Production method of curdlan by dissolvant method abstraction

A production method, a technology of solvent method, applied in the field of post-extraction production technology of curdlan gum, can solve the problems of difficult salt removal, difficult realization of gel press water removal method, low product purity, etc., and achieve high product purity , Improve the purity and appearance quality, and the effect of good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

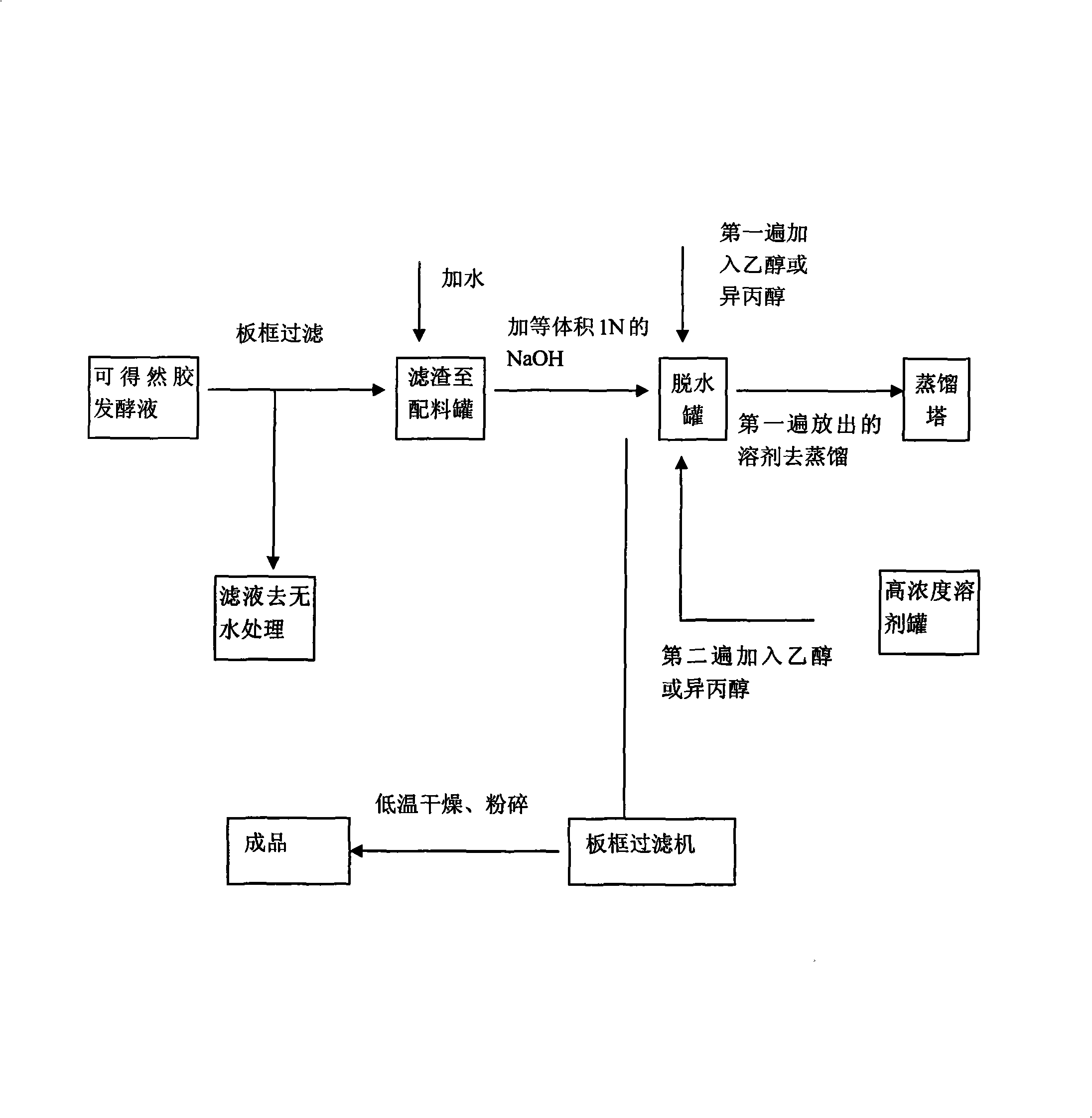

[0014] Below by example in conjunction with accompanying drawing the processing method of invention is further described:

[0015] 1. Curdlan gum fermentation broth comes from the previous existing process, and 3m 3 Curdlan gum fermentation broth (the curdlan gum content is about 2.4g / 100ml) is filtered through a plate frame to remove soluble impurities in the curdlan gum fermentation broth (such as fermentation by-product water-soluble polysaccharides, organic acids and Inorganic salts, etc.), the filtrate is anhydrous, and the obtained filter residue enters the batching tank and adds water to a volume of 1.5m 3 , to form a suspension after stirring; then pump into 10m 3 In the dehydration tank, start stirring, then pump into the NaOH solution with a molar concentration equal to that of the suspension to be 1mol / L from the lye storage tank, and stir to dissolve the curdlan to obtain the alkali solution of the curdlan. Pump the alkaline solution into the dehydration tank, sl...

example 2

[0019] 1. Curdlan gum fermentation broth comes from the previous existing process, and 3m 3 Curdlan gum fermentation broth (wherein curdlan gum content is about 2.4g / 100ml) is filtered through a plate frame to remove soluble impurities in curdlan gum fermentation broth, the filtrate is anhydrous, and the obtained filter residue enters the batching tank and adds water to a volume of 1.5m 3 , to form a suspension after stirring; then pump into 10m 3 In the dehydration tank, start stirring, then pump into the NaOH solution with a molar concentration equal to that of the suspension to be 1mol / L from the lye storage tank, and stir to dissolve the curdlan to obtain the alkali solution of the curdlan. The alkaline solution is pumped into the dehydration tank, slowly add 4m 3 About 88% (v / v) of isopropanol, stir evenly, let stand to stratify, open the overflow valve on the wall of the dehydration tank from top to bottom in turn, flow out the low-concentration organic solvent, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com