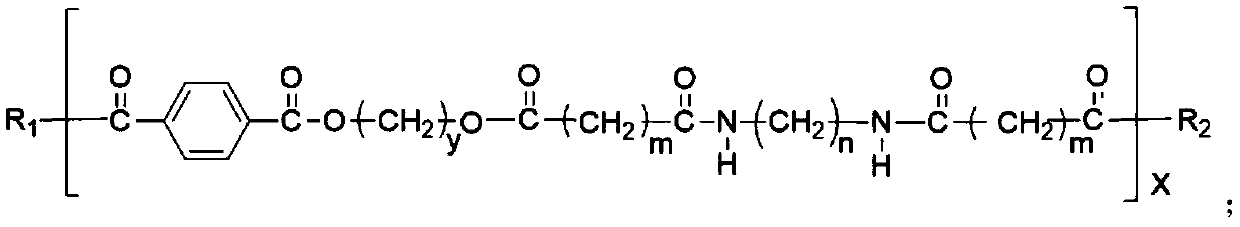

Polyesteramide as well as preparation method and application thereof

A polyamide ester and polycondensation reaction technology, which is applied in the field of modified polyester, can solve the problems of polyester amide yellowing and other problems, and achieve low b value, good cotton-like performance, and good fiber color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of polyamide ester, concrete steps are as follows:

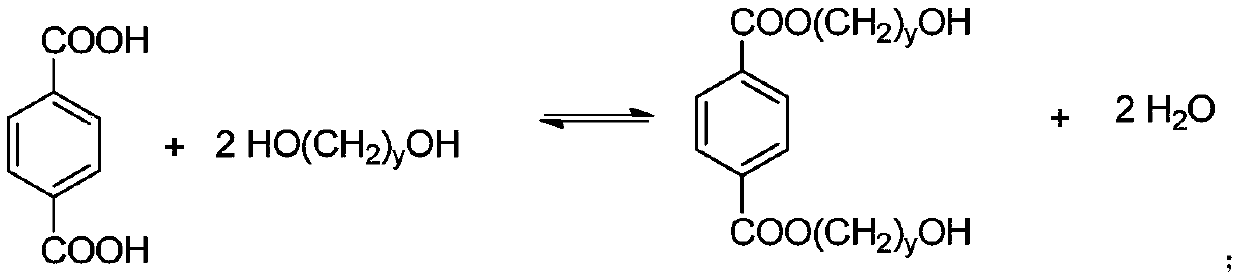

[0038] (a) After mixing PTA and ethylene glycol with a molar ratio of 1.0:1.2, the esterification reaction was carried out at a temperature of 230° C. for 4 hours to obtain diol terephthalate;

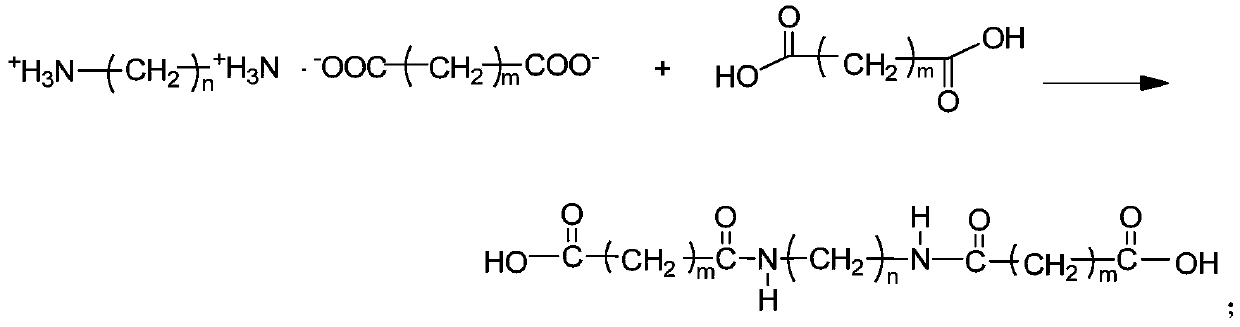

[0039](b) After adding B to an aqueous solution of A with a concentration of 50 wt%, react for 3 hours at a temperature of 180° C. to obtain a diamine dibasic acid derivative. The molar ratio of A and B is 1.0:1.2, and A is dibasic acid. Amine dibasic acid salt, B is a dibasic acid, the dibasic acid in A is the same as B, the diamine in the dibasic amine dibasic acid salt is 1,6-hexamethylenediamine, dibasic amine dibasic acid The dibasic acid in the salt is 1,6-adipic acid;

[0040] (c) After mixing the diol ester of terephthalate and the diamine dibasic acid derivative in a mass ratio of 80:20, add a catalyst and a stabilizer and react for 3 hours at a temperature of 260°C and a pressure of 30Pa...

Embodiment 2

[0047] A kind of preparation method of polyamide ester, concrete steps are as follows:

[0048] (a) After mixing PTA and ethylene glycol with a molar ratio of 1.0:1.2, the esterification reaction was carried out at a temperature of 240° C. for 4 hours to obtain diol terephthalate;

[0049] (b) After adding B to an aqueous solution of A with a concentration of 55 wt%, react for 2.5 hours at a temperature of 178° C. to obtain a diamine dibasic acid derivative. The molar ratio of A and B is 1.0:1.2, and A is Dibasic amine dibasic acid salt, B is dibasic acid, the dibasic acid in A is the same as B, the diamine in dibasic amine dibasic acid salt is 1,4-butylene diamine, dibasic amine dibasic acid The dibasic acid in the acid salt is 1,6-adipic acid;

[0050] (c) After mixing the diol ester of terephthalate and the diamine dibasic acid derivative in a mass ratio of 70:30, add a catalyst and a stabilizer and react for 3 hours at a temperature of 275°C and a pressure of 25Pa Obtain...

Embodiment 3

[0052] A kind of preparation method of polyamide ester, concrete steps are as follows:

[0053] (a) After mixing PTA and ethylene glycol with a molar ratio of 1.0:1.2, the esterification reaction was carried out at a temperature of 240° C. for 3.5 hours to obtain diol terephthalate;

[0054] (b) Add B to the aqueous solution of A with a concentration of 60 wt%, and then react for 3 hours at a temperature of 167° C. to obtain diamine dibasic acid derivatives. The molar ratio of A and B is 1.0:1.2, and A is dibasic acid. Amine dibasic acid salt, B is a dibasic acid, the dibasic acid in A is the same as B, the diamine in diamine dibasic acid salt is 1,5-pentanediamine, dibasic amine dibasic acid The dibasic acid in the salt is 1,6-adipic acid;

[0055] (c) After mixing the diol ester of terephthalate and the diamine dibasic acid derivative at a mass ratio of 95:5, add a catalyst and a stabilizer and react for 3 hours at a temperature of 275°C and a pressure of 20Pa Obtain the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com