Preparation method and application of main chain embedded terminal amino silicon oil with side chain containing tertiary amino group

A technology of pendant tertiary amino group and tertiary amino group, which is applied in the field of preparation of main chain-blocked amino silicone oil, can solve the problem of limiting the performance of main chain-blocked amino silicone oil softener, small adjustable space for ammonia value, and poor directional adsorption effect And other problems, to achieve the effect of industrial production and commercial promotion and application, wide adjustable range of ammonia value, and good directional adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

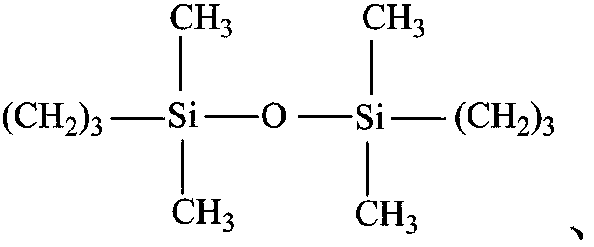

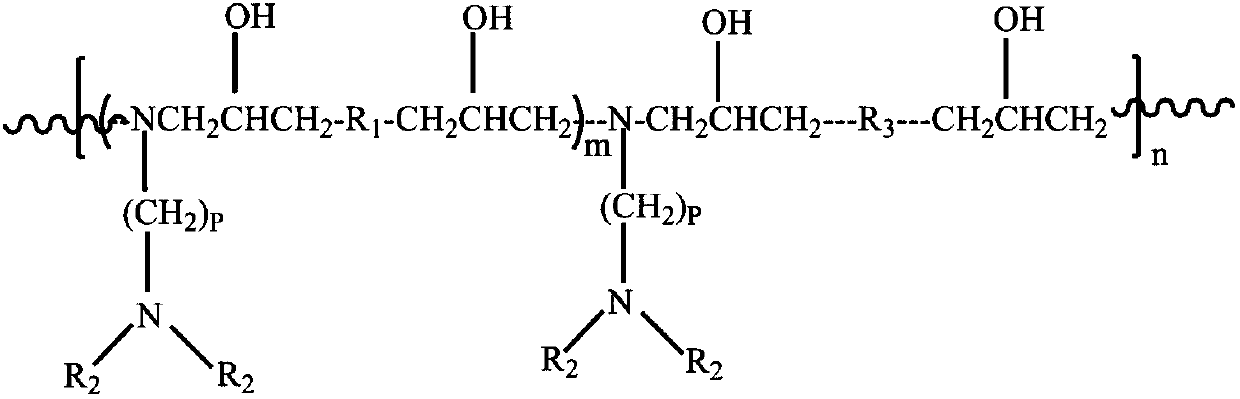

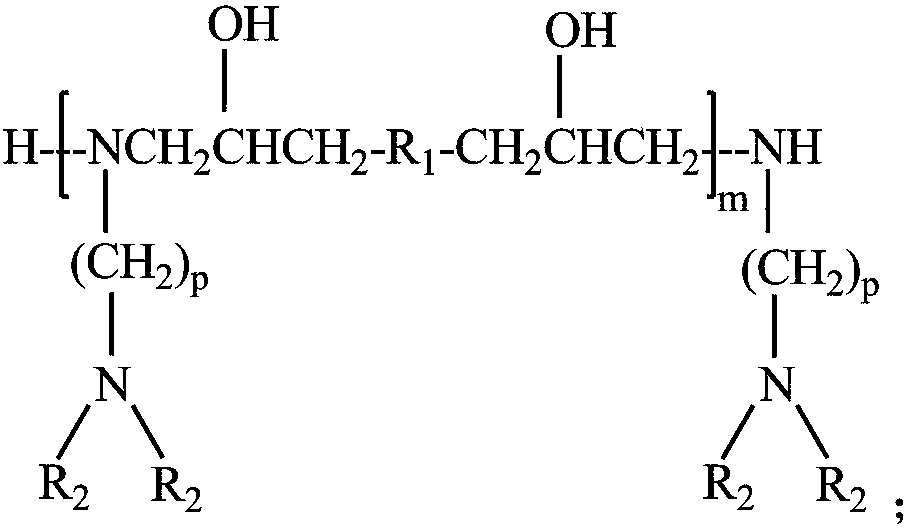

Method used

Image

Examples

Embodiment 1

[0037] In a 500mL three-necked flask with a thermometer, a stirrer and a condenser tube, add 3.06g of secondary amine-terminated linear comb-like epoxy polyamine compound 1 (306.4g / mol, m=1, p= 2, R 1 -O-), 101.71g epoxy-terminated silicone oil (20 342g / mol, q=270, x=0, y=0, the molar ratio of the two is 2:1, n=1) and 209.54g isopropanol (accounting for 200% of the mass ratio of the raw material), the temperature was raised to 60° C. for 24.0 h under stirring, and the main chain terminated amino silicone oil 1 (ammonia value 0.19 mmol / g) containing tertiary amino groups in the side chain was obtained.

Embodiment 2

[0039] In a 500mL three-necked flask with a thermometer, a stirrer and a condenser tube, add 2.73g of secondary amine-terminated linear comb-like epoxy polyamine compound 2 (2706g / mol, m=10, p= 3, R 1 for-OCH 2 CH 2 O-), 153.1g terminal epoxy silicone oil (15 310g / mol, q=202, x=0, y=0, the molar ratio of the two is 1.01:1, n=100) and 180.43g ethylene glycol butyl ether (accounting for 100% of the mass ratio of the raw material), the temperature was raised to 130° C. for 8.0 h under stirring, and the main chain-blocked amino silicone oil 2 (ammonia value 1.22 mmol / g) containing tertiary amino groups in the side chain was obtained.

Embodiment 3

[0041] In a 500mL three-necked flask with a thermometer, a stirrer and a condenser tube, add 28.75g of secondary amine-terminated linear comb-like epoxy polyamine compound 3 (784g / mol, m=2, p=4 , R 1 for-OCH 2 CH 2 OCH 2 CH 2 O-), 199.5g terminal epoxy silicone oil (5 986g / mol, q=76, x=0, y=0, the molar ratio of the two is 1.1:1, n=10) and 114.1g diethylene glycol butyl Ether (accounting for 50% of the mass ratio of raw materials) was heated to 150° C. under stirring for 1.0 h to obtain the main chain-terminated amino silicone oil 3 (ammonia value 0.96 mmol / g) containing tertiary amino groups in the side chain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com