Method for In Situ Fabrication of Titanium Dioxide Thin Films Exposing High Energy Crystal Facets

A titanium dioxide, in-situ preparation technology, applied in the field of materials, can solve problems such as difficulty in recycling, inability to expose the effective surface of titanium dioxide, application restrictions, etc., and achieve good performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

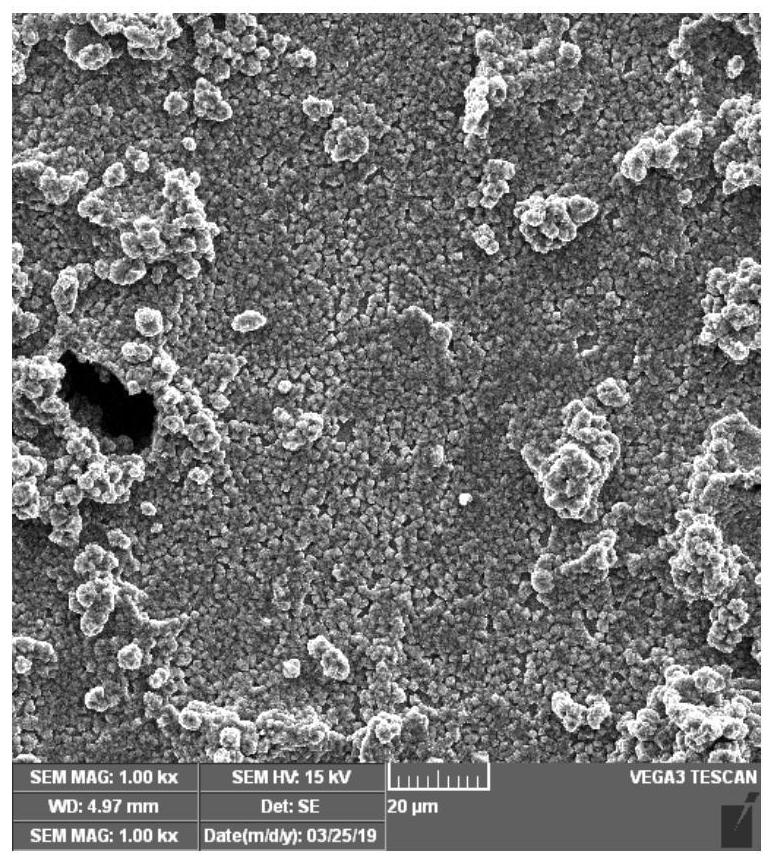

[0049] The method for in-situ preparation of anatase-type titanium dioxide thin film with high-energy {001} crystal plane exposure provided in this example includes the following steps:

[0050] (1) Annealing pretreatment of titanium sheet: cut 10×8mm 2 The titanium substrate was washed alternately with acetone and ethanol, each time for 5 min, 3 cycles, and then 3 times with deionized water. Afterwards, the titanium sheet was annealed at 450°C for 1.5 hours, cleaned in the same way after taking it out, and dried at room temperature for later use.

[0051] (2) prepare 200mL of reaction precursor solution, use ammonium fluotitanate as titanium source, the concentration of ammonium fluotitanate is 3.25mM, the concentration of hydrofluoric acid is 65mM, the concentration of boron oxide is 65mM; The ratio is 1:1, and the molar ratio of ammonium fluotitanate to hydrofluoric acid is 1:20.

[0052] (3) Put the precursor solution and the titanium sheet into a stainless steel autocla...

Embodiment 2

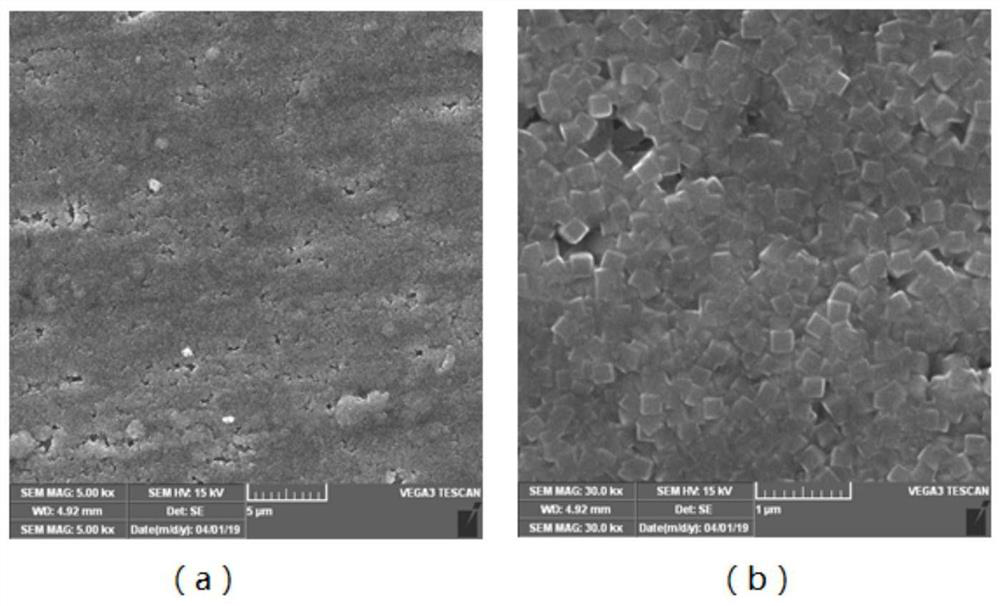

[0054] The method for in-situ preparation of anatase-type titanium dioxide thin film with high-energy {001} crystal plane exposure provided in this example includes the following steps:

[0055] (1) Annealing pretreatment of titanium sheet: cut 15×12mm 2 The titanium substrate was washed alternately with acetone and ethanol, each time for 5 min, 3 cycles, and then 3 times with deionized water. Afterwards, the titanium sheet was annealed at 450°C for 1.5 hours, cleaned in the same way after taking it out, and dried at room temperature for later use.

[0056] (2) Prepare 300mL of reaction precursor solution, use ammonium fluorotitanate as the titanium source, the concentration of ammonium fluorotitanate is 4.5mM, the concentration of hydrofluoric acid is 90mM, and the concentration of boron oxide is 180mM; The ratio is 1:2, and the molar ratio of ammonium fluotitanate to hydrofluoric acid is 1:20.

[0057] (3) Put the precursor solution and the titanium sheet into a stainless ...

Embodiment 3

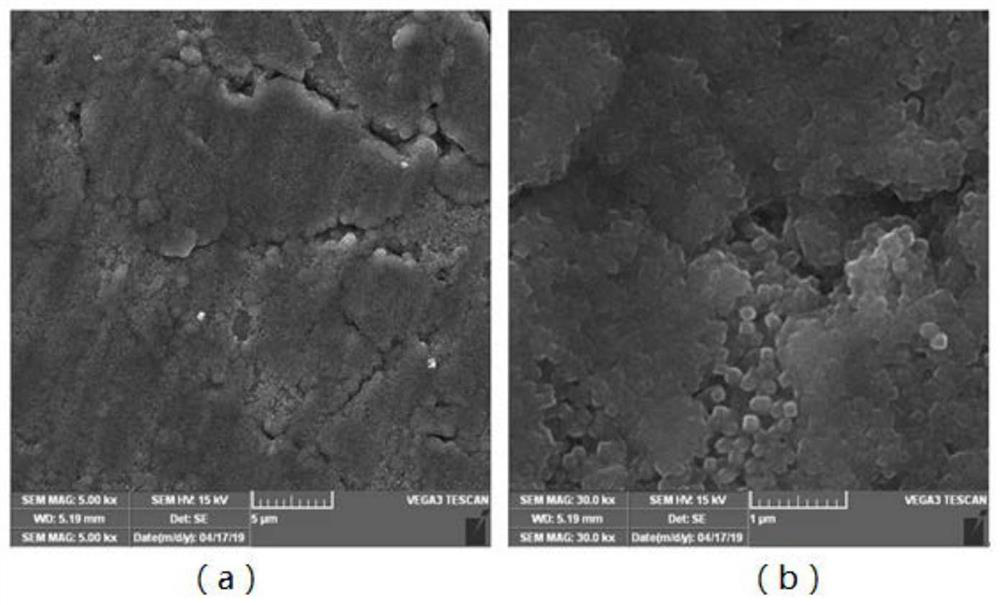

[0059] The method for in-situ preparation of anatase-type titanium dioxide thin film with high-energy {001} crystal plane exposure provided in this example includes the following steps:

[0060] (1) Annealing pretreatment of titanium sheet: cut 20×16mm 2 The titanium substrate was washed alternately with acetone and ethanol, each time for 5 min, 3 cycles, and then 3 times with deionized water. Afterwards, the titanium sheet was annealed at 450°C for 1.5 hours, cleaned in the same way after taking it out, and dried at room temperature for later use.

[0061] (2) Prepare 400mL of reaction precursor solution, use ammonium fluotitanate as titanium source, the concentration of ammonium fluotitanate is 6.5mM, the concentration of hydrofluoric acid is 130mM, the concentration of boron oxide is 1300mM; The ratio is 1:10, and the molar ratio of ammonium fluotitanate to hydrofluoric acid is 1:20.

[0062] (3) Put the precursor solution and the titanium sheet into a stainless steel aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com