Method for reducing yellowness of silver nanowire transparent conductive film through changing plasma resonance intensity

A technology of plasma resonance and transparent conductive film, which is applied in the direction of equipment, circuits, and electrical components used to manufacture conductive/semiconductive layers, and can solve problems such as inability to carry out industrial production, hazards to production personnel, and poor safety in use. The method is simple, the waterproof and aging resistance are good, and the effect of solving the yellowish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

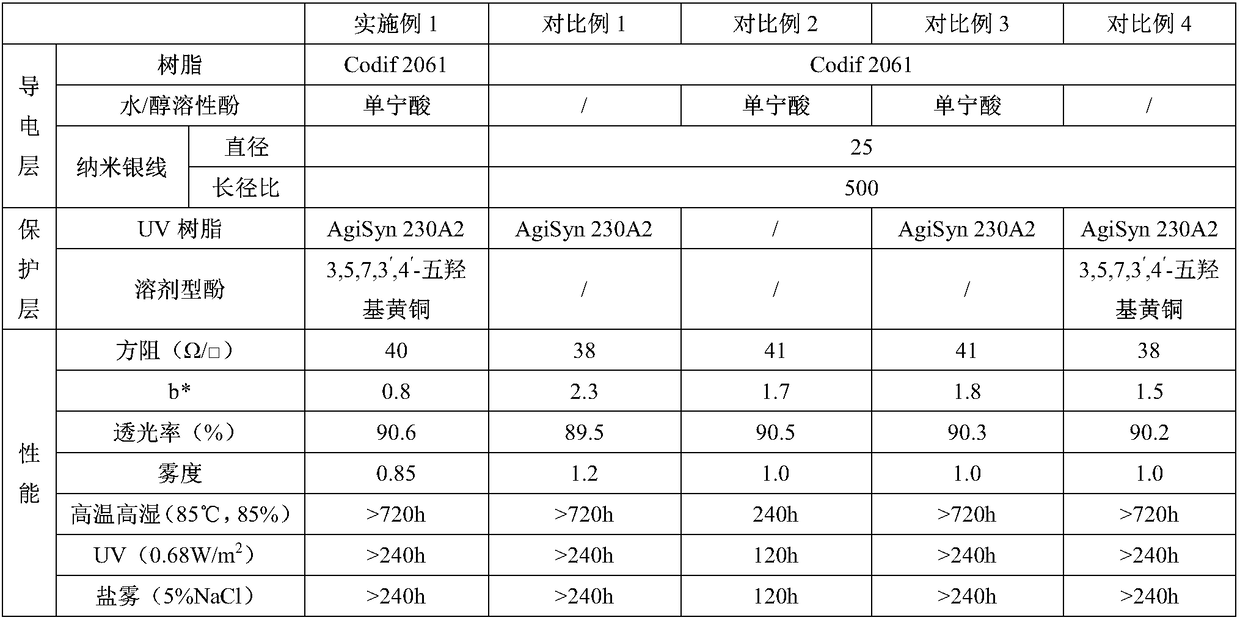

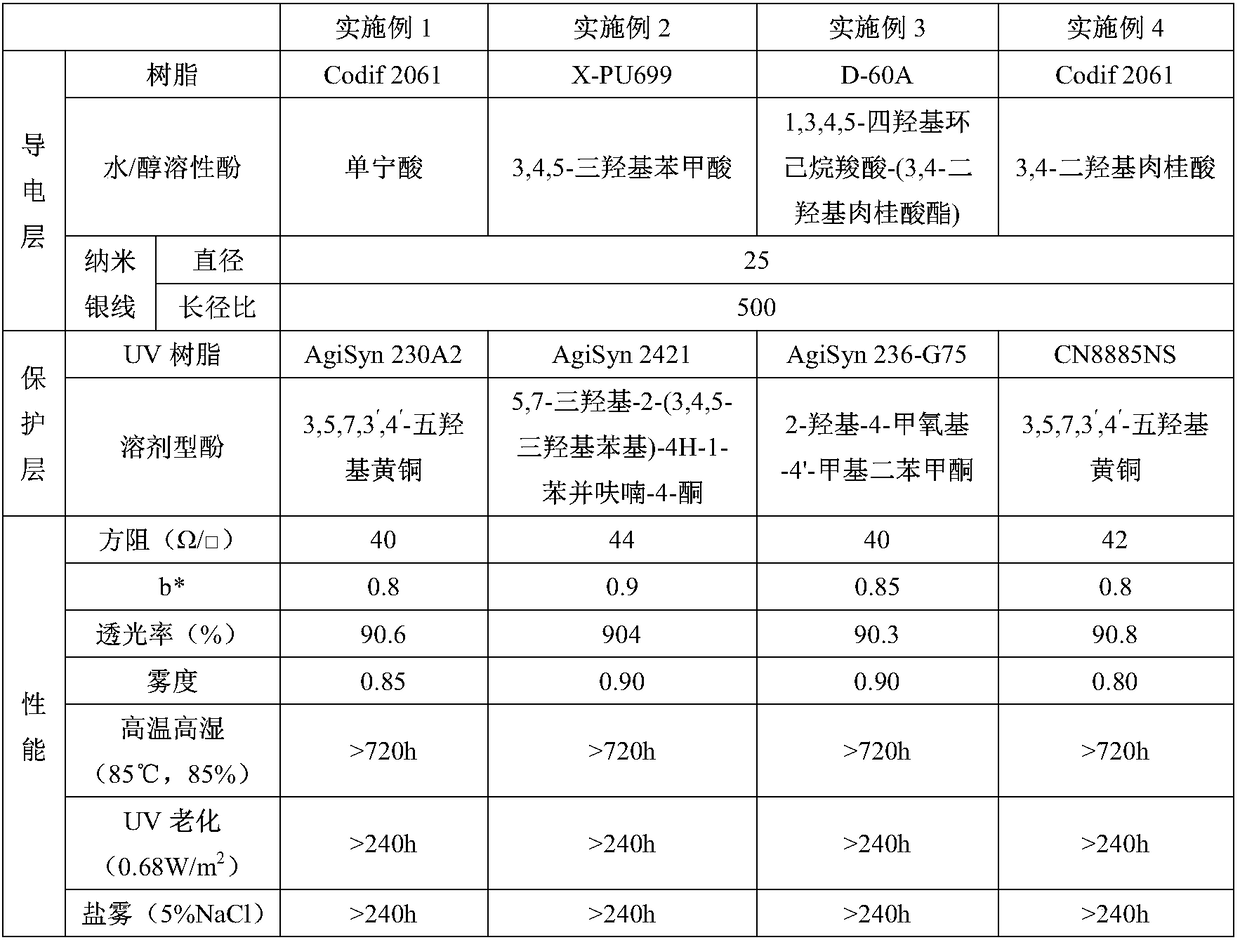

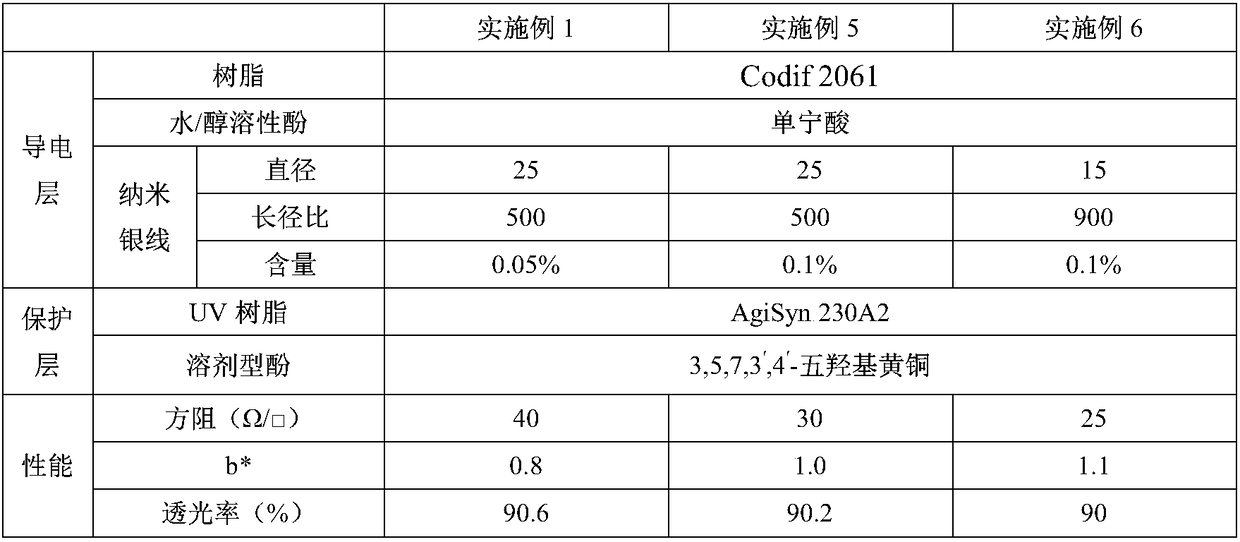

Embodiment 1

[0037] (1) Add 8.32kg of water and 1.663kg of ethanol into the dispersion tank, mechanically disperse uniformly, then add 10g of film-forming resin Codif 2061, 0.2g of dispersant DISPERBYK-191, and 0.2g of leveling agent in sequence 0.2g defoamer Foamex 805-N and 0.25g tannic acid were mechanically stirred uniformly, then 5g nano-silver wire 1 was added, and the stirring was continued to obtain the improved conductive ink;

[0038] The conductive ink was coated on the surface of PET by dimple coating process, and dried at 120°C for 30s to form a conductive layer.

[0039] (2) Add 3.26kg of acetone, 3.26kg of ethyl acetate, and 3.26kg of n-propanol into the dispersion tank to disperse uniformly, then add 200g of resin AgiSyn 230A2, 8g of photoinitiator 2-hydroxy-2-methyl-1-phenyl Acetone (1173), 2g photoinitiator isopropylthioxanthone (ITX), 2g leveling agent BYK-333 and 2g phenolic compound 3,5,7,3′,4′-pentahydroxybrass, continue stirring Homogeneous, the protective layer ...

Embodiment 2

[0042] (1) Add 8.32kg of water and 1.663kg of ethanol into the dispersion tank, mechanically disperse uniformly, then add 10g of film-forming resin X-PU699, 0.2g of dispersant in sequence 0.2g leveling agent 0.2g of antifoaming agent Lucrafoam PDT and 0.3g of phenolic compound 3,4,5-trihydroxybenzoic acid were mechanically stirred uniformly, then 5g of nano-silver wire 1 was added, and the stirring was continued to obtain an improved conductive ink;

[0043] The conductive ink was coated on the surface of PET by dimple coating process, and dried at 120°C for 30s to form a conductive layer.

[0044] (2) Add 3.26kg of ethyl acetate, 3.26kg of ethylene glycol, and 3.26kg of butanone into the dispersion tank to disperse uniformly, then add 200g of resin AgiSyn 2421, 8g of photoinitiator 2-hydroxy-2-methyl-1-benzene Diethyl acetone (1173), 2g photoinitiator isopropylthioxanthone (ITX), 2g leveling agent BYK-333 and 2g phenolic compound 5,7-trihydroxy-2-(3,4,5-trihydroxy Phenyl)...

Embodiment 3

[0047] (1) Add 8.32kg of water and 1.663kg of ethanol into the dispersion tank, mechanically disperse uniformly, then add 10g of film-forming resin D-60A and 0.2g of dispersant in sequence 0.2g leveling agent 0.2g defoamer Foamex1488 and 0.35g phenolic compound 1,3,4,5-tetrahydroxycyclohexanecarboxylic acid-(3,4-dihydroxycinnamate), mechanically stirred uniformly, then added 5g nano silver wire 1, continued to stir uniformly, Prepare the improved conductive ink;

[0048] The conductive ink was coated on the surface of PET by dimple coating process, and dried at 120°C for 30s to form a conductive layer.

[0049] (2) Add 3.26kg ethyl acetate, 3.26kg butyl acetate, and 3.26kg cyclohexanone to the dispersion cylinder to disperse uniformly, then add 200g resin AgiSyn 236-G75, 8g photoinitiator 2-hydroxyl-2-methyl- 1-phenylacetone (1173), 2g photoinitiator isopropylthioxanthone (ITX), 2g leveling agent BYK-333 and 2g phenolic compound 2-hydroxy-4-methoxy-4'-methyl Benzophenon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com