Composite curing agent for polyester powder coating and its preparation method and application

A composite curing agent and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of human germ cell mutation, heredity, thick coating pinholes, etc., and achieve high epoxy equivalent, comprehensive Excellent performance, less irritating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

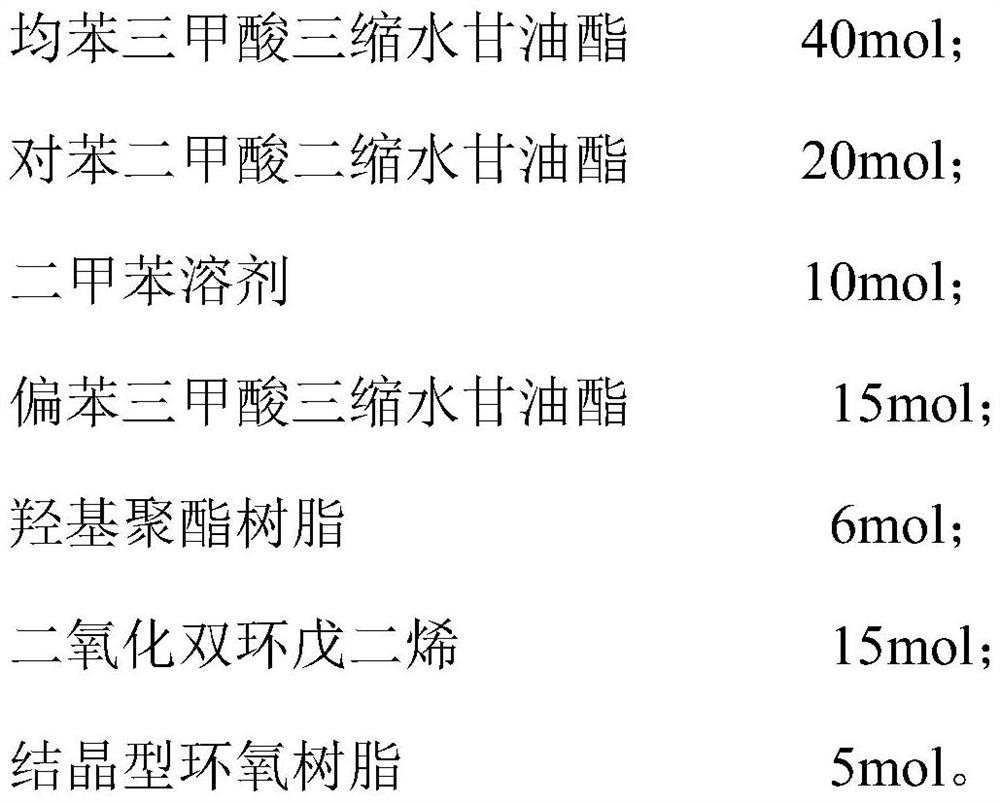

[0022] Composite curing agent for polyester resin powder coatings described in the present embodiment, its preparation raw material comprises following components:

[0023]

[0024] The preparation method of composite curing agent for polyester type resin powder coating described in the present embodiment comprises the steps:

[0025] (1) Add the organic solvent, triglycidyl trimellitate, and hydroxyl polyester resin in the recipe amount into the reaction kettle, heat up to 80°C and mix thoroughly, keep warm for 3 hours until completely dissolved into one phase; then add the recipe amount Diglycidyl terephthalate, crystalline epoxy resin, heat preservation reaction at 90°C for 4 hours, then add dicyclopentadiene dioxide for reaction, heat up to 110°C and heat preservation reaction for 6 hours, until all become homogeneous , lower the temperature to 70°C, add the prescribed amount of trimesic acid triglycidyl, continue to keep warm at 70°C for 1 hour, and stop the reaction a...

Embodiment 2

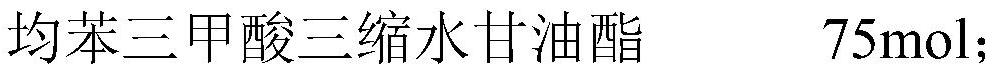

[0029] Composite curing agent for polyester resin powder coatings described in the present embodiment, its preparation raw material comprises following components:

[0030]

[0031]

[0032] The preparation method of composite curing agent for polyester type resin powder coating described in the present embodiment comprises the steps:

[0033] (1) Add the organic solvent, triglycidyl trimellitate, and hydroxyl polyester resin in the recipe amount into the reaction kettle, heat up to 90°C and mix thoroughly, keep warm for 1 hour until completely dissolved into one phase; then add the recipe amount Diglycidyl terephthalate, crystalline epoxy resin, heat preservation reaction at 95°C for 2 hours, then add dicyclopentadiene dioxide for reaction, heat up to 120°C and heat preservation reaction for 2 hours, until all become homogeneous , lower the temperature to 70°C, add the amount of trimesic acid triglycidyl tricarboxylate, continue the heat preservation reaction at 70°C fo...

Embodiment 3

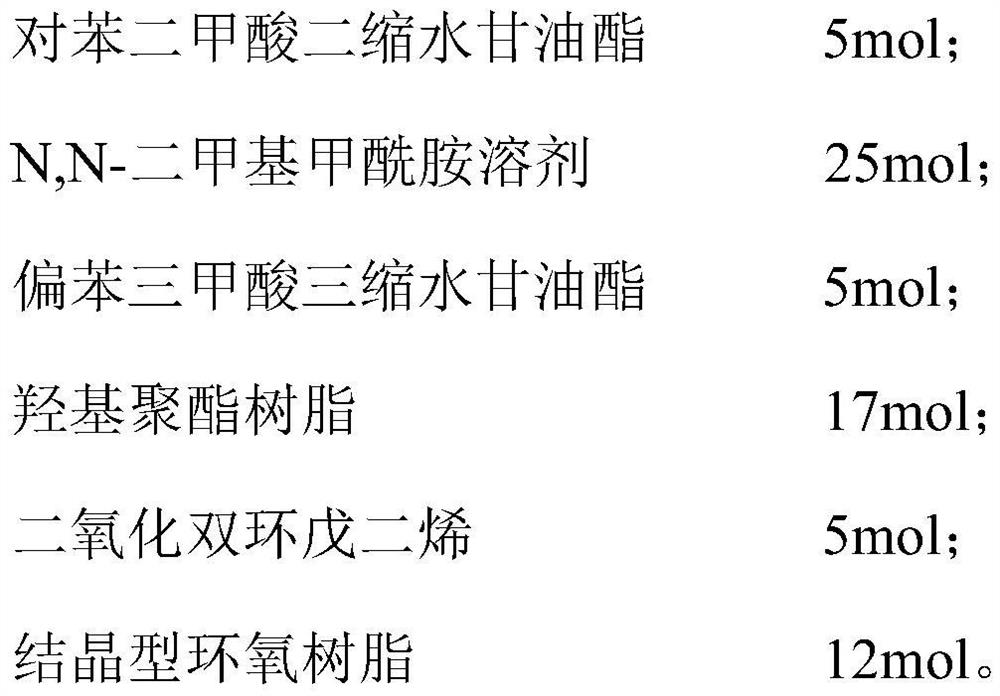

[0037] Composite curing agent for polyester resin powder coatings described in the present embodiment, its preparation raw material comprises following components:

[0038]

[0039]

[0040] The preparation method of composite curing agent for polyester type resin powder coating described in the present embodiment comprises the steps:

[0041] (1) Add the organic solvent, triglycidyl trimellitate, and hydroxyl polyester resin in the recipe amount into the reaction kettle, heat up to 85°C and mix thoroughly, keep warm for 2 hours until completely dissolved into one phase; then add the recipe amount Diglycidyl terephthalate, crystalline epoxy resin, heat preservation reaction at 92°C for 3 hours, then add dicyclopentadiene dioxide for reaction, raise the temperature to 115°C and heat preservation reaction for 4 hours, until all become homogeneous , lower the temperature to 70°C, add the amount of trimesic acid triglycidyl, continue to keep warm at 70°C for 2 hours, and sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com