Damping glue for vibration reducing plate and preparation method thereof

A technology of damping glue and damping plate, which is applied in the direction of adhesives, adhesive types, conjugated diene adhesives, etc., can solve problems such as inability to adapt to requirements, and achieve excellent damping characteristics, simple process methods, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

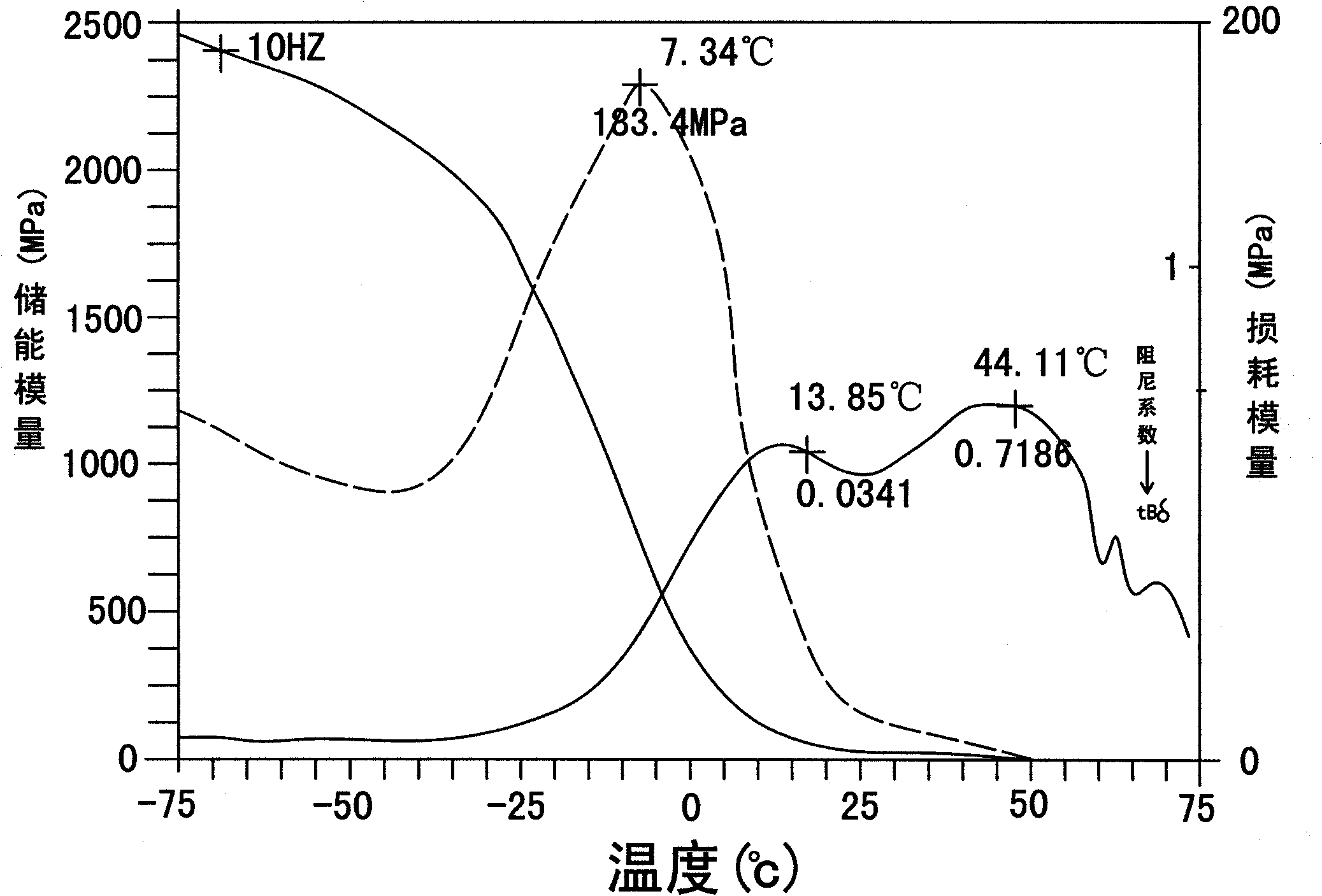

[0030] Masticate 100g of nitrile 26 on a two-roller machine for 5-10 minutes, then add 8g of zinc oxide and knead until the Vickers plasticity is 0.22 for later use; then masticate 60g of nitrile 40 on a two-roller until the Vickers plasticity is 0.39 for later use; then add nitrile 26 mixed material and nitrile 40 mixed material together into the stirring 800g butyl acetate and stir until fully dissolved; then add 56g phenolic resin, 40g additive, 124g epoxy resin, 20g curing agent and 1g of 2,4-dichlorobenzoyl peroxide and stirred until completely dissolved to form a uniform viscous liquid to obtain the normal temperature damping glue for the vibration damping plate. The performance indicators of the prepared damping glue are: solid content 34%; glue viscosity 5.5Pa·S (25°C); T-peel strength 26.2N / cm; tensile shear strength 7.4MPa; tanδ≥0.20 temperature range: -10~75℃.

Embodiment 2

[0032] Masticate 132g of nitrile 26 on a twin-roller for 5-10 minutes, then add 14g of zinc oxide and knead until the Vickers plasticity is 0.25 for later use; then masticate 120g of nitrile 40 on the twin-roller until the Vickers plasticity is 0.35 for subsequent use; then add nitrile 26 mixing material and nitrile 40 mixing material together into stirring 1000g butyl acetate, 600g dimethyl carbonate and stir until fully dissolved; then add 80g phenolic resin, 20g chlorinated polystyrene Stir ethylene, 28g chlorinated polypropylene, 186g epoxy resin, 36g curing agent and 7g 1,1-bis(tert-butylperoxy)cyclohexane until completely dissolved and form a uniform viscous liquid to obtain the damping plate Use normal temperature damping glue. The performance indicators of the prepared damping glue are: solid content: 28%; glue viscosity: 3.8Pa·S (25°C); T-peel strength: 27.3N / cm; tensile shear strength: 7.7MPa; tanδ≥ 0.20 temperature range: -10~75℃.

Embodiment 3

[0034]Masticate 120g of nitrile 26 on a two-roller machine for 5-10 minutes, then add 14g of zinc oxide and knead until the Vickers plasticity is 0.25 for later use; then masticate 120g of nitrile 40 on a two-roller until the Vickers plasticity is 0.35 for subsequent use; then nitrile 26 joins the mixing material and nitrile 40 mixing material together in stirring 800g butyl acetate, 800gMIBK and stirs until fully dissolved; then add 80g phenolic resin, 20g chlorinated polyethylene and 28g chlorine Thin polypropylene, 160g of bisphenol A epoxy resin (E-51) and 40g of bisphenol A benzoxazine, 31g of DDS and 7g of 1,1-bis(tert-butylperoxy)cyclohexane were stirred until completely dissolved The normal temperature damping glue for the vibration damping plate can be obtained in the form of a uniform viscous liquid. The performance indicators of the prepared damping glue are: solid content: 28%; glue viscosity: 4.5Pa·S (25°C); T-peel strength: 29.3N / cm; tensile shear strength: 9.5MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com