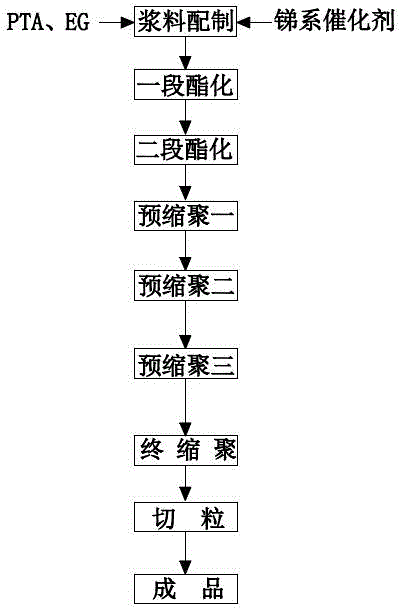

A kind of polyester production device and process

A production device and polyester technology, applied in the field of differential thermoplastic polyester preparation, can solve the problems of high processing cost and high content of terminal carboxyl groups, and achieve the effects of improving production capacity, reducing the content of terminal carboxyl groups, and low b value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

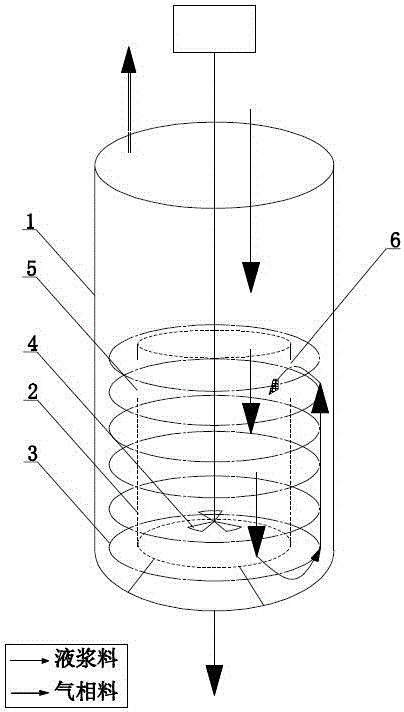

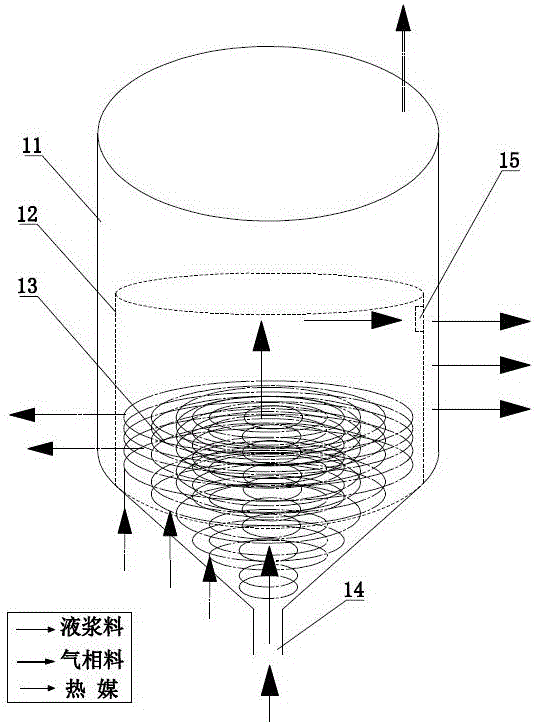

[0033] The polyester production device of the present embodiment comprises a still of esterification, a second still of esterification, a still of polycondensation, a second still of polycondensation and a final polycondensation still, wherein:

[0034] combine figure 2 , the first esterification kettle is a fully mixed reaction kettle, including a kettle body 1, a sleeve 2 and a heat medium coil 3, the height of the kettle body 1 is 5.6m, and a cylindrical sleeve is arranged inside the kettle body 1 One 2, the sleeve one 2 is 1.65m high and 1.25m in diameter, the sleeve one 2 is welded on the bottom of the kettle body one 1 by three legs; the thermal coal casing one 3 is arranged on the kettle body one 1 and the sleeve one Between 2, there are 15 layers from bottom to top, the layer spacing is 10cm, each layer is wound eight times, and the interval between each circle is 10cm; the kettle body-1 is provided with a stirrer-4, and the lower end of the stirrer-4 is located in th...

Embodiment 2

[0046] The polyester production device of the present embodiment is identical with embodiment 1, but its production process is specifically as follows:

[0047] (1) Slurry preparation: put purified terephthalic acid and ethylene glycol into the slurry kettle at a molar ratio of 1:1.2, and then add 190ppm catalyst ethylene glycol antimony for beating.

[0048] (2) Esterification: Esterification is divided into two stages of one-stage esterification and two-stage esterification. The first-stage esterification and the second-stage esterification are carried out in the first esterification kettle and the second esterification kettle respectively. The reaction temperature is about 92%, the reaction temperature is 256°C, the pressure is about 45KPa, and the reaction time is 5.5 hours; the esterification rate of the second-stage esterification is about 98%, the reaction temperature is 266°C, the pressure is about 12KPa, and the reaction time is 1.5 hours.

[0049] (3) Polycondensatio...

Embodiment 3

[0052] The polyester production device of the present embodiment is identical with embodiment 1, but its production process is specifically as follows:

[0053](1) Slurry preparation: put purified terephthalic acid and ethylene glycol into the slurry kettle at a molar ratio of 1:1.2, and then add 190ppm catalyst ethylene glycol antimony for beating.

[0054] (2) Esterification: Esterification is divided into two stages of one-stage esterification and two-stage esterification. The first-stage esterification and the second-stage esterification are carried out in the first esterification kettle and the second esterification kettle respectively. The reaction temperature is about 92%, the reaction temperature is 256°C, the pressure is about 50KPa, and the reaction time is 5 hours; the esterification rate of the second-stage esterification is about 98%, the reaction temperature is 267°C, the pressure is about 12KPa, and the reaction time is 1.5 hours.

[0055] (3) Polycondensation r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com