Vulcanized silicone rubber and preparing method thereof

A technology for vulcanizing silicone rubber and silicone rubber raw rubber, applied in the field of vulcanized silicone rubber and its preparation, can solve the problems of affecting damping performance and mechanical properties, silicone rubber cannot be vulcanized, and material compatibility is not good, and achieve excellent mechanical properties. , The effect of improving mechanical properties and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a kind of preparation method of above-mentioned vulcanized silicone rubber, comprises the following steps:

[0038] Mix raw silicone rubber, peroxide and damping modifier, and vulcanize at 170-180°C to obtain vulcanized silicone rubber.

[0039] The components and proportions of the raw silicone rubber, peroxide and damping modifier are the same as above, and will not be repeated here. In the present invention, there is no special limitation on the sources of the raw silicone rubber, peroxide and damping modifier, which may be commercially available.

[0040] The temperature of the vulcanization treatment is 170-180°C. In an embodiment of the present invention, the temperature of the vulcanization treatment is 175°C, 170°C or 180°C. In an embodiment of the present invention, the time for the vulcanization treatment is 5-15 minutes. In some embodiments of the present invention, the vulcanization treatment time is 10 minutes, 15 minute...

Embodiment 1

[0045] Homemade polyborosiloxane (PBS):

[0046] Disperse 26.6mg of boric acid evenly in toluene, then add 5g of PDMS, stir at room temperature for 2h, heat in an oil bath at 120°C for 48h, then remove the toluene under reduced pressure at 60°C to obtain polyborosilane polymer (PBS);

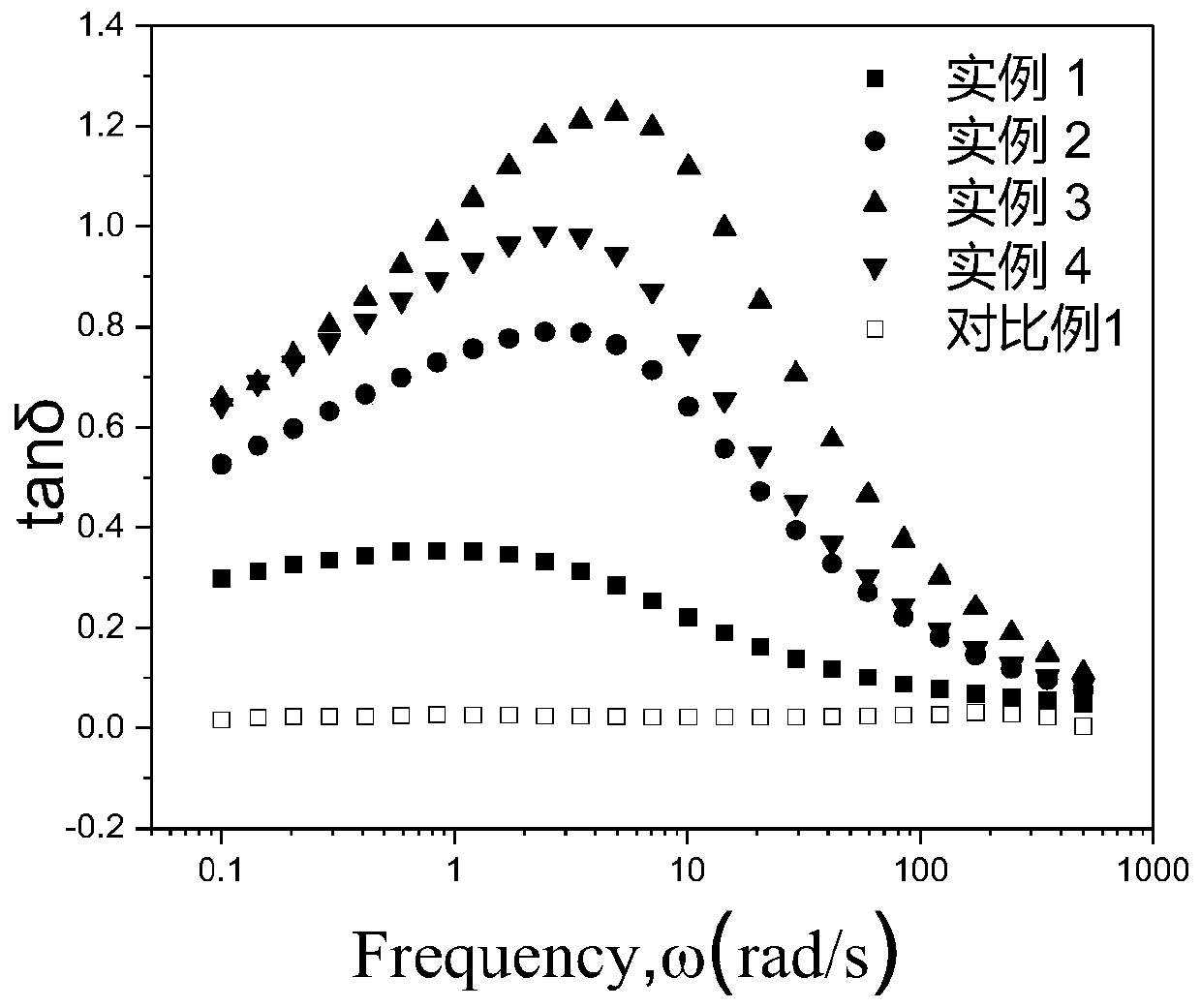

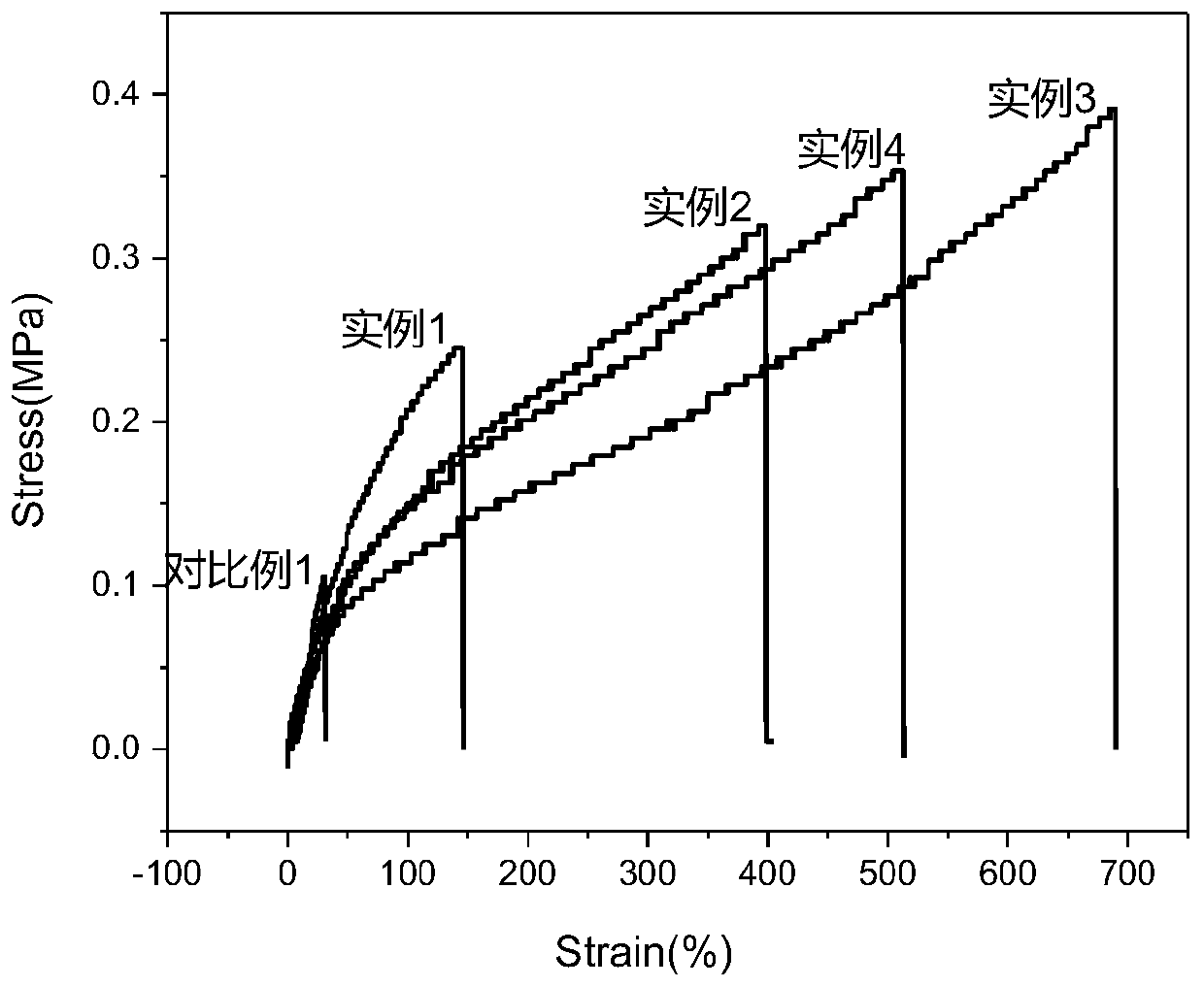

[0047] 10 parts by weight of methyl vinyl silicone rubber raw rubber with a molar mass of 70,0000 g / mol and a vinyl content of 0.18 wt%, adding 0.1 part by weight of vulcanizing agent 2,5-dimethyl-2, 5-bis(tert-butylperoxy)hexane, using a twin-stick vulcanizer to mix it evenly. Then 2 parts by weight of self-made PBS with a weight average molecular weight of 11,000 was added, and treated with a flat vulcanizer at 175° C. for 10 minutes to obtain vulcanized silicone rubber. Use the MCR302 rheometer of Austria Anton Paar to test its frequency sweep curve (room temperature) under linear strain. The test standard is based on GB / T 33095.1-2016 Determination of rheological properties by dynamic rotor...

Embodiment 2

[0052] Add 20 parts by weight of methyl phenyl vinyl silicone rubber raw rubber with a molar mass of 400,0000 g / mol, a phenyl content of 30 wt%, and a vinyl content of 0.20 wt%, and add 0.2 parts by weight of vulcanizing agent 2,5- Dimethyl-2,5-bis(tert-butylperoxy)hexane, after mixing evenly, add 10 parts by weight of DOW 3179, treated with a flat vulcanizer at 175°C for 10 minutes to obtain vulcanized silicone rubber. Use the MCR302 rheometer of Austria Anton Paar to test its frequency sweep curve (room temperature) under linear strain. The test standard is based on GB / T 33095.1-2016 Determination of rheological properties by dynamic rotorless rheometer for unvulcanized rubber Part 1: frequency scanning method. Reflects the value of the loss factor of the material under different speed impact conditions (see figure 1 ).

[0053] from figure 1 It can be seen that the vulcanized silicone rubber prepared in this example has excellent damping performance, and its damping fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com