Method for manufacturing directly-spun PET (polyethylene glycol terephthalate) polyester staple fibers by aid of titanium catalysts

A titanium-based catalyst and short fiber technology, which is applied in the textile field, can solve the problems of low physical and mechanical properties of fibers, yellowish appearance, and high solid PETb value, and achieve the effects of improving mechanical properties, reducing melt temperature, and uniform physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

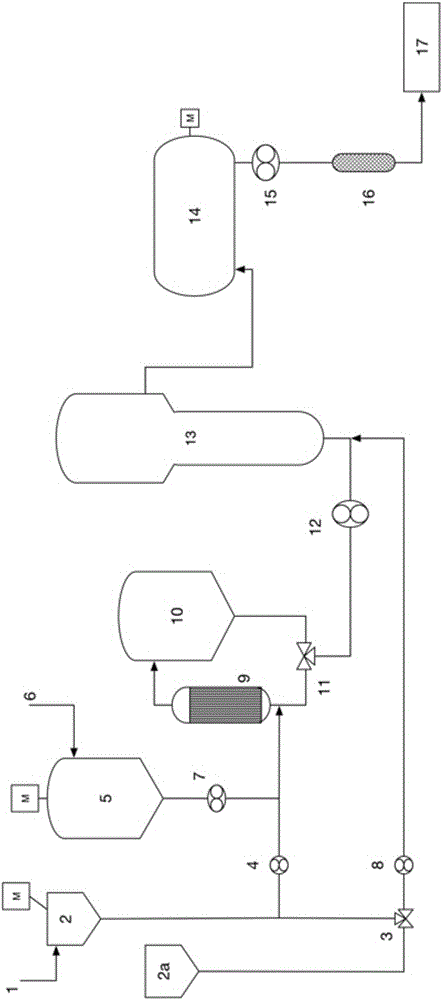

Method used

Image

Examples

Embodiment 1

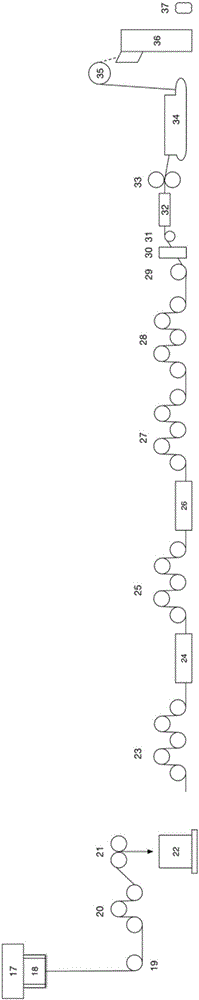

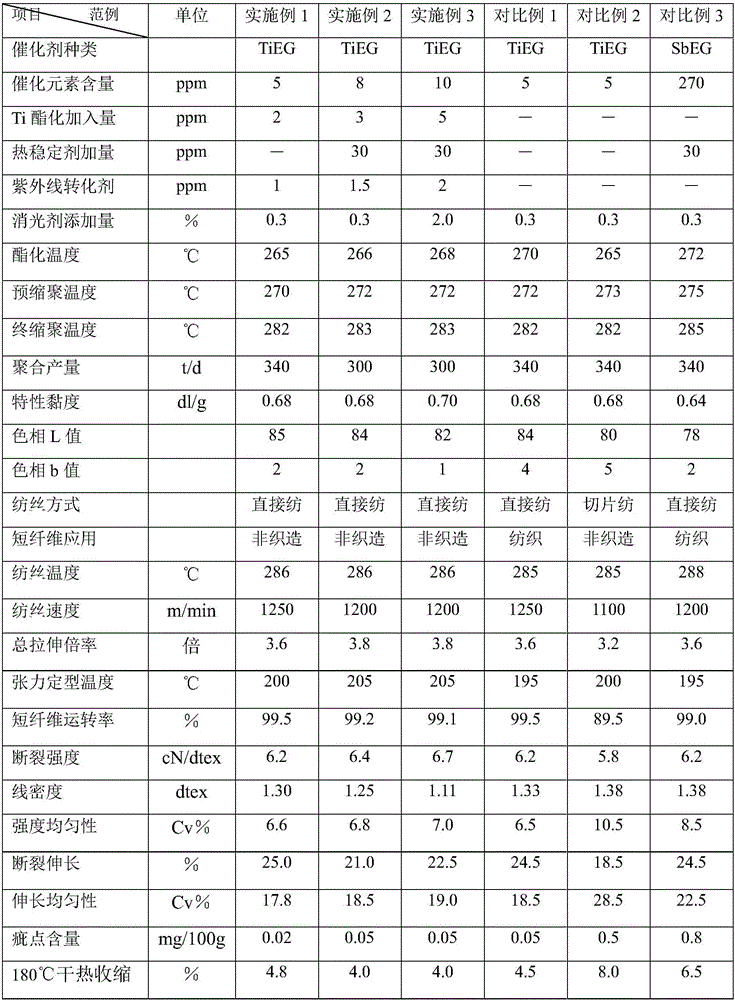

[0034] Example 1: 1.30dtex semi-dull high-strength low-stretch spunlace nonwovens directly spun short fibers

[0035]The goal is no heavy metals, relatively low fiber density, relatively high fiber breaking strength and 180°C dry heat shrinkage, that is, relatively high thermal stability of the fabric, high uniformity of physical and mechanical properties of the fiber, and low defect content. Therefore, the goal of setting the polyester process is a relatively high intrinsic viscosity of 0.680dl / g, a relatively low polymerization reaction temperature, and a relatively low melt temperature, so as to give more adjustable means of spinning. A set of polyester series corresponds to 4 spinning lines and a set of pelletizing facilities.

[0036] The daily output of polyester is 340 tons / day, adopting the domestic self-innovated three-pot process technology, using EG titanium as the catalyst (selected from Zezibo Xiaoguang Chemical Materials Co., Ltd.), and mixing the titanium series...

Embodiment 2

[0041] Example 2: 1.25dtex semi-dull high-strength low-stretch spunlace nonwovens directly spun short fibers

[0042] The goal is no heavy metals, relatively low fiber density, relatively high fiber breaking strength and 180°C dry heat shrinkage, that is, relatively high thermal stability of the fabric, high uniformity of physical and mechanical properties of the fiber, and low defect content. Therefore, the goal of setting the polyester process is a relatively high intrinsic viscosity of 0.60dl / g, a relatively low polymerization reaction temperature, and a relatively low melt temperature, so as to give more adjustable means of spinning. A set of polyester series corresponds to 4 spinning lines and a set of pelletizing facilities.

[0043] The daily output of polyester is 300 tons / day, using the domestic self-innovated three-pot process technology, using EG titanium as the catalyst (selected from Zezibo Xiaoguang Chemical Materials Co., Ltd.), and mixing the titanium series ca...

Embodiment 3

[0049] Example 3: 1.11dtex full-dull ultrafine spunlace nonwovens directly spun short fibers

[0050] The target value is no heavy metal, relatively low fiber density, relatively high fiber breaking strength and 180°C dry heat shrinkage, that is, relatively high fabric thermal stability, high uniformity of fiber physical and mechanical properties, and low defect content. Therefore, the goal of setting the polyester process is a relatively high intrinsic viscosity of 0.75dl / g, a relatively low polymerization reaction temperature, a high content of matting agent, and a relatively low melt temperature, so that it can give spinning more adjustable means. A set of polyester series corresponds to 4 spinning lines and a set of pelletizing facilities.

[0051] The daily output of polyester is 300 tons / day, using the domestic self-innovated three-pot process technology, using EG titanium as the catalyst (selected from Zezibo Xiaoguang Chemical Materials Co., Ltd.), and mixing the tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com