Patents

Literature

46results about How to "Lower b value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonwoven fabric of polyester composite fiber

ActiveUS7371701B2Quality improvementExcellent tonePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperCarboxylic acidTitanium

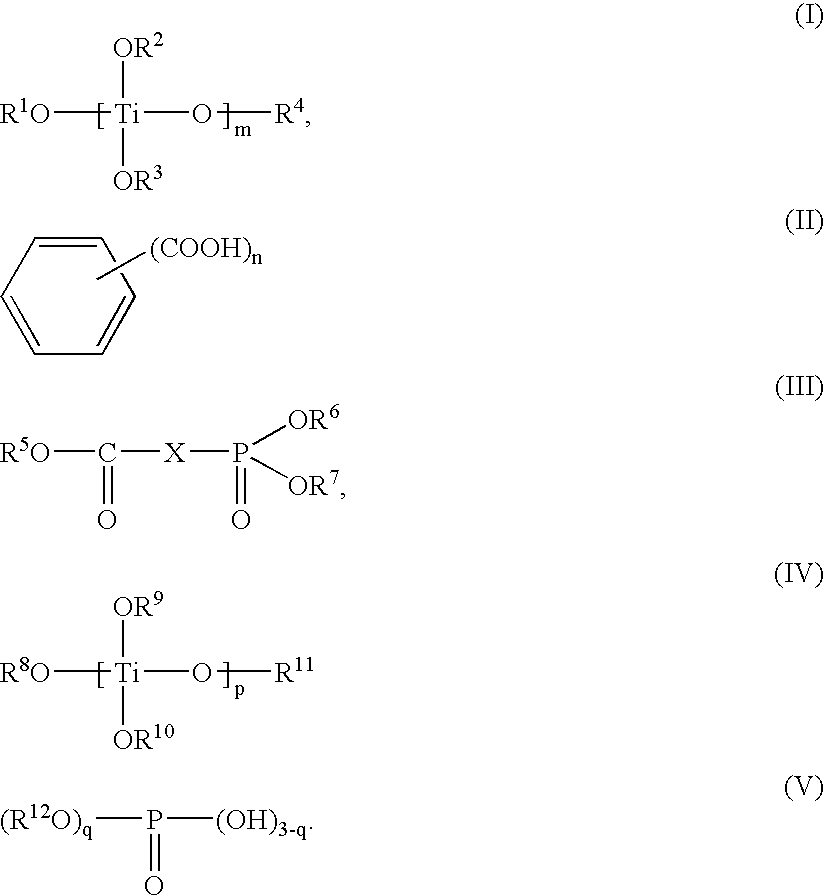

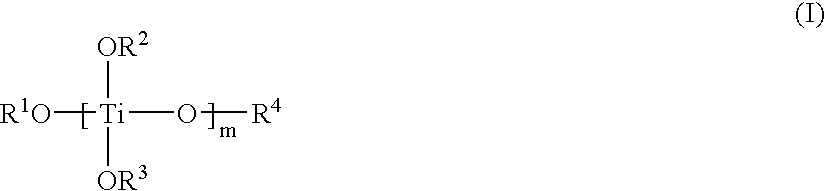

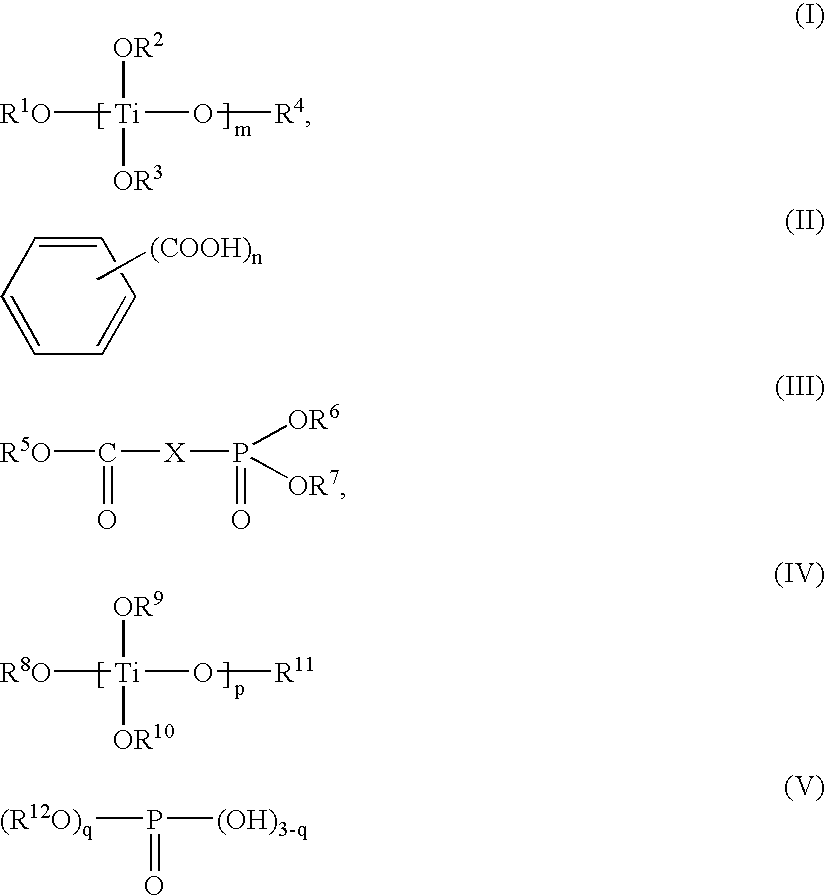

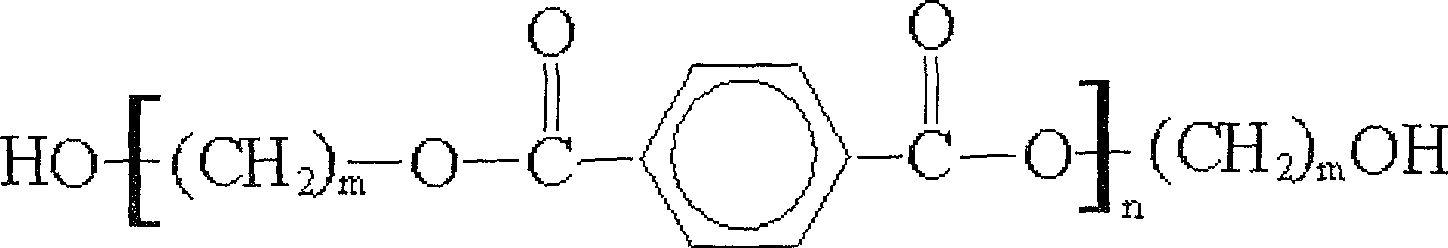

A nonwoven fabric of polyester composite fibers which has a satisfactory color tone (low value of b*). It is formed from short composite fibers obtained from a polyester polymer obtained with the following catalyst and a fusion-bondable polymer. The catalyst comprises: (1) a mixture of a phosphorus compound ingredient comprising a phosphorus compound represented by the formula (III) with a titanium compound ingredient comprising a titanium alkoxide represented by the following formula (I) and / or a product of the reaction of the titanium alkoxide with a carboxylic acid represented by the formula (II) or anhydride thereof; and / or (2) a product of the reaction of a phosphorus compound ingredient comprising a phosphorus compound represented by the formula (V) with a titanium compound ingredient comprising a titanium alkoxide (IV) represented by the formula (IV) and / or a product of the reaction of the titanium alkoxide with a carboxylic acid represented by the formula (III) or anhydride thereof

Owner:TEIJIN FRONTIER CO LTD

Nonwoven fabric of polyester composite fiber

ActiveUS20060057379A1Quality improvementExcellent tonePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceCarboxylic acid

A nonwoven fabric of polyester composite fibers which has a satisfactory color tone (low value of b*). It is formed from short composite fibers obtained from a polyester polymer obtained with the following catalyst and a fusion-bondable polymer. The catalyst comprises: (1) a mixture of a phosphorus compound ingredient comprising a phosphorus compound represented by the formula (III) with a titanium compound ingredient comprising a titanium alkoxide represented by the following formula (I) and / or a product of the reaction of the titanium alkoxide with a carboxylic acid represented by the formula (II) or anhydride thereof; and / or (2) a product of the reaction of a phosphorus compound ingredient comprising a phosphorus compound represented by the formula (V) with a titanium compound ingredient comprising a titanium alkoxide (IV) represented by the formula (IV) and / or a product of the reaction of the titanium alkoxide with a carboxylic acid represented by the formula (III) or anhydride thereof.

Owner:TEIJIN FRONTIER CO LTD

Flame-retardant polyester fiber and production method thereof

InactiveCN102691133AExcellent toneImprove qualityConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterFiber

The invention discloses a flame-retardant polyester fiber and a production method thereof; the flame-retardant polyester fiber is obtained by mixing and spinning flame-retardant copolymerization master batch and common polyester; the flame-retardant polyester fiber has a phosphorus content of 5000-7500 ppm, has excellent flame retardancy, a good color, a high melting point, superior heat resistance, and low cost, and is widely applicable to decoration material fields such as curtains, carpets, and materials and equipment in vehicles.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

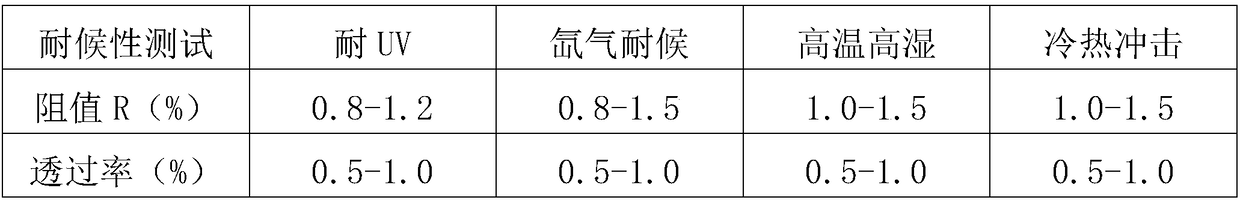

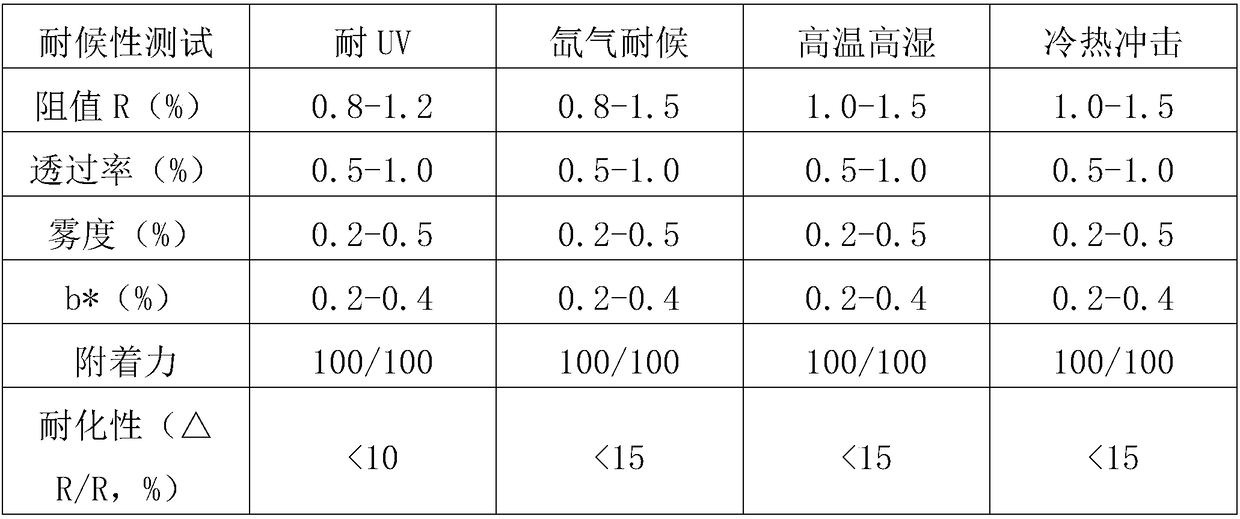

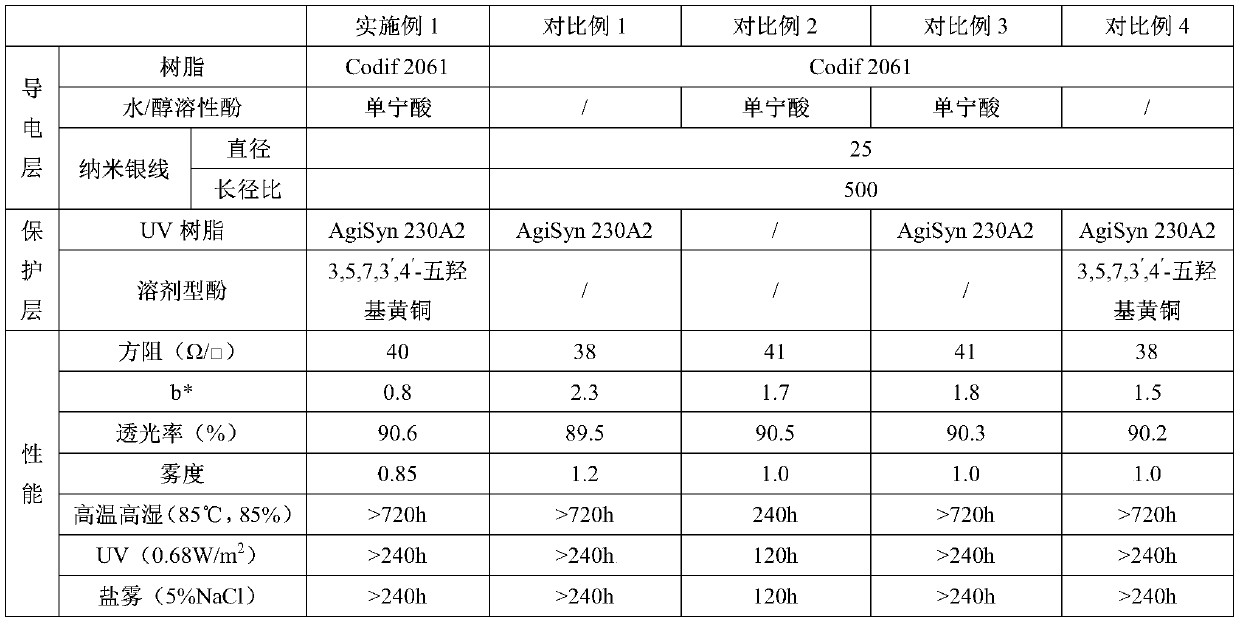

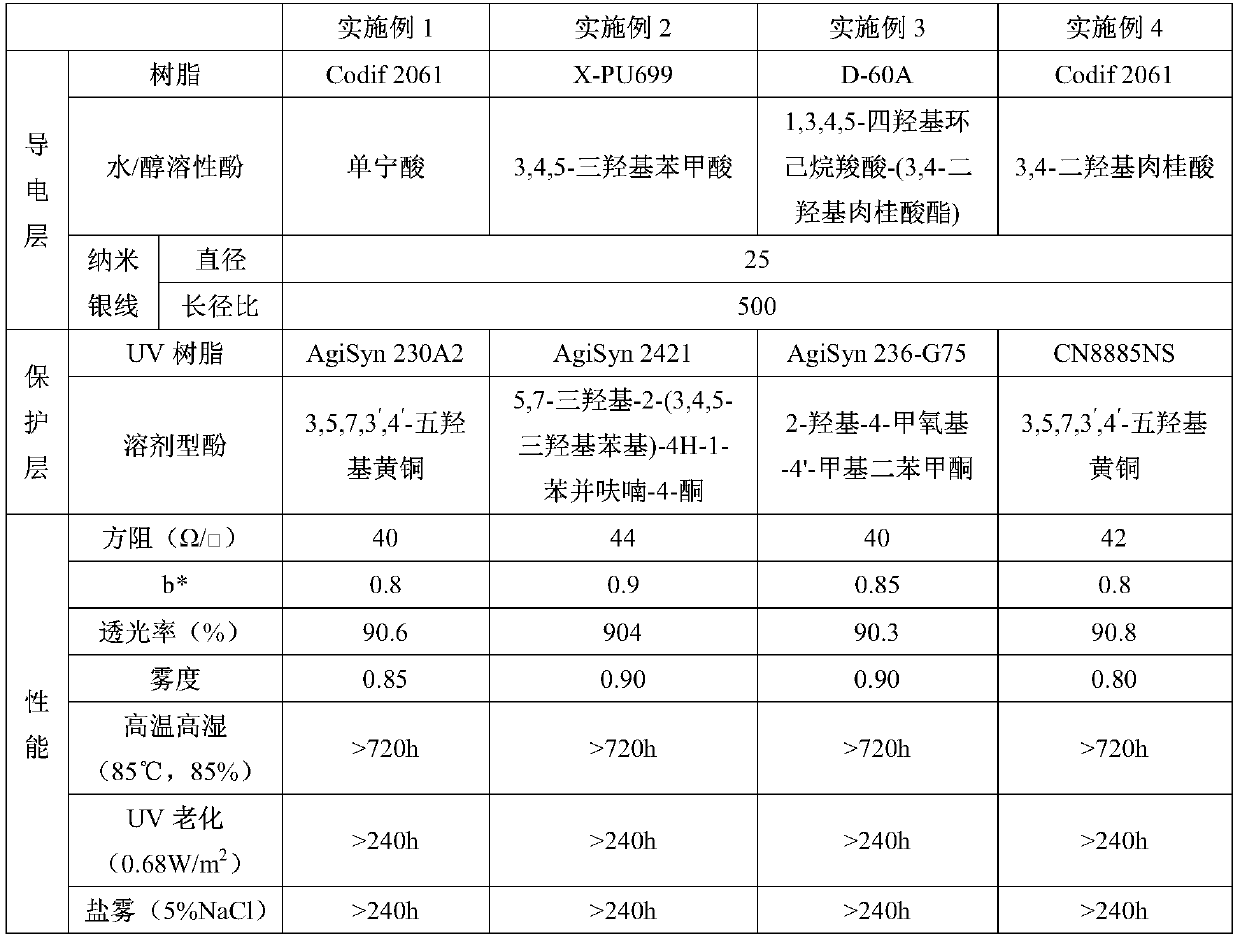

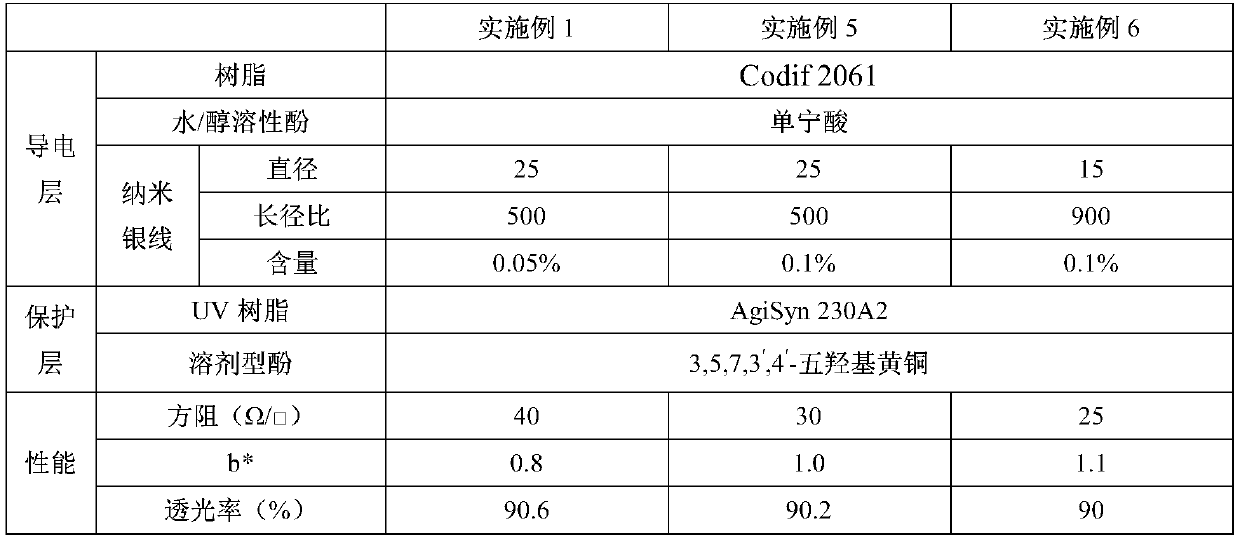

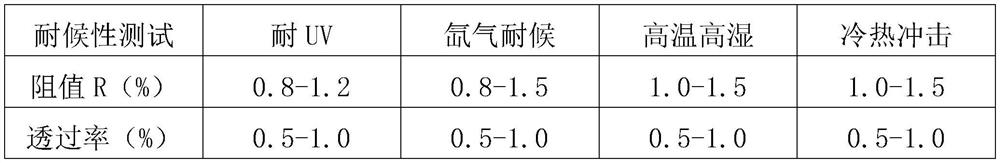

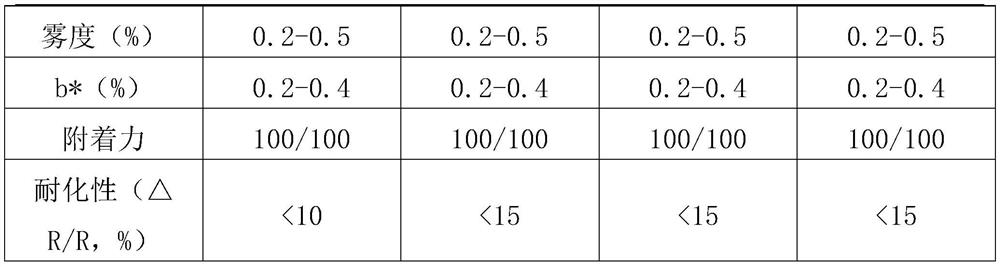

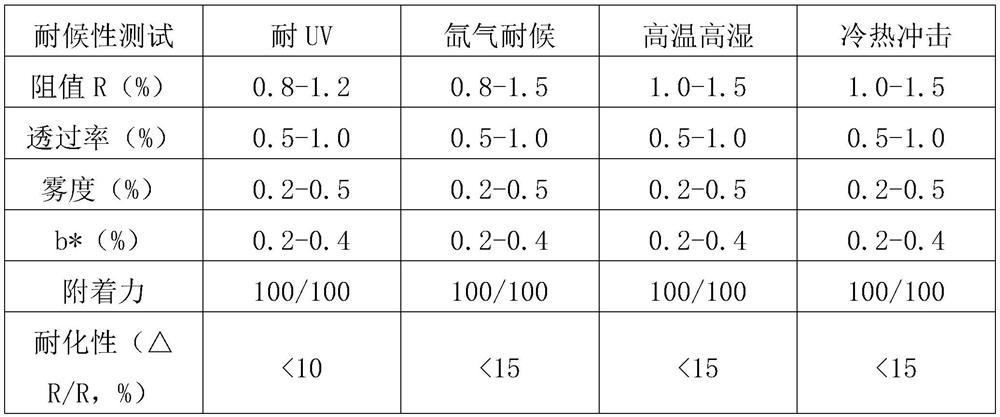

Transparent conductive film

ActiveCN109243677AImprove visibilityImprove transmittanceConductive layers on insulating-supportsInput/output processes for data processingVisibilityConductive paste

The invention relates to a transparent conductive film, which reduces the b* value of the conductive film by adding a coloring agent and improves the transmittance of the conductive film. The invention provides a transparent conductive film aiming at the technical problems that the color of the film material will be discolored and the visibility will be poor due to the coating of the conductive paste in the prior transparent conductive film. The transparent conductive film comprises a transparent carrier, a conductive layer and a protective layer sequentially coated on the transparent carrier;The protective layer consists of an acrylic resin, a mixed solvent and a dye. According to the CIE Lab* color model (Lab*), based on the human perception of color, the coloring agent corresponding tothe color of the conductive layer is added to the protective layer to compensate the visual effect of discoloration and improve the transmittance of the conductive film.

Owner:山东华科创智技术有限公司

Titanium-silicon catalyst, preparation method and uses thereof

The invention discloses a titanium-silicon catalyst and a preparation method as well as an application thereof. The preparation method includes the following steps: (1) organic titanic acid ester and 2 / 3 cubic content of anhydrous alcohol are mixed evenly, and stirred sufficiently to achieve A solution; deionized water is mixed with the remained 1 / 3 cubic content of anhydrous alcohol sufficiently, acid or alkali is added, the acid or alkali concentration is controlled within 0.01-1mol / L, B solution is prepared, and B solution is dripped into A solution by a burette; (2) the mixture is stirred for 3-5 hours after dripping, the precipitate achieved after centrifugal separation is grinded and calcined to achieve titanium-silicon catalyst. The titanium-silicon catalyst achieved by the method is stable during the process of polymerization without hydrolysis reaction; the method can be used to catalytic synthesis of aliphatic and aromatic co-polyester, the titanium-silicon catalyst can reduce the dosage of catalyst, shorten the duration of polymerization, improve the quality of biodegradation co-polyester product, and the terminal carboxyl group content in the product as well as the b value are reduced.

Owner:KINGFA SCI & TECH CO LTD +1

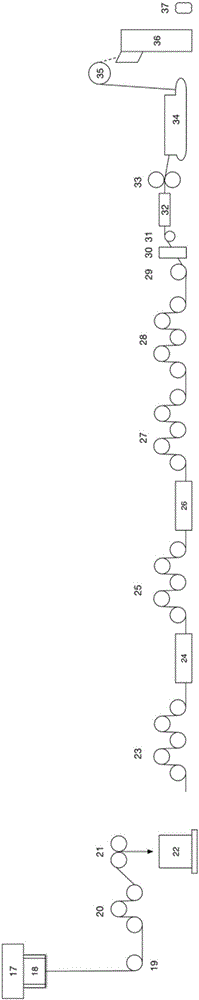

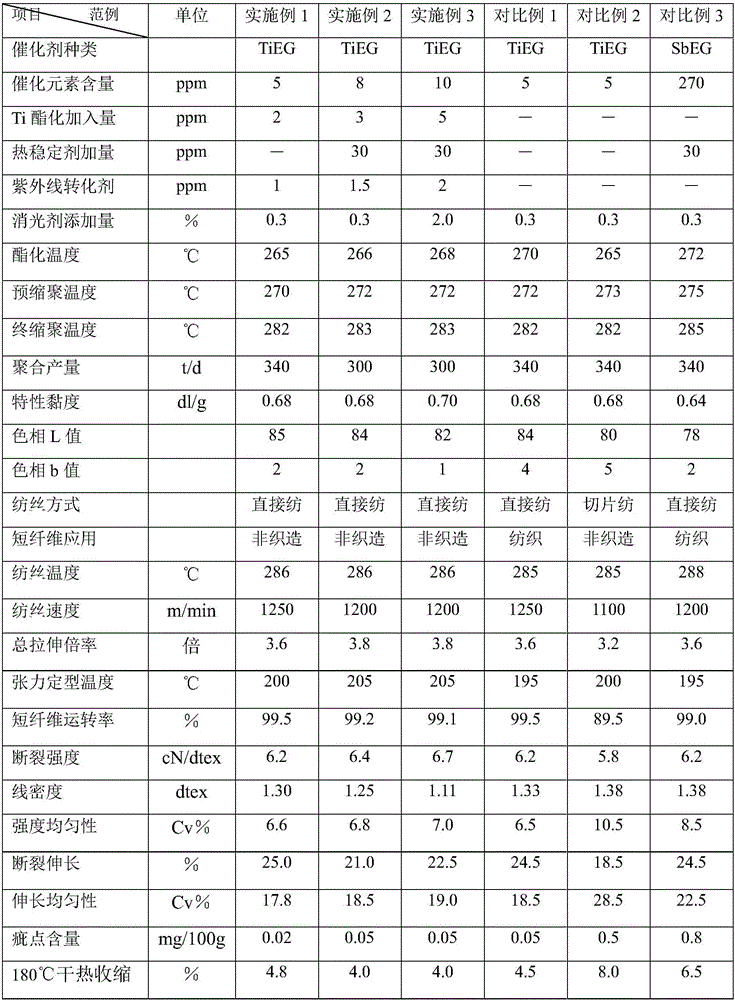

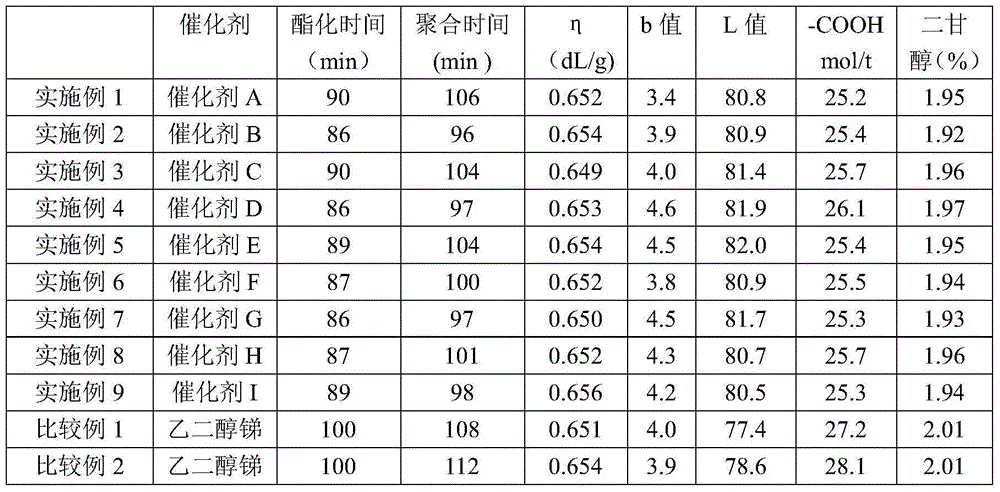

Method for manufacturing directly-spun PET (polyethylene glycol terephthalate) polyester staple fibers by aid of titanium catalysts

ActiveCN105970342ALower b valueImprove mechanical propertiesFilament forming substance formingArtificial filament heat treatmentPolyesterPolyethylene glycol

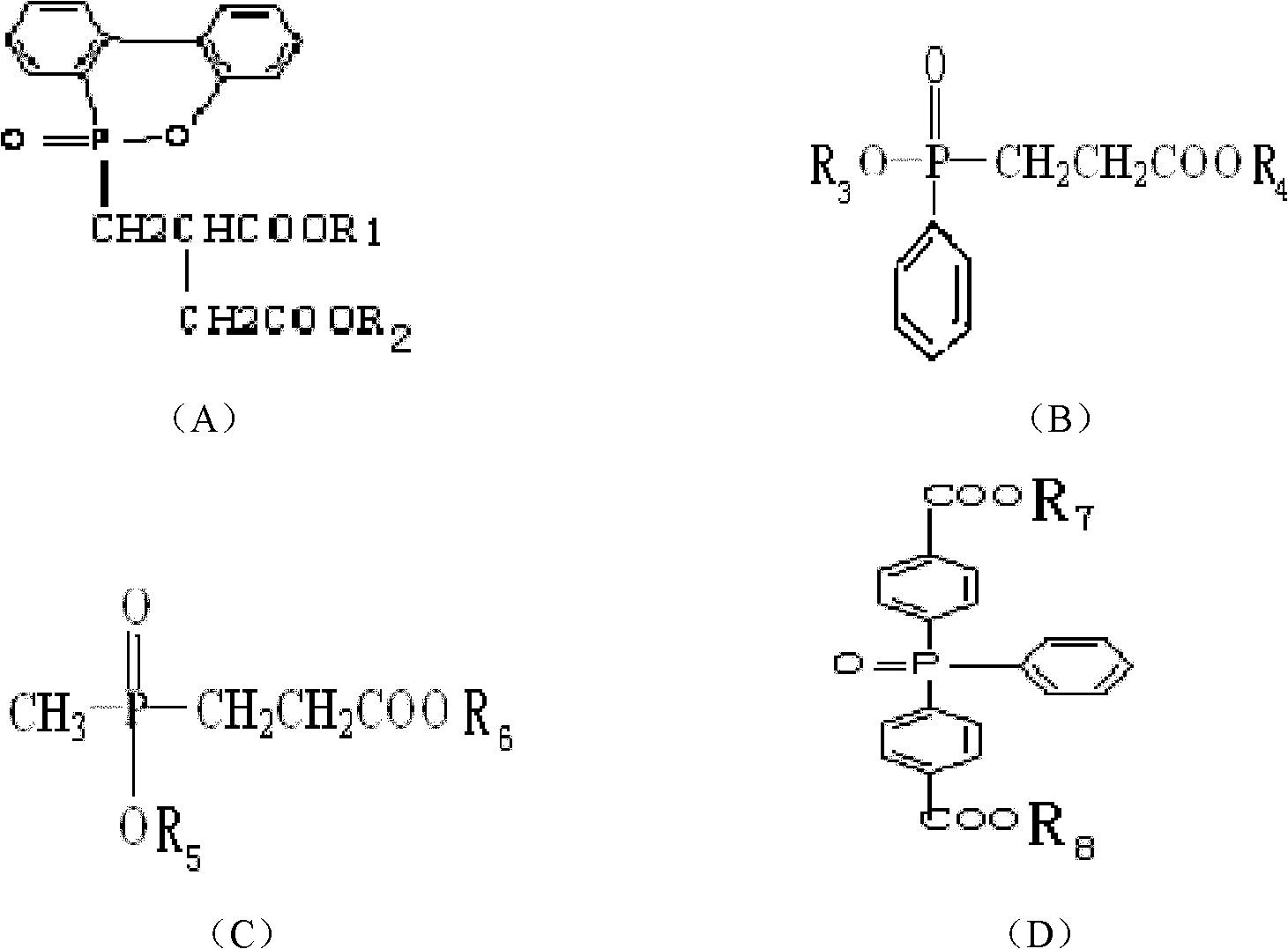

The invention discloses a method for manufacturing directly-spun PET (polyethylene glycol terephthalate) polyester staple fibers by the aid of titanium catalysts. The method includes steps of continuously adding the titanium catalysts blended in EG (ethylene glycol) during esterification reaction and pre-polycondensation reaction by the aid of direct spinning processes; adding ultraviolet transforming agents, phosphorus stabilizers and extinction agents; carrying out final polycondensation reaction, direct spinning and afterfinish to obtain the directly-spun PET polyester stable fibers. The method has the advantages that the titanium catalysts are simultaneously added in esterification reaction and polycondensation reaction working procedures by the aid of the direct spinning processes, bis-styrene heterocyclic ring compounds which do not participate in polyester synthetic reaction but can effectively convert ultraviolet rays into blue visible light are added in the esterification reaction and polycondensation reaction working procedures, the phosphorus stabilizers are added simultaneously, accordingly, the temperatures can be reduced by 1-5 DEG C in the integral reaction procedures as compared to antimony catalysts, the addition amounts of the titanium catalysts can be reduced, apparent color values b can be reduced, and the mechanical performance of the stable fibers can be improved.

Owner:江苏新苏化纤有限公司

Titanium composite catalyst for polyester and copolyester synthesis

A Ti-series composite catalyst for the polycondensation reaction in synthesizing polyester and copolyester is prepared from isopropyl (or tetrabutyl) titanate, a compound of the element in IVA family and the compounds of 1-3 metal elements chosen from IA, IIA, IIIA, IIIB, VIIB and VIII families through alkaline hydrolysis and deposition. Its advantage is high activity.

Owner:中国石化集团天津石油化工公司

Preparation of polyethylene glycol terephthalate for improving color value of product

InactiveCN1644600AReduce consumptionImprove product qualityPolyethylene terephthalatePolymer science

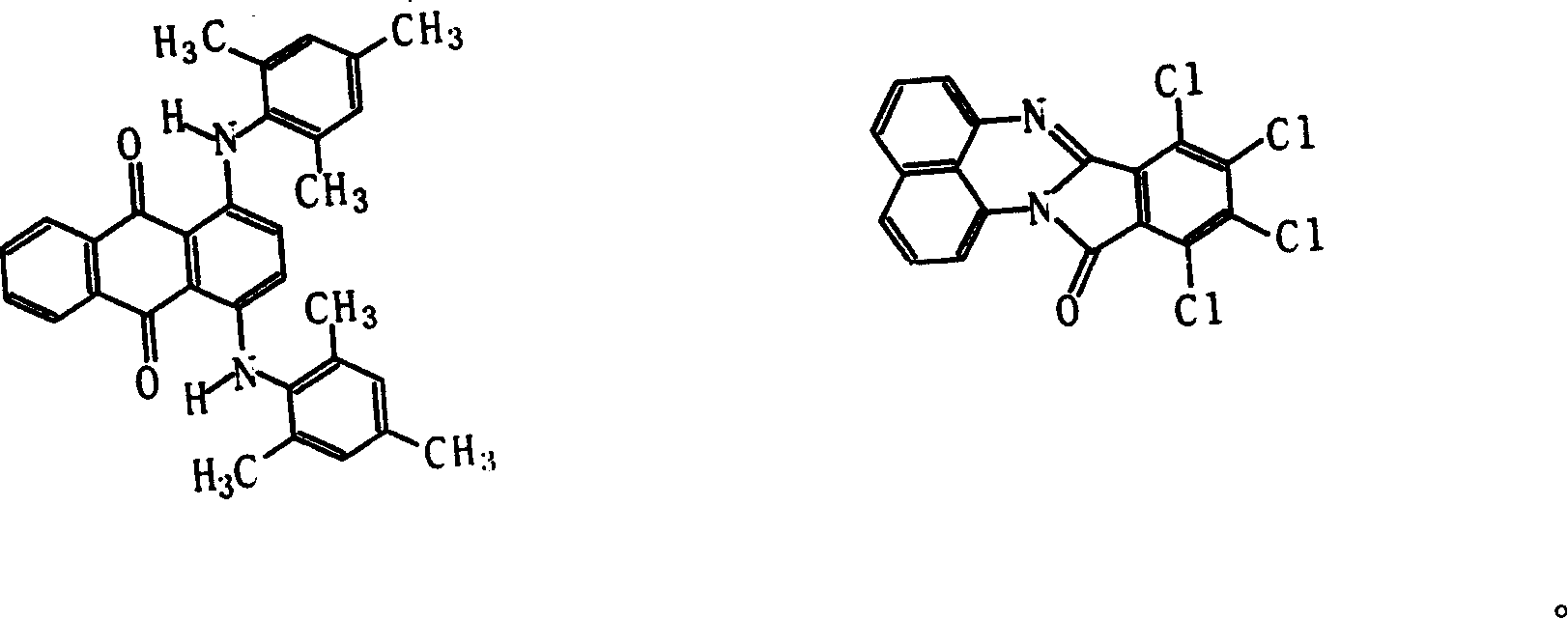

Production of poly-terephthalic acid glycol ester for improving product tone is carried out by: agitating terephthalic acid and glycol ester by proportioning in size mixed pot, pumping into size feeding pot, size feeding pot entering into esterifying pot by size inject nozzle, circulating by thermosiphon, size mixing reacting, injecting esterified oligomer and additive on pipeline into pre-polymerization pot, material reaching top of pre-polymerization, flowing into terminal-polymerization pot, filtering the product in melt filter, and removing cast heads to dicing cutter. It is characterized by adding blue agent or / and red agent and controlling its content in section 0-1PPM. It achieves low cost and heat energy consumption, and higher product quality.

Owner:JIANGYIN BOLUN CHEM FIBER

Method for improving visual whiteness of blanching chemimechanical pulp and blanching chemimechanical pulp

ActiveCN103374859AImprove the whitenessAdd lessPaper/cardboardChemical/chemomechanical pulpPurplish redWater soluble

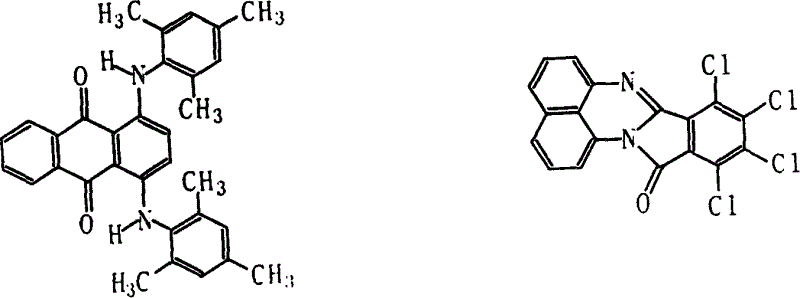

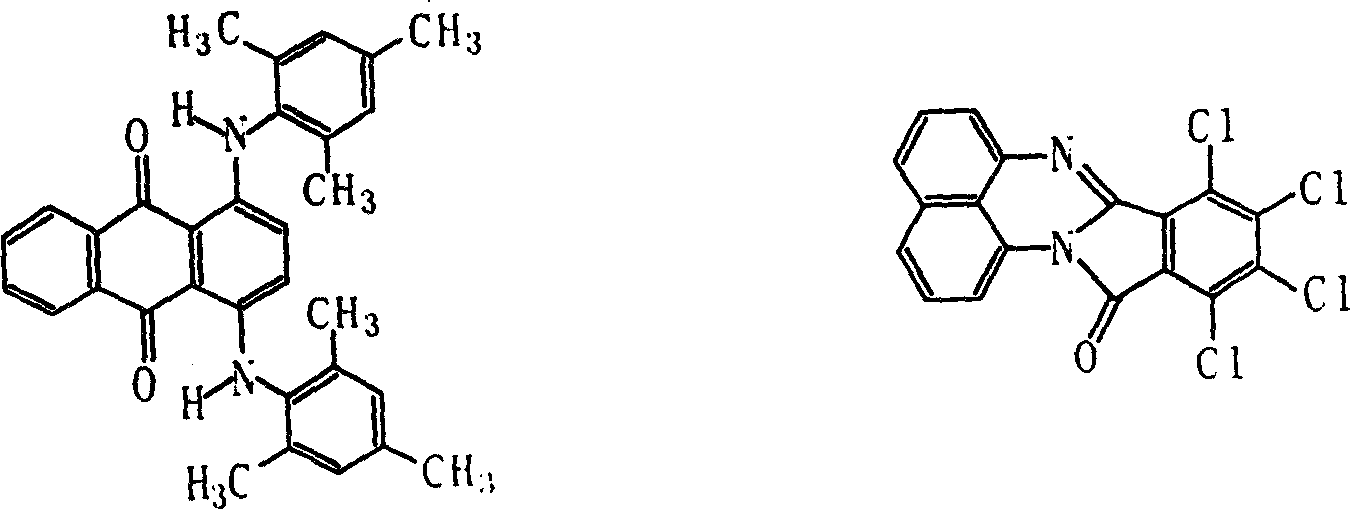

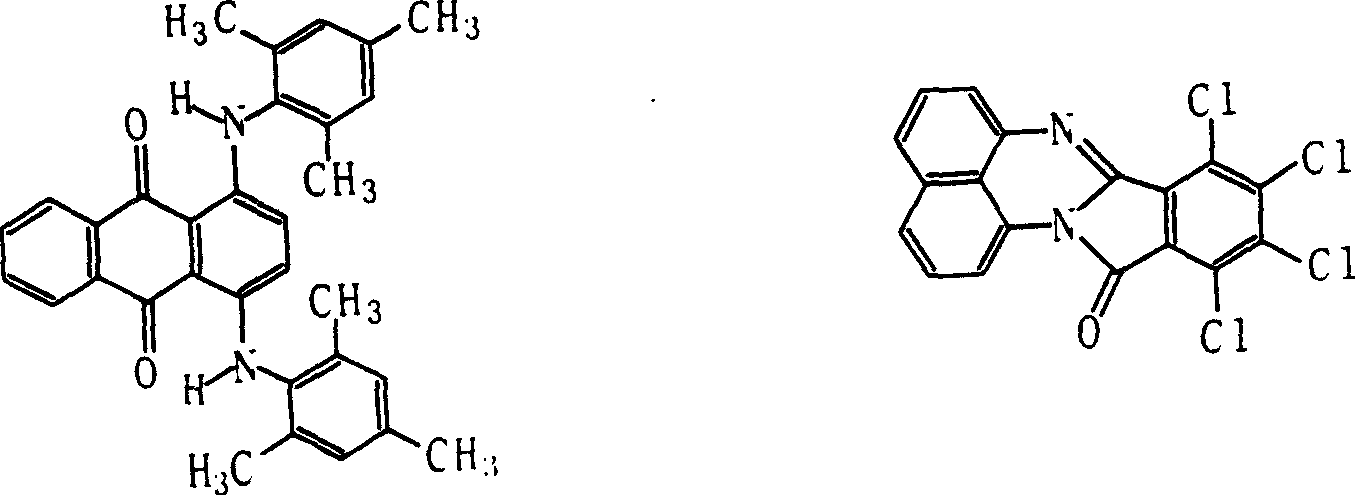

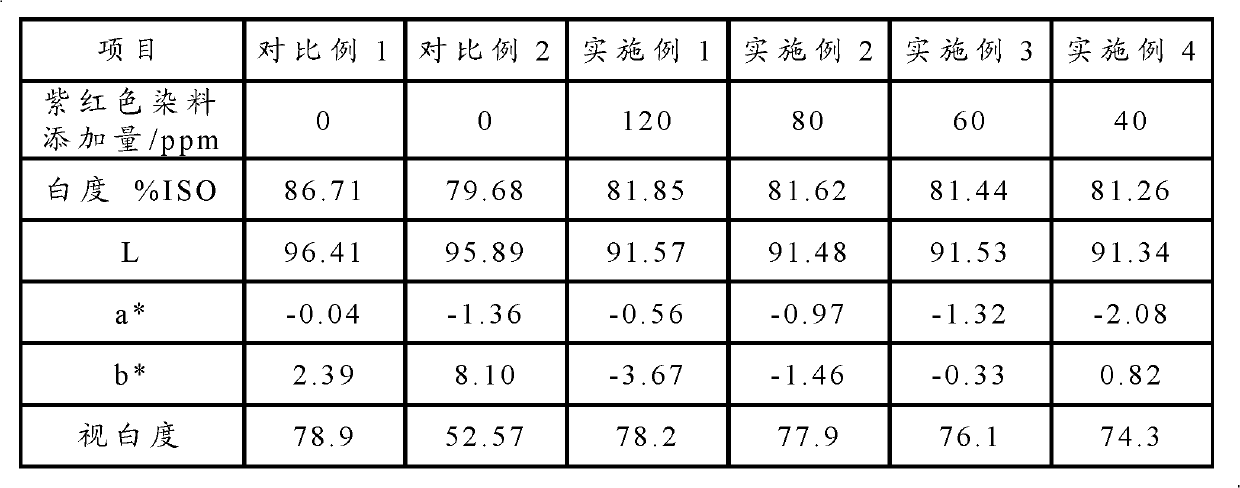

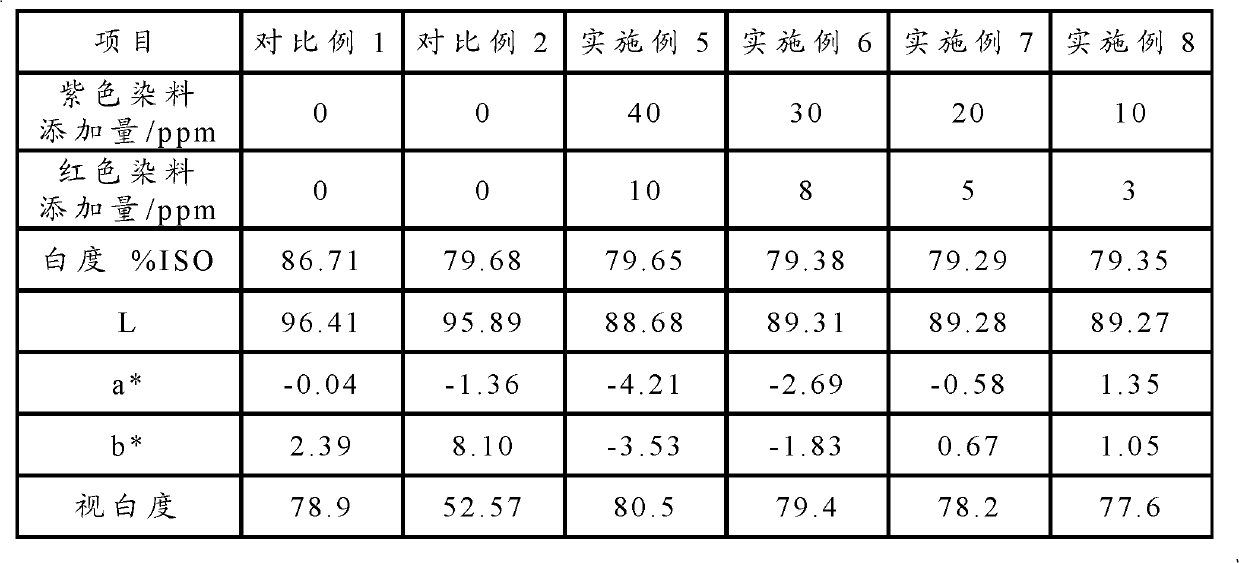

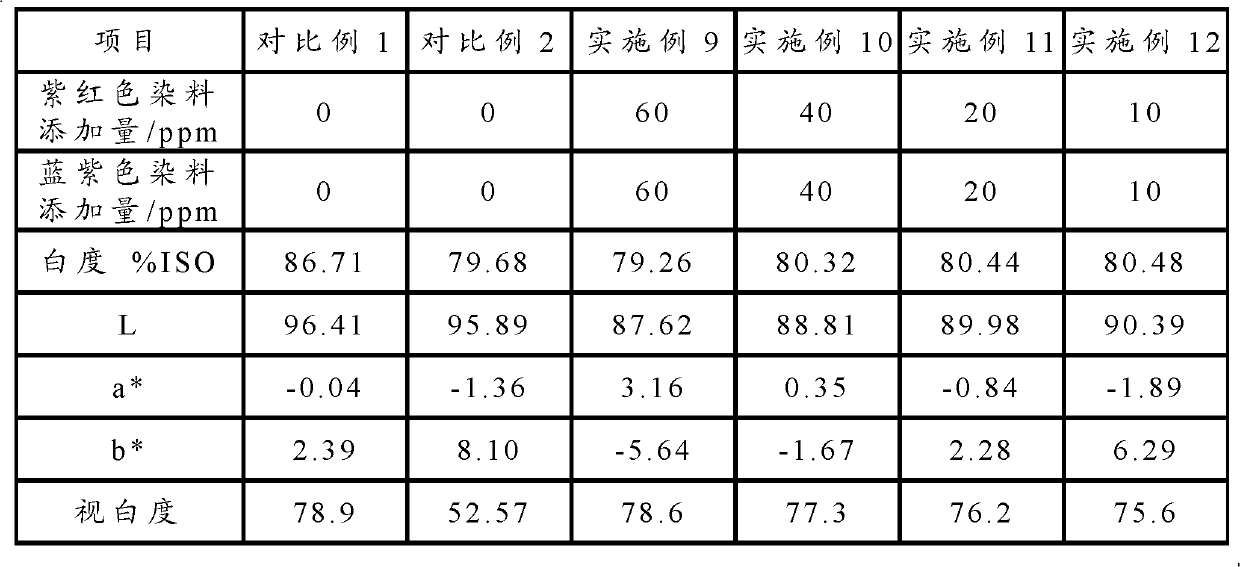

The invention discloses a method for improving visual whiteness of blanching chemimechanical pulp. The method comprises the following step of: adding 5-120 ppm of water-soluble dyestuff in a blanch process of a pulp line, a blanch full stuff process or a full stuff tower, wherein the dyestuff is amaranth dyestuff, blue dyestuff, purple dyestuff, bluish violet dyestuff, red dyestuff, a mixture of purple dyestuff and red dyestuff, a mixture of the amaranth dyestuff and the red dyestuff, the mixture of the amaranth dyestuff and the bluish violet dyestuff, or the mixture of the purple dyestuff and the blue dyestuff. The method provided by the invention has the advantages that through the dyestuff added in the blanching chemimechanical pulp, the yellow phase value is reduced, the a * value of pulp is also increased, a b* value is reduced, the whiteness of the full stuff is improved, in addition, the additive amount of a blanching chemical in the stuff is also reduced, and the cost is effectively reduced. The invention also provides the blanching chemimechanical pulp prepared by the method.

Owner:GOLD EAST PAPER JIANGSU

Method for preparing environment-friendly polyester

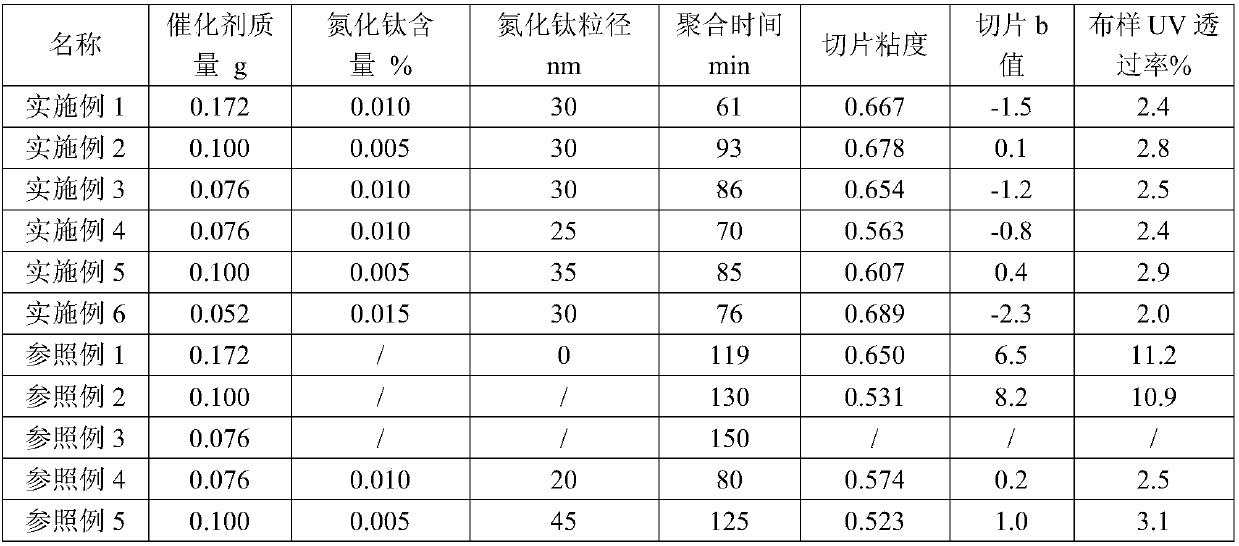

The invention relates to a method for preparing environment-friendly polyester, and belongs to the field of polymer materials. The method adopts dicarboxylic acid and dihydric alcohol as raw materials, titanate as a catalyst and nano-titanium nitride as an additive, and comprises the following steps: performing esterification; performing polycondensation; extruding, granulating and drying througha melt pump to obtain the environment-friendly polyester. In the polymerizing process, titanium nitride has the effect of a co-catalyst, the polycondensation can be improved by over 20 percent. The bvalue of the novel modified polyester is reduced by 6 unit and more in comparison with that of conventional titanium series polyester.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Modified polyester and preparing method thereof

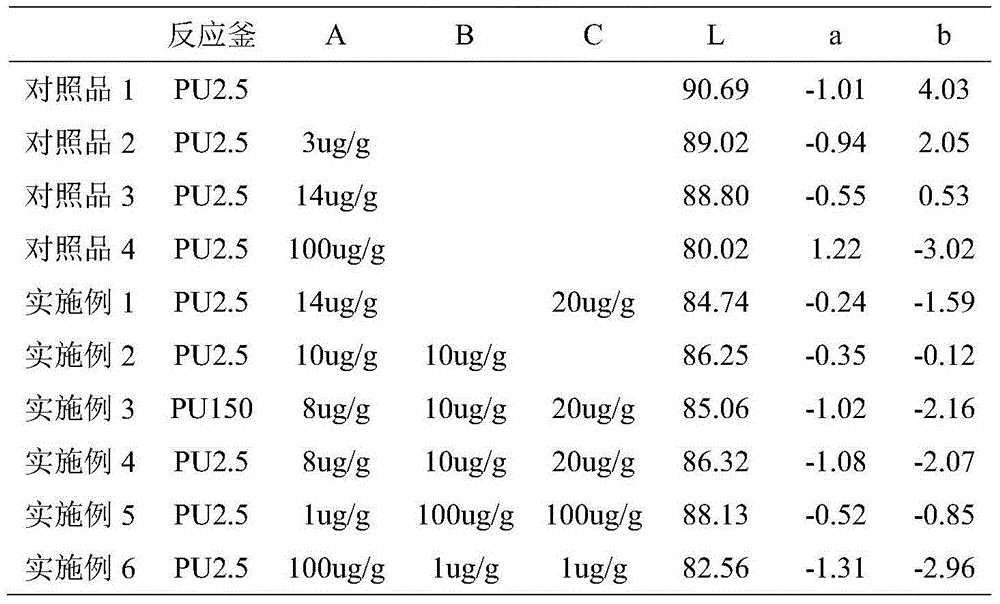

Modified polyester is disclosed. The modified polyester is prepared mainly from polybasic acid, polyol, a catalyst, a stabilizer and an additive improving polyester yellowing. A preparing process of the polyester is also provided. Compared with the prior art, the modified polyester prepared by the process can obviously improve yellowing of polyester, a cobalt salt adding amount is greatly reduced, and properties in each aspect are excellent.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Method for preparing semi-dull and full-dull titanium polyester through adding titanium dioxide

The invention relates to a method for preparing semi-dull and full-dull titanium polyester through adding titanium dioxide, and solves a problem that titanium dioxide used as a delustering agent in the prior art has an inhibition effect on the activity of titanium polyester catalysts. The method comprises the following steps: adding titanium dioxide used as the delustering agent to raw materials comprising terephthalic acid and ethylene glycol, carrying out an esterification reaction in the presence of a liquid titanium polyester catalyst, and carrying out a pre-polycondensation and polycondensation reaction under vacuum conditions to obtain the polyester product, wherein the liquid titanium polyester catalyst is a product prepared through a reaction of titanate, polyol, sulfonate and an alkaline metal compound, a molar ratio of titanate to polyol is 1:1 to 1:10, a molar ratio of titanate to sulfonate is 20:1 to 5:1, and a molar ratio of titanate to the alkaline metal compound is 10:1 to 2:1. The method allows semi-dull and full-dull titanium polyester with superior performances to be obtained, and can be used in practical industrial production of polyester.

Owner:CHINA PETROLEUM & CHEM CORP

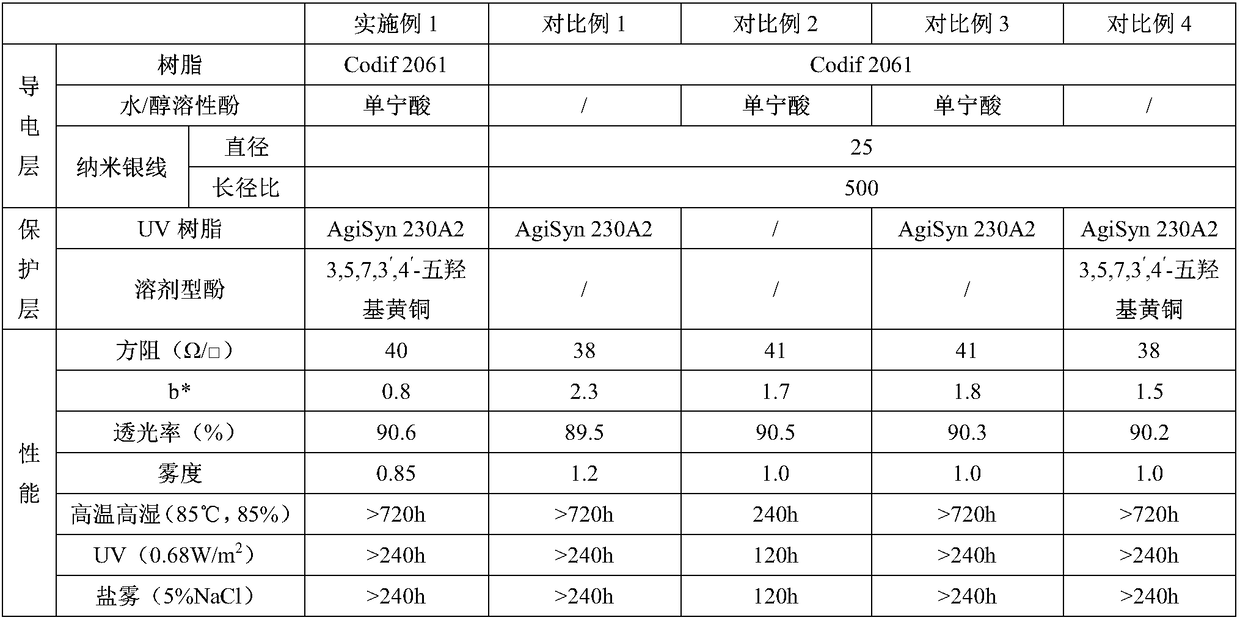

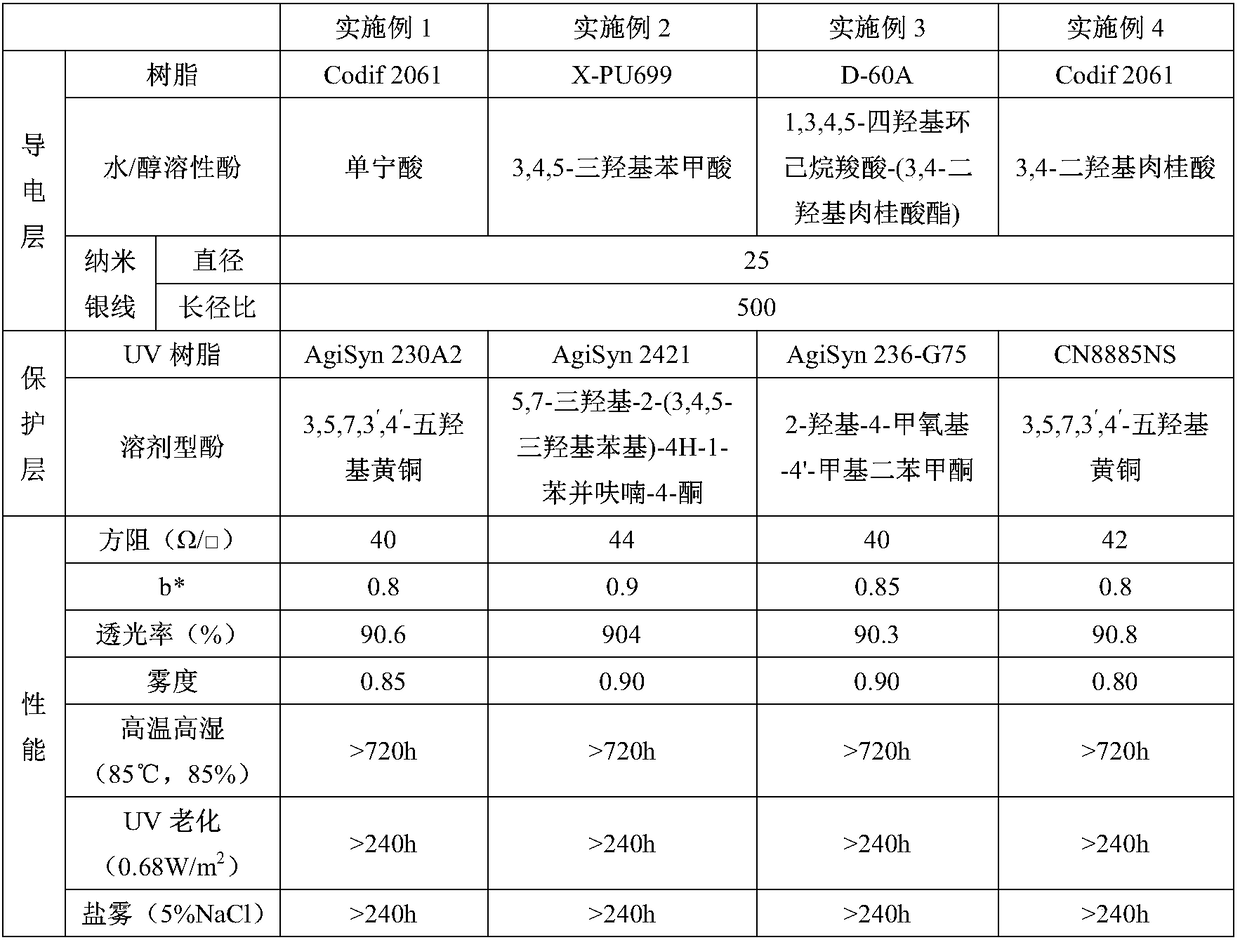

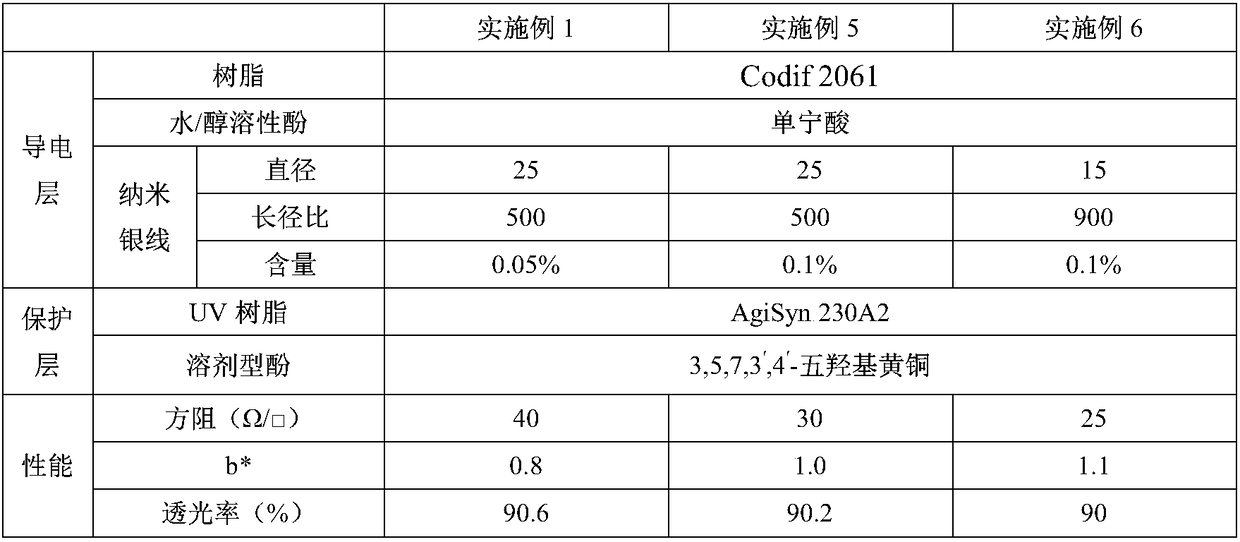

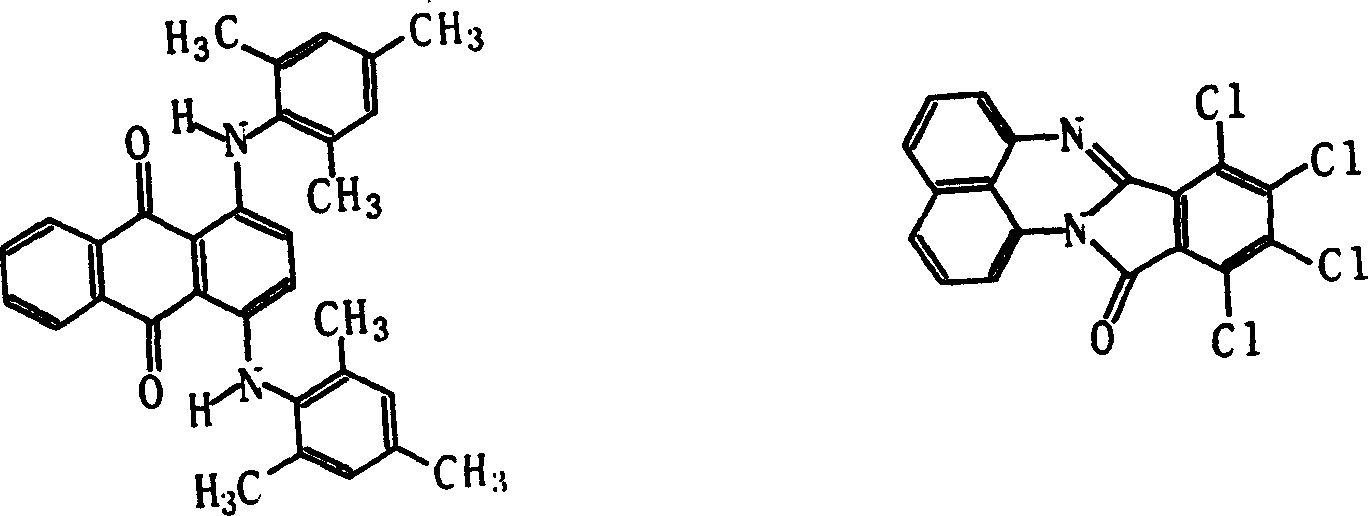

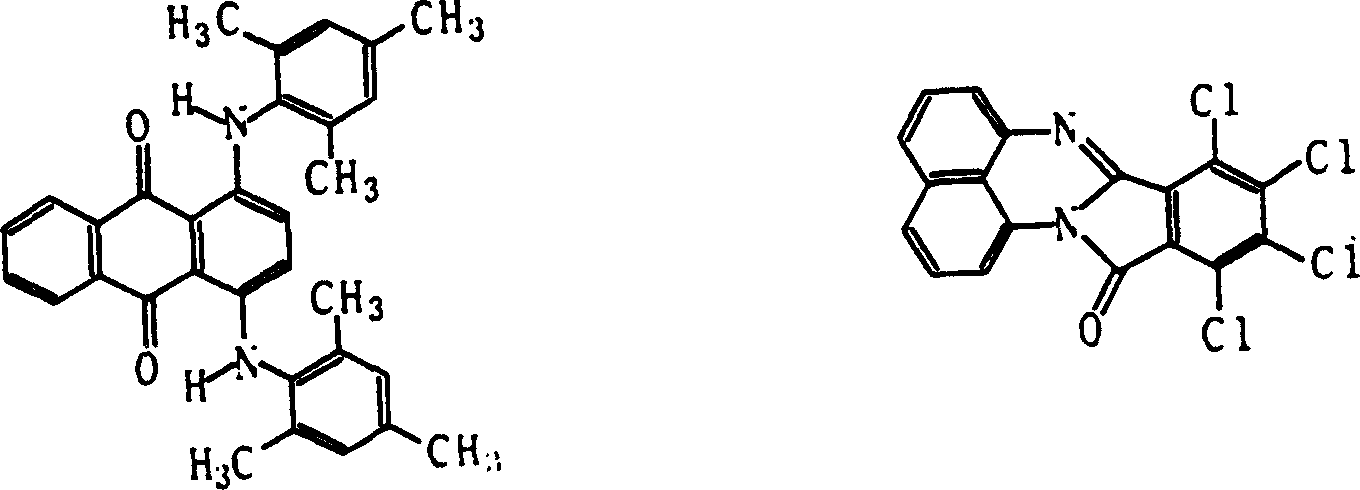

Method for reducing yellowness of silver nanowire transparent conductive film through changing plasma resonance intensity

ActiveCN108346493AReduce yellownessLower b* valueApparatus for manufacturing conducting/semi-conducting layersOptoelectronicsPhenol

The invention discloses a method for reducing yellowness of a silver nanowire transparent conductive film through changing plasma resonance intensity. Water / alcohol soluble phenol is added in the conductive ink so as to be combined with the surface PVP of the silver nanowire by forming hydrogen bonds to suppress silver nanowire surface plasma resonance, and thus the yellowness value of the conductive film can be reduced. The protective layer containing the phenolic compound can also be further arranged on the conductive layer to form the hydrogen bonds with the remaining PVP on the surface ofthe silver nanowire so as to further reduce the yellowness value. With application of the method, the b* value of the obtained conductive film is reduced to 0.8 so that the problem of high yellownessvalue of the conductive film can be completely solved, and display has no chromatic aberration if the conductive film is manufactured into the display screen.

Owner:合肥微晶材料科技有限公司

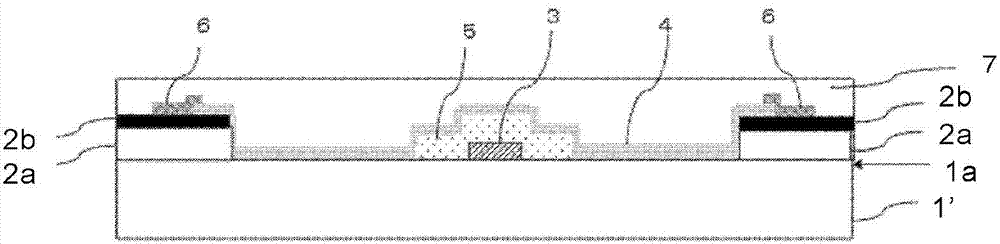

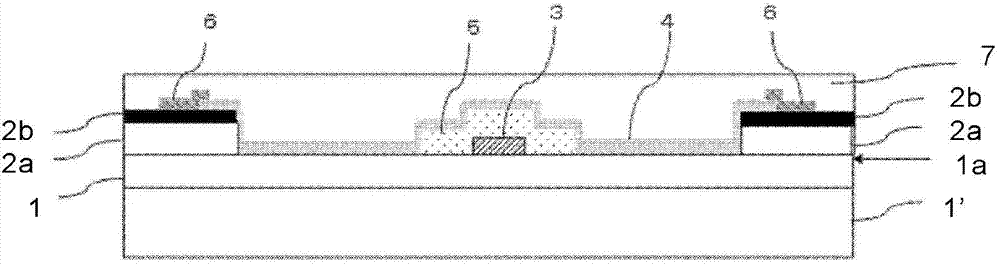

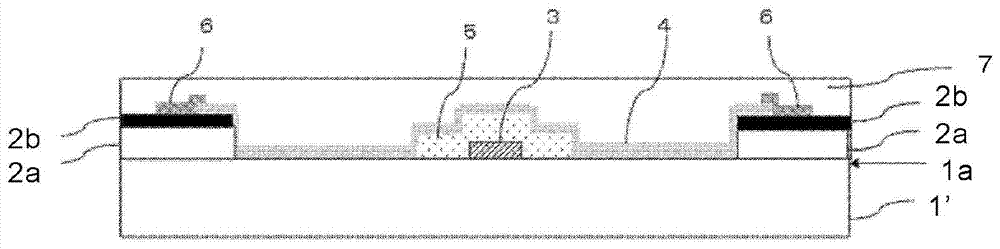

Decorative-material-attached substrate and manufacturing method therefor, touch panel and information display device

ActiveCN104756052ALower b valueNon-linear opticsInput/output processes for data processingInformation deviceBlocking layer

The present invention provides a decorative-material-attached substrate having a white colored layer and a light blocking layer, and for which the b value of the white colored layer after high temperature processing is small. This decorative-material-attached substrate has in the following order a substrate, the white colored layer, and the light blocking layer. Both the white colored layer and the light blocking layer include a resin having a siloxane bond in the main chain.

Owner:FUJIFILM CORP

Titanium-silicon catalyst, preparation method and uses thereof

The invention discloses a titanium-silicon catalyst and a preparation method as well as an application thereof. The preparation method includes the following steps: (1) organic titanic acid ester and 2 / 3 cubic content of anhydrous alcohol are mixed evenly, and stirred sufficiently to achieve A solution; deionized water is mixed with the remained 1 / 3 cubic content of anhydrous alcohol sufficiently, acid or alkali is added, the acid or alkali concentration is controlled within 0.01-1mol / L, B solution is prepared, and B solution is dripped into A solution by a burette; (2) the mixture is stirredfor 3-5 hours after dripping, the precipitate achieved after centrifugal separation is grinded and calcined to achieve titanium-silicon catalyst. The titanium-silicon catalyst achieved by the method is stable during the process of polymerization without hydrolysis reaction; the method can be used to catalytic synthesis of aliphatic and aromatic co-polyester, the titanium-silicon catalyst can reduce the dosage of catalyst, shorten the duration of polymerization, improve the quality of biodegradation co-polyester product, and the terminal carboxyl group content in the product as well as the b value are reduced.

Owner:KINGFA SCI & TECH CO LTD +1

Preparation of polyethylene glycol terephthalate for improving color value of product

InactiveCN1288186CReduce consumptionImprove product qualityPolyethylene terephthalatePolymer science

Production of poly-terephthalic acid glycol ester for improving product tone is carried out by: agitating terephthalic acid and glycol ester by proportioning in size mixed pot, pumping into size feeding pot, size feeding pot entering into esterifying pot by size inject nozzle, circulating by thermosiphon, size mixing reacting, injecting esterified oligomer and additive on pipeline into pre-polymerization pot, material reaching top of pre-polymerization, flowing into terminal-polymerization pot, filtering the product in melt filter, and removing cast heads to dicing cutter. It is characterized by adding blue agent or / and red agent and controlling its content in section 0-1PPM. It achieves low cost and heat energy consumption, and higher product quality.

Owner:JIANGYIN BOLUN CHEM FIBER

A method for reducing the yellowness of nano-silver wire transparent conductive film by changing the intensity of plasmon resonance

ActiveCN108346493BReduce yellownessLower b* valueApparatus for manufacturing conducting/semi-conducting layersHydrogenTransparent conducting film

Owner:合肥微晶材料科技有限公司

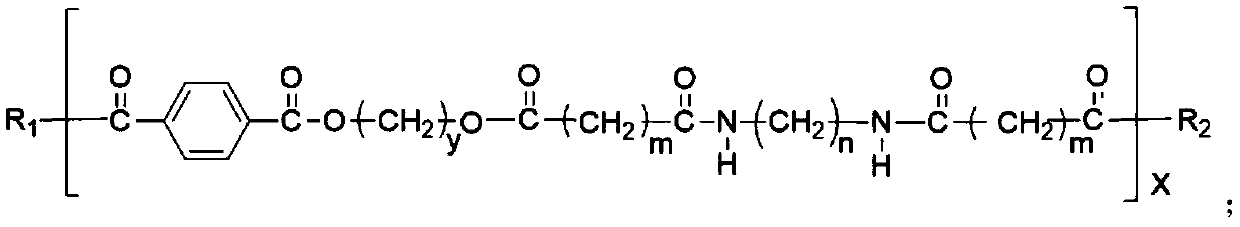

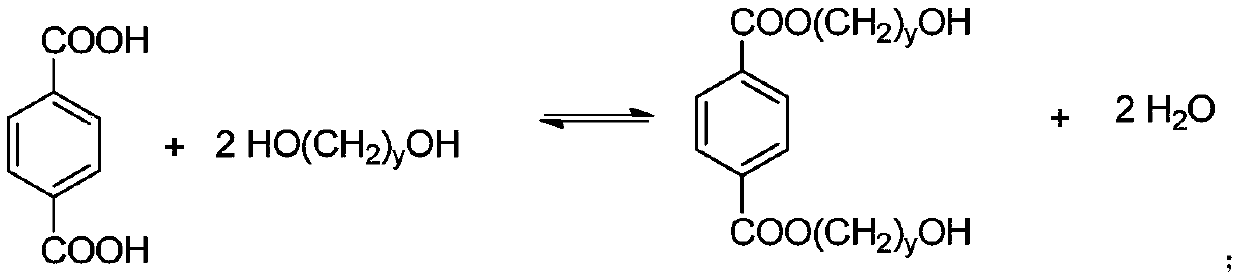

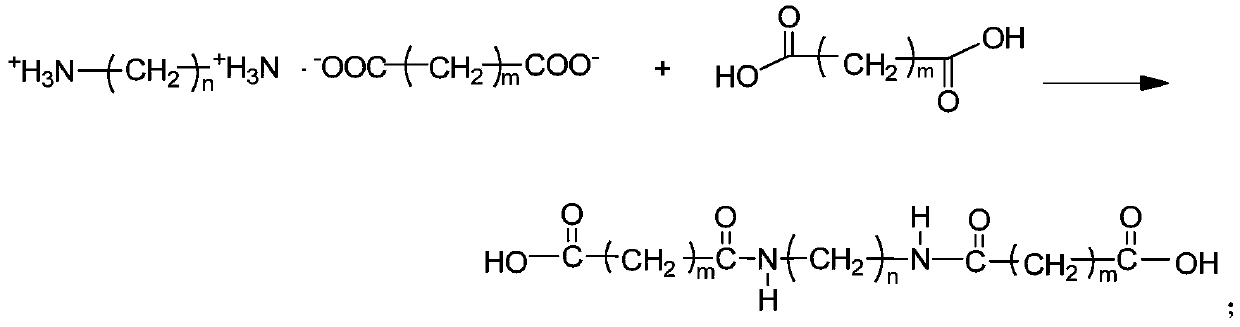

Polyesteramide as well as preparation method and application thereof

ActiveCN111440314AImprove responseAvoid yellowingMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to polyesteramide as well as a preparation method and application thereof. The method comprises the following steps: mixing terephthalic acid dihydric alcohol ester and a diaminedibasic acid derivative, and then carrying out condensation polymerization to obtain the polyesteramide, the end group of the diamine dibasic acid derivative is carboxyl, and is prepared by reactionof A and B, A is diamine dibasic acid salt, B is dibasic acid, and the dibasic acid in the A is the same as that in the B; the structural formula of the prepared polyesteramide is as shown in the specification, in the formula, R1 or R2 is-OH or-O (CH2) yOH, the value range of y is 2-8, the value range of m is 4-8, the value range of n is 4-10, and the value range of X is 20-80; the application isas follows: spinning the polyesteramide to obtain polyesteramide fiber. According to the preparation method, the problem of yellowing of the polyesteramide can be effectively avoided, the prepared polyesteramide has a low b value, and the color of the polyesteramide fiber prepared through spinning processing is good.

Owner:DONGHUA UNIV

Filter aid for improving washing efficiency and application thereof

InactiveCN109225148AIncrease profitHigh whitenessOther chemical processesTitanium dioxidePhysical chemistryTitanium

The invention provides a filter aid for improving the washing efficiency and an application thereof. The filter aid and the application provided by the invention have the beneficial effects that the application is an application of beech powder as a filter aid in production of titanium dioxide by a sulfuric acid method, and after the filter aid is added into hydrolyzed metatitanic acid suspension,the washing-water penetration speed can be increased, the benefit for washing away soluble impurities such as iron can be achieved, the washing time can be shortened, the reduction of loss of metatitanic acid can be guaranteed and the yield can be increased; the novel filter aid replaces the previous precoating, or compared with no addition of the filter aid, the washing speed and effect are improved and the washing time is shortened by more than 2 hours; the water consumption is reduced and the water can be saved by about 5 cubes in every ton of water; the loss of the material is reduced andthe titanium utilization rate is increased; simultaneously, the product quality is also improved; for the prepared titanium dioxide, the whiteness is improved; not only can the requirements of national standards GB / T1706-2006 be met, but also the b value and deltaE color difference are reduced compared with the titanium dioxide prepared before the process is changed.

Owner:JINAN YUXING CHEM

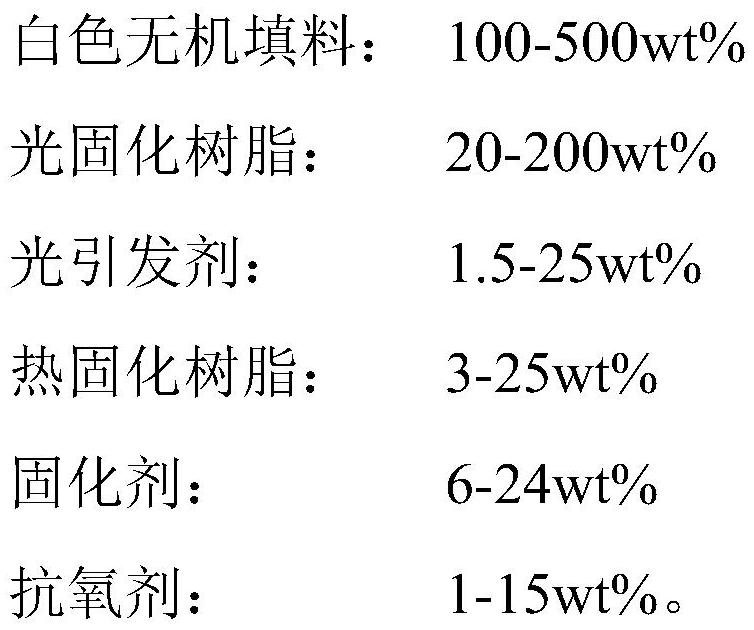

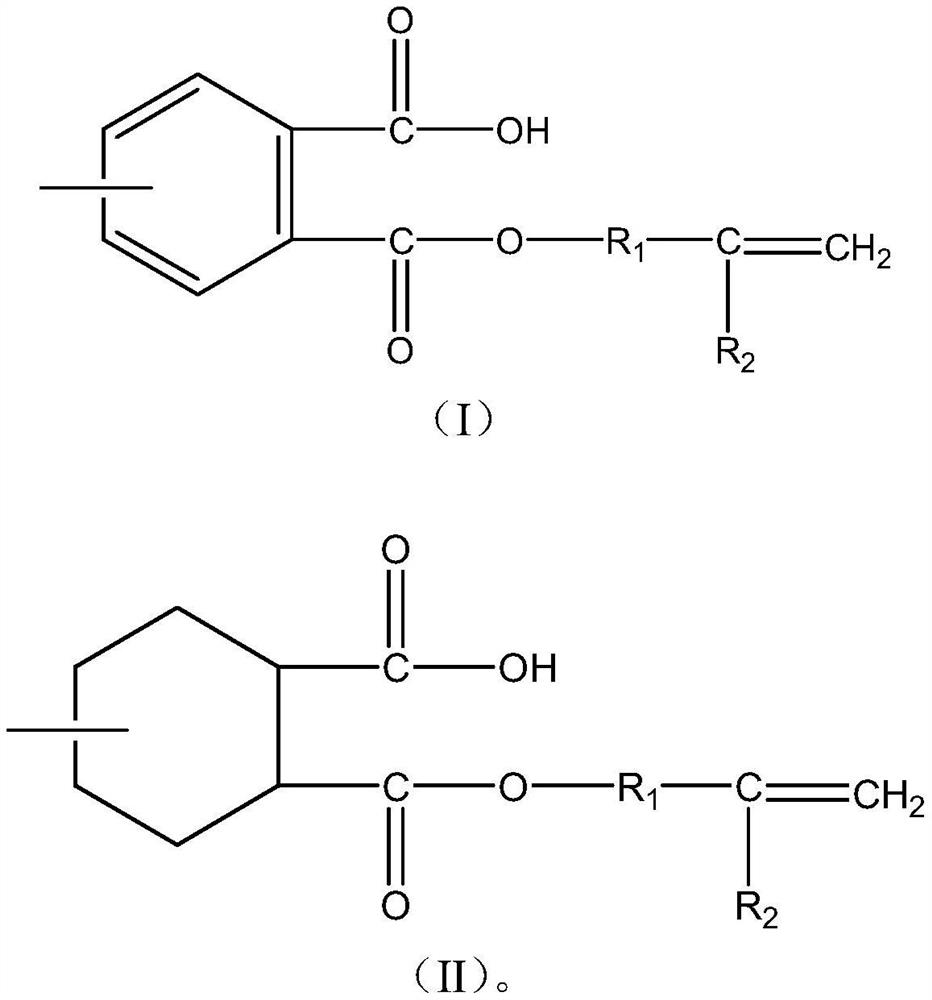

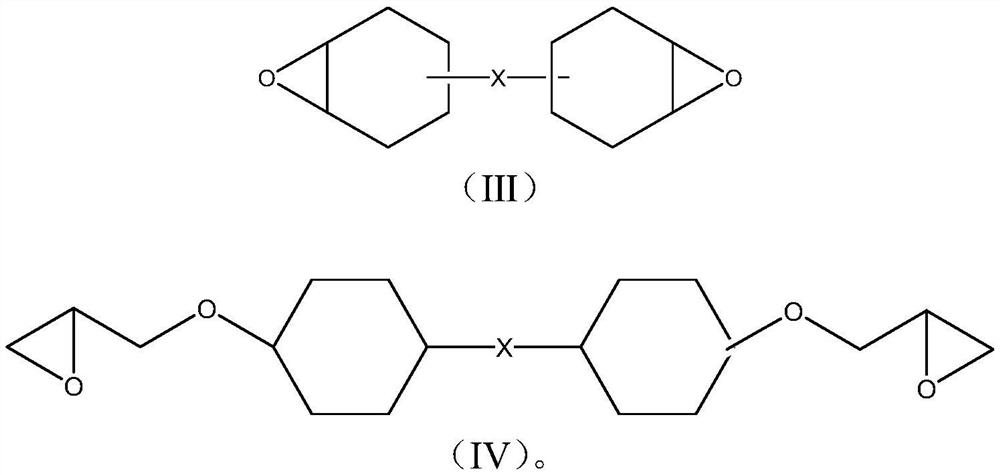

White photosensitive film, and preparation method and application thereof

PendingCN111650811AImprove reflectivityLower b valuePhotosensitive materials for photomechanical apparatusPolymer scienceSide chain

The invention discloses a white photosensitive film, and a preparation method and application thereof. The white photosensitive film comprises a white inorganic filler, alkali-soluble resin, light-cured resin, a photoinitiator, heat-cured resin, a curing agent and an antioxidant; and the curing agent is an anhydride curing agent. A white photosensitive film formula is used to form a coating liquid, a carrier film is coated with the coating liquid, and the carrier film is heated and baked to obtain the white photosensitive film. According to the white photosensitive film, the formula is improved, and by adding the anhydride curing agent and the alkali-soluble resin with the side chain and / or the tail end containing a carboxyl group, the prepared white photosensitive cover film can meet therequirements of an existing product in the aspects of development precision, high temperature resistance and the like; and the cured film is low in b value and high in reflectivity.

Owner:SHANGHAI FUSAITE NEW MATERIAL

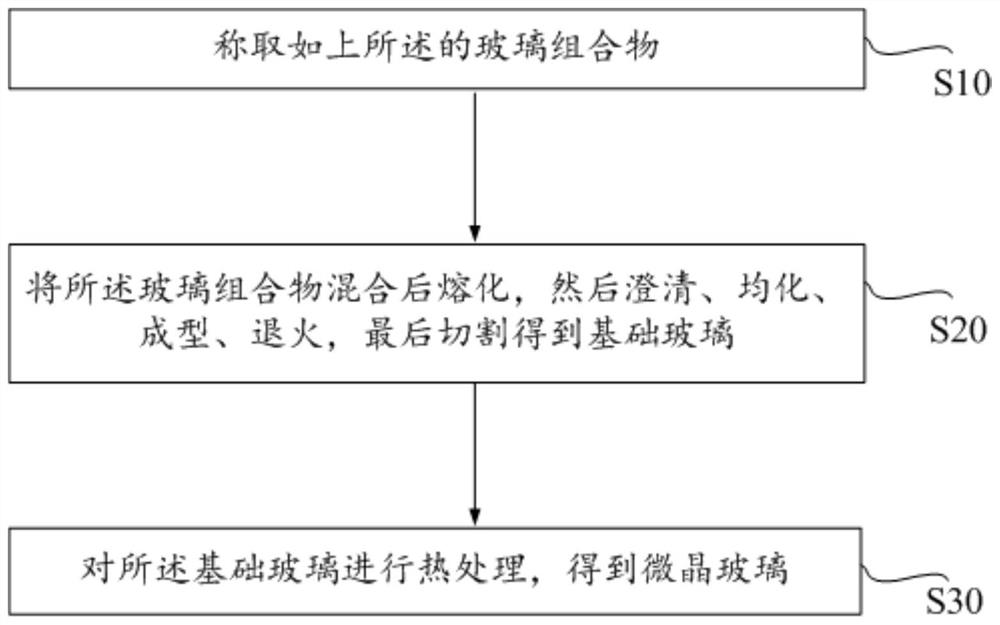

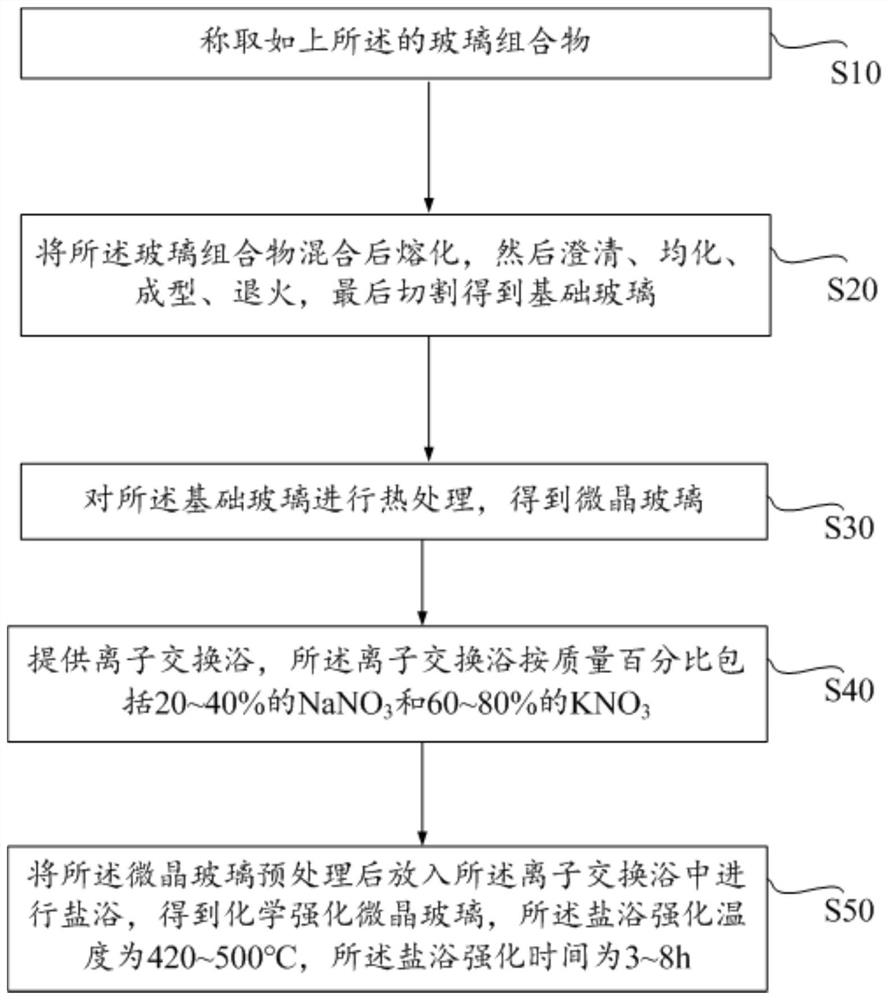

Glass composition, microcrystalline glass as well as preparation method and application of microcrystalline glass

InactiveCN114195392ADo not excessively break the interlock structureImprove the strengthening effectGlass forming apparatusGlass rolling apparatusPhysical chemistryDouble crystal

The invention discloses a glass composition, glass ceramic and a preparation method and application of the glass ceramic, and the glass composition comprises the following components in percentage by mass: 72 to 74.3 percent of SiO2, 7 to 8.5 percent of Al2O3, 1.8 to 3 percent of P2O5, 0.2 to 12.5 percent of Li2O, 0.5 to 2 percent of Na2O and 3.5 to 4.7 percent of ZrO2. According to the technical scheme, the components SiO2, Al2O3, P2O5, Li2O, Na2O and ZrO2 in the glass composition are combined according to a specific proportion, and a glass ceramic crystallization process and a strengthening process are combined, so that the b value and the haze can be remarkably reduced, the crystal content is not excessively reduced after chemical strengthening, and an interlocking structure of double crystal phases is not excessively damaged; the microcrystalline glass with excellent strengthening performance is obtained.

Owner:SHENZHEN NEW KIBING TECH CO LTD

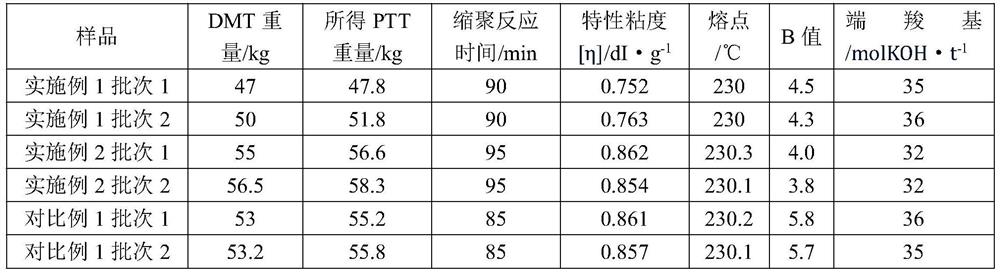

Regenerated PTT polymer and preparation method and application thereof

The invention relates to a regenerated PTT polymer and a preparation method and application thereof. According to the preparation method, the recycled PET is used as a raw material, DMT is prepared through alcoholysis and transesterification, polymer conversion is achieved through transesterification, recycling of waste PET resources is achieved, new polymer PTT is manufactured through conversion, and the method is safe, non-toxic, green and environmentally friendly; after refined DMT and PDO are subjected to transesterification, a catalytic system compounded by a titanium catalyst and a plurality of metal ion solutions is used as a catalyst in a PTT polymerization process, so that effective balance between rapid reaction and product quality is achieved, the quality stability in the production process is controllable, and compared with a pure titanium catalyst, the method has the advantages that the yield is high; according to the preparation method, the inhibition effect on side reactions is obviously improved, and the B value is obviously reduced. The PTT polymer finally prepared by the preparation method disclosed by the invention is relatively narrow in molecular weight distribution, few in side reaction products and good in quality, can be used for preparing fibers, films or engineering plastic products, and has a great application prospect.

Owner:FUJIAN SAILON TECH CO LTD

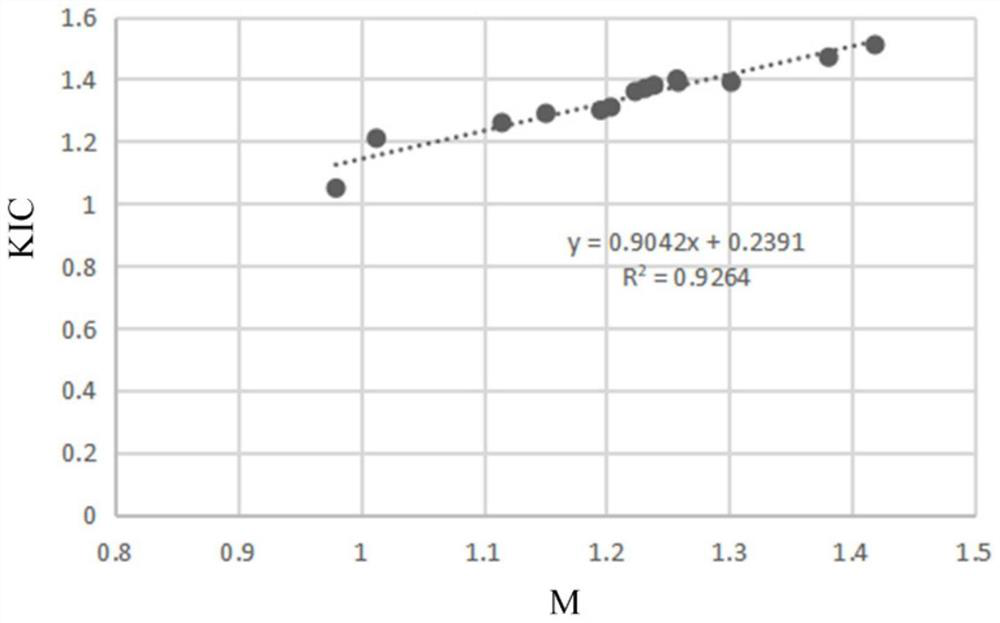

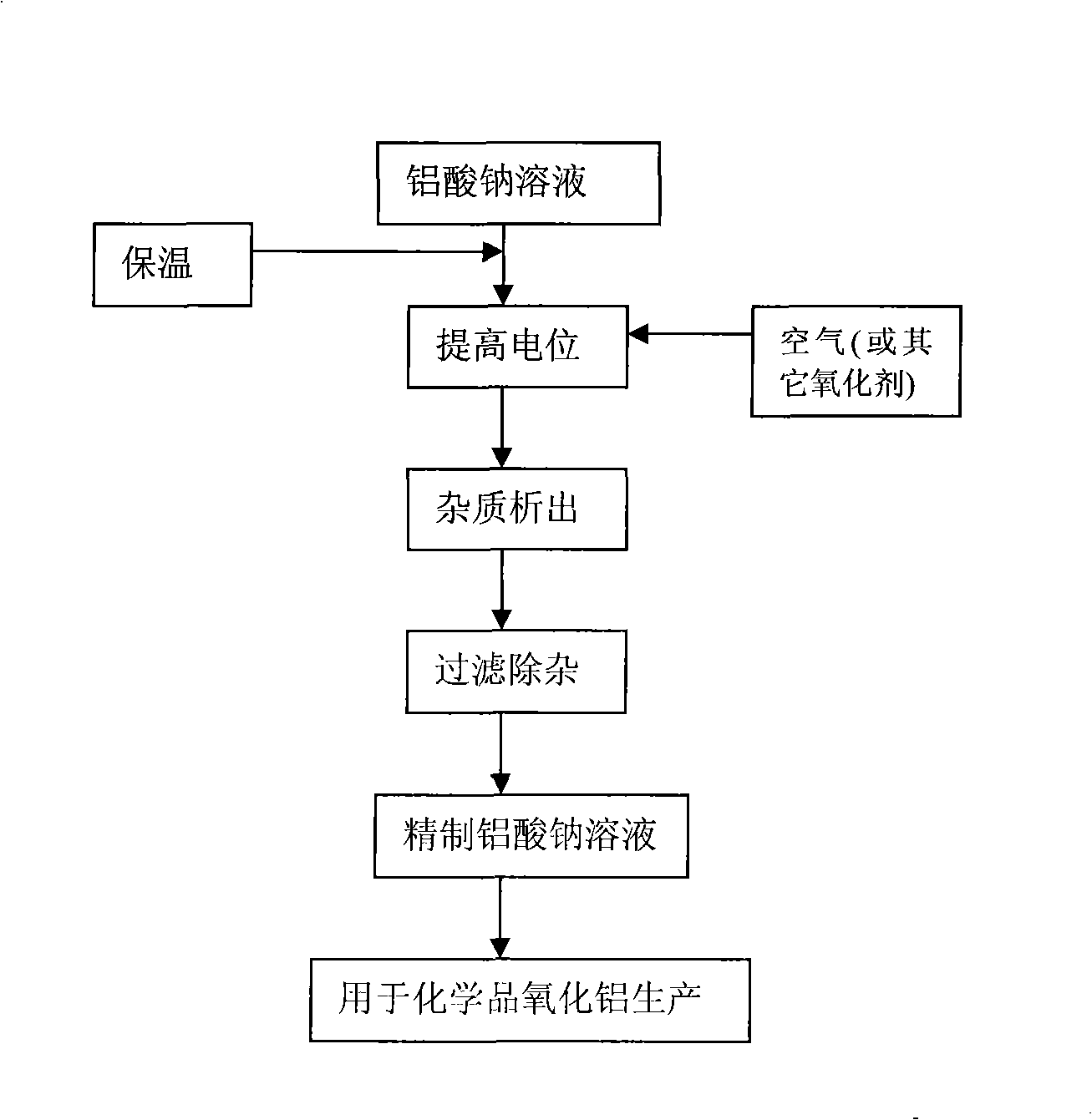

Control method for b value of sodium aluminate solution

ActiveCN101343075ALower b valueEasy to controlAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateOxidizing agent

The invention relates to a control method of b value of a sodium aluminate solution, which belongs to the alumina production industrial technology, the b value of the solution is reduced through increasing the electric potential of the solution, and when the solution electric potential reaches 0.8 to 1.2V, an oxidizing agent can be added into the sodium aluminate solution for increasing the solution electric potential. The method can conveniently control the b value of the sodium aluminate solution, and achieve the purpose of reducing the b value of the sodium aluminate solution, thereby reducing the b value of aluminum hydroxide of products, and guaranteeing the product qualification rate.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

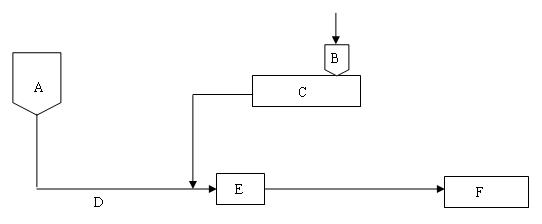

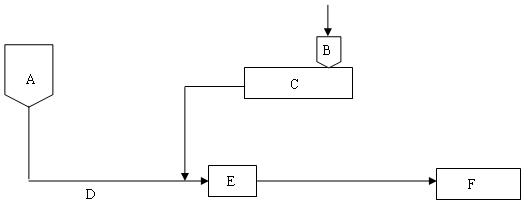

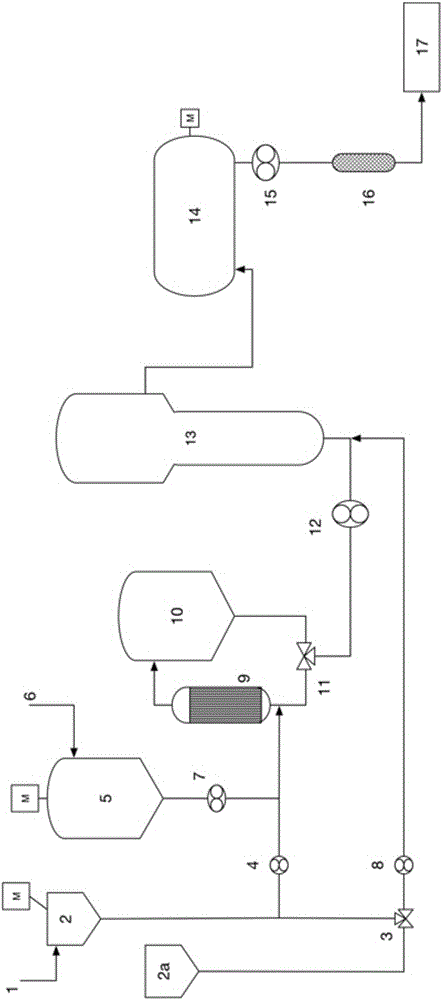

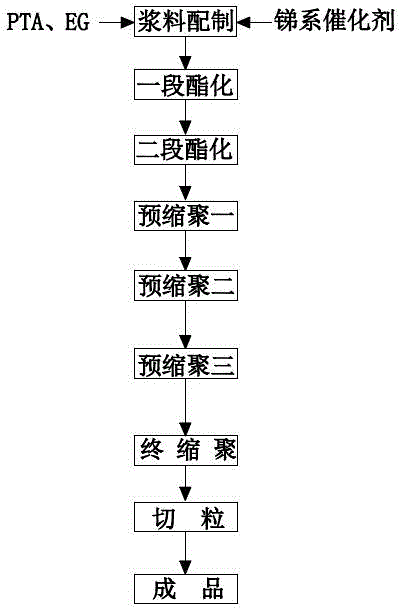

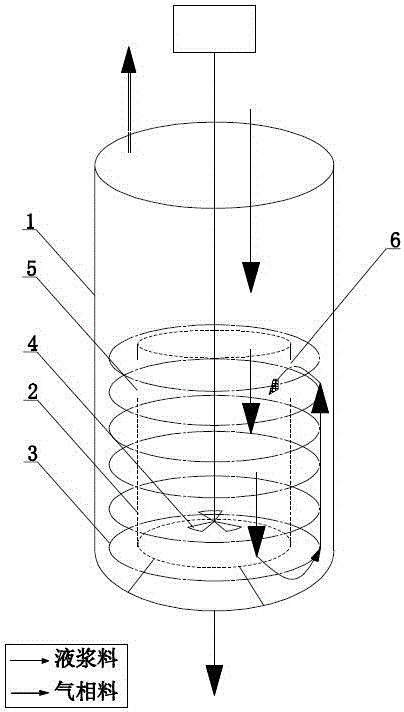

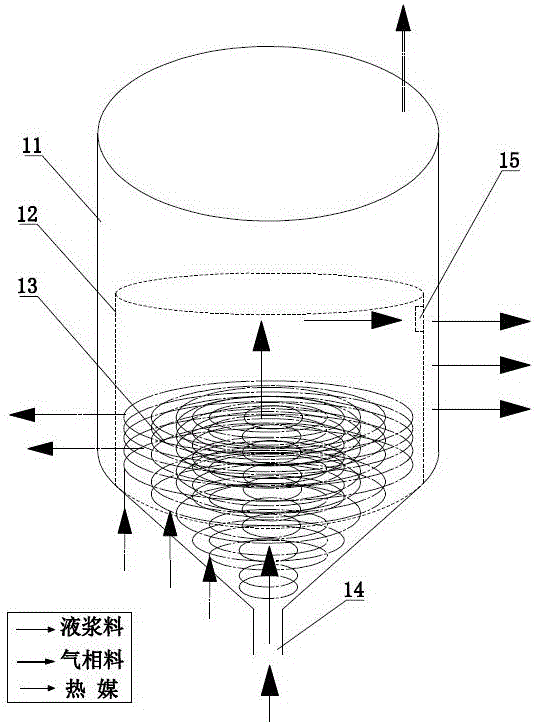

A kind of polyester production device and process

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Process for preparing polyester and copolyester

The process of preparing polyester and copolymer includes the following steps: 1. the ester interchange reaction of dicarboxylic ester or the reaction of dicarboxylic acid with diol to obtain ester oligomer mixture; and 2. the further polycondensation in the presence of polycondensation catalyst. It features the polycondensation catalyst comprising homogeneous diol solution of Ti-Si catalyst. The homogeneous catalytic reaction has simple mass transfer process, raised mass transfer efficiency, raised catalyst activity and selectivity, raised polyester product quality, lowered product b value and shortened polycondensation time.

Owner:SHANGHAI HUAMING HI TECH GRP

A transparent conductive film

ActiveCN109243677BImprove visibilityImprove transmittanceConductive layers on insulating-supportsInput/output processes for data processingConductive pasteAcrylic resin

The invention relates to a transparent conductive film, which can reduce the b* value of the conductive film and improve the transmittance of the conductive film by adding a dyeing agent. The present invention provides a transparent conductive film in view of the technical problems of discoloration of the film material and poor visibility due to the coating of the conductive paste in the existing transparent conductive film. The transparent conductive film includes a transparent carrier, a conductive layer and a protective layer sequentially coated on the transparent carrier; the components of the protective layer include acrylic resin, mixed solvent and coloring agent. According to the CIE Lab* color model (Lab*), based on people's perception of color, by adding a colorant corresponding to the color displayed by the conductive layer on the protective layer, the visual effect of discoloration can be compensated and the transmission of the conductive film can be improved. Rate.

Owner:山东华科创智技术有限公司

Substrate with decorative material, manufacturing method thereof, touch screen, and information display device

ActiveCN104756052BLower b valueNon-linear opticsInput/output processes for data processingOptoelectronicsBlocking layer

The present invention provides a decorative-material-attached substrate having a white colored layer and a light blocking layer, and for which the b value of the white colored layer after high temperature processing is small. This decorative-material-attached substrate has in the following order a substrate, the white colored layer, and the light blocking layer. Both the white colored layer and the light blocking layer include a resin having a siloxane bond in the main chain.

Owner:FUJIFILM CORP

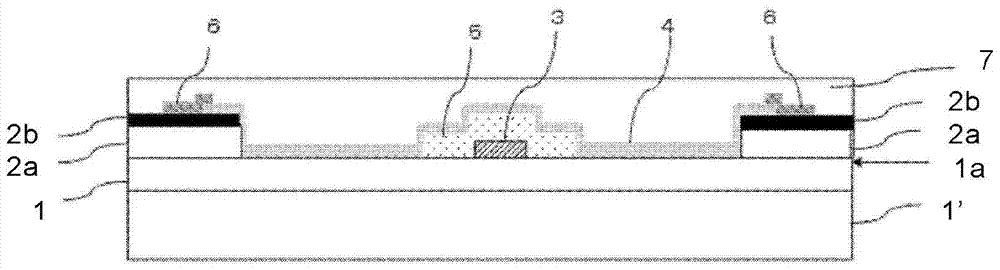

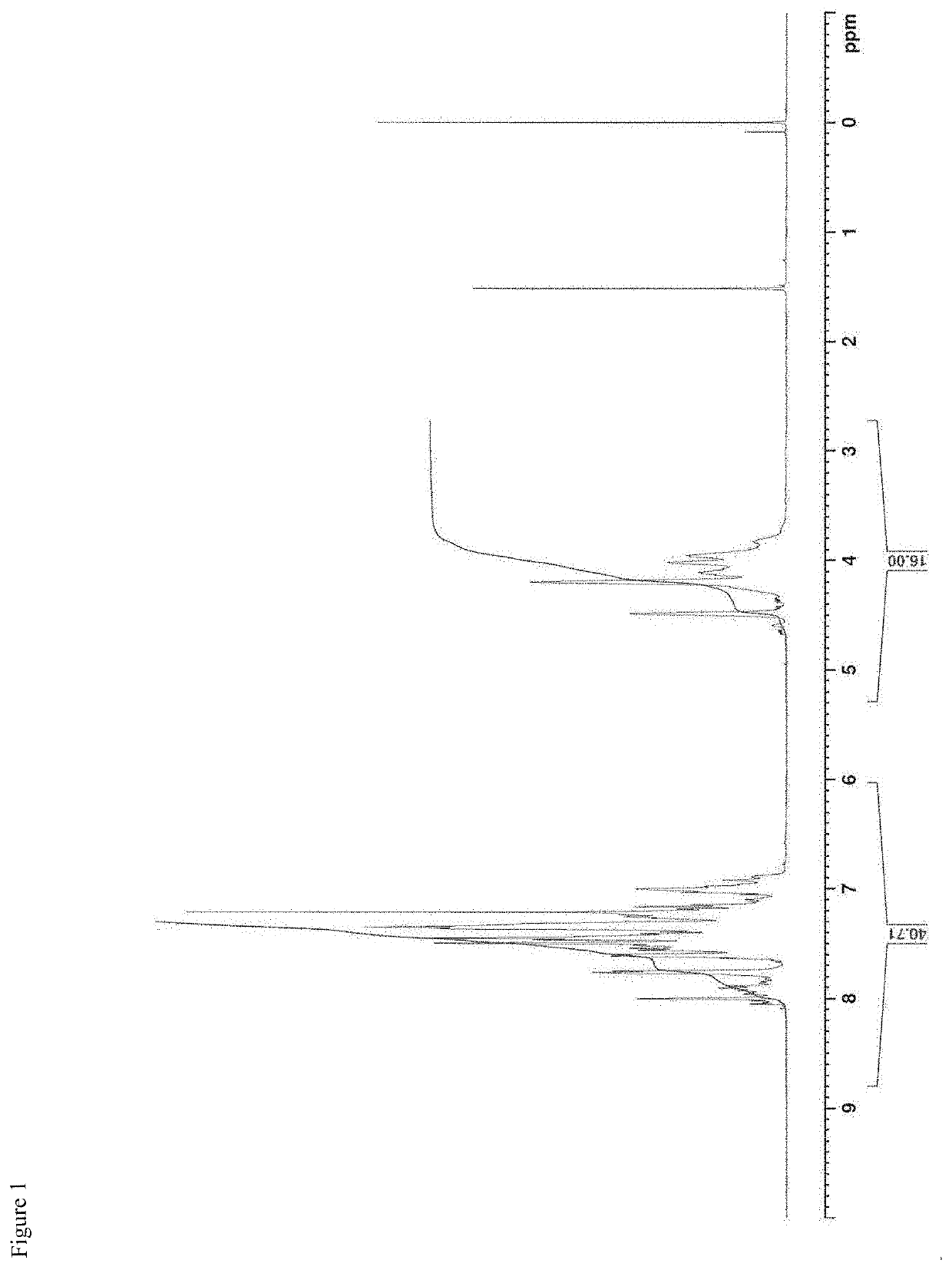

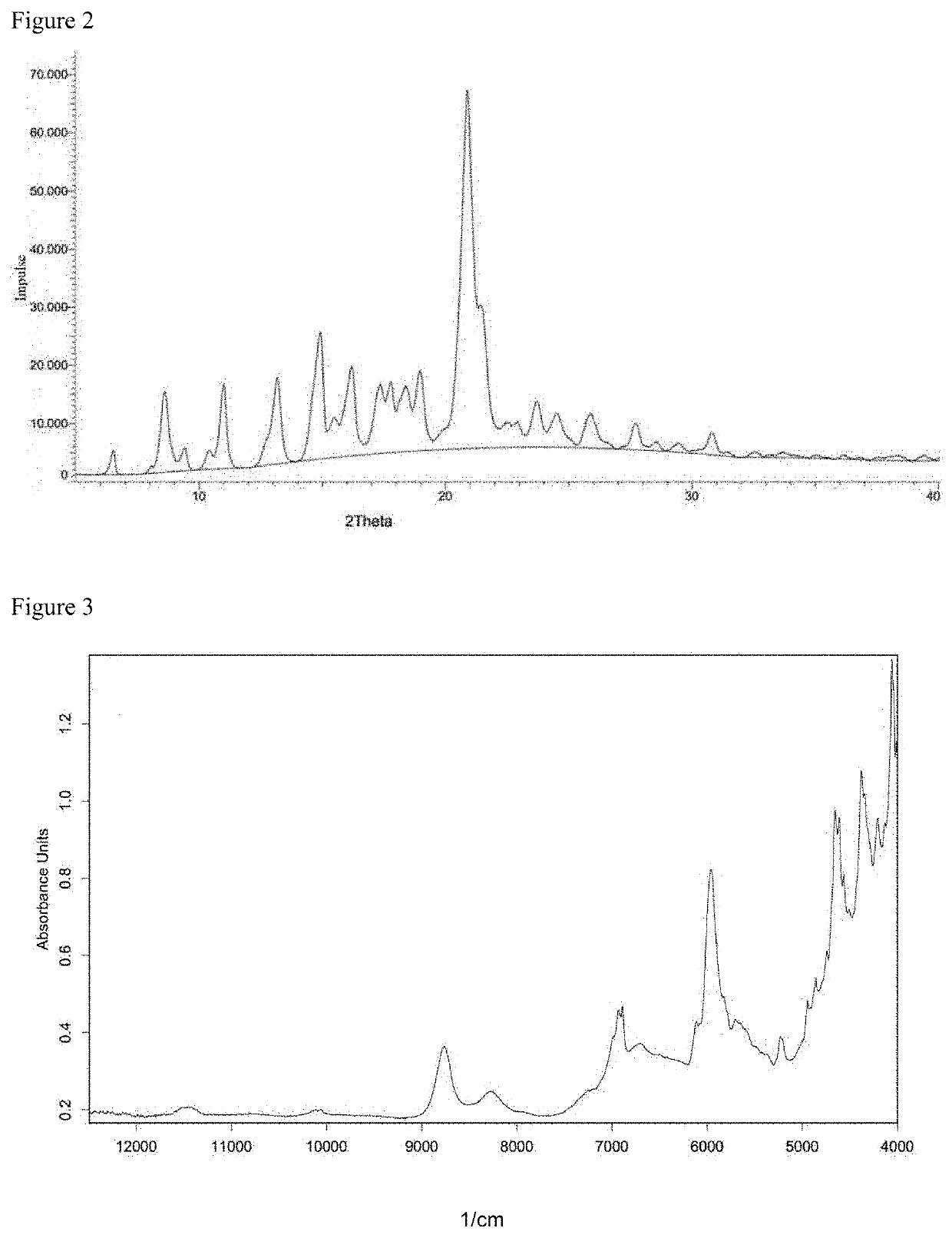

Thermoplastic resin, method for manufacturing same, and optical lens

PendingUS20220243008A1High refractive indexLower b valueOptical elementsPolymer scienceLens crystalline

Crystalline solvate forms and amorphous forms of 6,6′-diphenyl-2,2′-bis(2-hydroxyethoxy)-1,1′-binaphthyl, where the organic solvent is selected from methanol, toluene, and methyl ethyl ketone, and an amorphous form of 6,6′-diphenyl-2,2′-bis(2-hydroxyethoxy)-1,1′-binaphthyl having a purity of at least 99.0% by weight, based on organic matter. Thermoplastic resins containing a structural unit derived from 6,6′-diphenyl-2,2′-bis(2-hydroxyethoxy)-1,1′-binaphthyl. Optical lenses containing the thermoplastic resins containing a structural unit derived from 6,6′-diphenyl-2,2′-bis(2-hydroxyethoxy)-1,1′-binaphthyl.

Owner:MITSUBISHI GAS CHEM CO INC

A method of adding titanium dioxide to prepare semi-dull and full-dull titanium series polyester

The invention relates to a method for preparing semi-dull and full-dull titanium polyester through adding titanium dioxide, and solves a problem that titanium dioxide used as a delustering agent in the prior art has an inhibition effect on the activity of titanium polyester catalysts. The method comprises the following steps: adding titanium dioxide used as the delustering agent to raw materials comprising terephthalic acid and ethylene glycol, carrying out an esterification reaction in the presence of a liquid titanium polyester catalyst, and carrying out a pre-polycondensation and polycondensation reaction under vacuum conditions to obtain the polyester product, wherein the liquid titanium polyester catalyst is a product prepared through a reaction of titanate, polyol, sulfonate and an alkaline metal compound, a molar ratio of titanate to polyol is 1:1 to 1:10, a molar ratio of titanate to sulfonate is 20:1 to 5:1, and a molar ratio of titanate to the alkaline metal compound is 10:1 to 2:1. The method allows semi-dull and full-dull titanium polyester with superior performances to be obtained, and can be used in practical industrial production of polyester.

Owner:CHINA PETROLEUM & CHEM CORP

Thermoplastic resin, method for manufacturing same, and optical lens

Provided is a thermoplastic resin including constituent units represented by general formula (1). (In formula (1), R1 and R2 each independently represent: a hydrogen atom; a fluorine atom; a chlorine atom; a bromine atom; an iodine atom; a C1-6 alkyl group; a monocyclic or polycyclic C6-36 aryl group; a monocyclic or polycyclic heteroaryl group having 5-36 ring atoms, 1, 2, 3, or 4 of the ring atoms being selected from nitrogen, sulfur, and oxygen, and the other ring atoms being carbon in the heteroaryl group; a C2-6 alkenyl group; a C1-6 alkoxy group; or a C7-17 aralkyl group. In formula (1), X, a, and bare each as described in the present specification.)

Owner:MITSUBISHI GAS CHEM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com