Transparent conductive film

A transparent conductive film and conductive layer technology, which is applied to the conductive layer on the insulating carrier, electrical digital data processing, instruments, etc., can solve the problems of poor visibility and discoloration of the film material, and achieve low surface resistance, good conductivity, The effect of b* value reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

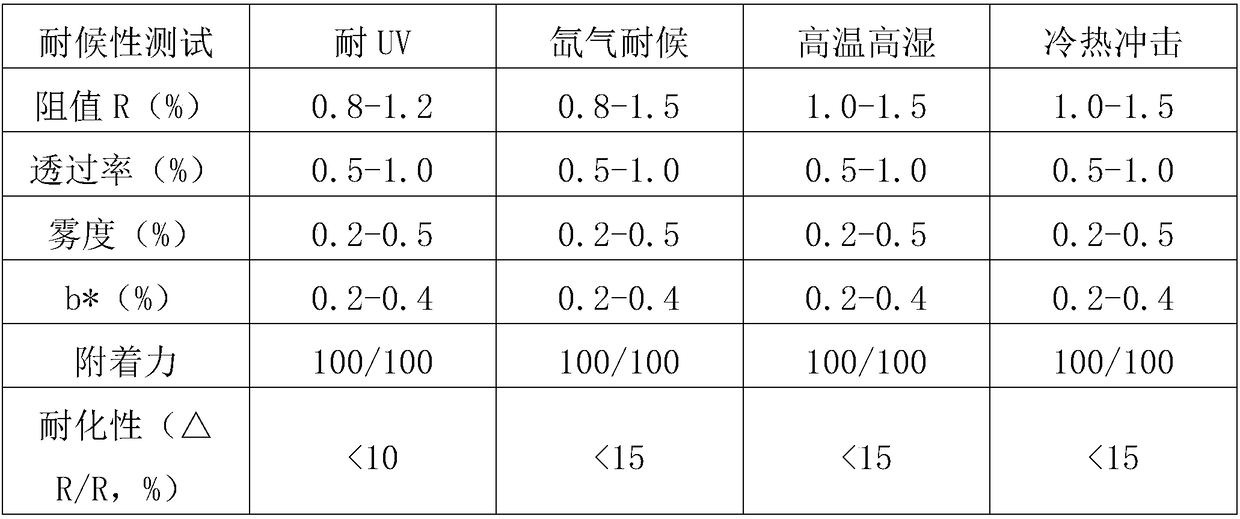

Embodiment 1

[0048] Using PET as a transparent carrier, the silver nanowire slurry is evenly coated on the PET surface by slit coating, the pump speed is 30ml / min, the wet film thickness is 30um, the coating speed is 100cm / min, and the curing temperature is 70°C , forming a uniform conductive layer;

[0049] Take 6 parts of acrylate resin, 90 parts of mixed solvent (ethanol: butanone: ethyl acetate: diethylene glycol monomethyl ether) with a mass ratio of 1:1:1:1, initiators 2, 4, 6 (three Add 2 parts of methylbenzoyl)diphenylphosphine oxide and 2 parts of leveling agent BYK333 into a glass container, stir and mix evenly to obtain a mixed solution, and then add 0.02wt% alkaline Stir the blue 6B blue dyeing agent for 30 minutes to make it evenly mixed to obtain a protective layer coating solution;

[0050] The protective layer coating liquid is coated on the conductive layer by slit coating, the coating speed is 200cm / min, and the curing temperature is 60°C to form a dense protective layer...

Embodiment 2

[0071] Using PET as a transparent carrier, the silver nanowire slurry is evenly coated on the PET surface by slit coating, the pump speed is 50ml / min, the wet film thickness is 40um, the coating speed is 80cm / min, and the curing temperature is 100°C , forming a uniform conductive layer;

[0072] Take 7 parts of acrylate resin, 88 parts of mixed solvent (ethanol: butanone: ethyl acetate: diethylene glycol monomethyl ether) with a mass ratio of 1:1:1:1, initiator 2-hydroxy-2-methyl Add 3 parts of base-1-phenyl-1-acetone and 2 parts of leveling agent BYK306 into a glass container, stir and mix evenly to obtain a mixed solution, and then add bromophenol blue accounting for 0.03wt% of the total mixed solution to the mixed solution Stir the blue dyeing agent for 40 minutes to make it evenly mixed to obtain a protective layer coating solution;

[0073] The protective layer coating solution was coated on the conductive layer by slit coating, the coating speed was 180cm / min, and the c...

Embodiment 3

[0087] Using PET as a transparent carrier, the silver nanowire slurry was evenly coated on the PET surface by slit coating, the pump speed was 55ml / min, the wet film thickness was 45um, the coating speed was 120cm / min, and the curing temperature was 130°C , forming a uniform conductive layer;

[0088] Take 10 parts of acrylate resin, 82 parts of mixed solvent (ethanol: butanone: ethyl acetate: diethylene glycol monomethyl ether) with a mass ratio of 1:1:1:1, initiator 1-hydroxyl-cyclohexyl- Add 5 parts of phenyl ketone and 3 parts of leveling agent Digo 450 into a glass container and stir to mix evenly to obtain a mixed solution, then add bromophenol blue dyeing agent accounting for 0.05wt% of the total mixed solution to the mixed solution Stir for 35 minutes to make it evenly mixed to obtain a protective layer coating liquid;

[0089] The protective layer coating solution was coated on the conductive layer by slit coating, the coating speed was 220cm / min, and the curing temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com