Hydrophilic softening agent and preparing method thereof

A softener and hydrophilic technology, applied in textiles and papermaking, fiber treatment, fiber raw material treatment, etc., can solve the problems of high equipment, personnel, process technology requirements, few products research, production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

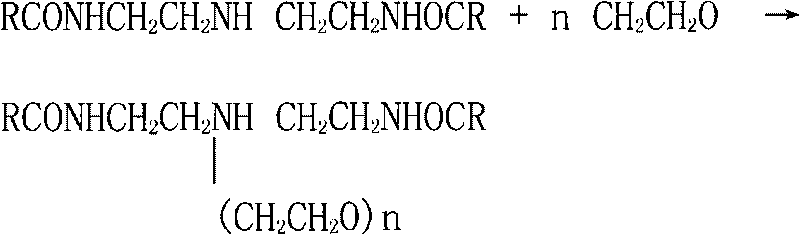

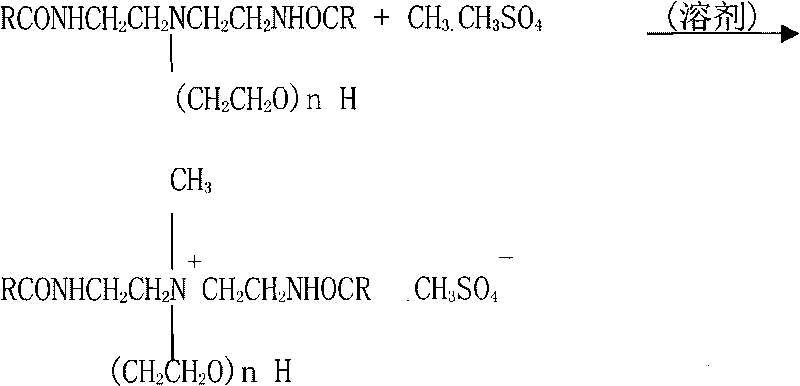

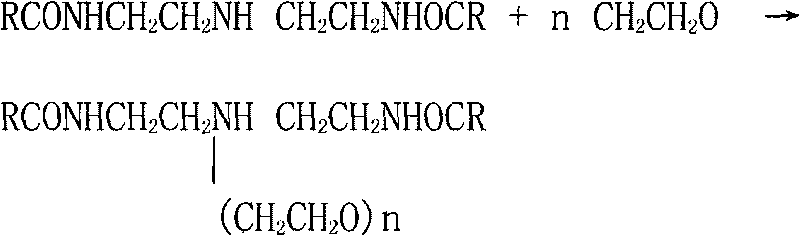

Method used

Image

Examples

Embodiment 1

[0024] In a stainless steel reaction kettle with conditions such as heating, cooling, nitrogen protection, stirring, temperature, pressure indication (recording) and feeding, add acid value 210mgKOH / g, iodine value greater than 100GI2 / 100g refined vegetable oil fatty acid (oleic acid) 534.3 g (2.00 mole), replaced with nitrogen in vacuum, stirred, and added 103 g (1.0 mole) of diethylenetriamine under the protection of nitrogen, and the molar ratio of the two was 2:1. Slowly raise the temperature to 160°C and keep it warm for 5 hours. During this process, water is generated and escapes from the system until the acid value is less than 3mgKOH / g, and a yellow liquid amidoamine intermediate is obtained. The amidation reaction of fatty acid and diethylenetriamine needs to be dehydrated. In theory, one mole of fatty acid is dehydrated to one mole. Generally, the molar ratio of the two is about 2:1. If this ratio is exceeded, triamide is easy to form, and it is difficult to disperse ...

Embodiment 2

[0029] In Example 1, using refined tallow oil instead of vegetable oil, the molar ratio to diethylenetriamine is 1.90:1.00, the molar ratio of ethylene oxide to diethylenetriamine is 5.0:1.0, other raw materials and diethylenetriamine The mol ratio of triamine is constant, and reaction condition is constant, and solvent is changed into 1,2-propanediol, and other conditions according to example 1 can obtain bis-tallow amido ethyl polyethoxymethyl methylsulfate ammonium quaternary ammonium salt. The appearance is paste, and the content of active matter is 90%. Product requires warm water to disperse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com