Modified polyester and preparing method thereof

A technology for modifying polyester and polybasic acid, applied in the field of polyester preparation, can solve the problems of poor polyester product performance, reduced polyester thermal stability, and gray polyester color, etc., and achieves high dye uptake, reduced dosage, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

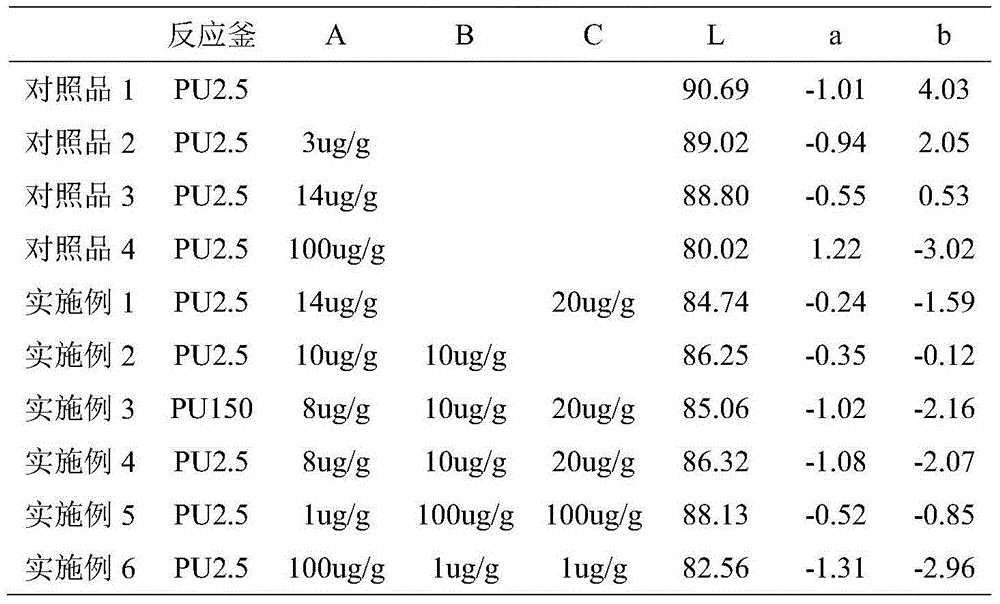

[0026] Preparation of Control 1:

[0027] Add 500g PTA, 280g EG (the molar ratio of PTA and EG is 1:1.5), 150ug / g ethylene glycol antimony in turn in the PU2.5 reaction polymerization kettle, and carry out the esterification reaction at 240°C, 0.2-0.3MPa, and 40rpm rotating speed. , when the esterification rate reaches more than 95%, vent to normal pressure, end the esterification, put in 300ug / g triphenyl phosphite, raise the temperature to 280°C, drop the absolute pressure below 100pa, react for 2 hours, and use Nitrogen to eliminate vacuum, discharge, cut into pellets, and dry to obtain polyester chips.

[0028] Preparation of Control 2:

[0029] 500g PTA, 280g EG, 150ug / g ethylene glycol antimony, 3ug / g cobalt phosphate were sequentially added to the PU2.5 reaction polymerization kettle, and the esterification reaction was carried out at 240°C, 0.2-0.3MPa, and 40rpm. More than 95%, vent to normal pressure, end esterification, put in 300ug / g triphenyl phosphite, raise the...

Embodiment 1

[0035] Add 500g PTA, 280gEG, 150ug / g ethylene glycol antimony, 14ug / g cobalt phosphate, 20ug / g calcium carbonate in sequence to the PU2.5 reaction polymerization kettle, and carry out the esterification reaction at 240°C, 0.2-0.3MPa, and 40rpm. , when the esterification rate reaches more than 95%, vent to normal pressure, end the esterification, put in 300ug / g triphenyl phosphite, raise the temperature to 280°C, drop the absolute pressure below 100pa, react for 2 hours, and use Nitrogen to eliminate vacuum, discharge, cut into pellets, and dry to obtain polyester chips.

Embodiment 2

[0037] 500g PTA, 280g EG, 150ug / g ethylene glycol antimony, 10ug / g cobalt phosphate, 10ug / g barium sulfate were added in sequence to the PU2.5 reaction polymerization kettle, and the esterification reaction was carried out at 240°C, 0.2-0.3MPa, and 40rpm. , when the esterification rate reaches more than 95%, vent to normal pressure, end the esterification, add 300ug / g triphenyl phosphite, raise the temperature to 280°C, drop the absolute pressure below 100pa, react for 2 hours, and use Nitrogen to eliminate vacuum, discharge, cut into pellets, and dry to obtain polyester chips.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com