Glass composition, microcrystalline glass as well as preparation method and application of microcrystalline glass

A technology of glass composition and glass-ceramics, which is applied in glass manufacturing equipment, glass molding, glass rolling, etc., can solve the problem of reducing the content of glass-ceramic crystals, high haze, and the lack of optimal performance of glass-ceramics To achieve the effect of excellent strengthening performance, reducing b value and haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

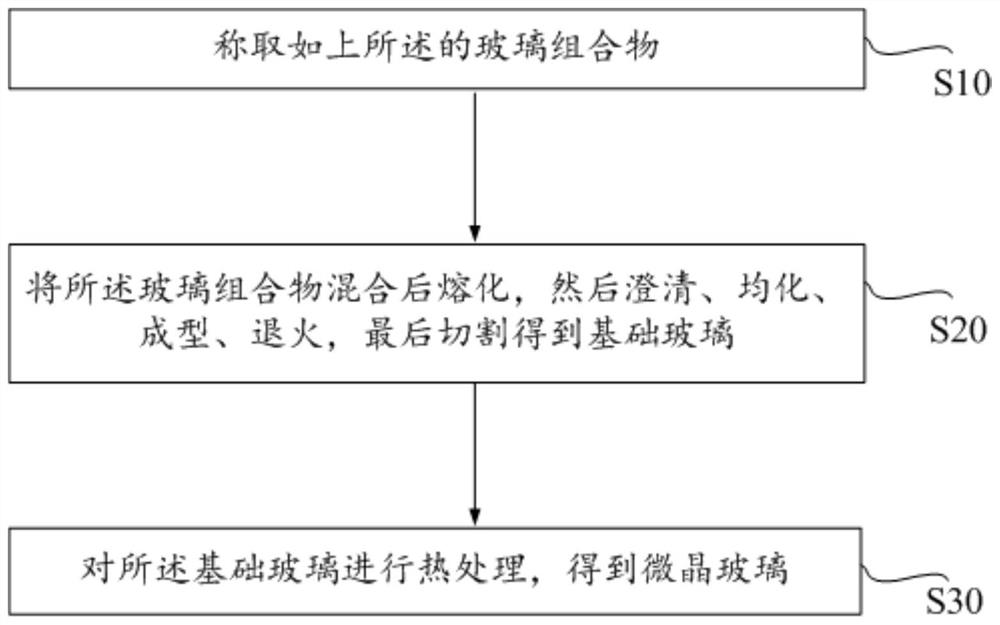

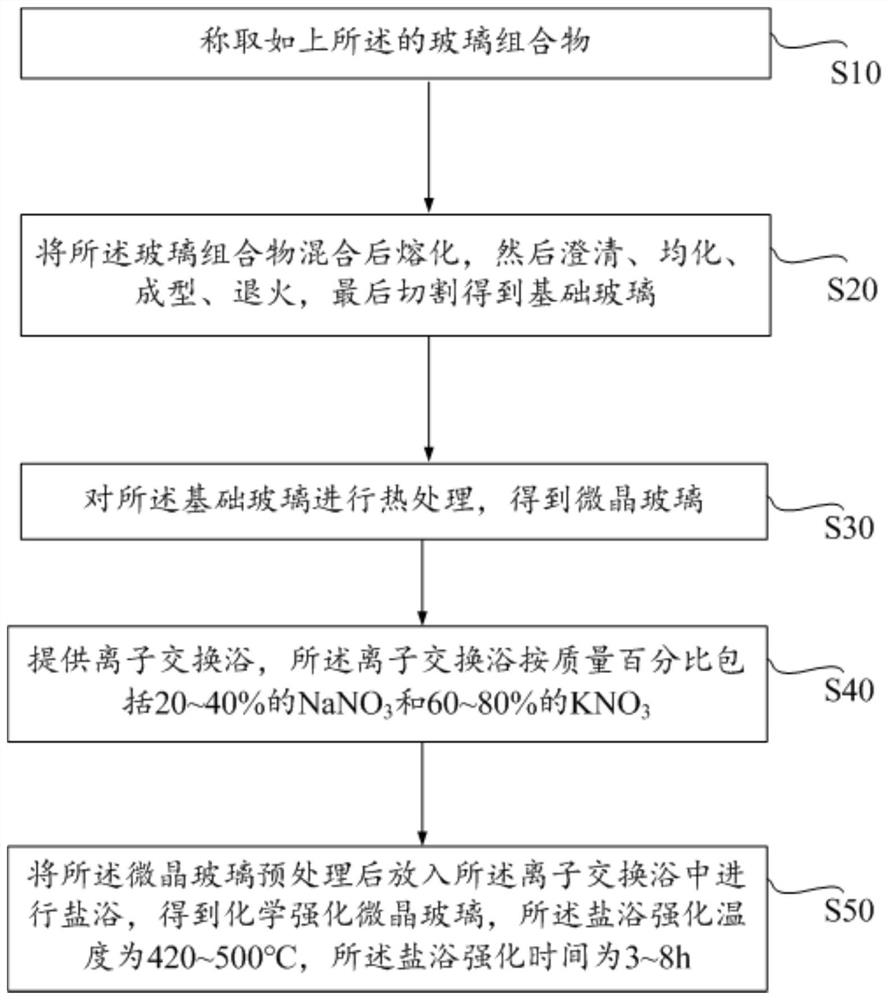

[0067] In addition, the present invention also proposes a preparation method of glass-ceramics, which is used to prepare the above-mentioned glass-ceramics, such as figure 1 shown, including the following steps:

[0068] Step S10, weighing the above-mentioned glass composition.

[0069] In step S20, the glass composition is mixed and melted, then clarified, homogenized, shaped, annealed, and finally cut to obtain a base glass.

[0070] Specifically, in step S20, the forming method includes float forming, overflow forming, calender forming or slit down-draw forming. Other clarification, homogenization, annealing and cutting processes are conventional processes in the field of glass technology, and will not be described here. After the above processes, the obtained basic glass has a thickness of 0.3-1.5 mm.

[0071] Step S30 , performing heat treatment on the basic glass to obtain a glass-ceramic.

[0072] Specifically, step S30 includes: raising the temperature of the basic gl...

Embodiment 1

[0080] (1) Weigh the glass composition, by mass percentage, including: SiO 2 72%, Al 2 o 3 7%, P 2 o 5 3%, Li 2 O12.5%, Na 2 O2% and ZrO 2 3.5%.

[0081] (2) The glass composition is mixed and then melted, then clarified, homogenized, shaped, annealed, and finally cut to obtain the base glass.

[0082] (3) The basic glass is heated from room temperature to 530°C in 20 minutes for nucleation treatment, and the nucleation treatment time is 3 hours; it is heated to 680°C in 30 minutes for crystallization treatment, and the crystallization treatment The time is 3h; cooled to room temperature to obtain glass-ceramics.

[0083] (4) An ion exchange bath is provided, which comprises 40% NaNO by mass percentage 3 and 60% KNO 3 , putting the glass-ceramics into the ion exchange bath for salt bath after pretreatment to obtain chemically strengthened glass-ceramics, the salt bath strengthening temperature is 420°C, and the salt bath strengthening time is 3h.

[0084] The raw ma...

Embodiment 8 to 14

[0101] Table 2 Examples 8 to 14 glass composition components and glass properties

[0102]

[0103]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com