Preparation of polyethylene glycol terephthalate for improving color value of product

A technology of polyethylene terephthalate and terephthalic acid, which is applied in the field of preparation of polyethylene terephthalate, can solve the problems of high product b value and high reaction temperature, and improve product quality , Reduce heat energy consumption and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

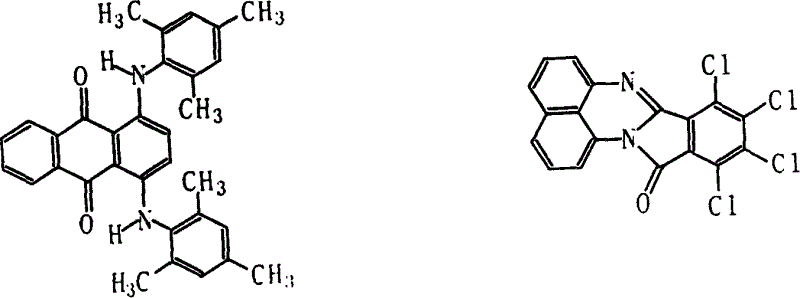

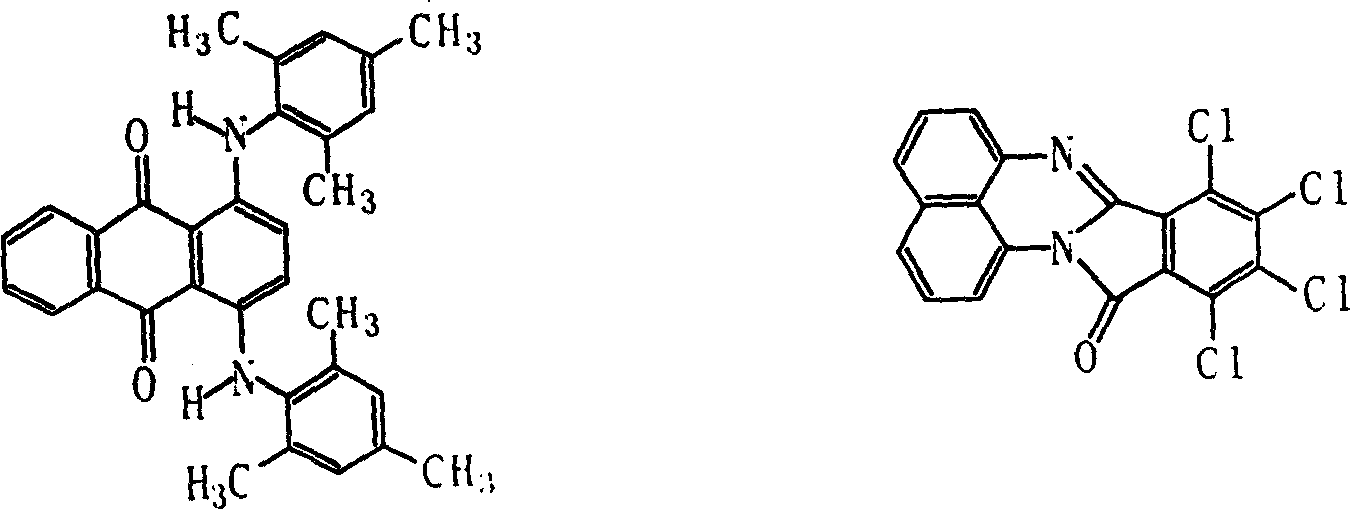

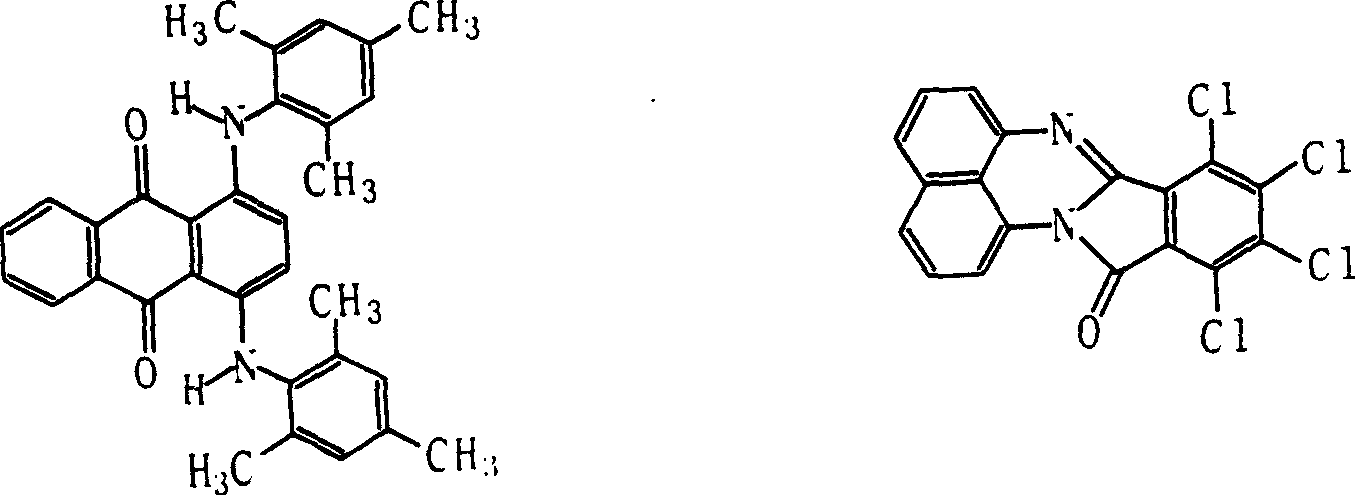

[0017] The blue agent and the red agent are injected in the slurry feeding tank at a ratio of 0.0035, the esterification temperature is 270°C, the precondensation temperature is 285°C, the absolute pressure is 19-20mmHg, the final polymerization temperature is 287°C, and the absolute pressure is ≤1.3mmHg. The ratio of blue agent to red agent is 1.5:1

Embodiment 2

[0019] The blue agent is injected in the slurry feeding tank at a ratio of 0.0030, the esterification temperature is 260°C, the precondensation temperature is 290°C, the absolute pressure is 20mmHg, the final polymerization temperature is 285°C, and the absolute pressure is ≤1.3mmHg. The ratio of blue agent to red agent is 2:1

Embodiment 3

[0021] The red agent is injected in the slurry feeding tank at a ratio of 0.0028, the esterification temperature is 280°C, the precondensation temperature is 280°C, the absolute pressure is 19.5mmHg, the final polymerization temperature is 295°C, and the absolute pressure is ≤1.3mmHg. The ratio of blue agent to red agent is 2.5:1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com