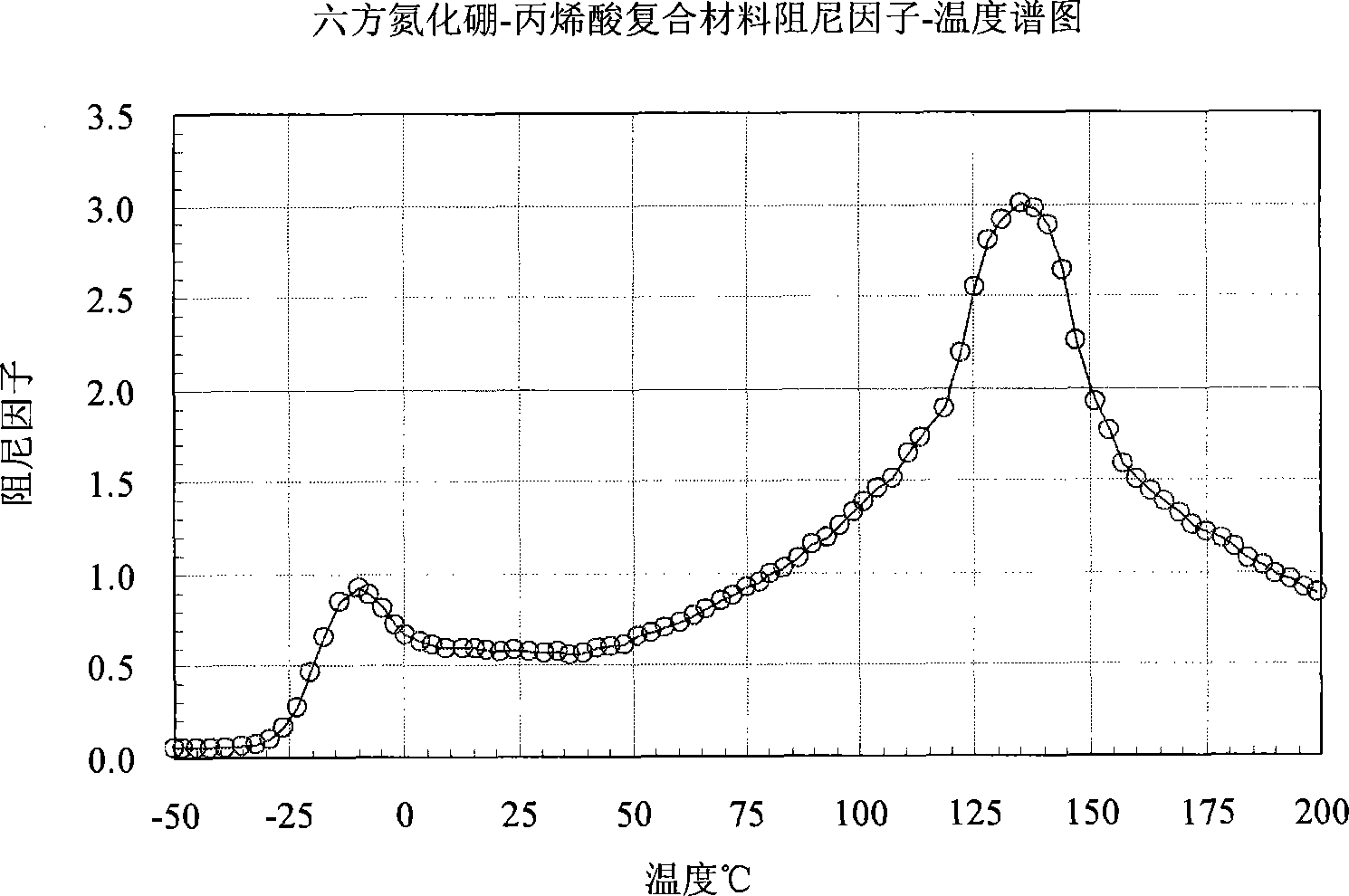

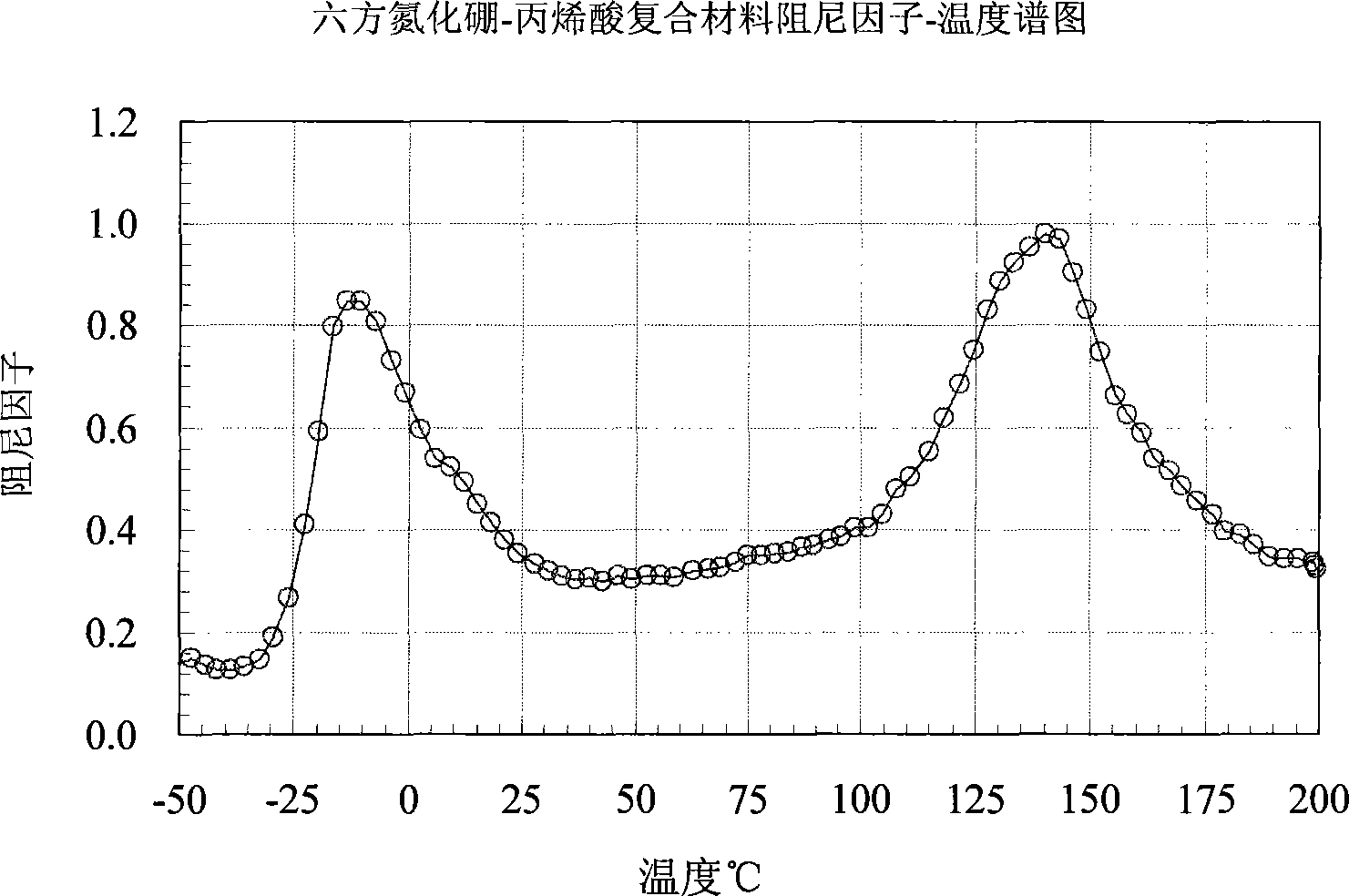

Method for preparing wide temperature range high damping acrylic emulsion material

An acrylic emulsion and high damping technology, which is applied in the field of inorganic-organic composites, can solve the problems of complex damping material preparation process and insignificant modification results, and achieve good stability, simple synthesis process, and enhanced material damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Experimental method 1: boron nitride composite acrylic emulsion

[0020] 1) Mix 60 grams of water, 19.2 grams of MMA, 12.8 grams of St, 0.8 grams of hexagonal boron nitride, 0.4 grams of emulsifier, 0.2 grams of cross-linking agent, and 0.2 grams of buffer. After ultrasonic dispersion for 30 minutes, put it into a single-port circle Stir in a bottom flask, pre-emulsify at room temperature at high speed for 1 hour to obtain a pre-emulsion. Under the condition of a water bath of 60°C, add 1 / 4 of the pre-emulsion liquid to a four-necked round bottom flask connected with a condenser, a dropping device, and a stirring device, and when the temperature is raised to 75°C with stirring, add 1 / 4 of the initiator and continue Raise the temperature to 78-80°C, and add the remaining pre-emulsion and initiator dropwise at a constant speed for 1.5-2 hours after the reaction system turns blue. After the dropwise addition, keep the temperature at 79-80° C. for 2 hours, and filter with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping temperature range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com