Wide temperature range acrylate rubber based graphene oxide damping material and preparation method thereof

A technology of acrylate and damping materials, which is applied in the field of wide temperature range acrylate rubber (ACM)-based graphene oxide damping materials and its preparation, and can solve the problems of loss of damping effect, high damping performance, migration and loss of small molecule damping agents, etc. , to achieve the effect of increasing the glass transition temperature, improving the damping performance, and broadening the effective damping temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

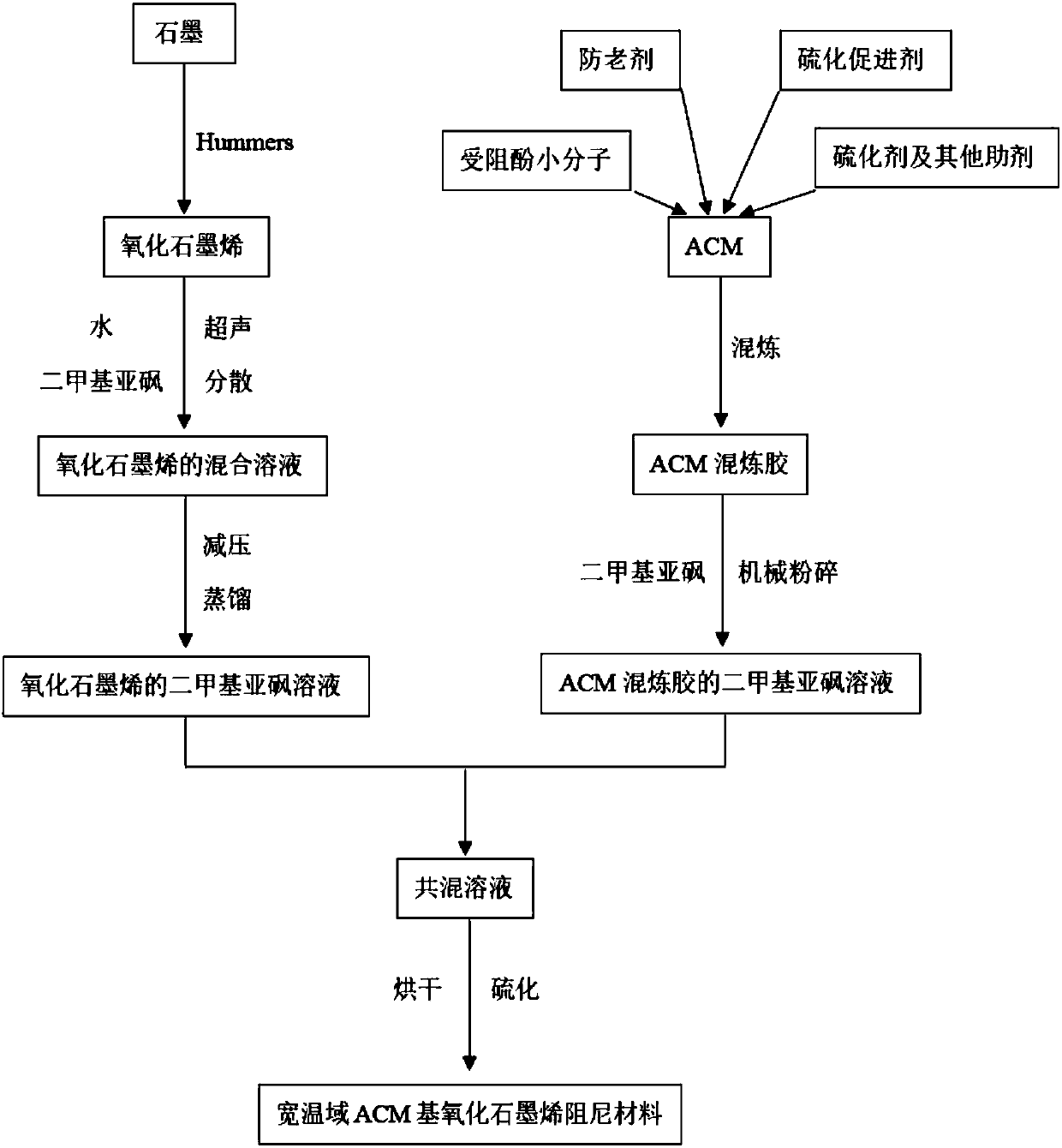

Method used

Image

Examples

Embodiment 1

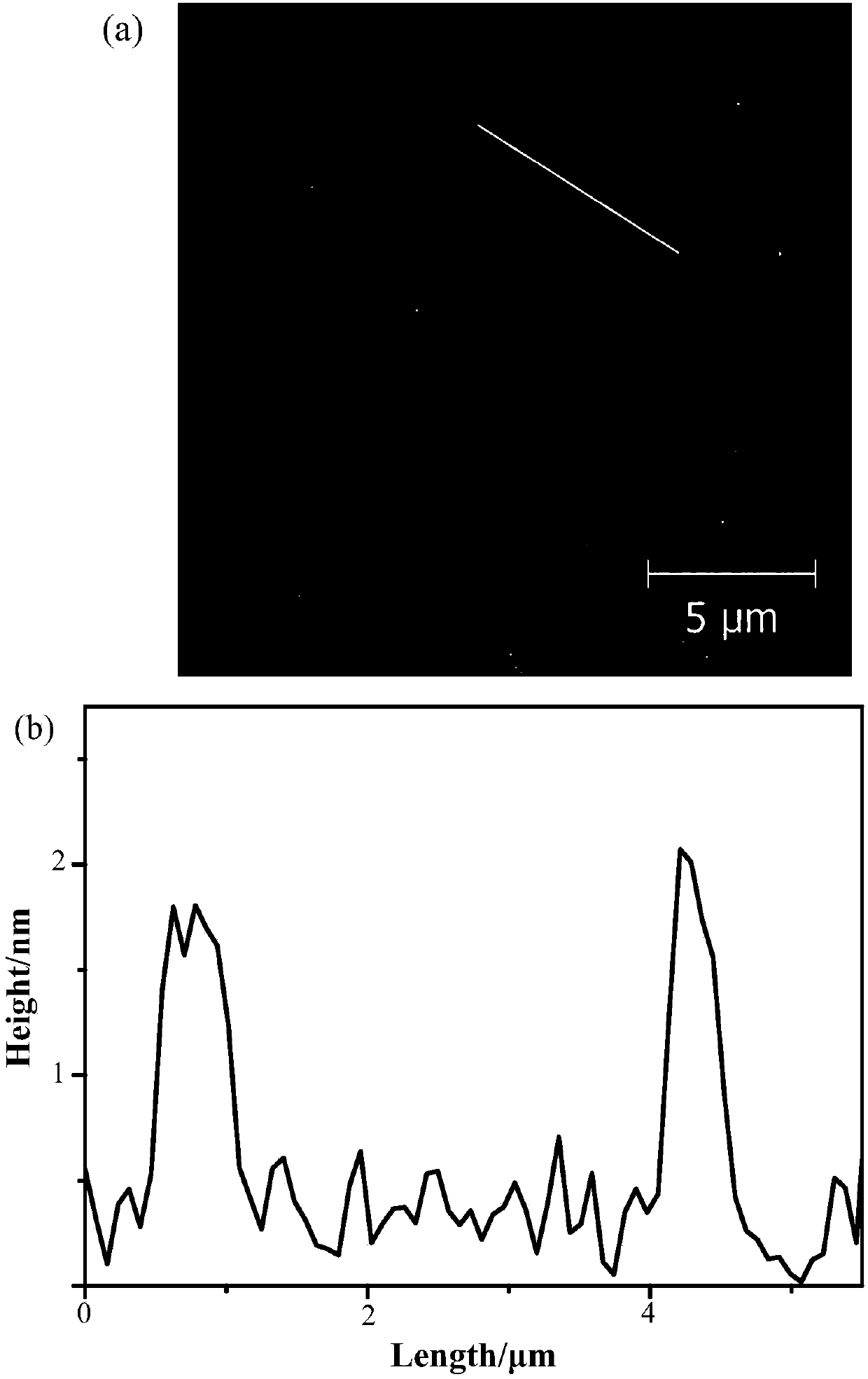

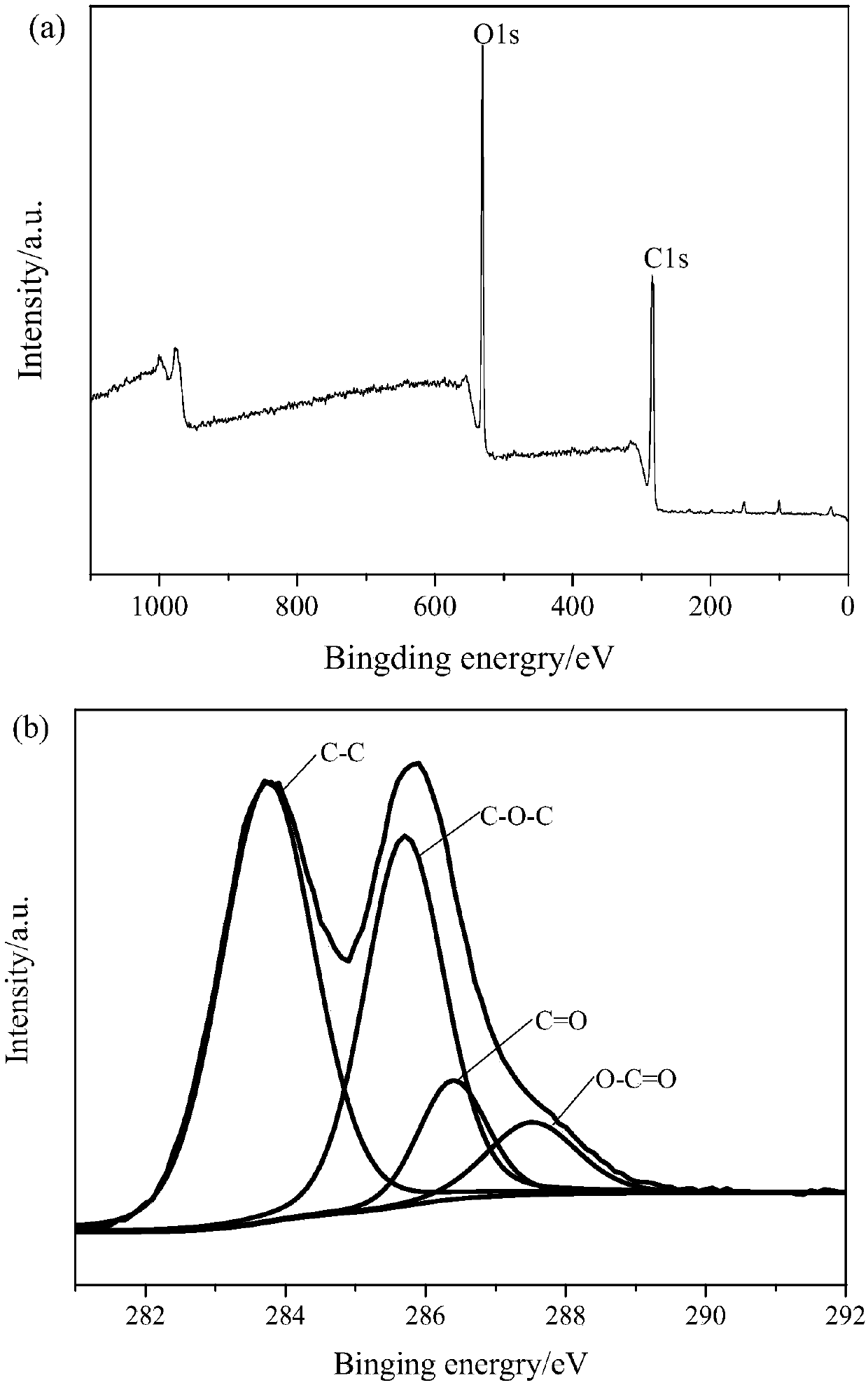

[0031] Step 1, measure 230 mL of concentrated sulfuric acid in a four-neck flask, place in an ice bath, and cool down to about 0 °C. Add 10 g of graphite and 5 g of sodium nitrate in turn, and stir the solution for 15 min. Then slowly add 30 g of potassium permanganate three times within 1 h, keeping the temperature below 20 °C. After mixing evenly, the temperature was raised to 35 °C and kept stirring for 2 h. After that, 460 mL of deionized water was slowly added. During this process, the temperature of the solution was kept below 100 °C for 15 min. The liquid was transferred to a beaker, and 750 mL of deionized water and 250 mL of 5% hydrogen peroxide solution were added. Then the graphene oxide is processed by ultrasound, dialysis, and drying, and the graphene oxide is characterized. The AFM map and its corresponding height map are as follows figure 2 As shown, the XPS diagram is as follows image 3 shown;

[0032] Step 2, put 0.5 g of large-sized graphene oxide obtai...

Embodiment 2

[0037] Repeat the method of Example 1, but in step one, the amount of potassium permanganate is 21 g; in step two, the amount of graphene oxide is 0.4 g; in step three, the mixing formula is 100 parts of ACM rubber, 50 parts of hindered phenol small molecules AO-80, 3 parts of stearic acid, 2 parts of vulcanization accelerator D, 4 parts of vulcanization accelerator DOTG, 2 parts of antioxidant 4010NA, 3 parts of antioxidant DPPD, 1 part of processing aid RL210, 3 parts of processing aid WS280, 4 parts sulfur. The effective damping temperature range of the obtained damping material is -7.2°C to 38.0°C, the temperature range width reaches 45.2°C, and the damping temperature range of the material after aging can also reach 42.4°C.

Embodiment 3

[0039]Repeat the method of Example 1, but in step one, the amount of potassium permanganate is 15 g; in step two, the amount of graphene oxide is 0.3 g; in step three, the mixing formula is 100 parts of ACM rubber, 30 parts of hindered phenol small molecules AO-60, 2 parts of stearic acid, 2 parts of vulcanization accelerator DOTG, 3 parts of antioxidant DPPD, 2 parts of processing aid WB222, 1 part of processing aid WS280, 3 parts of sulfur. The effective damping temperature range of the obtained damping material is -6.8°C to 37.8°C, the temperature range width reaches 44.6°C, and the damping temperature range of the material after aging can also reach 42.7°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping temperature range | aaaaa | aaaaa |

| Damping temperature range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com