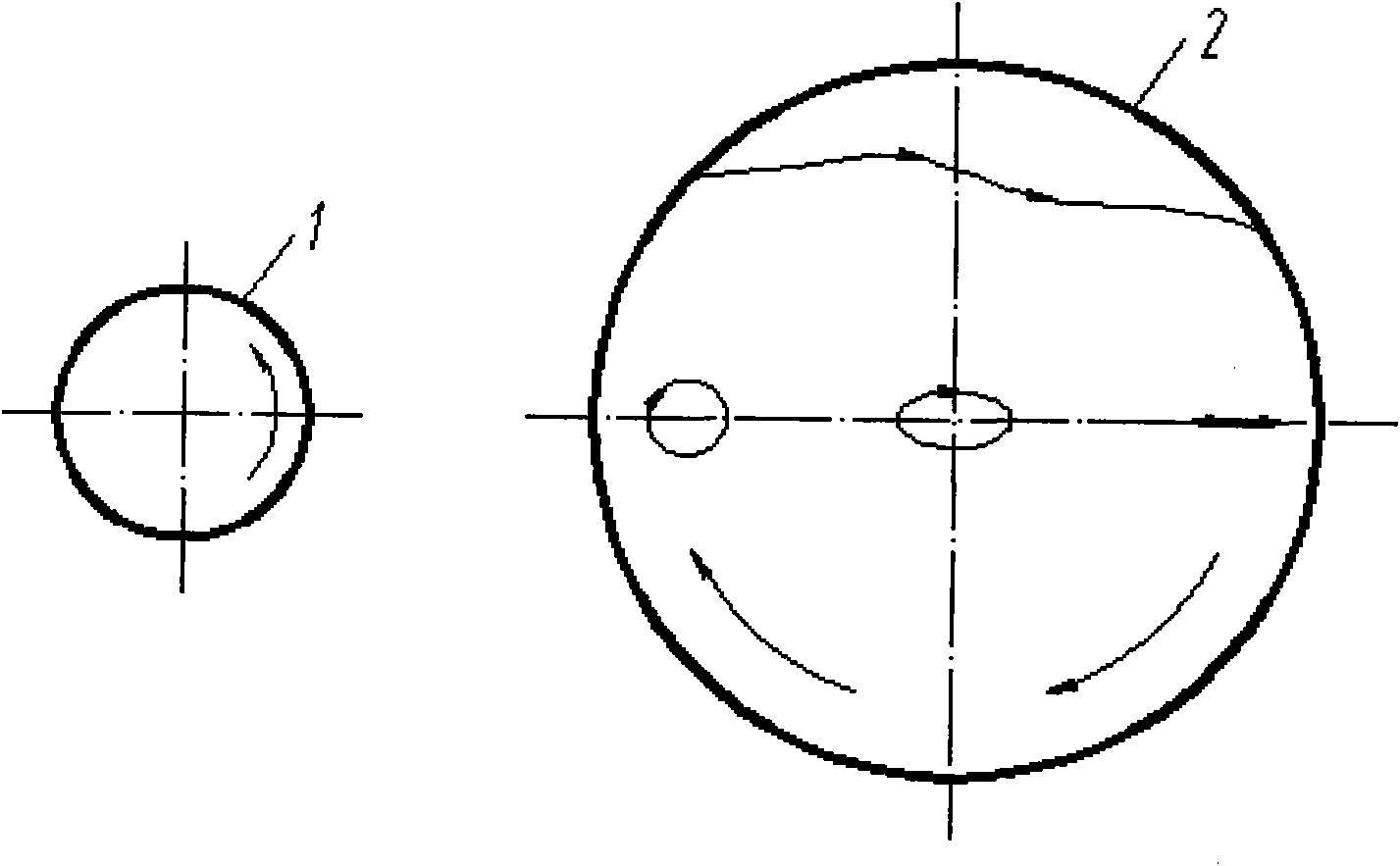

[0039] attached Figure 1-2 In the shown structure, the cylinder body 2 is movably supported on the lower mass body 7 via the main vibration spring 12 . On the right side of the cylinder 2, the vibration motor 1 is rigidly fixed with the right coupling frame 12, and the axis of the main vibrating spring 5 on the driving side is located between the gravity axis of the cylinder 2 and the vibration motor 1. The inner diameter of the main vibration spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com