Method for preparing environment-friendly polyester

An environmentally friendly polyester technology, applied in the field of polymer materials, can solve the problems of affecting the cleanliness of polyester, prolonging the polymerization time, and many side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

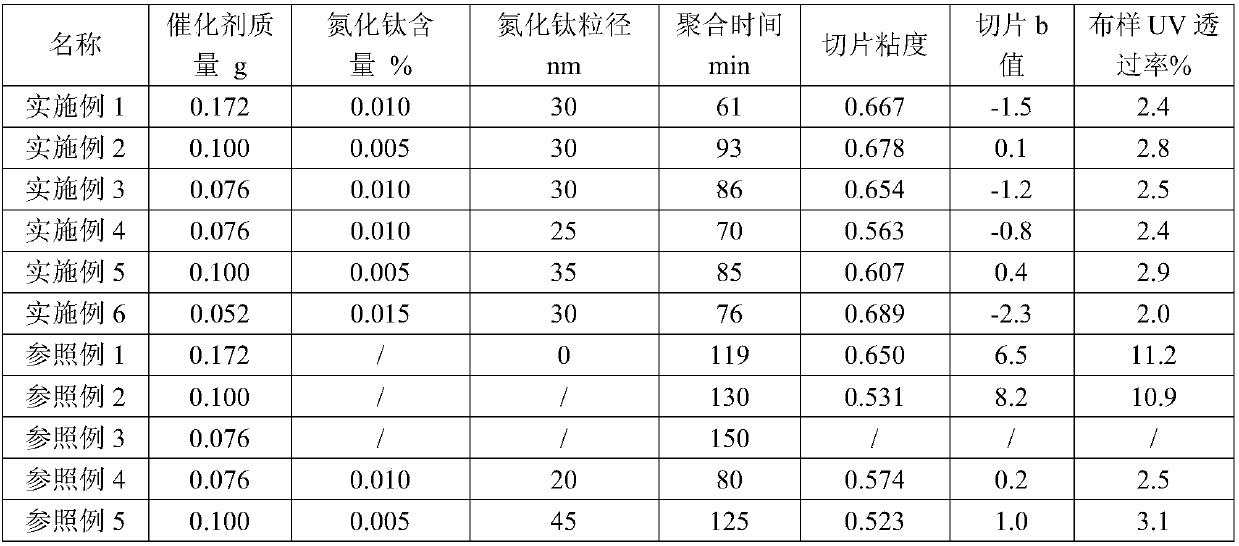

Examples

Embodiment 1

[0019] Titanium nitride powder and ethylene glycol were pre-dispersed and ground to prepare a suspension containing 15% titanium nitride concentration for use, and the median particle size of the nano-titanium nitride used was 30nm.

[0020] Add 5000g of terephthalic acid, 1960g of ethylene glycol, 1.05:1 molar ratio of ethylene glycol to PTA, 0.172g of tetraisopropyl titanate catalyst, 3.86g of the above-mentioned titanium nitride / ethylene glycol in a 20L general-purpose polymerization reactor. The alcohol suspension is subjected to esterification reaction at 245°C and an absolute pressure of 0.35Mpa. When the water output reaches 1100ml, the pressure is released to normal pressure. The polycondensation reaction was carried out for 61 minutes at an internal temperature of 280° C. and an absolute pressure of 70 Pa. After the reaction was completed, 5,783 g of environmentally friendly polyester were obtained through extrusion by a melt pump, pelletizing, and drying. The conten...

Embodiment 2

[0022] Titanium nitride powder and ethylene glycol were pre-dispersed and ground to prepare a suspension containing 15% titanium nitride concentration for use, and the median particle size of the nano-titanium nitride used was 30nm.

[0023] Add 5000g of terephthalic acid, 2241g of ethylene glycol, 1.20:1 molar ratio of ethylene glycol to PTA, 0.100g of tetraisopropyl titanate catalyst, 1.93g of the above-mentioned titanium nitride / ethylene glycol in a 20L general-purpose polymerization reactor. The alcohol suspension is subjected to esterification reaction at 225°C and an absolute pressure of 0.30Mpa, and when the water output reaches 1100ml, the pressure is released to normal pressure. The polycondensation reaction was carried out for 93 minutes at an internal temperature of 275° C. and an absolute pressure of 30 Pa. After the reaction was completed, 5,783 g of environmentally friendly polyester were obtained through extrusion by a melt pump, pelletizing, and drying. The co...

Embodiment 3

[0025] Titanium nitride powder and ethylene glycol were pre-dispersed and ground to prepare a suspension containing 15% titanium nitride concentration for use, and the median particle size of the nano-titanium nitride used was 30nm.

[0026] Add 5000g of terephthalic acid, 2614g of ethylene glycol, 1.40:1 molar ratio of ethylene glycol to PTA, 0.076g of tetraisopropyl titanate catalyst, 3.86g of the above-mentioned titanium nitride / ethylene glycol in a 20L general-purpose polymerization reactor. The alcohol suspension is subjected to esterification reaction at 265°C and an absolute pressure of 0.25Mpa. When the water output reaches 1100ml, the pressure is released to normal pressure. The polycondensation reaction was carried out for 86 minutes at an internal temperature of 285° C. and an absolute pressure of 90 Pa. After the reaction was completed, 5,783 g of environmentally friendly polyester were obtained through extrusion by a melt pump, pelletizing, and drying. The conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com