High-salt organic wastewater evaporation method and device based on energy gradient utilization

A technology of organic wastewater and high temperature evaporation, applied in chemical instruments and methods, water softening, water pollutants, etc., can solve problems such as high energy consumption, and achieve the effects of simple maintenance, cost reduction, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

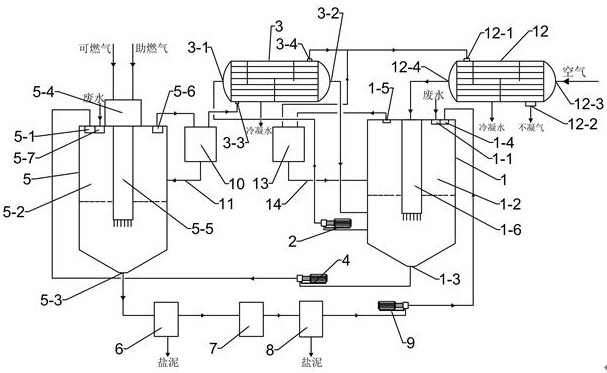

[0065] Example: Control figure 1

[0066] A device for continuous treatment of high-salt organic wastewater, including low-temperature evaporation equipment 1, a first circulating pump 2, a second circulating pump 4, a third circulating pump 9, a first heat exchanger 3, a second heat exchanger 12, a high temperature Evaporation equipment 5, first solid-liquid separation equipment 6, regulating tank 7, second solid-liquid separation equipment 8, first separator 10, second separator 13, first return pipe 11, second return pipe 14; the The low-temperature evaporation equipment 1 is characterized by comprising a first feed port 1-1, a first evaporation chamber 1-2, a first liquid discharge port 1-3, a third feed port 1-4, and a second exhaust port 1-5, bubbling chamber 1-6, wherein the lower part of the bubbling chamber 1-6) is an air-distributing bubbling structure; the described high temperature evaporation equipment is characterized in that it comprises the second feeding port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com