Preparation method for in-situ synthesis of CNT (carbon nano tube) modified carbon fiber reinforced resin structure-damping composite material

A technology of carbon nanotube modification and damping composite materials, which is applied in the direction of carbon fiber, fiber treatment, metal material coating technology, etc., can solve the problems of complex repair process of carbon fiber composite materials, reduce system stability, and material fatigue damage, etc., to achieve Good application prospects, strong repeatability, and the effect of improving damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

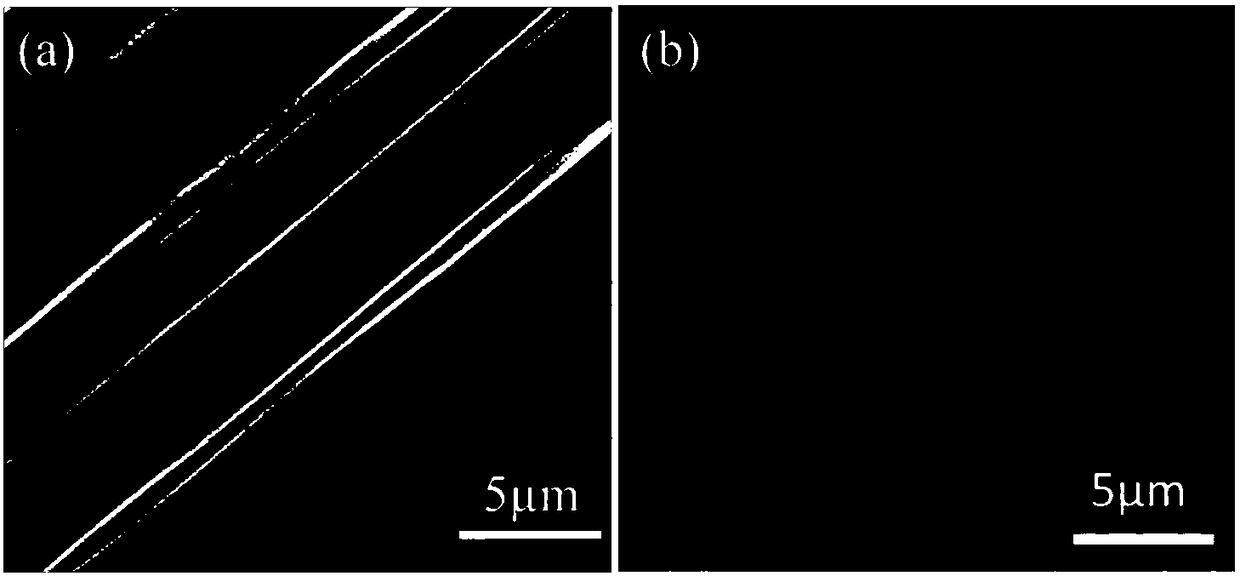

[0023] Soak the carbon fiber in an acetone solution, let it stand for 8 hours, take out the carbon fiber and place it in deionized water for 30 minutes, then clean it with deionized water and dry it in an environment of 90 °C for 8 hours; 0.202g of Fe(NO 3 ) 3 Dissolve in 100ml of absolute ethanol and stir for 30 minutes; apply the prepared solution on the surface of the dried carbon fiber, and then place the carbon fiber at 90°C for 30 minutes; place the dried carbon fiber in a tube furnace , then pass Ar into the tube furnace at 240 sccm, raise the temperature of the furnace at 10°C / min to 250°C and stop feeding Ar, put H 2 Pass it into the tube furnace at 150 sccm and keep it warm for 1 hour, raise the temperature of the furnace to 450°C at 10°C / min and keep it warm for 1 hour in an atmosphere, stop passing H 2 , Ar is passed into the tube furnace at 240 sccm, the furnace temperature is raised to 600 °C at 10 °C / min, and then C 2 h 2 , and keep warm for 1 hour. The carb...

Embodiment 2

[0025] Soak the carbon fiber in an acetone solution, let it stand for 8 hours, take out the carbon fiber and place it in deionized water for 30 minutes, and then clean it with deionized water and dry it in an environment of 90°C for 8 hours; 0.404g of Fe(NO 3 ) 3 Dissolve in 100ml of absolute ethanol and stir for 30 minutes; apply the prepared solution on the surface of the dried carbon fiber, and then place the carbon fiber at 90°C for 30 minutes; place the dried carbon fiber in a tube furnace , then pass Ar into the tube furnace at 240 sccm, raise the temperature of the furnace at 10°C / min to 250°C and stop feeding Ar, put H 2 Pass it into the tube furnace at 150 sccm and keep it warm for 1 hour, raise the temperature of the furnace to 450°C at 10°C / min and keep it warm for 1 hour in an atmosphere, stop passing H 2 , Ar is passed into the tube furnace at 240 sccm, the furnace temperature is raised to 600 °C at 10 °C / min, and then C 2 h 2 , and keep warm for 1 hour. The c...

Embodiment 3

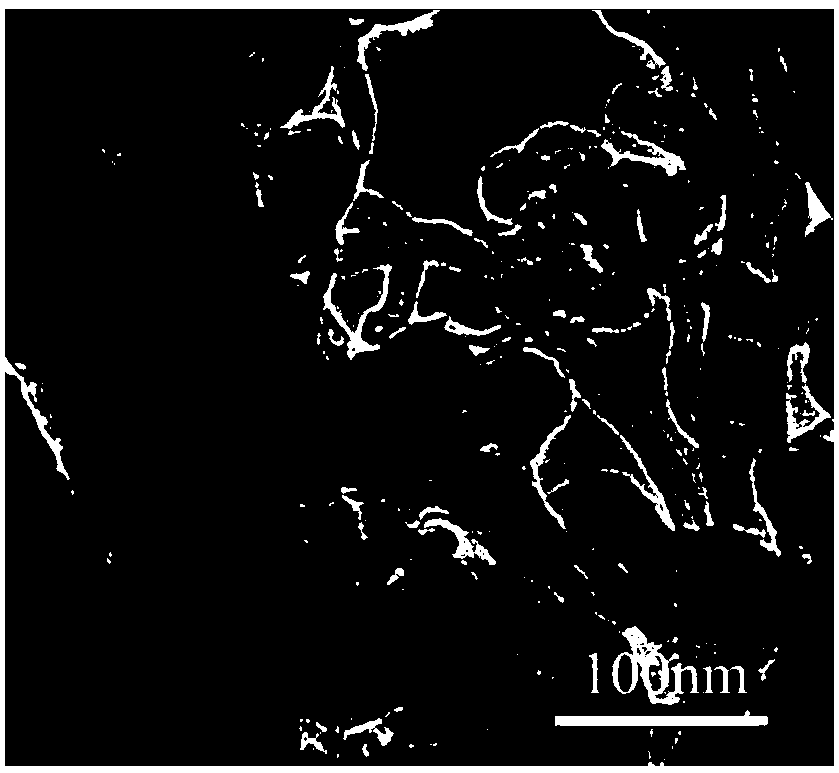

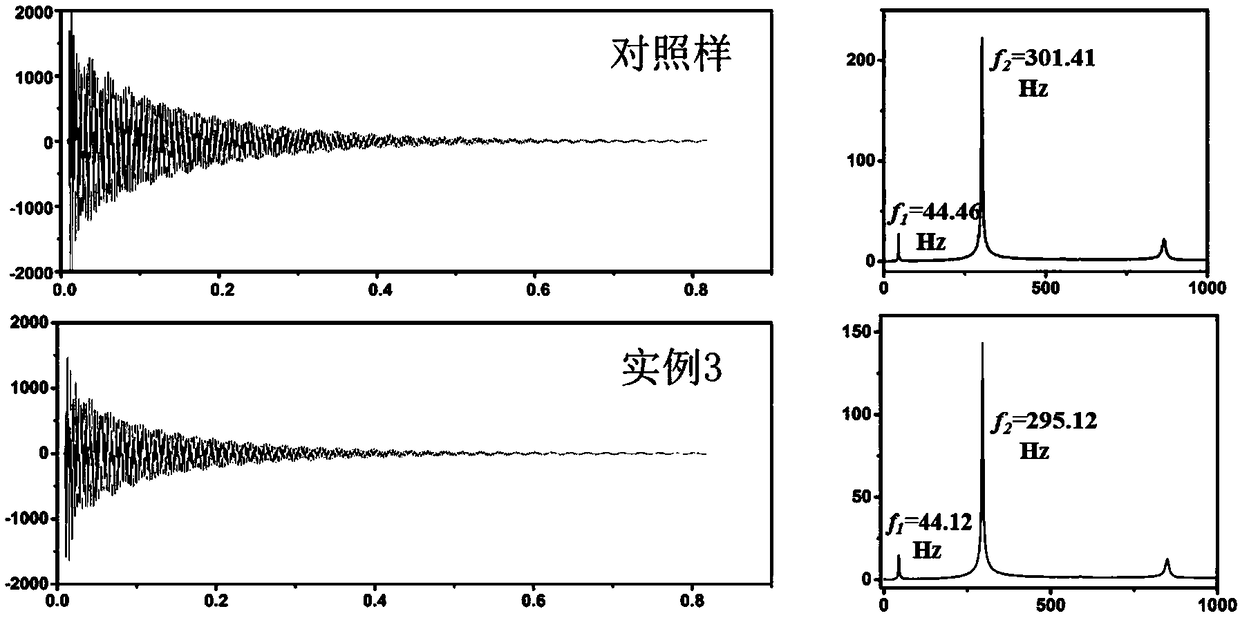

[0027] Soak the carbon fiber in an acetone solution, let it stand for 8 hours, take out the carbon fiber and place it in deionized water for 30 minutes of ultrasonication, then clean it with deionized water and dry it in an environment of 90°C for 8 hours; 0.808g of Fe(NO 3 ) 3 Dissolve in 100ml of absolute ethanol and stir for 30 minutes; apply the prepared solution on the surface of the dried carbon fiber, and then place the carbon fiber at 90°C for 30 minutes; place the dried carbon fiber in a tube furnace , then pass Ar into the tube furnace at 240 sccm, raise the temperature of the furnace at 10°C / min to 250°C and stop feeding Ar, put H 2 Pass it into the tube furnace at 150 sccm and keep it warm for 1 hour, raise the temperature of the furnace to 450°C at 10°C / min and keep it warm for 1 hour in an atmosphere, stop passing H 2 , Ar is passed into the tube furnace at 240 sccm, the furnace temperature is raised to 600 °C at 10 °C / min, and then C 2 h 2 , and keep warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com