Compound preparation method for piezoelectric ceramic and carbon material

A technology of piezoelectric ceramics and carbon materials, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve complex problems, achieve the effects of reducing randomness, improving damping performance, and effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below is the material used for the example

[0020] Absolute ethanol: analytically pure, Beijing Chemical Plant.

[0021] Maleic acid: analytically pure, Sinopharm Chemical Reagent Co., Ltd. It is a double-headed carboxylic acid.

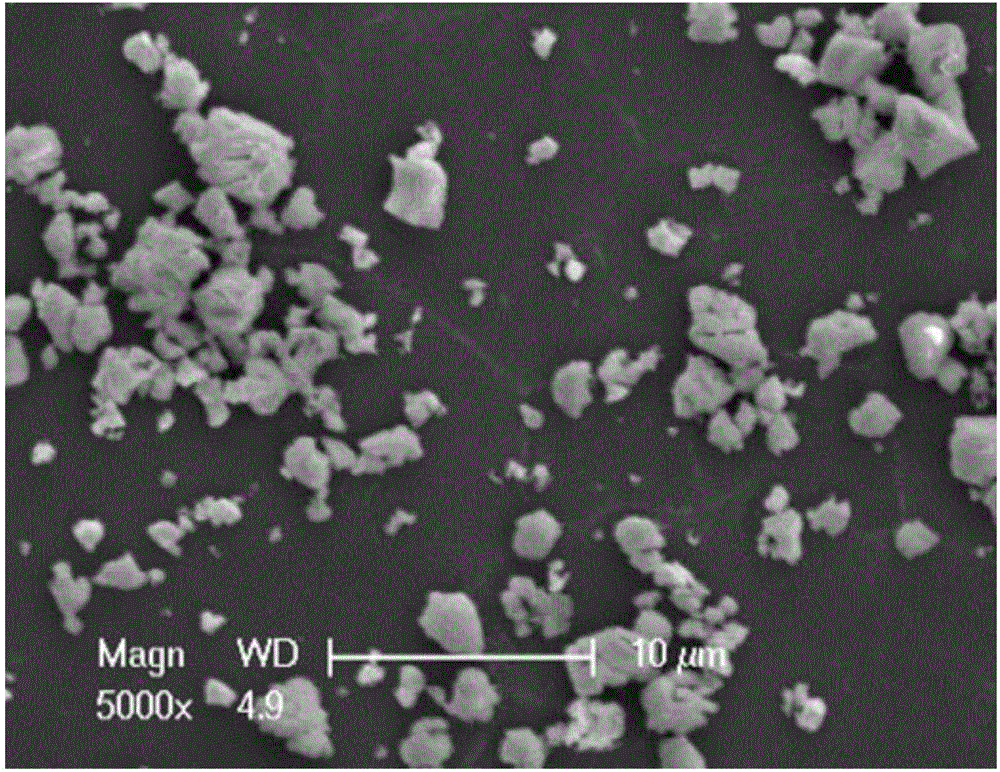

[0022] Lead niobium magnesium zirconate titanate (PMN): purchased from Baoding Hongsheng Acoustic Electronic Equipment Co., Ltd., Hebei Province. Its particle size is: 200nm ~ 5000nm.

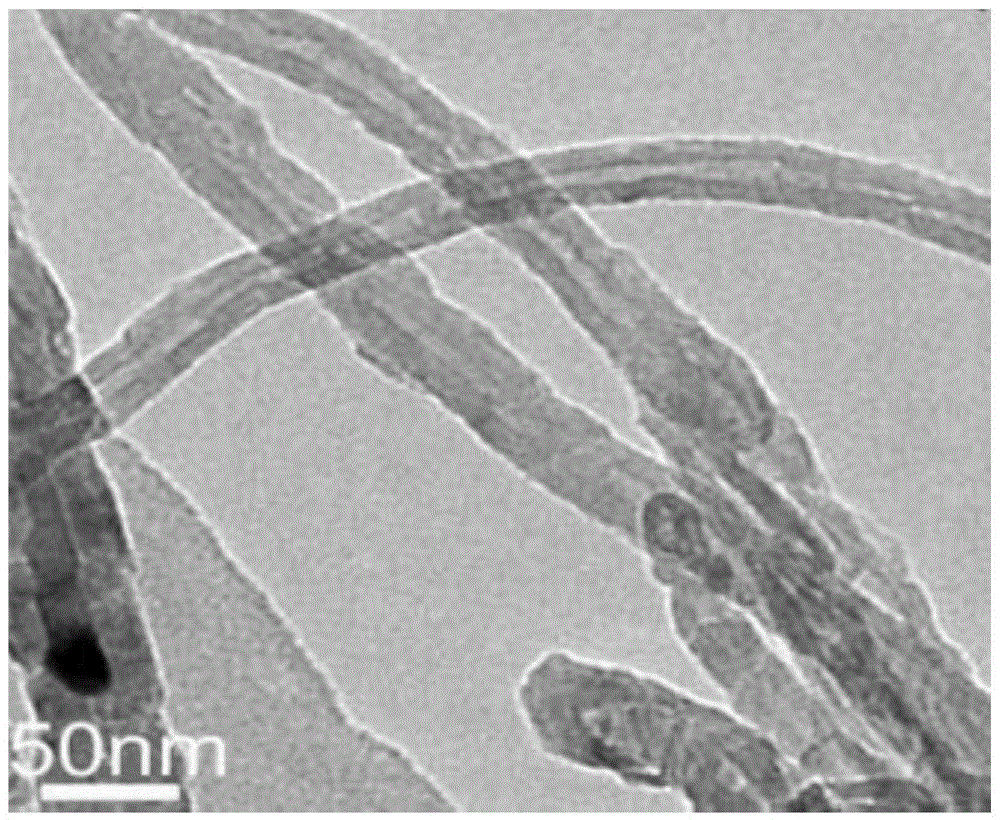

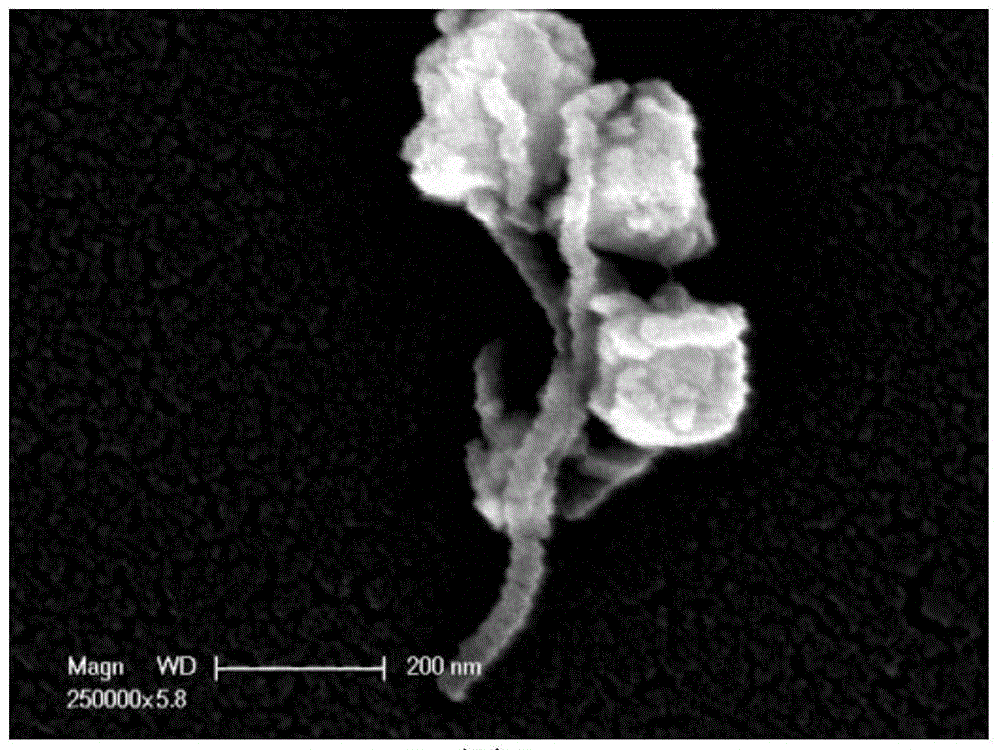

[0023] Carbon nanotubes: purchased from Beijing Nachen Technology Development Co., Ltd. It is a multi-walled carbon nanotube with an outer diameter of 50nm-100nm and a length of 10-20μm.

[0024] Specifically, the compound preparation method of piezoelectric ceramics and carbon material (carbon nanotube, carbon fiber or graphene etc.), it comprises the steps:

[0025] (1) Sieve the piezoelectric ceramic powder to keep the powder with a particle size below 2 μm;

[0026] (2) ultrasonically dissolve 15-30 g of maleic acid in 100-150 ml of ethanol, then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com