Regenerated PTT polymer and preparation method and application thereof

A technology for polymer and polycondensation, applied in the field of polymerization, can solve the problems of high cost and large environmental pollution, and achieve the effect of less side reaction products, good quality, and reducing reverse side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of preparation of regenerated PTT polymer

[0041] Using the hosiery material (140kg) with a polyester fiber content of 91% as the raw material, 104.8kg of crude DMT was obtained through alcoholysis and transesterification, and the yield was 104.8÷(140×91%)=82.3%. 104.8 kg of crude DMT was rectified to obtain 97 kg of technically pure DMT. 97kg of refined DMT was subjected to subsequent reactions in two batches, the first batch of 47kg and the second batch of 50kg.

[0042] The first batch: 47kg of refined DMT and 43kg of 1,3-propanediol (1,3-PDO) were added to the reactor. Under normal pressure, the temperature in the reaction kettle was raised to 70 °C, and the reaction was carried out for 1.5 h. Then, add composite catalyst and stabilizer to the reactor, vacuumize, reduce the pressure to a vacuum negative pressure of 25Pa, maintain this vacuum for 100 minutes, and control the reaction temperature at 260~280 ℃ to obtain 47.8kg of regenerated PTT ...

Embodiment 2

[0045] Embodiment 2 A kind of preparation of regenerated PTT polymer

[0046] Using hosiery material (150kg) with polyester fiber content of 96% as raw material, 121.6kg crude DMT was obtained through alcoholysis and transesterification reaction, and the yield was 121.6÷(150×96%)=84.44%. 121.6 kg of crude DMT was rectified to obtain 111.5 kg of technically pure DMT. 111.5kg of refined DMT was subjected to subsequent reactions in two batches, the first batch of 55kg and the second batch of 56.5kg.

[0047] The first batch: 55kg of refined DMT and 50.3kg of 1,3-propanediol (1,3-PDO) were added to the reactor. Under normal pressure, the temperature in the reaction kettle was raised to 80 °C, and the reaction was carried out for 1.5 h. Next, add composite catalyst and stabilizer to the reactor, vacuumize, reduce the pressure to a vacuum negative pressure of 30Pa, maintain this vacuum for 100 minutes, and control the reaction temperature at 260~280 ℃ to obtain 56.5kg of regenerat...

experiment example

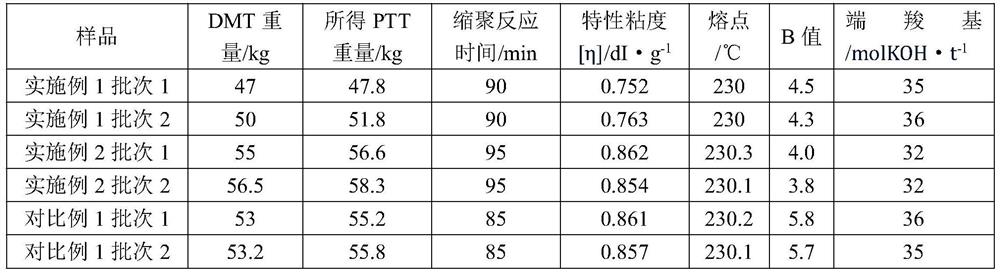

[0056] Performance tests were performed on the regenerated PTT slices of Examples 1 to 2 and Comparative Example 1, and the test results are shown in Table 1.

[0057] (1) Determination method of intrinsic viscosity: adopt GB / T14189-93 standard and test with automatic viscosity tester. Using 1:1 phenol / tetrachloroethane as the solvent, the melting temperature of the slices is 90-100°C, and the temperature control range of the viscometer water bath is 25±0.05°C.

[0058] (2) Determination method of melting point: adopt GB / T14189-93 standard and test with polarizing microscope.

[0059] (3) Determination method of chromaticity B value (yellow index): adopt GB / T14189-93 standard and test with SC-100 automatic color difference meter. The test temperature was room temperature, the number of tests was 5 times, and the results were averaged.

[0060] Hue is an important indicator of PTT products, usually expressed by B value. When the B value of the product is larger, the color of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com